Content Menu

● Introduction

● What Are Carbide Saw Tips?

>> Key Properties:

>> Main Applications:

● How Are Carbide Saw Tips Manufactured?

● Top 10 Carbide Saw Tip Manufacturers You Can Trust

>> 1. Kennametal Inc. (USA/Global)

>> 2. Freud Tools (Italy/Global)

>> 3. Bosch (Germany/Global)

>> 4. DeWalt (USA/Global)

>> 5. DLTC Tools (China/Global OEM)

>> 6. TechMet Carbide (USA)

>> 7. Zhongbo Carbide (China)

>> 8. PILANA (Czech Republic/EU)

>> 9. Leitz (Germany)

>> 10. Amana Tool (USA)

● Deep Dive: The Science of Carbide Saw Tips

>> The Chemistry

>> The Engineering

● How to Choose the Right Carbide Saw Tip Manufacturer

● Conclusion

● FAQ: Carbide Saw Tips (Frequently Asked Questions)

>> 1. What are Carbide Saw Tips made of?

>> 2. How can I tell if a Carbide Saw Tip is high quality?

>> 3. What OEM services are available for Carbide Saw Tips?

>> 4. How do you attach Carbide Saw Tips to a saw blade?

>> 5. Can Carbide Saw Tips be resharpened or replaced?

Introduction

Precision and durability are non-negotiable features when it comes to industrial cutting tools, and for those who work with saw blades, Carbide Saw Tips stand at the heart of reliable production. As the backbone of the woodworking, metalworking, and construction industries, Carbide Saw Tips deliver outstanding wear resistance and cutting performance, directly influencing the quality and efficiency of your finished products.

Choosing a reputable supplier is critical. In this comprehensive guide, we present the top 10 Carbide Saw Tip manufacturers you can trust, exploring their unique technologies, product ranges, and quality standards. We'll also delve into the science behind Carbide Saw Tips, their manufacturing processes, key applications, and provide rich visual resources with photos and videos. Whether you are a brand owner, wholesaler, manufacturer, or seeking OEM services, this article will be your go-to reference.

What Are Carbide Saw Tips?

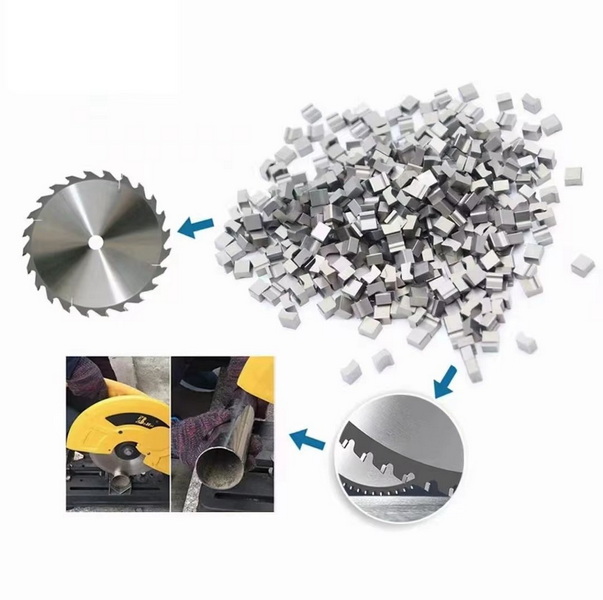

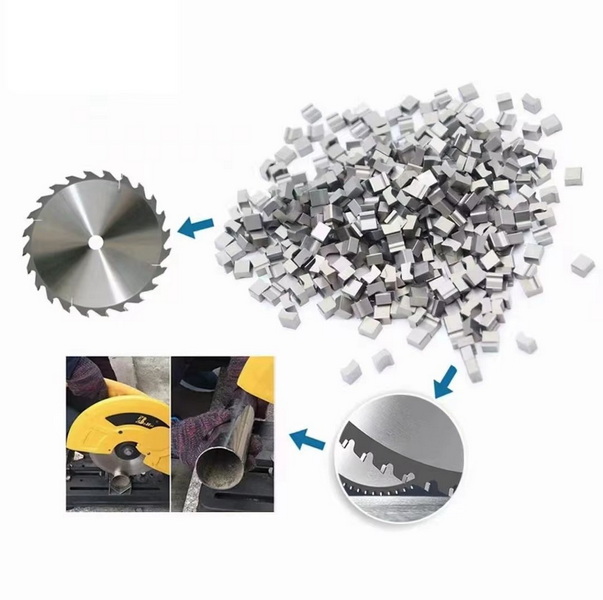

Carbide Saw Tips are small, hard inserts made from cemented carbide (typically tungsten carbide with cobalt as a binder) that are brazed or welded onto the teeth of saw blades. Their job is to provide exceptional hardness and abrasive resistance, making them vital for cutting hard woods, metals, composites, and stone.

