Content Menu

● Understanding Tungsten Carbide: Hardness and Properties

● What Can Scratch Tungsten Carbide?

>> 1. Diamonds and Other Hard Crystals

>> 2. Aluminum Oxide (Sandpaper Abrasive)

>> 3. Other Tungsten Carbide or Similar Hard Materials

>> 4. Hard Ceramics and Sharpening Stones

>> 5. Environmental Abrasives: Sand, Dust, and Small Rocks

● Why Does Tungsten Carbide Sometimes Appear Scratched?

● How to Care for Tungsten Carbide to Minimize Scratches

>> Daily Care Tips

>> Cleaning Instructions

>> Maintenance

● Advanced Care and Handling Tips

● Industrial Applications and Scratch Resistance

● Historical Background of Tungsten Carbide

● Environmental Impact and Sustainability

● Visual Examples of Tungsten Carbide Scratches and Care

● Comparison Table: Tungsten Carbide vs Other Materials in Scratch Resistance

● Additional Insights: Tungsten Carbide in Everyday Life

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. Can everyday objects scratch tungsten carbide?

>> 2. Is tungsten carbide scratch-proof?

>> 3. How can I remove scratches from tungsten carbide jewelry?

>> 4. Does the coating on tungsten carbide rings affect scratch resistance?

>> 5. How does tungsten carbide compare to titanium in terms of scratch resistance?

Tungsten carbide is renowned for its exceptional hardness and durability, making it a popular choice in industrial tools, jewelry, and wear-resistant applications. However, despite its toughness, tungsten carbide is not completely impervious to scratches. This comprehensive article explores what materials and conditions can scratch tungsten carbide, how to care for tungsten carbide items, and answers common questions about its scratch resistance.

Understanding Tungsten Carbide: Hardness and Properties

Tungsten carbide is a composite material made by combining tungsten and carbon atoms, typically in a 1:1 ratio. It is produced through powder metallurgy, where tungsten powder and carbon black are compacted and sintered at high temperatures to form a dense, extremely hard structure.

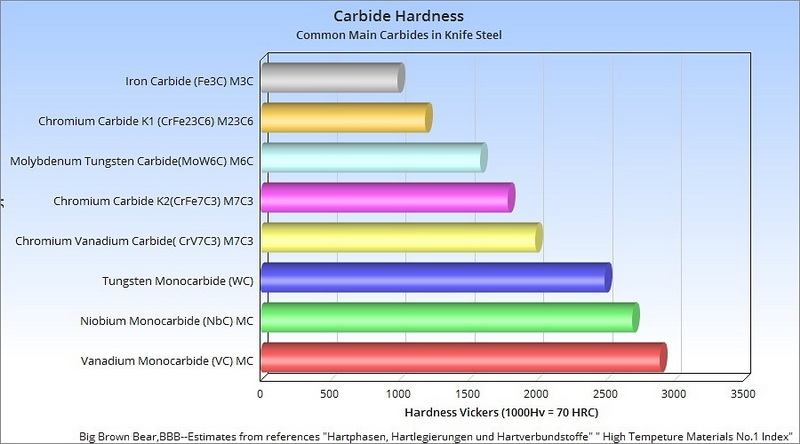

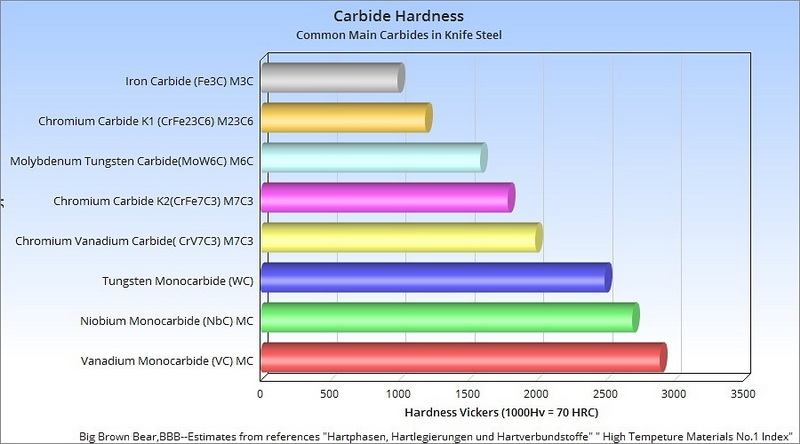

- Hardness: Tungsten carbide ranks between 8.5 and 9 on the Mohs hardness scale, making it one of the hardest materials available, just below diamond, which ranks 10.

- Durability: Its hardness translates to excellent scratch resistance, but it is also brittle compared to metals like titanium.

- Corrosion Resistance: Tungsten carbide does not tarnish or oxidize easily, maintaining its appearance over time.

