Content Menu

● Composition and Structure

● Properties of Tungsten Carbide

● Raw Materials for Producing Tungsten Carbide

● Manufacturing Processes

● Applications of Tungsten Carbide

● Cemented Carbides

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the chemical formula of tungsten carbide?

>> 2. What are the primary raw materials used in the production of tungsten carbide?

>> 3. How hard is tungsten carbide compared to other materials?

>> 4. What are some common applications of tungsten carbide?

>> 5. What is the process of making cemented carbide?

● Citations:

Tungsten carbide (WC) is a chemical compound comprising equal parts of tungsten and carbon atoms[6][7]. In its most basic form, tungsten carbide is a fine gray powder that can be pressed and formed into shapes through a process called sintering for use in industrial equipment, cutting tools, abrasives, armor-piercing shells, and jewelry[1][6][7]. Renowned for its remarkable hardness and wear resistance, it is a crucial material in various industrial applications[1][3].

Composition and Structure

Tungsten carbide, with the chemical formula WC, consists of equal parts of tungsten (W) and carbon (C)[3]. It features a strong triple bond between the tungsten IV cation (W⁴⁺) and the carbon anion (C⁴⁻), forming either a hexagonal or cubic structure depending on synthesis conditions[3]. The molar mass is approximately 195.85 g/mol[3]. For α-tungsten carbide, the stoichiometric ratio of tungsten to carbon must be nearly exact, typically within 49.5-50.5 mol % C[3][4]. This precise composition contributes to its exceptional hardness and resistance to high temperatures and abrasive conditions[3].

Properties of Tungsten Carbide

Tungsten carbide is known for its exceptional physical and chemical properties, making it suitable for a wide array of applications.

- Hardness: Tungsten carbide is exceptionally hard, ranking between 9 and 9.5 on the Mohs hardness scale, making it one of the hardest materials available, second only to diamonds[3]. It has a Vickers hardness of about 2600, indicating its superior hardness compared to most industrial materials[3].

- Density: With a density of about 15.6 g/cm³, tungsten carbide is significantly denser than carbides such as silicon carbide, which has a density of around 3.21 g/cm³[1].

- Stiffness: Tungsten carbide is approximately three times stiffer than steel, with a Young's modulus between 530–700 GPa[3].

- Wear Resistance: It exhibits outstanding wear resistance, lasting significantly longer in abrasive conditions[3]. These properties make it ideal for high-stress applications such as cutting tools and wear-resistant parts, where maintaining a sharp edge is crucial[3].

- Melting Point: Tungsten carbide has a high melting point, ranging from 2780 to 2830 ℃[1].

- Chemical Stability: Tungsten carbide does not interact with chlorine when it is below 400 °C. It reacts violently with fluorine at room temperature and is oxidized into tungsten oxide when heated in the air[5].

Raw Materials for Producing Tungsten Carbide

The production of tungsten carbide involves several raw materials, each playing a crucial role in the final product[1].

1. Tungsten Ore: Black ore is the primary source of tungsten[1].

2. Ammonium Paratungstate (APT): A purified chemical compound derived from tungsten ore that serves as an intermediate in the production of tungsten metal and tungsten carbide[1].

3. Tungsten Oxide: Produced by calcinating APT at high temperatures, which is then reduced to tungsten metal powder in a hydrogen atmosphere[1].

4. Carbon Sources: Soot or graphite are used to convert tungsten metal powder into tungsten carbide through a high-temperature carburization process[1].

Manufacturing Processes

The manufacturing of tungsten carbide involves several methods, each designed to produce materials with specific properties and applications[4][6].

1. Direct Carburization: Tungsten metal is reacted with carbon at temperatures between 1400 and 2000 degrees Celsius[6].

W + C → WC

2. Fluid Bed Process: A lower temperature fluid bed process reacts tungsten metal or blue WO3 with a CO/CO2 mixture and H2 between 900 and 1200 °C[6].

3. Tungsten Oxide Reduction: WO3 is heated with graphite at 900 degrees Celsius directly or in hydrogen at 670 degrees Celsius, followed by carburization in argon at 1000 degrees Celsius[6].

