Content Menu

● Composition of Electrode Paste

>> 1. Calcined Anthracite

>> 2. Petroleum Coke

>> 3. Coal Tar Pitch

>> 4. Additives

● Manufacturing Process: From Raw Materials to Electrodes

>> 1. Raw Material Selection and Pre-Treatment

>> 2. Mixing and Extrusion

>> 3. Baking in the Furnace

● Operational Role in Calcium Carbide Furnaces

>> 1. Energy Transfer Mechanism

>> 2. Self-Baking Electrode System

>> 3. Performance Optimization

● Critical Performance Factors

>> 1. Electrical Resistivity

>> 2. Thermal Conductivity

>> 3. Oxidation Resistance

● Innovations in Electrode Paste Technology

>> 1. Nanostructured Additives

>> 2. Eco-Friendly Binders

>> 3. AI-Driven Quality Control

● Global Market Trends (2025–2030)

● Challenges and Mitigation Strategies

● Conclusion

● FAQs

>> 1. How does particle size affect electrode paste performance?

>> 2. Can electrode paste be reused or recycled?

>> 3. What causes electrode paste to crack during sintering?

>> 4. How do closed vs. open furnaces affect paste requirements?

>> 5. What are the alternatives to coal tar pitch binders?

● Citations:

Calcium carbide (CaC₂) production is a cornerstone of modern industrial chemistry, enabling applications from acetylene gas synthesis to steelmaking. At the heart of this process lies electrode paste for calcium carbide production, a specialized carbon-based material that powers electric arc furnaces (EAFs). This article delves into its composition, manufacturing, operational role, and cutting-edge advancements, providing actionable insights for industries reliant on high-purity calcium carbide.

Composition of Electrode Paste

Electrode paste is engineered to balance conductivity, thermal stability, and mechanical strength. Its core components include:

1. Calcined Anthracite

- Role: Primary conductive material (fixed carbon >88%).

- Processing: Heated to 1350°C to remove volatile matter, enhancing electrical properties.

- Particle Size: 1–15 mm granules ensure optimal packing density.

2. Petroleum Coke

- Function: Reduces resistivity and improves thermal shock resistance.

- Grades: Needle coke (low thermal expansion) vs. sponge coke (cost-effective).

3. Coal Tar Pitch

- Binding Agent: Penetrates carbon particles, forming a cohesive matrix during sintering.

- Softening Point: 75–95°C to ensure flowability before baking.

4. Additives

- Graphite Flakes: Boost conductivity and reduce electrode consumption by 12–18%.

- Recycled Carbon: Spent electrodes or anode butts (up to 20%) lower costs and waste.

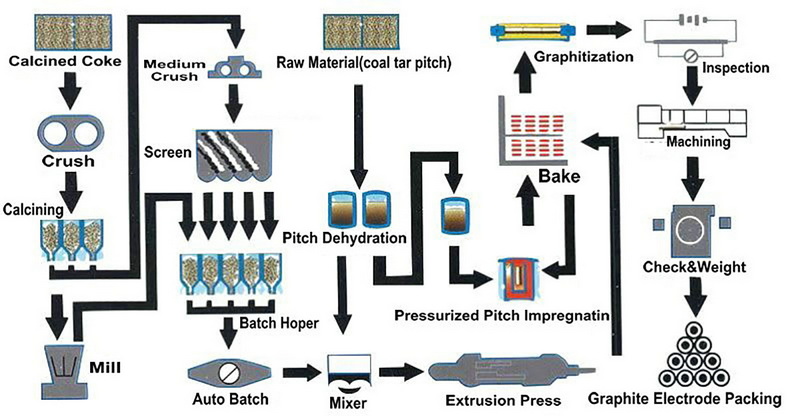

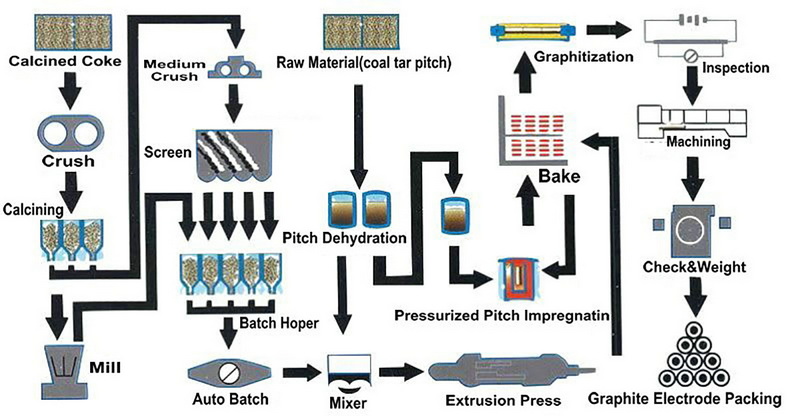

Manufacturing Process: From Raw Materials to Electrodes

1. Raw Material Selection and Pre-Treatment

- Anthracite Calcination: Rotary kilns heat raw anthracite to 1250–1350°C, reducing volatile content to <5%.