Key Properties:

- Extreme hardness and wear resistance: The inherent hardness of tungsten carbide, second only to diamond, provides superior resistance to abrasion and wear, ensuring the saw blade maintains its sharpness over extended periods of use.

- Long tool life: Due to their extreme durability, Carbide Saw Tips significantly extend the lifespan of saw blades, reducing the frequency of replacements and regrinds, which in turn leads to lower operational costs and increased productivity.

- Superior cutting performance: The precise geometry and sharp edges of Carbide Saw Tips allow for clean, efficient cuts across a wide range of materials, leading to higher quality finishes and reduced material waste.

- Maintains sharpness under heavy-duty applications: Unlike steel blades that quickly dull under stress, Carbide Saw Tips retain their cutting edge even when subjected to high temperatures and friction generated during aggressive cutting operations. This stability is crucial for consistent performance in industrial settings.

Main Applications:

- Circular saw blades: Widely used in woodworking for ripping, crosscutting, and panel sizing. Carbide Saw Tips are indispensable for cutting engineered wood products, hardwoods, and even non-ferrous metals.

- Band saws: Employed in metalworking and large-scale wood processing. Carbide Saw Tips on band saw blades enable efficient cutting of thick materials and contribute to smoother cuts.

- Panel saws: Essential for cutting large sheets of wood, laminates, and plastics in furniture manufacturing and cabinet making. The precision of Carbide Saw Tips ensures accurate, chip-free edges.

- Industrial and carpentry blades: From portable job-site saws to massive industrial machines, Carbide Saw Tips are the standard for any application requiring high-volume, high-precision cutting. This includes specialized blades for plastics, aluminum, and composite materials.

How Are Carbide Saw Tips Manufactured?

The science of Carbide Saw Tips production involves advanced metallurgy, precision engineering, and strict quality control. Here is an inside look at the process:

1. Raw Material Selection: Fine tungsten carbide powders are mixed with cobalt, which acts as a binder. The purity and particle size of these raw materials are critical, as they directly influence the final properties of the Carbide Saw Tips, such as hardness, toughness, and wear resistance. Other binders like nickel may be used for specific applications, especially where corrosion resistance is paramount.

2. Pressing/Compaction: The blended powder is then compacted into the desired tip shapes using high-pressure presses. This forms what is known as a "green compact," which is fragile but holds the general shape of the final tip. The precision of this step ensures the dimensional accuracy of the tips before sintering.

3. Sintering: The compacted tips are placed in high-temperature furnaces, where they undergo a sintering process. During sintering, the material is heated to temperatures approaching the melting point of the binder (cobalt), causing the tungsten carbide particles to bond together. This process creates a dense, non-porous, and ultra-hard structure, giving the Carbide Saw Tips their legendary durability and wear resistance. Sintering atmosphere and temperature profiles are carefully controlled to optimize the material's properties.

4. Finishing: After sintering, the Carbide Saw Tips are extremely hard. Precision grinding techniques are employed to achieve the exact dimensions, angles, and surface finishes required for specific saw blade applications. This step ensures consistent tip size, accurate tooth geometry, and a sharp, clean cutting edge. Some tips may also undergo tumbling or other surface treatments for improved adhesion.

5. Pretin or Brazing Preparation: Many Carbide Saw Tips are pre-tinned with a thin layer of solder and flux coating. This pre-tinning simplifies the subsequent brazing process, where the tips are permanently attached to the steel saw blade body, ensuring a strong and reliable bond. This preparation step significantly improves manufacturing efficiency for saw blade producers.

