Content Menu

● What Is Tungsten Carbide?

● Types of Tungsten Carbide

● Physical and Chemical Properties

>> Physical Characteristics

>> Chemical Characteristics

● Detailed Physical Properties

● Manufacturing Process

● Advanced Manufacturing Techniques

● Applications of Tungsten Carbide

● Expanded Applications

>> Industrial Cutting and Machining

>> Wear-Resistant Components

>> Medical and Dental Instruments

>> Jewelry and Fashion

>> Environmental and Safety Applications

● Environmental and Safety Considerations

● Future Trends and Research

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What makes tungsten carbide so hard?

>> 2. How is tungsten carbide different from high-speed steel?

>> 3. Can tungsten carbide be used for cutting all types of metals?

>> 4. Is tungsten carbide resistant to corrosion?

>> 5. How is tungsten carbide coated onto tools?

Tungsten carbide is a remarkable material widely used in various industrial applications due to its exceptional hardness, strength, and durability. This article explores what tungsten carbide is, its types, properties, manufacturing processes, applications, and frequently asked questions, providing a comprehensive understanding of this versatile material.

What Is Tungsten Carbide?

Tungsten carbide is a chemical compound composed of equal parts tungsten and carbon atoms, with the chemical formula WC. It typically appears as a fine gray powder but can be pressed and sintered into solid shapes for industrial use. Known for its extreme hardness and toughness, tungsten carbide is often referred to as cemented carbide, solid carbide, or hardmetal.

The material combines the hardness of ceramic tungsten carbide with the toughness of metallic binders such as cobalt or nickel, resulting in a composite known as cermet. This combination provides both wear resistance and mechanical resilience, making tungsten carbide ideal for cutting tools, mining equipment, jewelry, and more.

Types of Tungsten Carbide

Tungsten carbide comes in several types, primarily differentiated by their composition and intended use:

- Tungsten Carbide for Non-Iron Cutting: This type is used for machining non-ferrous metals such as aluminum, brass, copper, and magnesium. It mainly consists of tungsten carbide and cobalt (WC-Co).

- Tungsten Carbide for Iron Cutting: Designed for cutting ferrous metals like low-carbon steel and stainless steel, this type includes additives such as titanium carbide (TiC) and tantalum carbide (TaC) to enhance cutting performance and durability.

- Special Grades: Some tungsten carbide grades include titanium carbide with nickel or molybdenum binders, optimized for specific industrial requirements.

Physical and Chemical Properties

Physical Characteristics

- Hardness: Tungsten carbide ranks about 9 on the Mohs scale, second only to diamond, making it incredibly resistant to scratching and wear.

- Young's Modulus: Approximately 530–700 GPa, indicating very high stiffness, nearly three times that of steel.

- Density: About 15.6 g/cm³, roughly twice the density of steel.

- Melting Point: Around 2,780 °C, one of the highest melting points among engineering materials.

- Thermal Conductivity: Approximately 110 W/(m·K), allowing efficient heat dissipation.

- Thermal Expansion: Low coefficient of thermal expansion (about 5.5 μm/m·K), which helps maintain dimensional stability under temperature changes.

Chemical Characteristics

- Stability: Tungsten carbide is highly stable and does not oxidize at room temperature.

- Resistance: It resists corrosion and does not dissolve in water, hydrochloric acid, or sulfuric acid but can dissolve in nitric acid.

- Reactivity: Reacts with fluorine at room temperature and chlorine at high temperatures (above 400 °C).

- Oxidation: Begins oxidizing around 500–600 °C, forming tungsten oxide (WO₃) at higher temperatures.

Detailed Physical Properties

Tungsten carbide exhibits remarkable physical properties that make it suitable for extreme conditions. Its hardness, close to that of diamond, is complemented by its high compressive strength, which allows it to withstand heavy mechanical loads without deformation. The material's fracture toughness, although lower than metals, is significantly enhanced by the metallic binder, which helps absorb impact energy and prevent brittle failure.

The thermal conductivity of tungsten carbide is relatively high for a ceramic material, enabling it to dissipate heat efficiently during high-speed machining operations. This property reduces thermal damage to both the tool and the workpiece, improving tool life and machining accuracy.

Additionally, tungsten carbide's low thermal expansion coefficient ensures dimensional stability during temperature fluctuations, which is critical in precision tooling and aerospace applications.