- Brittleness: Despite its hardness, it can chip or crack under high impact or pressure.

These properties make tungsten carbide ideal for cutting tools, mining equipment, aerospace components, and jewelry such as wedding bands.

What Can Scratch Tungsten Carbide?

1. Diamonds and Other Hard Crystals

Diamonds, the hardest known natural material, can scratch tungsten carbide. Other hard crystals like sapphires and certain ceramics can also cause scratches because their hardness exceeds tungsten carbide's.

2. Aluminum Oxide (Sandpaper Abrasive)

Aluminum oxide, commonly used in sandpaper and abrasive materials, can scratch tungsten carbide under enough pressure. Even though it is softer than diamond, the abrasive particles can cause surface scratches if rubbed forcefully.

3. Other Tungsten Carbide or Similar Hard Materials

Tungsten carbide can be scratched by other tungsten carbide tools or materials of similar hardness, especially if there is enough force applied. Industrial tooling made from tungsten carbide or similar carbides can cause scratches or wear marks.

4. Hard Ceramics and Sharpening Stones

Certain ceramic materials and sharpening stones, often used in tool maintenance, can scratch tungsten carbide surfaces due to their hardness and abrasive nature.

5. Environmental Abrasives: Sand, Dust, and Small Rocks

Small abrasive particles like sand or dust can scratch tungsten carbide if they are pressed against it with sufficient force or rubbed repeatedly. This is common in everyday wear scenarios where tungsten carbide rings or tools come into contact with gritty materials.

Why Does Tungsten Carbide Sometimes Appear Scratched?

- Surface Coatings: Many tungsten carbide rings and items have a polished coating or plating that can wear or scratch more easily than the underlying carbide.

- Residue or Metal Transfer: Sometimes what looks like a scratch is actually residue or powder transferred from another metal or surface, which can often be cleaned off.

- Localized Alloy Differences: Some tungsten carbide items include binder metals like cobalt or nickel in narrow sections, which are softer and more prone to scratching.

How to Care for Tungsten Carbide to Minimize Scratches

Daily Care Tips

- Avoid contact with abrasive surfaces such as concrete, sandpaper, or rough metals.

- Remove tungsten carbide jewelry when performing heavy manual labor or using harsh chemicals.

- Clean regularly with mild soap, warm water, and a soft toothbrush or microfiber cloth to remove dirt and residues that may cause abrasions.

Cleaning Instructions

1. Prepare a mild soap and warm water solution.

2. Soak the tungsten carbide item for 5-10 minutes.

3. Gently scrub with a soft toothbrush, especially in crevices.

4. Rinse thoroughly with lukewarm water.

5. Dry with a soft towel, avoiding aggressive rubbing.

Maintenance

- Inspect monthly for scratches or chips.

- For minor scratches, professional polishing can restore the surface.

- Avoid DIY polishing with abrasive materials that could worsen scratches.

Advanced Care and Handling Tips

To further extend the life and appearance of tungsten carbide items, consider the following advanced care tips:

- Separate Storage: Store tungsten carbide jewelry separately in a soft pouch or lined box to prevent contact with other hard materials.

- Temperature Control: Avoid exposure to extreme temperatures which can affect the binder metals and cause microfractures.

- Professional Services: Use professional cleaning services periodically to maintain the finish and inspect for any damage.

- Proper Handling: When working with tungsten carbide tools, ensure proper handling and avoid dropping or striking them against hard surfaces to prevent chipping.

- Avoid Chemical Exposure: Refrain from exposing tungsten carbide items to harsh chemicals or cleaning agents that might degrade coatings or binders over time.

- Regular Inspection: Schedule regular inspections for any signs of wear, especially in high-stress areas such as the edges of rings or the tips of tools.

Industrial Applications and Scratch Resistance

Tungsten carbide's hardness and scratch resistance make it invaluable in various industrial applications:

- Cutting Tools: Used in machining metals, wood, and composites where durability and edge retention are critical. Examples include milling cutters, saw blades, and lathe tools.

- Mining and Drilling: Drill bits and mining tools made from tungsten carbide withstand abrasive rock and soil conditions, making them essential for resource extraction industries.

- Aerospace Components: Parts exposed to high wear and temperature benefit from tungsten carbide's properties, including turbine blades, nozzles, and engine components.

- Jewelry: Rings and watches use tungsten carbide for its scratch resistance and aesthetic appeal. Its hypoallergenic properties make it suitable for sensitive skin.

- Medical Instruments: Surgical tools and dental drills leverage tungsten carbide's hardness for precision and longevity.

Understanding what can scratch tungsten carbide helps industries select appropriate materials and maintenance routines to maximize tool life.

