Content Menu

● Introduction

● Understanding Tungsten Carbide Drawing Dies

● Manufacturing Process and Quality Control

● Applications and Industry Uses

● Technical Specifications and Design Considerations

● Maintenance and Performance Optimization

● Conclusion

● Frequently Asked Questions

>> Q1: What is the typical lifespan of a carbide drawing die?

>> Q2: How does the surface finish of a carbide die affect wire quality?

>> Q3: What are the key factors in selecting the right carbide grade?

>> Q4: How often should carbide dies be inspected?

>> Q5: What are the main advantages of carbide dies over other materials?

Introduction

Carbide drawing dies represent a cornerstone technology in modern manufacturing, particularly in wire processing and metal forming industries. These precision-engineered tools are essential components in the production of various metal products, from fine wires to complex shaped materials. This comprehensive guide explores the multifaceted aspects of carbide drawing dies, their applications, manufacturing processes, and technical specifications.

Understanding Tungsten Carbide Drawing Dies

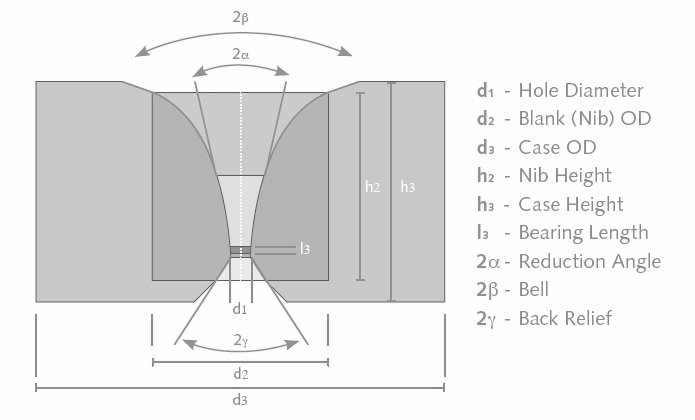

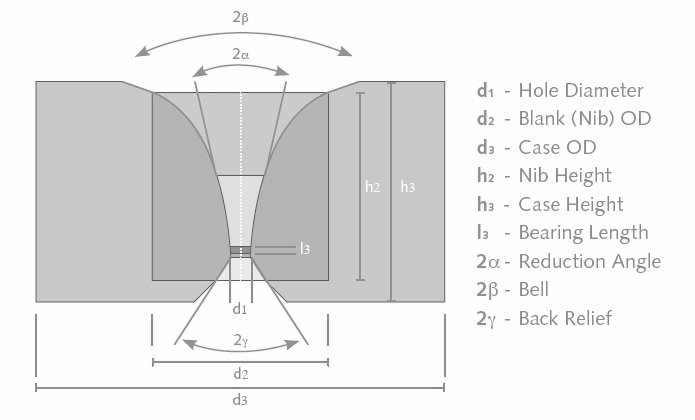

Tungsten carbide drawing dies are sophisticated tools designed for precision metal forming operations. These dies consist of a tungsten carbide blank secured within a steel casing, providing both mechanical protection and ease of handling during die exchanges. The exceptional hardness and wear resistance of tungsten carbide make it an ideal material for drawing applications, particularly in processing abrasive and high-carbon materials. The dies are manufactured with precise geometrical specifications, including carefully calculated approach angles, bearing lengths, and exit angles, all of which contribute to optimal drawing performance and product quality.

Manufacturing Process and Quality Control

The manufacturing of carbide drawing dies involves several critical steps:

1. Powder Metallurgy: The process begins with the careful selection and mixing of tungsten carbide powders with binding agents.

2. Pressing and Sintering: The mixture is compressed under high pressure and sintered at elevated temperatures.

3. Precision Machining: Advanced CNC machines create the complex internal geometries.

4. Surface Treatment: Various finishing processes ensure optimal surface quality.

5. Quality Inspection: Rigorous testing procedures verify dimensional accuracy and surface finish.

Applications and Industry Uses

Carbide drawing dies find extensive applications across various industries:

- Wire Manufacturing: Production of electrical wires, steel cables, and specialty alloy wires

- Automotive Industry: Manufacturing of control cables, spring wires, and reinforcement materials

- Construction Sector: Production of prestressing wires and structural cables

- Electronics Industry: Fine wire drawing for electronic components

- Medical Device Manufacturing: Production of precise medical grade wires

Technical Specifications and Design Considerations

The technical aspects of carbide drawing dies require careful attention to:

- Die Geometry: Precise calculation of approach angles, bearing lengths, and exit angles

- Surface Finish: Achieving and maintaining optimal surface roughness values

- Material Grade Selection: Choosing appropriate carbide grades for specific applications

- Dimensional Tolerances: Maintaining strict adherence to size specifications

- Wear Resistance: Implementing appropriate measures for extended die life

Maintenance and Performance Optimization

Proper maintenance of carbide drawing dies is crucial for optimal performance and longevity:

1. Regular Inspection: Monitoring wear patterns and surface conditions

2. Cleaning Procedures: Implementing proper cleaning protocols

3. Storage Requirements: Maintaining appropriate storage conditions

4. Performance Monitoring: Tracking die performance metrics

5. Preventive Maintenance: Scheduling regular maintenance intervals

Conclusion

Carbide drawing dies continue to evolve with technological advancements, offering improved performance, longer service life, and enhanced precision in metal forming operations. Understanding their proper application, maintenance, and technical specifications is crucial for achieving optimal results in manufacturing processes.

Frequently Asked Questions

Q1: What is the typical lifespan of a carbide drawing die?

A1: The lifespan varies depending on the application, but properly maintained carbide dies can typically process several tons of material before requiring replacement or reconditioning.

Q2: How does the surface finish of a carbide die affect wire quality?

A2: The surface finish directly impacts wire surface quality, drawing force requirements, and overall process efficiency. A properly finished die reduces friction and ensures consistent wire quality.

Q3: What are the key factors in selecting the right carbide grade?

A3: Key factors include the wire material being processed, drawing speed requirements, production volume, and specific wear resistance needs.

Q4: How often should carbide dies be inspected?

A4: Regular inspections should be conducted based on production volume, typically every 8-12 hours of operation or at the beginning of each shift.

Q5: What are the main advantages of carbide dies over other materials?

A5: Carbide dies offer superior wear resistance, maintain dimensional stability, provide excellent surface finish, and can handle higher drawing speeds compared to traditional materials.