Top 10 Carbide Saw Tip Manufacturers You Can Trust

1. Kennametal Inc. (USA/Global)

A global leader in carbide technology, Kennametal offers an extensive range of Carbide Saw Tips for woodworking, metal cutting, and stone processing. Their consistent innovation, high-precision standards, and vast inventory make them a staple for OEMs worldwide. Kennametal is renowned for its proprietary carbide grades designed for specific applications, offering optimized combinations of hardness, toughness, and wear resistance. They invest heavily in R&D to push the boundaries of carbide technology, ensuring their products meet the evolving demands of industrial cutting. Their global distribution network and technical support make them a preferred partner for complex projects and high-volume requirements.

- Key Features: Custom solutions, extensive grade selection, stellite offerings, global technical support.

- Best for: High-volume industrial and automotive production, specialized cutting applications requiring custom carbide grades.

2. Freud Tools (Italy/Global)

Famed for their precision cutting tools, Freud's Diablo series leads the market in carbide circular saw blades. Their proprietary TiCo™ Hi-Density Carbide ensures durability and an edge that lasts. This unique titanium cobalt high-density carbide blend is formulated and manufactured by Freud, allowing them to control the quality and consistency of their Carbide Saw Tips from raw material to finished product. Their unique Perma-SHIELD® coating dramatically reduces heat buildup, prevents gumming, and protects the blade from corrosion, further extending the life of the Carbide Saw Tips. Freud's commitment to innovation is evident in their continuous development of cutting-edge technologies.

- Key Features: Proprietary carbide blends (TiCo™ Hi-Density), innovative coatings (Perma-SHIELD®), precision grinding for superior finishes.

- Best for: Professional woodworking, construction, and precision industries where clean cuts and long tool life are paramount.

3. Bosch (Germany/Global)

Bosch, a household name in power tools, also produces high-quality circular saw blades that utilize advanced Brute Carbide™ technology. This carbide formulation provides exceptional toughness and resistance to fracture, even in heavy-duty, high-impact scenarios where other carbides might chip or break. The Speed Coat™ finish applied to their blades further enhances cutting efficiency by reducing friction and heat buildup, which extends the life of the Carbide Saw Tips. Bosch's broad product portfolio and extensive R&D capabilities ensure they offer a wide range of Carbide Saw Tips optimized for various materials and cutting tasks, from wood to metal and plastics.

- Key Features: Broad selection of blades and tips, robust engineering background, Brute Carbide™ technology for extreme durability.

- Best for: General manufacturing, woodworking, renovation projects, and demanding applications where durability is key.

4. DeWalt (USA/Global)

DeWalt is synonymous with high-performance cutting tools. Their *Precision Trim™* and *Series 20* blades are engineered with ToughCoat™ finishes and Thin Kerf technology — all leveraging premium Carbide Saw Tips for longevity and performance. DeWalt focuses on user experience, designing Carbide Saw Tips that not only last but also deliver smooth, efficient cuts with minimal effort. Their innovation extends to unique tooth geometries and anti-vibration designs that enhance the performance and lifespan of their Carbide Saw Tips, particularly in demanding construction environments.

- Key Features: Innovative friction-reducing finishes (ToughCoat™), international reach, optimized tip geometries for specific cutting tasks.

- Best for: Framing, construction, and finishing carpentry, where speed, accuracy, and durability are essential.

5. DLTC Tools (China/Global OEM)

DLTC, a premier Chinese saw blade and Carbide Saw Tip manufacturer, excels in customized solutions and OEM/ODM services for international brands and wholesalers. They have established a strong reputation for producing high-quality Carbide Saw Tips that comply with strict international quality standards, making them a reliable partner for those seeking large-scale, high-quality supplies at competitive prices. DLTC's flexibility in manufacturing allows them to produce a wide array of Carbide Saw Tips with various geometries, grades, and coatings tailored to specific client needs, making them an ideal choice for private label brands and distributors.

- Key Features: Flexible OEM/ODM capabilities, custom geometries on request, competitive pricing, consistent quality assurance.

- Best for: Private label brands, distributors, and brand owners looking for high-quality, cost-effective Carbide Saw Tips manufactured in China.