Manufacturing Process

Tungsten carbide is manufactured by combining tungsten and carbon powders, which are then sintered under high pressure and temperature. The sintering process bonds the tungsten carbide particles with a metallic binder such as cobalt or nickel, creating a dense, hard composite.

The grain size of tungsten carbide and the proportion of binder metal significantly influence the material's hardness, toughness, and wear resistance. Smaller grain sizes typically yield higher hardness but lower toughness, while larger grains improve toughness.

Advanced Manufacturing Techniques

Beyond traditional powder metallurgy and sintering, tungsten carbide components are increasingly produced using advanced manufacturing methods. Hot isostatic pressing (HIP) applies uniform pressure and heat to densify the material, resulting in improved mechanical properties and reduced porosity.

Additive manufacturing (3D printing) of tungsten carbide composites is an emerging field, allowing complex geometries and customized tool designs that were previously impossible or cost-prohibitive. Techniques such as binder jetting followed by sintering are being explored to produce near-net-shape parts with minimal waste.

Coating technologies have also evolved, with chemical vapor deposition (CVD) and physical vapor deposition (PVD) methods enabling thin, uniform tungsten carbide layers on substrates, enhancing surface hardness and wear resistance without compromising the core material's toughness.

Applications of Tungsten Carbide

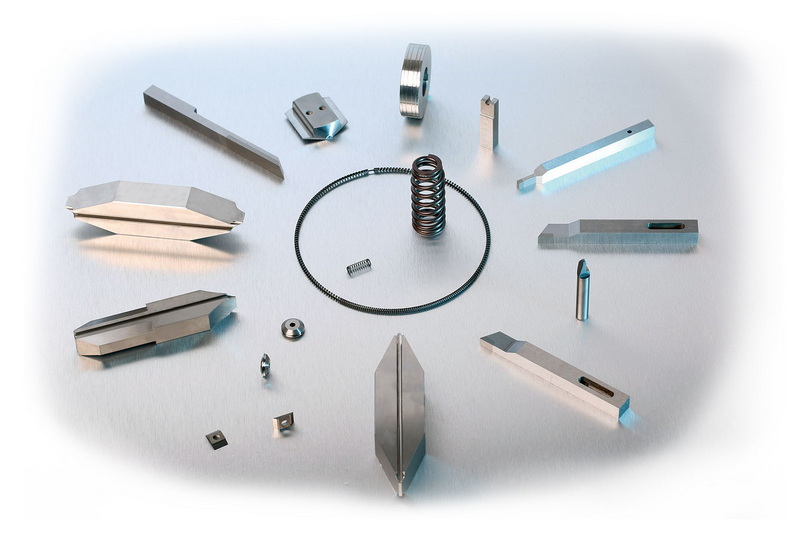

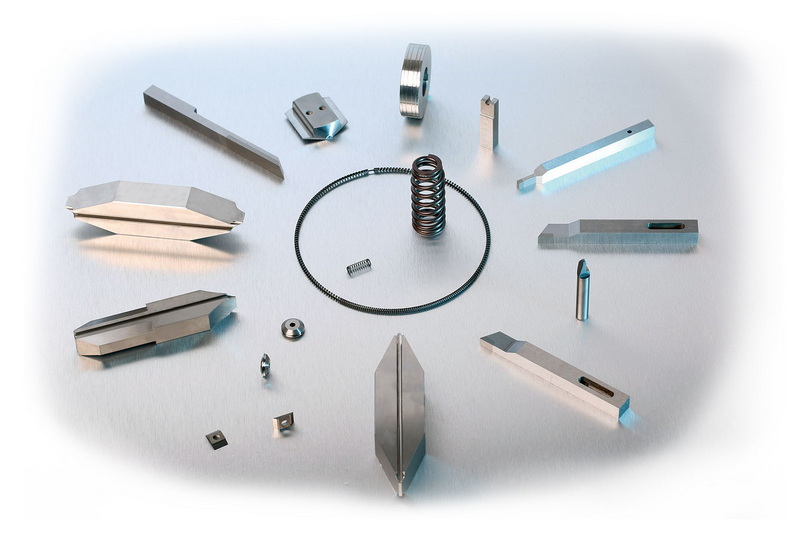

Tungsten carbide's unique combination of hardness and toughness makes it indispensable in many industries:

- Cutting Tools: Used extensively in drills, end mills, inserts, and saw blades for machining metals and other materials at high speeds.

