Content Menu

● Introduction to Titanium Carbide Powder

● Overview of Titanium Carbide Powder Production Methods

● 1. Carbothermal Reduction Method

>> Process Description

>> Detailed Steps

>> Advantages

>> Limitations

● 2. Direct Carbonization Method

>> Process Description

>> Process Details

>> Advantages

>> Limitations

● 3. Chemical Vapor Deposition (CVD)

>> Process Description

>> Process Details

>> Advantages

>> Limitations

● 4. High-Frequency Induction Carbothermal Reduction

>> Process Description

>> Process Details

>> Advantages

● 5. Reactive Ball Milling Technology

>> Process Description

>> Process Details

>> Advantages

>> Limitations

● Quality Control and Purification

● Industrial Considerations in Titanium Carbide Powder Production

● Environmental Impact and Safety Measures

● Advances and Future Trends in Titanium Carbide Powder Production

● Summary of Key Production Parameters

● Applications of Titanium Carbide Powder

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the most common method for producing titanium carbide powder?

>> 2. Why is carbothermal reduction preferred for TiC production?

>> 3. What are the challenges of the direct carbonization method?

>> 4. How does chemical vapor deposition produce titanium carbide powder?

>> 5. What role does purification play in TiC powder production?

Titanium carbide (TiC) powder is a critical material widely used in various industrial applications, including cemented carbides, cutting tools, wear-resistant coatings, and electrodes. It is valued for its exceptional hardness, high melting point, chemical stability, and excellent thermal and electrical conductivity. As a high-tech enterprise engaged in the research, production, and sales of carbide products for industrial, military, metallurgical, petroleum drilling, mining tools, and construction applications, understanding the standard production process of titanium carbide powder is essential. This article provides a comprehensive overview of the titanium carbide powder production process, exploring the main synthesis methods, equipment, and quality control measures.

Introduction to Titanium Carbide Powder

Titanium carbide is a gray metallic powder with a face-centered cubic (FCC) crystal structure similar to NaCl, exhibiting remarkable hardness second only to diamond. It has a melting point of approximately 3140°C and a boiling point around 4820°C. TiC is chemically stable, insoluble in water, and resistant to many acids, making it suitable for harsh environments. Its properties make it indispensable in manufacturing wear-resistant materials, cermets, heat-resistant alloys, and high-temperature vacuum equipment.

Overview of Titanium Carbide Powder Production Methods

Several methods exist for producing titanium carbide powder, each with unique advantages and limitations. The most widely used industrial method is carbothermal reduction, but other methods such as direct carbonization, chemical vapor deposition (CVD), high-frequency induction carbothermal reduction, and reactive ball milling are also employed depending on the desired powder characteristics.

1. Carbothermal Reduction Method

Process Description

Carbothermal reduction is the most commonly used industrial method due to its cost-effectiveness and scalability. It involves the reduction of titanium dioxide (TiO₂) with carbon (usually carbon black) at high temperatures ranging from 1700°C to 2300°C, typically held for 10 to 24 hours.

The chemical reaction is:

TiO2(s)+3C(s)→TiC(s)+2CO(g)

Detailed Steps

- Raw Material Preparation: High-purity TiO₂ and carbon black powders are weighed and mixed thoroughly, often using high-energy ball mills to ensure uniformity.

- Pressing: The powder mixture is pressed into blocks or pellets to improve contact between particles and facilitate the reduction reaction.

- High-Temperature Reduction: The pressed blocks are heated in a carbon tube furnace or electric furnace under an inert or reducing atmosphere (hydrogen or argon) at 1900-2300°C. This step induces the carbothermal reduction reaction forming TiC.

- Cooling and Pulverization: After the reaction, the blocks are cooled and then ground using ball mills or jet mills to obtain fine titanium carbide powder.

- Purification: The powder may undergo acid washing (using hydrochloric acid, nitric acid, or sulfuric acid) to remove residual impurities and improve purity.

Advantages

- Economical and suitable for large-scale production.

- Uses readily available raw materials.

- Produces TiC powder with good stoichiometry and particle size distribution.

Limitations

- High energy consumption due to elevated temperatures.

- Long reaction times.

- Difficulty in controlling submicron particle size and agglomeration.

2. Direct Carbonization Method

Process Description

This method involves the direct reaction of metallic titanium powder with carbon powder at high temperatures (1500°C to 1700°C) in a hydrogen atmosphere.

The chemical reaction is:

Ti(s)+C(s)→TiC(s)

Process Details

- Titanium powder (often submicron size) is mixed with carbon black and pressed into pellets.

- The pellets are heated in a graphite container within a hydrogen atmosphere furnace.

- The reaction proceeds over 5 to 20 hours, forming TiC.

- The product is then ground to fine powder and chemically purified if necessary.

Advantages

- Produces highly pure TiC powder.

- Lower reaction temperature compared to carbothermal reduction.