6. TechMet Carbide (USA)

TechMet Carbide has built a reputation in North America for supplying a vast catalog of standard and custom Carbide Saw Tips. Their focus on rapid response, strict quality assurance protocols, and logistical flexibility makes them a go-to for many saw blade re-tippers and manufacturers who require immediate and consistent supply. TechMet's commitment to quality is underpinned by rigorous inspection processes, ensuring every Carbide Saw Tip meets stringent performance criteria. They offer a wide range of carbide grades, allowing customers to select the optimal material for their specific cutting applications.

- Key Features: Same-day shipping for stocked items, huge product range, Six Sigma processes for quality control, technical support.

- Best for: Blade repair and re-tipping services, custom manufacturing operations requiring specialized tips, and businesses needing fast delivery.

7. Zhongbo Carbide (China)

One of China's most trusted sources for Carbide Saw Tips, Zhongbo Carbide specializes in both OEM and ODM services. They provide hundreds of tip profiles tailored for cutting hard wood, soft wood, and various alloys, catering to a diverse global customer base. Their extensive experience in carbide manufacturing allows them to produce high-performance Carbide Saw Tips with consistent quality and superior wear resistance. Zhuzhou Huijin invests in modern production facilities and advanced testing equipment to ensure the reliability and durability of their products, making them a strong contender for international procurement.

- Key Features: Wide customization options, abundant stock of standard tips, consistent quality control, strong R&D capabilities.

- Best for: OEM customers, wood and metal processing industries seeking reliable and customizable Carbide Saw Tips from a Chinese manufacturer.

8. PILANA (Czech Republic/EU)

Renowned for industrial cutting tools, PILANA offers high-precision Carbide Saw Tips suitable for European and international market standards. They focus on research-driven product development and efficient logistics, ensuring their Carbide Saw Tips meet the demanding requirements of various industries. PILANA's expertise lies in producing Carbide Saw Tips that offer excellent performance in terms of cutting speed, accuracy, and tool life, particularly for specialized industrial applications like forestry and furniture manufacturing. Their commitment to quality and environmental responsibility further enhances their appeal.

- Key Features: European styles and standards, innovative metallurgy, strong focus on industrial applications, efficient logistics.

- Best for: Furniture manufacturing, forestry, and other specialty manufacturing sectors in Europe and beyond that require high-performance cutting tools.

9. Leitz (Germany)

Leitz is a premier woodworking tool manufacturer, with Carbide Saw Tips renowned for their durability and exceptional sharpness. Their research labs focus on incremental improvements for blades used in high-speed, industrial environments, where precision and longevity are critical. Leitz's Carbide Saw Tips are engineered for extreme tolerance and advanced performance, contributing to smoother cuts, reduced noise, and longer tool life in demanding industrial settings. Their expertise in tool design and material science ensures that their Carbide Saw Tips deliver consistent, high-quality results.

- Key Features: Extreme tolerance manufacturing, advanced engineering, focus on industrial woodworking applications, continuous innovation.

- Best for: Professional woodshops and industrial saw lines that demand the highest levels of precision, efficiency, and tool lifespan.

10. Amana Tool (USA)

Amana specializes in industrial and CNC cutting tools, offering a line of circular saw blades with Sub-Micrograin Carbide tips for maximum edge performance. They are favored in woodworking, composites processing, and sign-making due to the superior edge retention and durability of their Carbide Saw Tips. Amana Tool also incorporates advanced coatings like Silver I.C.E.™ (Industrial Cooling Element) which reduces heat buildup and resin adhesion, significantly extending the life and performance of their Carbide Saw Tips. Their commitment to quality and innovative solutions makes them a top choice for precision cutting applications.

- Key Features: Superior tip microstructure (Sub-Micrograin Carbide), Silver I.C.E.™ anti-corrosion coating, precision manufacturing.

- Best for: Precision machining, sign industry, processing of woods and laminates, where clean cuts and prolonged tool life are essential.

Deep Dive: The Science of Carbide Saw Tips

The Chemistry

Carbide Saw Tips are made through a sophisticated process of powder metallurgy, primarily combining fine tungsten carbide particles with a metallic binder, most commonly cobalt. The tungsten carbide provides the extreme hardness and wear resistance, while the cobalt binder gives the material its toughness and ability to withstand impact and thermal stresses without fracturing. The precise ratio of tungsten carbide to cobalt (typically 6% to 15% cobalt by weight) is crucial and is carefully controlled to achieve specific material properties.