WO3 + 4C → WC + 3CO

4. Chemical Vapor Deposition (CVD): At 670 °C, tungsten hexachloride is reacted with hydrogen and methane[6].

WCl6 + H2 + CH4 → WC + 6HCl

5. Carburization of Tungsten Oxides and Salts: Tungsten oxides, tungstic acid, ammonium paratungstate, and scheelite can also be carburized directly[4].

WO3 + 4 C → WC + 3 CO

H2WO4 + 4 C → WC + 3 CO + H2O

(NH4)10W12O41 x 5 H2O + 48 C → 12 WC + 10 NH3 + 10 H2O + 36 CO

CaWO4 + 4 C → WC + CaO + 3 CO

Applications of Tungsten Carbide

Tungsten carbide's unique properties make it essential in many industries[2][5][8]. Its applications span across various fields due to its hardness, wear resistance, and thermal stability[2][3].

1. Cutting Tools: Known for its extreme hardness and durability, tungsten carbide is used to manufacture wear-resistant abrasives and cutting tools such as knives, drills, circular saws, and milling tools[2][3][8]. These tools are crucial in sectors like metalworking, woodworking, mining, petroleum, and construction[2][8].

2. Wear-Resistant Parts: Tungsten carbide is used in components that require high wear resistance, such as nozzles, bearings, and valve seats[3][5].

3. Jewelry: Tungsten carbide finds applications in the jewelry industry, producing durable and abrasion-resistant rings[2][6]. Tungsten carbide rings are much more durable than gold and silver rings[6]. Tungsten rings are rated between 8 and 9 on the Mohs scale of hardness[6].

4. Military Applications: Tungsten alloys, often combined with nickel, iron, or cobalt, are used in kinetic energy penetrators and other military projectiles[2]. These alloys are preferred over depleted uranium because they avoid radioactive hazards[2]. Tungsten is also utilized in dense inert metal explosives, designed to minimize collateral damage while increasing lethality within a confined radius[2].

5. Electronics and Electrical Industry: Tungsten's high melting point and excellent electrical conductivity make it suitable for various high-temperature applications[2]. It is commonly used in incandescent light bulb filaments, older television tubes (cathode-ray tubes), vacuum tubes, and rocket engine nozzles[2]. Tungsten is also essential in TIG (Tungsten Inert Gas) welding processes[2]. In the electronics sector, tungsten is used in integrated circuits and the production of semiconductors, X-ray tubes, and other electronic instruments[2].

6. Enhancing Steel Properties: By alloying tungsten with steel, the resulting material gains increased strength, hardness, and wear resistance[2]. Examples include high-speed steel, tungsten steel, and tungsten cobalt magnetic steel[2]. These alloys are used to manufacture tools such as drills, milling cutters, and wire drawing dies, where durability and precision are paramount[2].

7. Chemical Applications: Tungsten compounds are utilized in several chemical applications due to their unique properties[2]. Tungsten(IV) sulfide serves as a high-temperature lubricant and is used in hydrodesulfurization catalysts[2]. Tungsten oxides, like tungsten trioxide (WO₃), are employed in ceramic glazes, fluorescent lighting, and as components of catalysts in coal-fired power plants to reduce nitrogen oxides[2].

8. Medical Field: Tungsten is used for radiation shielding due to its high density and excellent radiation absorption capabilities[2]. It is employed in X-ray targets and gamma imaging devices, ensuring patient and operator safety in medical imaging procedures[2]. Tungsten carbide is often used to create surgical instruments because it enhances their performance and is also corrosion-resistant[8].

9. Aerospace and Automotive: In aerospace, tungsten is used as a ballast material to balance aircraft and spacecraft[2]. Its high density also makes it suitable for automotive applications, where it is used in components designed for vibration dampening and balancing[2].