- Mining and Drilling: Core drill bits and mining tools often feature tungsten carbide tips for durability against abrasive rock and soil.

- Aerospace: Coatings on turbine blades and compressor seals protect against erosion and high-temperature wear.

- Oil and Gas: Drill bits, valve stems, and pump components benefit from tungsten carbide's resistance to wear and corrosion in harsh environments.

- Jewelry: Tungsten carbide is used to make rings and other jewelry items due to its scratch resistance and polished finish.

- Medical Tools: Precision cutters and surgical instruments utilize tungsten carbide for its sharpness and longevity.

- Consumer Electronics: Components requiring durability and wear resistance often incorporate tungsten carbide coatings.

Expanded Applications

Industrial Cutting and Machining

Tungsten carbide remains the material of choice for cutting tools in automotive, aerospace, and general manufacturing industries. Its ability to maintain sharp edges at high temperatures allows for faster machining speeds and longer tool life, reducing downtime and production costs.

Wear-Resistant Components

In addition to cutting tools, tungsten carbide is used in wear-resistant parts such as valve seats, pump seals, and nozzles. These components operate in abrasive environments where conventional materials would quickly degrade.

Medical and Dental Instruments

The biocompatibility and hardness of tungsten carbide make it ideal for surgical instruments, dental drills, and implants. Its resistance to corrosion and wear ensures reliability and longevity in medical applications.

Jewelry and Fashion

Tungsten carbide's scratch resistance and ability to take a high polish have made it popular in jewelry, especially for wedding bands and watches. Its unique metallic luster and durability appeal to consumers seeking long-lasting accessories.

Environmental and Safety Applications

Tungsten carbide is used in radiation shielding and protective coatings due to its density and hardness. It also finds applications in safety equipment such as bulletproof vests and armor plating.

Environmental and Safety Considerations

While tungsten carbide offers many benefits, its production and disposal raise environmental concerns. The mining of tungsten and cobalt, essential raw materials, can have significant ecological impacts. Efforts are underway to improve recycling processes for tungsten carbide tools to reduce waste and conserve resources.

Handling tungsten carbide powders requires precautions to avoid inhalation, as fine particles can pose respiratory hazards. Manufacturers implement strict safety protocols to protect workers during production.

Future Trends and Research

Research into tungsten carbide focuses on enhancing its properties and expanding its applications. Nanostructured tungsten carbide composites aim to improve toughness without sacrificing hardness. Hybrid materials combining tungsten carbide with ceramics or polymers are being developed for specialized uses.

Advances in additive manufacturing promise more efficient production and innovative designs. Additionally, environmentally friendly manufacturing processes and recycling technologies are priorities to reduce the material's ecological footprint.

Conclusion

Tungsten carbide is a highly versatile and durable material characterized by its extraordinary hardness, strength, and thermal stability. Its unique properties make it essential in a wide range of industrial applications, from cutting tools and mining equipment to aerospace components and jewelry. The combination of tungsten carbide with metallic binders creates a composite material that balances hardness with toughness, enabling superior performance in demanding environments. As manufacturing technologies advance, tungsten carbide continues to find new uses, proving its value as an indispensable material in modern industry.

Frequently Asked Questions (FAQs)

1. What makes tungsten carbide so hard?

Tungsten carbide's hardness comes from its strong covalent bonds between tungsten and carbon atoms arranged in a dense hexagonal crystal structure, combined with the fine grain size and metallic binder that enhance toughness.

2. How is tungsten carbide different from high-speed steel?

Tungsten carbide is significantly harder and more wear-resistant than high-speed steel, allowing cutting tools made from it to operate at higher speeds and last longer under abrasive conditions.

3. Can tungsten carbide be used for cutting all types of metals?

There are different grades of tungsten carbide optimized for cutting ferrous (iron-based) and non-ferrous metals. Additives like titanium carbide improve performance for specific materials such as stainless steel or aluminum.

4. Is tungsten carbide resistant to corrosion?

Yes, tungsten carbide is highly resistant to corrosion in most environments but can be attacked by certain acids like nitric acid and reacts with fluorine and chlorine under specific conditions.

5. How is tungsten carbide coated onto tools?

Tungsten carbide coatings are commonly applied using processes such as high-velocity oxygen fuel (HVOF) spraying or detonation gun (D-Gun) spraying, which produce dense, well-bonded coatings that enhance wear resistance.