The manufacturing process involves:

- Mixing: Tungsten carbide powder and cobalt powder are thoroughly mixed to ensure homogeneity.

- Milling: This step reduces particle size and mixes the components intimately, ensuring a uniform distribution.

- Pressing: The mixed powder is pressed into the desired shape under high pressure, forming a "green" compact.

- Sintering: The green compacts are heated in a vacuum or inert gas furnace to temperatures between 1300°C and 1600°C. During sintering, the cobalt binder melts and wets the tungsten carbide particles, causing them to fuse together and create a dense, hard, and wear-resistant composite material. This process is critical in determining the final grain structure, hardness, and toughness of the Carbide Saw Tips.

Different binder contents and grain sizes of tungsten carbide allow for the creation of various grades of carbide, each optimized for specific applications. For instance, higher cobalt content typically results in tougher, more impact-resistant Carbide Saw Tips, while lower cobalt content and finer tungsten carbide grains yield harder, more wear-resistant tips suitable for abrasive materials.

The Engineering

Beyond the material composition, the engineering of Carbide Saw Tips, particularly their geometry, plays a critical role in their performance. The shape, angle, and grind of each tip are meticulously designed to optimize cutting efficiency, chip evacuation, and finish quality for specific materials and cutting operations.

Common tip geometries include:

- Flat-Top Grind (FTG): This is a basic grind with a flat top face, suitable for ripping applications in wood and general-purpose cutting where finish quality is less critical.

- Alternate-Top Bevel (ATB): Features alternating bevels on the top of the teeth, creating a knife-like edge that scores the wood before the main cut. This results in cleaner crosscuts in wood and plywood, reducing splintering.

- Triple Chip Grind (TCG): This geometry consists of alternating trapezoidal and flat teeth. The trapezoidal tooth makes a preliminary cut, followed by the flat tooth which clears the kerf. TCG is ideal for cutting hard materials like laminates, MDF, and non-ferrous metals, providing excellent finish and longer tool life due to reduced heat buildup.

- Conical Grind (CG): Often used for specialized applications, offering specific cutting characteristics.

- Combination Grind: Combines different tooth geometries on a single blade, offering versatility for both ripping and crosscutting.

The clearance angles (relief behind the cutting edge) and rake angles (angle of the cutting edge relative to the blade) are also precisely engineered. Positive rake angles are common for woodworking, allowing the tip to "bite" into the material aggressively, while negative rake angles are often used for cutting metals or materials that require a more controlled, scraping action, enhancing safety and reducing chipping. The precision grinding of these geometries after sintering ensures that each Carbide Saw Tip performs optimally and contributes to the overall efficiency and longevity of the saw blade.

How to Choose the Right Carbide Saw Tip Manufacturer

Selecting the right manufacturer for Carbide Saw Tips is a strategic decision that can significantly impact your product quality, operational efficiency, and bottom line. Consider the following factors:

1. Certifications and Quality Control: Look for manufacturers that adhere to international quality management standards such as ISO 9001. Enquire about their internal quality assurance (QA) and quality control (QC) processes, including raw material inspection, in-process monitoring, and final product testing. Manufacturers employing Six Sigma methodologies or similar rigorous statistical process controls often demonstrate a higher commitment to consistency and defect reduction.

2. Material and Grade Options: A reputable manufacturer should offer a diverse range of carbide grades, each with specific properties optimized for different applications. Discuss your material cutting needs (e.g., hardwood, softwood, laminates, non-ferrous metals, composites) and ensure the manufacturer can supply Carbide Saw Tips with the appropriate hardness, toughness, and wear resistance. They should be able to advise on the best carbide grade for your specific use case.

3. Customization and OEM/ODM Services: If you are a brand owner, wholesaler, or manufacturer looking for unique product offerings, the ability to customize Carbide Saw Tips is crucial. This includes custom tip geometries, specialized coatings (e.g., for reduced friction or corrosion resistance), specific dimensions, and even pre-tinning for easier brazing. For private labeling, inquire about their Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) capabilities, including custom packaging and branding options.

4. Lead Time and Inventory: For continuous industrial operations, consistent supply and predictable lead times are paramount. Assess the manufacturer's production capacity, inventory management systems, and their ability to meet your volume requirements within reasonable timeframes. Discuss minimum order quantities (MOQs) and the potential for long-term supply agreements.