Cemented Carbides

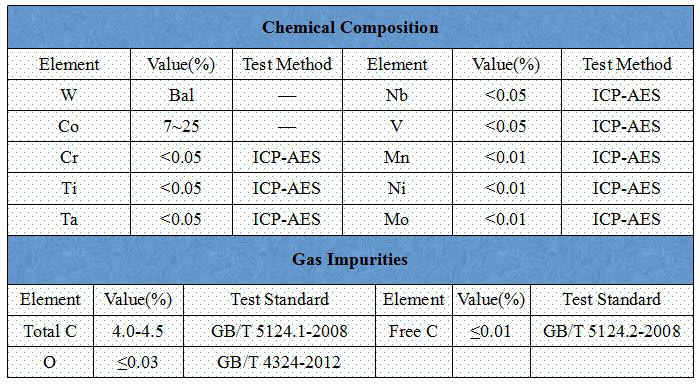

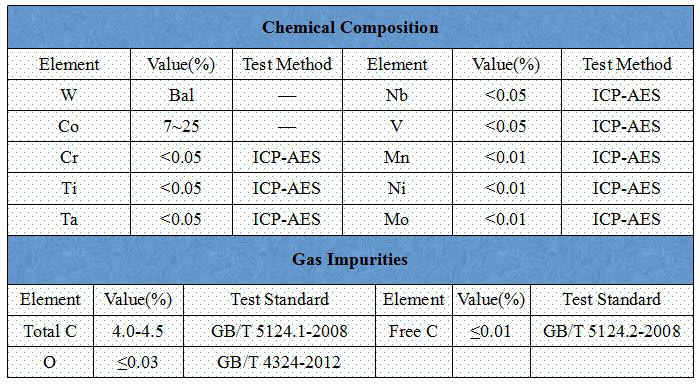

Cemented carbide is a material made by "cementing" tungsten carbide grains in a binder matrix of cobalt metal by liquid phase sintering[4]. Often referred to as "cemented carbide," it is a composite material formed through a powder metallurgy process[3]. This process involves mixing tungsten carbide powder with a binder metal such as cobalt or nickel, then compacting and sintering the mixture at high temperatures to achieve a strong, cohesive material[3][9]. Sintering is usually carried out below the melting temperature, so that a liquid phase is normally not present[9]. Sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten, molybdenum, or uranium dioxide ceramics[9].

Conclusion

Tungsten carbide is a remarkable material with a unique chemical composition and exceptional properties that make it indispensable in various industries. Its high hardness, wear resistance, and thermal stability contribute to its wide range of applications, from cutting tools and wear-resistant parts to jewelry and military projectiles. The ongoing research and development in tungsten carbide manufacturing processes continue to expand its potential, ensuring its significance in modern technology and engineering.

Frequently Asked Questions (FAQ)

1. What is the chemical formula of tungsten carbide?

The chemical formula of tungsten carbide is WC, indicating that it consists of equal parts of tungsten and carbon atoms[1][3][7].

2. What are the primary raw materials used in the production of tungsten carbide?

The primary raw materials include tungsten ore, ammonium paratungstate (APT), tungsten oxide, and carbon sources such as soot or graphite[1].

3. How hard is tungsten carbide compared to other materials?

Tungsten carbide ranks between 9 and 9.5 on the Mohs hardness scale, making it one of the hardest materials available, second only to diamonds[3].

4. What are some common applications of tungsten carbide?

Common applications include cutting tools, wear-resistant parts, jewelry, military projectiles, and components in the electronics and medical fields[2][5][6][8].

5. What is the process of making cemented carbide?

Cemented carbide is made by "cementing" tungsten carbide grains in a binder matrix of cobalt metal by liquid phase sintering, involving mixing tungsten carbide powder with a binder metal, compacting, and sintering the mixture at high temperatures[3][4][9].

Citations:

[1] https://heegermaterials.com/blog/90_how-is-tungsten-carbide-made-.html

[2] https://shop.machinemfg.com/understanding-tungsten-properties-applications-and-stability/

[3] https://shop.machinemfg.com/tungsten-carbide-an-overview/

[4] https://hpvchemicals.oecd.org/ui/handler.axd?id=ed1c76bf-dad9-4baa-8d1b-70fed7f92862

[5] https://www.refractorymetal.org/tungsten-carbide-uses-properties.html

[6] https://www.vedantu.com/chemistry/tungsten-carbide

[7] https://www.insaco.com/material/tungsten-carbide/

[8] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[9] https://material-properties.org/tungsten-carbide-properties-application-price/