Content Menu

● Introduction

● What Are Carbide Saw Tips?

>> Key Properties of Carbide Saw Tips

>> Types of Carbide Saw Tips

● What Are Steel Tips?

>> Key Properties of Steel Tips

● Head-to-Head Comparison

>> Durability and Longevity

>> Cutting Performance

>> Heat and Wear Resistance

>> Cost Considerations

>> Maintenance

● Real-World Applications

>> Carbide Saw Tips

>> Steel Tips

● Advantages of Carbide Saw Tips

● Limitations of Carbide Saw Tips

● Innovations in Carbide Saw Tip Technology

● Environmental and Economic Impact

● Choosing the Right Tip for Your Application

● Safety Considerations

● Conclusion

● FAQ: Carbide Saw Tips vs. Steel Tips

>> 1. What are the main advantages of carbide saw tips over steel tips?

>> 2. Are carbide saw tips worth the higher cost?

>> 3. Can carbide saw tips be sharpened at home?

>> 4. When should I choose steel tips instead of carbide saw tips?

>> 5. Do carbide saw tips work with all types of saws?

Introduction

In the world of industrial cutting, the choice of saw tip material is a critical factor that impacts efficiency, longevity, and cost-effectiveness. Among the most debated options are Carbide Saw Tips and traditional Steel Tips. Both materials offer unique advantages and limitations, but which one truly delivers better performance for your specific needs? This comprehensive guide explores the differences, advantages, applications, and considerations to help you make an informed decision.

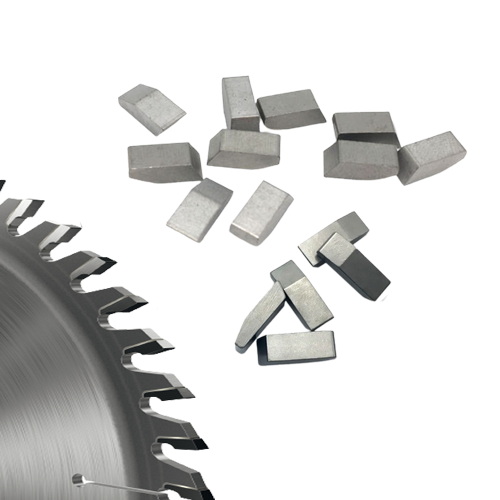

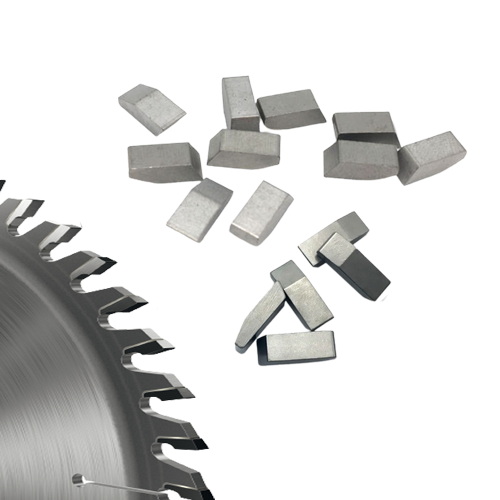

What Are Carbide Saw Tips?

Carbide Saw Tips are cutting tool inserts made primarily from tungsten carbide—a compound renowned for its exceptional hardness and wear resistance. These tips are brazed onto the teeth of saw blades, providing a durable cutting edge that maintains sharpness far longer than steel.

Key Properties of Carbide Saw Tips

- Hardness: Typically between 1,700 and 2,200 Vickers Hardness (HV), much higher than steel.

- Wear Resistance: Superior resistance to abrasion, making them ideal for heavy-duty and high-volume cutting.

- Heat Resistance: Can withstand high temperatures without losing cutting efficiency.

- Edge Retention: Remain sharp for extended periods, reducing downtime for sharpening.

Types of Carbide Saw Tips

| Type of Carbide | Application | Hardness (HV) | Wear Resistance |

| C1 Carbide | Softwood, non-ferrous metals | 1,700–2,200 | High |

| C2 Carbide | Hardwood, metals | 1,700–2,200 | High |

| C3 Carbide | MDF, hardwood | 1,800–2,200 | Very High |

| C4 Carbide | Very hard materials | 2,200–2,400 | Highest |

| Micrograin | Precision wood/metal cuts | 1,800–2,200 | Very High |

| PCD (Diamond) | Ultra-hard, high-volume | 6,000–10,000 | Ultra-High |

What Are Steel Tips?

Steel Tips are made from high-carbon or alloy steel and are commonly used in traditional saw blades. While steel is strong and relatively easy to sharpen, it does not offer the extreme hardness and longevity of carbide.

Key Properties of Steel Tips

- Affordability: Lower cost, making them accessible for general-purpose and budget-conscious users.

- Ease of Sharpening: Can be easily sharpened with standard tools.

- Versatility: Suitable for cutting softer materials and occasional use.

Head-to-Head Comparison

Durability and Longevity

- Carbide Saw Tips: Far more durable, maintain sharpness much longer, and require less frequent replacement.

- Steel Tips: Wear down faster, need regular sharpening or replacement, especially when used on hard materials.

Cutting Performance

- Carbide Saw Tips: Excel at cutting hard and abrasive materials such as hardwood, metals, composites, and plastics. Deliver cleaner, more precise cuts.

- Steel Tips: Suitable for softer materials but may struggle with hard or abrasive substances, leading to reduced efficiency over time.

Heat and Wear Resistance

- Carbide Saw Tips: Withstand high temperatures and resist wear, making them ideal for high-speed and high-volume operations.

- Steel Tips: More prone to heat deformation and wear, especially during prolonged or intensive use.