Historical Background of Tungsten Carbide

Tungsten carbide was first developed in the early 20th century as a super-hard material for industrial use. Its discovery revolutionized cutting and drilling technologies, replacing traditional steel tools in many applications. Over the decades, advances in powder metallurgy and sintering techniques have improved its toughness and versatility, making it a staple in modern manufacturing and consumer products.

Key Milestones:

- 1920s: Development of tungsten carbide for industrial cutting tools.

- 1950s: Introduction of advanced sintering methods, enhancing material properties.

- 1980s-Present: Expansion into consumer products, including jewelry and precision instruments.

Environmental Impact and Sustainability

While tungsten carbide is durable and long-lasting, its production involves mining tungsten and carbon sources, which have environmental footprints. Mining activities can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly.

- Recycling: Recycling tungsten carbide scrap is common in industry to reduce waste and conserve resources. Scrap carbide is collected, processed, and reused, significantly lowering the environmental impact.

- Sustainable Practices: Manufacturers are increasingly adopting sustainable sourcing and eco-friendly production methods to minimize their carbon footprint.

- Lifecycle Assessment: Tungsten carbide's long lifespan and recyclability contribute to its sustainability, but responsible disposal and recycling are essential to mitigate environmental harm.

Visual Examples of Tungsten Carbide Scratches and Care

- Close-up of a tungsten carbide ring with minor surface scratches.

- Comparison between a polished and a scratched tungsten carbide surface.

- Step-by-step cleaning process with mild soap and soft brush.

- Illustration of materials ranked by Mohs hardness scale showing tungsten carbide relative to diamond and aluminum oxide.

- Diagram showing the brittleness and chipping potential under impact.

Comparison Table: Tungsten Carbide vs Other Materials in Scratch Resistance

| Material | Mohs Hardness | Scratch Resistance | Comments |

| Diamond | 10 | Can scratch tungsten carbide | Hardest natural material |

| Tungsten Carbide | 8.5 - 9 | Highly scratch resistant | Can chip under impact |

| Aluminum Oxide | ~9 | Can scratch tungsten carbide | Common abrasive in sandpaper |

| Titanium | ~6 | Moderate | More impact resistant but softer |

| Platinum | 4 - 5 | Low | Easily scratched |

| Gold | 2.5 - 3 | Low | Soft and prone to scratches |

Additional Insights: Tungsten Carbide in Everyday Life

Beyond industrial and jewelry applications, tungsten carbide is found in everyday items that benefit from its hardness and durability:

- Sports Equipment: Golf club inserts and cleats use tungsten carbide for wear resistance.

- Automotive Parts: Brake pads and engine components may incorporate tungsten carbide for improved performance.

- Consumer Electronics: Some high-end watches and device components utilize tungsten carbide for scratch resistance.

Conclusion

Tungsten carbide is one of the hardest and most scratch-resistant materials available, widely used in jewelry and industrial tools. However, it is not completely scratch-proof. Materials harder than tungsten carbide, such as diamonds and aluminum oxide abrasives, can scratch it, especially under sufficient pressure. Environmental factors like sand and dust may also cause surface abrasions. Additionally, coatings and binder metals in tungsten carbide products can be more vulnerable to scratches.

Proper care, including avoiding abrasive contact, regular cleaning, and professional maintenance, can help preserve tungsten carbide's appearance and durability. Understanding the limits of tungsten carbide's hardness and brittleness allows users to enjoy its benefits while minimizing damage.

Frequently Asked Questions (FAQs)

1. Can everyday objects scratch tungsten carbide?

Everyday objects like steel, glass, or plastic generally cannot scratch tungsten carbide due to its high hardness. However, abrasive particles like sand or dust, or accidental contact with harder materials like diamonds or aluminum oxide, can cause scratches under enough pressure.

2. Is tungsten carbide scratch-proof?

No material is completely scratch-proof. Tungsten carbide is highly scratch-resistant but can be scratched or chipped by harder materials or severe impacts. Its toughness is balanced by brittleness, meaning it can crack or chip under force.

3. How can I remove scratches from tungsten carbide jewelry?

Many surface marks are residue or minor scratches that can be cleaned off with warm soapy water and a soft cloth. For deeper scratches, professional polishing by a jeweler is recommended to restore the finish without damaging the item.

4. Does the coating on tungsten carbide rings affect scratch resistance?

Yes. Coatings or plating on tungsten carbide rings can be more susceptible to scratches than the underlying material. Colored or plated rings may show scratches more readily than uncoated polished tungsten carbide.

5. How does tungsten carbide compare to titanium in terms of scratch resistance?

Tungsten carbide is significantly harder and more scratch-resistant than titanium, which ranks about 6 on the Mohs scale. Titanium offers better impact resistance but is more prone to scratches, making tungsten carbide preferable for scratch resistance.