Limitations

- Preparation of submicron titanium powder is difficult and costly.

- Reactants tend to agglomerate, requiring additional grinding.

- Less commonly used on an industrial scale.

3. Chemical Vapor Deposition (CVD)

Process Description

CVD synthesizes TiC powder by reacting titanium tetrachloride (TiCl₄) with hydrogen and a carbon source (hydrocarbons) at high temperatures on a heated filament substrate.

Process Details

- TiCl₄ vapor is mixed with hydrogen and hydrocarbons like methane or benzene.

- The gas mixture passes over a heated tungsten or carbon filament.

- TiC crystals deposit directly on the filament.

- The powder is harvested after deposition.

Advantages

- Produces high-purity TiC with controlled morphology.

- Suitable for fine particle production.

Limitations

- Low production yield and limited scalability.

- Corrosive reactants require special handling.

- High operational complexity and cost.

4. High-Frequency Induction Carbothermal Reduction

Process Description

This method uses high-frequency induction heating to rapidly heat pressed blocks of TiO₂ and carbon mixture under an inert atmosphere (argon), promoting carbothermal reduction.

Process Details

- TiO₂ and charcoal powders are mixed in specific ratios and ball milled.

- The mixture is pressed into blocks and placed in a graphite crucible.

- The crucible is heated by high-frequency induction equipment to about 500A current.

- The reaction proceeds for about 20 minutes under argon protection.

- After cooling, the product is ground into ultra-fine TiC powder.

Advantages

- Short reaction time.

- Energy-efficient due to rapid heating.

- Produces fine particle size powder.

5. Reactive Ball Milling Technology

Process Description

Reactive ball milling uses mechanical energy to induce chemical reactions between titanium or titanium alloys and carbon powders during milling.

Process Details

- Titanium powder and carbon are loaded into a high-energy ball mill.

- Mechanical impacts induce solid-state reactions forming TiC.

- Process can be controlled to produce nano-crystalline powders.

Advantages

- Lower temperature synthesis.

- Can produce nano-sized powders.

- Suitable for laboratory-scale and specialized applications.

Limitations

- Slow reaction process.

- Limited scalability for mass production.

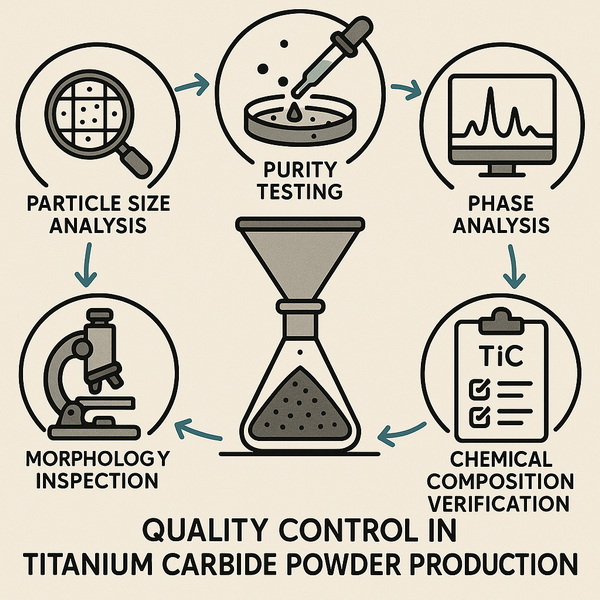

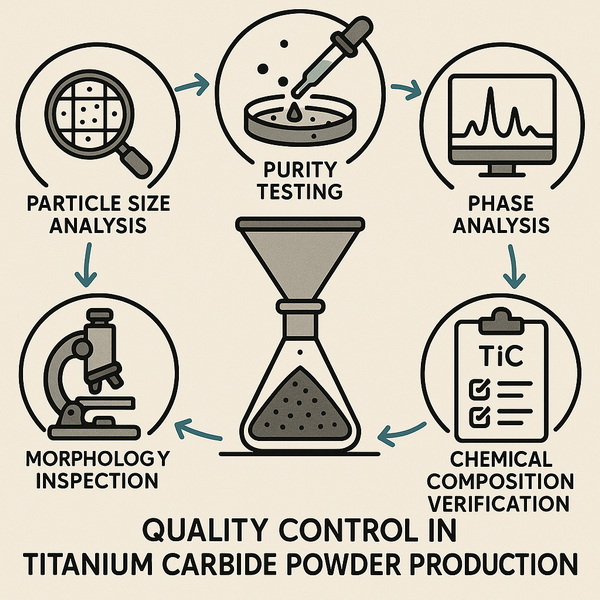

Quality Control and Purification

After synthesis, titanium carbide powder undergoes several quality control steps:

- Particle Size Analysis: Ensures powder meets specifications for particle size distribution.

- Purity Testing: Acid washing removes residual oxides and impurities.

