Content Menu

● Introduction to Titanium Carbide

● Essential Raw Materials for Titanium Carbide Production

>> 1. Titanium Source

>> 2. Carbon Source

● Additional Materials and Additives

● Overview of Titanium Carbide Production Processes

>> 1. Carbothermal Reduction

>> 2. Direct Carbonization

>> 3. Self-Propagating High-Temperature Synthesis (SHS)

>> 4. Chemical Vapor Deposition (CVD)

>> 5. Mechanical Alloying and Reactive Ball Milling

● Detailed Titanium Carbide Production Process

>> Step 1: Preparation of Raw Materials

>> Step 2: Shaping and Binding

>> Step 3: Heat Treatment and Carburization

>> Step 4: Cooling and Pulverization

>> Step 5: Purification and Quality Control

● Applications of Titanium Carbide

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What are the main raw materials used in titanium carbide production?

>> 2. Why is titanium dioxide preferred over metallic titanium in TiC production?

>> 3. What role do binders play in the titanium carbide production process?

>> 4. How does the self-propagating high-temperature synthesis (SHS) method differ from carbothermal reduction?

>> 5. What impurities must be controlled in titanium carbide raw materials?

Titanium carbide (TiC) is a highly valuable ceramic material known for its exceptional hardness, thermal stability, and wear resistance. It is widely used in industrial applications such as cutting tools, abrasives, military hardware, metallurgy, petroleum drilling, mining tools, and construction. Understanding the raw materials required for titanium carbide production is fundamental to optimizing its synthesis and ensuring high-quality end products. This article provides an in-depth exploration of the raw materials used in titanium carbide production, the various synthesis methods, and the detailed titanium carbide production process.

Introduction to Titanium Carbide

Titanium carbide has been a critical material in advanced manufacturing and engineering since its discovery in the early 20th century. Its unique combination of hardness, thermal stability, and chemical inertness has made it indispensable in environments where conventional materials fail. Over the decades, continuous research and development have improved the production techniques and broadened the applications of titanium carbide, making it a cornerstone in modern industry.

Titanium carbide is a ceramic compound composed of titanium and carbon atoms arranged in a face-centered cubic (FCC) lattice structure. It exhibits a melting point around 3140–3160°C, a density of approximately 4.93 g/cm³, and hardness values ranging from 2800 to 3000 HV, making it one of the hardest known materials after diamond. Its chemical stability and resistance to corrosion further enhance its industrial appeal.

Essential Raw Materials for Titanium Carbide Production

The production of titanium carbide primarily involves two key raw materials:

1. Titanium Source

- Titanium Dioxide (TiO₂): The most common and cost-effective raw material for TiC production is titanium dioxide, especially in its purified forms such as rutile, which contains about 98% TiO₂. Titanium dioxide is preferred for carbothermal reduction methods due to its availability and relatively low cost.

- Metallic Titanium Powder: High-purity titanium powder can also be used, especially in direct carbonization or mechanical alloying methods. However, submicron titanium powder is difficult and expensive to prepare, limiting its widespread use.

- Titanium Salts and Titanium Tetrachloride (TiCl₄): Used mainly in chemical vapor deposition (CVD) methods, titanium tetrachloride is a volatile compound that reacts with hydrocarbons to deposit TiC.

The sourcing of raw materials for titanium carbide production is a complex process that involves not only the procurement of high-purity titanium dioxide and carbon sources but also stringent quality control measures. Titanium dioxide is often extracted from mineral ores such as ilmenite and rutile, which undergo extensive refining to remove impurities. The refining process ensures that impurities such as magnesium, calcium, aluminum, silicon, and iron oxides are minimized, as these can degrade the quality of the final TiC product.

2. Carbon Source

- Carbon Black: A pure form of carbon commonly used due to its high surface area and reactivity.

- Petroleum Coke: Finely divided and calcined petroleum coke is favored for its low ash content and reducing properties.

- Charcoal or Graphite: These carbonaceous materials are also used, especially in carbothermal reduction processes.

- Other Carbonaceous Materials: Sawdust, molasses, pitch, and other binders may be used in shaping the raw material mixture but primarily act as binders or secondary carbon sources.

Carbon sources must be carefully selected to ensure minimal ash content and high reactivity, as impurities can significantly affect the final product's performance. The carbon's particle size and purity influence the reaction kinetics and the microstructure of the resulting titanium carbide.

Additional Materials and Additives

- Binders: Pitch, molasses, or other organic binders are often added to the raw material mixture to aid in shaping and compaction before high-temperature treatment.

- Reducing Agents: In some synthesis routes, magnesium or calcium may be added to facilitate metallothermic reduction reactions.

Overview of Titanium Carbide Production Processes

Several methods exist for synthesizing titanium carbide, each with specific raw material requirements and process conditions.