5. Technical Support and After-sales Service: A reliable manufacturer provides excellent technical support, assisting with product selection, application advice, and troubleshooting. This includes pre-sales consultation and robust after-sales service, such as addressing quality concerns, providing material safety data sheets (MSDS), and offering technical training if needed. Good communication and quick resolution of issues are indicators of a strong partnership.

6. Cost-Effectiveness and Value: While price is always a consideration, focus on the overall value proposition. A slightly higher initial cost for a superior Carbide Saw Tip may result in significantly longer tool life, fewer blade changes, and better cut quality, leading to lower total operating costs in the long run. Seek a balance between competitive pricing and uncompromising quality.

7. Reputation and References: Research the manufacturer's industry reputation. Look for customer testimonials, case studies, and industry awards. If possible, request references from existing clients, especially those with similar requirements to yours, to gain insights into their experience with the manufacturer's product quality and service.

Conclusion

Carbide Saw Tips are the unsung heroes driving productivity and quality in modern cutting operations. They represent a significant investment in the efficiency, safety, and performance of any cutting tool. By carefully selecting suppliers—especially those offering robust OEM, customization, and technical support—you're not just purchasing a component; you're investing in the longevity of your tools, the quality of your output, and the overall profitability of your operations.

The ten manufacturers highlighted in this article have forged international reputations through consistent innovation, rigorous quality management, and service excellence. Each offers unique strengths, catering to different market segments and specific needs, from high-volume industrial production to specialized precision cutting. Whether you're a global brand seeking a consistent OEM partner, a small business aiming for superior performance, or an OEM distributor looking for reliable supplies, their Carbide Saw Tips can be the keystone of your success. Making an informed choice among these top-tier manufacturers will ensure your saw blades perform at their peak, delivering exceptional results and a competitive edge in your industry.

FAQ: Carbide Saw Tips (Frequently Asked Questions)

1. What are Carbide Saw Tips made of?

Carbide Saw Tips are primarily made of tungsten carbide powder, which provides extreme hardness and wear resistance, bound together with a metallic binder, most commonly cobalt. This composite material is created through a high-temperature powder metallurgy process known as sintering, resulting in a dense, durable insert that is brazed onto the teeth of saw blades.

2. How can I tell if a Carbide Saw Tip is high quality?

High-quality Carbide Saw Tips exhibit uniform grain structure, consistent material composition, and precise dimensions achieved through meticulous manufacturing processes. Indicators of quality include certifications (e.g., ISO standards), a manufacturer's adherence to strict quality control protocols, excellent surface finish, and a lack of visible imperfections such as pores or cracks. Performance in terms of sharpness retention and longevity under typical operating conditions is the ultimate test.

3. What OEM services are available for Carbide Saw Tips?

Top Chinese and international manufacturers offer a wide range of OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services for Carbide Saw Tips. These services typically include custom tip geometry design and production, selection of specific carbide grades to match application requirements, pre-tinning for simplified brazing, specialized coatings (e.g., for friction reduction or corrosion resistance), custom dimensions, and branded packaging. This allows brands and distributors to offer unique, tailored products to their markets.

4. How do you attach Carbide Saw Tips to a saw blade?

Carbide Saw Tips are typically attached to the steel body of a saw blade using a brazing process. This involves placing a small piece of silver solder and flux between the carbide tip and the blade body, then heating the assembly. The solder melts and flows, creating a strong metallic bond as it cools. Modern industrial processes often use automated brazing machines to ensure consistent heat distribution and precise tip placement, which is crucial for the accuracy and durability of the finished saw blade.

5. Can Carbide Saw Tips be resharpened or replaced?

Yes, one of the significant advantages of Carbide Saw Tips is their ability to be resharpened multiple times. Professional blade sharpening services use specialized diamond grinding wheels to precisely regrind the tips, restoring their original sharpness and cutting efficiency. If a Carbide Saw Tip becomes severely damaged, chipped, or broken, it can often be carefully removed from the blade body and a new tip brazed in its place. This process, known as re-tipping, significantly extends the overall life of the saw blade, making it a cost-effective solution for industrial users.