- Coke Grinding: Jaw crushers and roller mills pulverize petroleum coke to 0.5–5 mm particles.

- Pitch Modification: Coal tar pitch is blended with anthracene oil to adjust viscosity for uniform mixing.

2. Mixing and Extrusion

- Closed Kneaders: Prevent oxidation during blending (mixing time: 30–45 minutes).

- Extrusion Molding: Hydraulic presses shape the paste into cylinders (e.g., 400×600 mm) with a density of 1.6–1.8 g/cm³.

3. Baking in the Furnace

- Electrode Column Assembly: Steel shells are filled with paste and suspended above the EAF.

- Sintering Phase: As the furnace operates, heat ascends, baking the paste at 500–800°C. Volatiles (e.g., toluene, phenols) are captured via scrubbers.

Key Quality Metrics:

- Resistivity: ≤75 μΩ·m

- Compressive Strength: ≥22 MPa

- Ash Content: ≤6.5%

Operational Role in Calcium Carbide Furnaces

1. Energy Transfer Mechanism

- Arc Generation: Electrodes transmit 3-phase AC/DC current, creating arcs at 2000–2200°C.

Reaction Chemistry:

CaO+3C→CaC2+CO↑

Electrode paste supplies the carbon needed for this reaction.

2. Self-Baking Electrode System

- Continuous Consumption: Electrodes erode at 2–5 cm/hour, requiring paste replenishment.

- Sintering Zone: The "paste-to-solid" transition occurs within 1.5–2.5 meters of the furnace top.

3. Performance Optimization

- Electrode Positioning: Automated regulators maintain optimal arc length (15–30 cm).

- Slip-Free Operation: Properly sintered paste prevents electrode slippage in clamps.

Critical Performance Factors

1. Electrical Resistivity

- Low Resistivity: Minimizes energy loss (target: 65–80 μΩ·m).

- Testing Method: Four-probe technique at 1000°C (ASTM D6113).

2. Thermal Conductivity

- High thermal conductivity (4–6 W/m·K) prevents localized overheating.

3. Oxidation Resistance

- Anti-Oxidation Coatings: Boron nitride (BN) coatings reduce electrode tip oxidation by 40%.

Innovations in Electrode Paste Technology

1. Nanostructured Additives

- Carbon Nanotubes (CNTs): Adding 0.5–1% CNTs lowers resistivity by 25% and improves tensile strength.

- Patent Example: CN108585255A (China) uses graphene-modified pitch for ultra-high conductivity.

2. Eco-Friendly Binders

- Bio-Based Pitches: Lignin-derived binders reduce VOC emissions by 60% (EU-funded CarbiCel project).

3. AI-Driven Quality Control

- Machine Learning Models: Predict optimal sintering speed based on furnace parameters (e.g., current load, raw material moisture).

Global Market Trends (2025–2030)

| Region | Growth Driver | CAGR |

| Asia-Pacific | Rising steel and PVC demand | 5.8% |

| Europe | Shift to renewable-powered EAFs | 4.2% |

| North America | Shale gas drilling (acetylene welding) | 3.9% |

Closed furnaces require faster-sintering pastes (additives like Fe₂O₃ accelerate baking).

Challenges and Mitigation Strategies

| Challenge | Solution | Economic Impact |

| Electrode breakage | Real-time thermal imaging of sintering | Reduces downtime by 20% |

| High energy costs | Ultra-low resistivity pastes (e.g., +CNTs) | Saves $120/ton CaC₂ |

| Environmental regulations | Closed-loop VOC recovery systems | Cuts compliance fines by 35% |

Conclusion

Electrode paste for calcium carbide production is a linchpin of industrial chemistry, enabling efficient, large-scale CaC₂ synthesis. With innovations like CNT-enhanced formulations and AI-driven sintering, the industry is poised to reduce energy consumption by 15–25% by 2030. As decarbonization pressures mount, sustainable electrode paste solutions will be critical for aligning calcium carbide production with global climate goals.

FAQs

1. How does particle size affect electrode paste performance?

Smaller particles (1–5 mm) improve packing density and sintering uniformity, reducing resistivity fluctuations.

2. Can electrode paste be reused or recycled?

Spent electrode tips are crushed and reintroduced into new batches (up to 20% recycled content).

3. What causes electrode paste to crack during sintering?

Rapid temperature gradients or excessive volatile release. Solution: Gradual pre-heating zones in the furnace.

4. How do closed vs. open furnaces affect paste requirements?

Closed furnaces require faster-sintering pastes (additives like Fe₂O₃ accelerate baking).

5. What are the alternatives to coal tar pitch binders?

Synthetic mesophase pitch (higher cost) or lignin-phenol resins (eco-friendly but lower thermal stability).