Cost Considerations

- Carbide Saw Tips: Higher initial cost but longer lifespan and fewer replacements offset the expense for professional users.

- Steel Tips: Lower upfront cost but may become more expensive over time due to frequent replacements.

Maintenance

- Carbide Saw Tips: Require specialized equipment for sharpening, often necessitating professional services.

- Steel Tips: Can be sharpened easily with standard tools, making maintenance more convenient for DIY users.

Real-World Applications

Carbide Saw Tips

- Industrial Metal Cutting: Essential for cutting stainless steel, carbon steel, and alloys.

- Woodworking: Perfect for hardwood, MDF, plywood, and composite panels.

- Construction: Used for cutting concrete, stone, and abrasive materials.

- OEM Manufacturing: Preferred by brands and wholesalers for reliable, long-lasting performance.

- Automotive and Aerospace: Used in precision cutting of hard metals and composite materials.

- Plastic and Composite Processing: Effective in cutting reinforced plastics and engineered materials.

Steel Tips

- General Carpentry: Suitable for softwoods, plastics, and occasional metal cutting.

- DIY Projects: Ideal for users who prioritize cost and ease of maintenance.

- Light Manufacturing: Used where high performance is not critical.

- Small Workshops: Beneficial for operations with limited budgets or less frequent cutting needs.

Advantages of Carbide Saw Tips

- Exceptional Hardness: Outlast steel tips by maintaining sharpness longer, reducing the frequency of blade changes.

- Reduced Downtime: Less frequent blade changes and sharpening, leading to increased productivity.

- Superior Cutting Quality: Cleaner, more precise cuts with minimal burring, essential for high-quality finishes.

- Versatility: Effective on a wide range of materials, including metals, woods, and composites.

- Increased Productivity: Faster cutting speeds and less operator fatigue due to efficient material removal.

- Consistency: Delivers uniform results over extended periods, crucial for industrial and OEM applications.

- Heat Resistance: Maintains performance even under high-speed and high-friction conditions.

Limitations of Carbide Saw Tips

- Higher Upfront Cost: More expensive initially than steel tips, which can be a barrier for budget-conscious users.

- Specialized Maintenance: Require professional sharpening tools and expertise, increasing maintenance complexity.

- Potential for Chipping: Hardness can make carbide tips more brittle under extreme shock or improper use.

- Compatibility: Not all saws are designed for carbide-tipped blades, requiring users to check tool compatibility.

Innovations in Carbide Saw Tip Technology

Advancements in manufacturing and material science have led to the development of micrograin carbide and polycrystalline diamond (PCD) tips. These innovations further enhance the durability, sharpness, and application range of carbide saw tips, making them suitable for ultra-high-volume and precision cutting tasks. Modern brazing techniques and improved tip geometries also contribute to longer tool life and better performance.

Environmental and Economic Impact

The extended lifespan and reduced frequency of replacement associated with carbide saw tips contribute to less waste and lower overall tool consumption. While the initial manufacturing process for carbide tips is more energy-intensive, the long-term environmental footprint is often smaller due to fewer discarded blades and reduced raw material usage. Economically, businesses benefit from lower total cost of ownership, improved productivity, and less downtime.

Choosing the Right Tip for Your Application

When deciding between carbide saw tips and steel tips, consider the following factors:

- Material to be Cut: For hard, abrasive, or composite materials, carbide is the clear winner.

- Project Volume: High-volume and industrial projects benefit from the durability of carbide.

- Budget: Steel tips are suitable for budget-conscious users or occasional use.

- Maintenance Capability: If you prefer easy sharpening, steel tips may be more convenient.

- Cutting Precision: For applications requiring fine finishes and tight tolerances, carbide tips deliver superior results.

- Tool Compatibility: Ensure your saw is compatible with the chosen tip material.

Safety Considerations

Proper use and maintenance of saw blades are essential for safety, regardless of tip material. Carbide tips, due to their hardness, can shatter if subjected to excessive force or improper handling. Always follow manufacturer guidelines for installation, operation, and maintenance. Use appropriate personal protective equipment (PPE) and ensure that blades are securely mounted and regularly inspected for damage.

Conclusion

Carbide saw tips deliver superior performance for demanding applications, offering unmatched durability, cutting precision, and efficiency. While steel tips remain a cost-effective choice for lighter tasks and easier maintenance, the long-term benefits of carbide—especially for industrial and OEM use—make them the preferred option for professionals seeking reliability and productivity. Investing in carbide saw tips ensures fewer blade changes, reduced downtime, and consistently high-quality results. Ultimately, the best choice depends on your specific cutting needs, budget, and maintenance capabilities.

FAQ: Carbide Saw Tips vs. Steel Tips

1. What are the main advantages of carbide saw tips over steel tips?

Carbide saw tips offer greater hardness, longer edge retention, superior wear resistance, and the ability to cut tougher materials without dulling quickly. They are ideal for industrial and high-volume cutting tasks.

2. Are carbide saw tips worth the higher cost?

Yes, for professional and heavy-duty applications, the longer lifespan and reduced maintenance of carbide tips offset the higher initial investment, resulting in lower overall costs over time.

3. Can carbide saw tips be sharpened at home?

Sharpening carbide saw tips typically requires specialized equipment and expertise. While it is possible to sharpen them by hand, professional sharpening is recommended for best results.

4. When should I choose steel tips instead of carbide saw tips?

Steel tips are suitable for softer materials, occasional use, and situations where low upfront cost and easy sharpening are priorities. They are less ideal for hard or abrasive materials.

5. Do carbide saw tips work with all types of saws?

Carbide saw tips can be used on various saw types, including circular saws, band saws, and specialized cutting tools. Their versatility makes them a popular choice across industries, but always check tool compatibility before use.