1. Carbothermal Reduction

This is the most widely used industrial method. It involves mixing titanium dioxide with a carbon source in a stoichiometric ratio, pressing the mixture into blocks or pellets, and heating it at high temperatures (typically 1700–2300°C) in an inert or reducing atmosphere (hydrogen or argon).

Chemical Reaction:

TiO2+3C→TiC+2CO

This process requires high-purity TiO₂ and carbon to minimize impurities in the final product. The mixture is often ball-milled to ensure homogeneity before heating. Carbothermal reduction is cost-effective and scalable but requires precise temperature control and atmosphere management to prevent unwanted side reactions such as the formation of titanium oxycarbides or free carbon residues.

2. Direct Carbonization

In this method, metallic titanium powder is mixed with carbon powder and heated to 1500–1700°C under a hydrogen atmosphere. The reaction forms TiC directly:

Ti+C→TiC

This method is limited by the availability and cost of fine titanium powder and the difficulty in controlling the reaction. However, it offers a more straightforward reaction path without the intermediate formation of oxides.

3. Self-Propagating High-Temperature Synthesis (SHS)

SHS is a combustion synthesis method where an exothermic reaction between titanium dioxide, carbon, and sometimes magnesium or other additives initiates a self-sustaining reaction producing TiC rapidly at high temperatures.

Example Reaction:

TiO2+C+2Mg→TiC+2MgO

SHS offers advantages such as lower external energy input and the production of nano-sized TiC powders. However, it can produce powders with variable particle sizes and may require further processing to achieve uniformity.

4. Chemical Vapor Deposition (CVD)

This method involves the reaction of titanium tetrachloride (TiCl₄) with hydrocarbons like methane in the presence of hydrogen at elevated temperatures. TiC deposits on substrates as thin films or powders.

Reaction Example:

TiCl4+CH4→TiC+4HCl

CVD allows for precise control of TiC morphology and composition but involves complex equipment and handling of corrosive gases, making it less common for bulk powder production.

5. Mechanical Alloying and Reactive Ball Milling

Titanium and carbon powders are milled together in high-energy ball mills, inducing mechanical alloying and sometimes self-propagating reactions to form TiC at lower temperatures than traditional methods.

This method is versatile and can produce fine powders with controlled particle sizes but may introduce contamination from milling media, requiring careful selection of milling materials and conditions.

Detailed Titanium Carbide Production Process

Step 1: Preparation of Raw Materials

- Purification: Titanium dioxide is purified to remove impurities such as magnesium, calcium, aluminum, silicon, and iron oxides, which can adversely affect TiC quality.

- Particle Size Reduction: Both titanium dioxide and carbon sources are ground to fine powders to increase surface area and reaction efficiency.

- Mixing: The powders are mixed in precise stoichiometric ratios, commonly TiO₂ to carbon at 1:3 molar ratio for carbothermal reduction. Mixing is often done using ball mills or high-speed mixers to ensure homogeneity.