- Phase Analysis: X-ray diffraction (XRD) confirms TiC phase purity.

- Morphology Inspection: Electron microscopy examines particle shape and agglomeration.

- Chemical Composition: Elemental analysis verifies stoichiometry.

Industrial Considerations in Titanium Carbide Powder Production

Producing titanium carbide powder at an industrial scale requires careful consideration of several factors beyond the basic chemical reactions. These include energy consumption, equipment durability, environmental regulations, and cost management. High-temperature furnaces used in carbothermal reduction must be designed to withstand extreme heat and corrosive gases generated during the process. Continuous monitoring of temperature and atmosphere composition is essential to maintain product quality and prevent contamination.

Moreover, the choice of carbon source can influence the final powder properties. Carbon black, graphite, and activated carbon are commonly used, each imparting different characteristics to the TiC powder. The particle size and purity of raw materials directly affect the reaction kinetics and the morphology of the resulting powder.

Environmental Impact and Safety Measures

The production of titanium carbide powder involves high-temperature processes that consume significant energy and generate gaseous byproducts such as carbon monoxide. Proper ventilation and gas treatment systems are necessary to mitigate environmental pollution and ensure worker safety. Recycling of off-gases and heat recovery systems can improve the overall sustainability of the production process.

Handling fine TiC powders requires strict safety protocols to prevent inhalation hazards and dust explosions. Personal protective equipment (PPE), dust collection systems, and regular safety training are critical components of a safe manufacturing environment.

Advances and Future Trends in Titanium Carbide Powder Production

Research continues to improve the efficiency and quality of titanium carbide powder production. Novel synthesis methods such as plasma-assisted carbothermal reduction and microwave heating are being explored to reduce energy consumption and reaction times. Additionally, the development of nano-sized TiC powders with controlled morphology opens new possibilities for advanced composite materials and coatings.

Automation and digital monitoring technologies are increasingly integrated into production lines to enhance precision and reduce human error. These advancements contribute to more consistent product quality and lower operational costs.

Summary of Key Production Parameters

| Parameter | Typical Range | Impact on Product Quality |

| Temperature | 1700°C - 2300°C | Higher temperatures improve reaction completion but increase energy costs |

| Reaction Time | 10 - 24 hours | Longer times ensure complete conversion but reduce throughput |

| Carbon Source | Carbon black, graphite, activated carbon | Affects powder purity and particle morphology |

| Atmosphere | Argon, hydrogen, or vacuum | Prevents oxidation and contamination |

| Particle Size of Raw Materials | Submicron to micron scale | Influences reaction kinetics and final powder size |

Applications of Titanium Carbide Powder

- Cemented Carbides: TiC is a key component in tungsten carbide-based cutting tools, enhancing hardness and wear resistance.

- Wear-Resistant Coatings: Used in coatings for mining and drilling equipment.

- Abrasives: Utilized in grinding wheels and polishing compounds.

- Electrodes: Employed in arc lamps and electrical discharge machining.

- High-Temperature Materials: Used in heat-resistant alloys and vacuum equipment.

Conclusion

The standard production process for titanium carbide powder primarily revolves around the carbothermal reduction of titanium dioxide with carbon at high temperatures, favored for its cost-effectiveness and scalability. Alternative methods such as direct carbonization, chemical vapor deposition, high-frequency induction heating, and reactive ball milling offer different advantages in purity, particle size control, and production scale. Each method involves critical steps of raw material preparation, high-temperature reaction, powder grinding, and purification to ensure high-quality TiC powder suitable for demanding industrial applications. Industrial-scale production must also address energy efficiency, environmental impact, and safety. Advances in synthesis technologies and automation promise to enhance product quality and reduce costs in the future, supporting the growing demand for titanium carbide powder in diverse sectors.

Frequently Asked Questions (FAQ)

1. What is the most common method for producing titanium carbide powder?

The most common industrial method is carbothermal reduction, which involves reducing titanium dioxide with carbon at high temperatures between 1700°C and 2300°C to produce TiC powder efficiently and economically.

2. Why is carbothermal reduction preferred for TiC production?

Carbothermal reduction is preferred because it uses inexpensive raw materials, is scalable for large production volumes, and produces TiC powder with good purity and particle size distribution.

3. What are the challenges of the direct carbonization method?

Direct carbonization requires submicron titanium powder, which is difficult and costly to prepare. The reaction process can lead to agglomeration and requires additional grinding and purification steps.

4. How does chemical vapor deposition produce titanium carbide powder?

CVD produces TiC by reacting titanium tetrachloride with hydrogen and hydrocarbons at high temperatures, depositing TiC crystals on heated filaments. This method yields high-purity powders but has low production yield and high costs.

5. What role does purification play in TiC powder production?

Purification removes residual oxides and impurities from the powder, improving chemical purity and performance. Acid washing and sieving are common purification steps to ensure high-quality TiC powder.