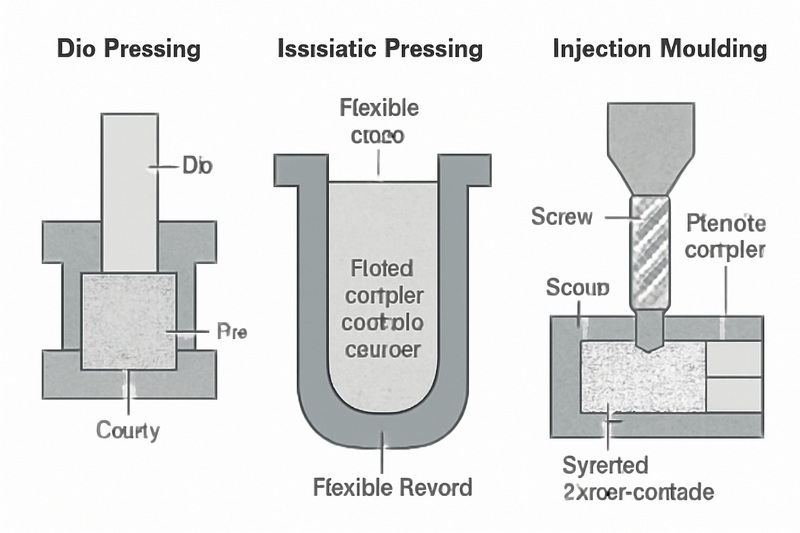

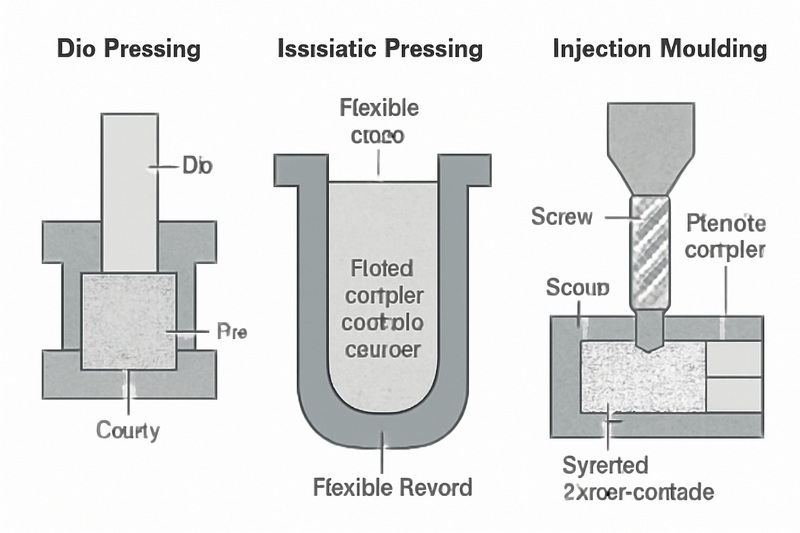

Step 2: Shaping and Binding

- The mixed powders are combined with binders like pitch or molasses to facilitate compaction.

- The mixture is shaped into pellets, blocks, or green compacts using pressing machines under pressures of 150–200 MPa.

Step 3: Heat Treatment and Carburization

- The shaped compacts are heated in resistance furnaces, induction furnaces, or tube furnaces under inert or reducing atmospheres.

- The temperature is raised gradually to 1400–3000°C, with most industrial processes operating between 1700–2300°C.

- During heating, carbothermal reduction occurs, converting TiO₂ and carbon into TiC and releasing CO gas.

Step 4: Cooling and Pulverization

- After reaction completion, the product is cooled under protective atmosphere to avoid oxidation.

- The solid TiC blocks are then crushed and ground to obtain fine TiC powders suitable for further applications.

Step 5: Purification and Quality Control

- Impurities and free carbon are minimized through additional purification steps if necessary, such as acid leaching or magnetic separation.

- The final TiC powder is analyzed for particle size distribution, purity, phase composition, and hardness to ensure it meets industrial standards.

Applications of Titanium Carbide

Due to its exceptional properties, titanium carbide is utilized in:

- Industrial Cutting Tools: Cemented carbides with TiC are used for machining steel, cast iron, and other hard materials. TiC enhances hardness and wear resistance in tungsten carbide composites.

- Military and Aerospace: Components requiring high hardness and thermal stability, such as armor plating and heat shields.

- Mining and Drilling: Wear-resistant coatings and tools for petroleum and mineral exploration, including drill bits and cutting edges.

- Metallurgy: As additives to improve hardness and wear resistance of metal alloys and as crucible materials for high-temperature processes.

- Construction: Durable materials for abrasive and structural applications, including wear plates and cutting tools.

Looking ahead, titanium carbide is poised to play an even more significant role in emerging technologies. Its use in cutting-edge aerospace components, high-performance coatings, and additive manufacturing is expanding rapidly. Researchers are exploring nano-engineered TiC composites to enhance mechanical properties and thermal conductivity. Additionally, the development of environmentally friendly production methods is gaining momentum, aiming to reduce the carbon footprint of titanium carbide manufacturing.

Conclusion

In summary, the production of titanium carbide is a sophisticated process that hinges on the quality of raw materials and the choice of synthesis method. High-purity titanium dioxide and carbon sources form the backbone of TiC synthesis, while additional materials like binders and reducing agents facilitate shaping and reaction efficiency. Various production methods, including carbothermal reduction, direct carbonization, SHS, CVD, and mechanical alloying, offer different advantages and challenges depending on the desired TiC properties and application.

As industrial demands evolve, so too will the technologies and materials used in TiC production. Continued innovation promises to unlock new applications and improve the sustainability of this vital material, ensuring its relevance for decades to come.

Frequently Asked Questions (FAQs)

1. What are the main raw materials used in titanium carbide production?

The primary raw materials are high-purity titanium dioxide (TiO₂) or metallic titanium powder and a carbon source such as carbon black, petroleum coke, or charcoal.

2. Why is titanium dioxide preferred over metallic titanium in TiC production?

Titanium dioxide is more abundant and cost-effective. Carbothermal reduction of TiO₂ with carbon is easier to scale industrially compared to direct carbonization of metallic titanium powder, which is expensive and difficult to prepare finely.

3. What role do binders play in the titanium carbide production process?

Binders like pitch or molasses help in shaping and compacting the raw material mixture before heat treatment, ensuring uniformity and structural integrity during carburization.

4. How does the self-propagating high-temperature synthesis (SHS) method differ from carbothermal reduction?

SHS is a combustion synthesis that uses exothermic reactions to produce TiC rapidly with less external energy, often resulting in nano-sized powders, while carbothermal reduction requires sustained high temperatures over longer periods.

5. What impurities must be controlled in titanium carbide raw materials?

Impurities such as oxides of magnesium, calcium, aluminum, silicon, and iron must be minimized as they can form unwanted carbides, degrade TiC quality, and affect its mechanical properties.