Citations:

[1] https://www3.epa.gov/ttnchie1/ap42/ch11/final/c11s04.pdf

[2] https://www.el6group.ru/en/klientam/produkcziya-i-texnologii/produkcziya/uglerodnaya-massa/

[3] https://saxincarbon.com/7-key-factors-influencing-electrode-paste-consumption-in-closed-calcium-carbide-furnaces-i/

[4] https://www.linkedin.com/pulse/electrode-paste-calcium-carbide-production-process-leevi-zhou

[5] https://patents.google.com/patent/CN105590661B/en

[6] https://jinsuncarbon.com/carbon-electrode-paste-uses/

[7] https://tanlincarbon.com/blog/electrode-paste-mainly-has-the-following-uses/

[8] https://www.gufancarbon.com/news/electrode-paste-uses/

[9] https://www.elkem.com/products/carbon/elsep-soderberg-electrode-paste/

[10] https://www.gufancarbon.com/electrode-paste-overview/

[11] https://www.linkedin.com/pulse/4-ways-reduce-consumption-electrode-paste-calcium-carbide-anna-li

[12] https://www.linkedin.com/pulse/types-application-characteristics-electrode-paste-anna-li

[13] https://www.linkedin.com/pulse/electrode-paste-calcium-carbide-production-process-leevi-zhou

[14] https://electrodepaste.en.made-in-china.com/product/xjanVFmHbZhc/China-V-M-11-14-Electrode-Paste-for-Calcium-Carbide-Factory.html

[15] https://patents.google.com/patent/CN102951914A/en

[16] https://jinsuncarbon.com/es/uses-of-electrode-paste/

[17] https://www.gufancarbon.com/electrode-paste-overview/

[18] https://saxincarbon.com/what-is-the-use-of-electrode-paste/

[19] https://saxincarbon.com/7-key-factors-influencing-electrode-paste-consumption-in-closed-calcium-carbide-furnaces-ii/

[20] https://saxincarbon.com/what-are-the-heat-sources-for-heating-electrode-paste-in-a-calcium-carbide-furnace/

[21] https://jinsuncarbon.com/zh/uses-of-electrode-paste/

[22] https://electrodepaste.com/article/53.html

[23] https://www.ascconline.com/img/services/project_report/Calcium_Carbide_Project_Report_Sample.pdf

[24] http://www.hengqiaocarbon.com/product/cylinder-soderberg-electrode-paste-for-calcium-carbide-production

[25] https://julongchemical.en.made-in-china.com/product/AJGUZzydvTpa/China-China-Carbon-Electrode-Paste-for-Smelting-Calcium-Carbide.html

[26] http://www.hengqiaocarbon.com/product/egg-shaped-carbon-electrode-paste

[27] https://www.hbrbts.com/2021-high-quality-electrode-paste-for-calcium-carbide-production-cleanness-graphite-electrode-scrap-electrode-paste-at-competitive-price-rubang-2-product/

[28] https://www.sciencedirect.com/science/article/pii/S2212982024001707

[29] https://www.eastcarb.com/el/electrode-paste/

[30] https://xingshi2019.en.made-in-china.com/product/ldtmzFhZfJWj/China-Self-Baked-Electrode-Paste-for-Ferro-Alloy-and-Calcium-Carbide-Factory.html

[31] https://patents.google.com/patent/US20050255347A1

[32] https://jinsuncarbon.com/zh/%E4%BA%A7%E5%93%81/electrode-paste/

[33] https://www.instagram.com/p/DITFvMBzjf8/

[34] https://saxincarbon.com/blog/

[35] https://www.eastcarb.com/electrode-paste/

[36] https://www.sciencedirect.com/science/article/pii/S1385894724034442

[37] https://www.youtube.com/watch?v=m79K4RMnoPE

[38] https://jinsuncarbon.com/fr/uses-of-electrode-paste/

[39] https://www.tjtywh.com/common-faqs-about-calcium-carbide-10-key-questions-customers-care-about.html

[40] https://jinsuncarbon.com/differences-between-graphite-electrodes-and-carbon-electrodes/

[41] https://www3.epa.gov/ttnchie1/ap42/ch11/final/c11s04.pdf

[42] https://electrodepaste.en.made-in-china.com/product/bweESBrKlfcq/China-Low-Ash-Carbon-Electrode-Paste-for-Calcium-Carbide-Production-Industry.html

[43] https://dataintelo.com/report/global-soderberg-electrode-paste-market

[44] https://saxincarbon.com/analysis-of-causes-for-soft-breakage-accidents-during-electrode-paste-usage/

[45] https://gaftp.epa.gov/ap42/ch11/s04/related/rel01_c11s04.pdf

[46] https://aimehq.org/doclibrary-assets/books/Electric%20Furnace%201966/Electric%20Furnace%201966%20-%20040.pdf

[47] https://www.sciencedirect.com/topics/chemical-engineering/calcium-carbide

[48] https://patents.google.com/patent/CN205843343U/en

[49] https://www.el6group.ru/en/klientam/produkcziya-i-texnologii/produkcziya/uglerodnaya-massa/

[50] https://saxincarbon.com/how-the-electrode-paste-work-in-the-submerged-arc-furnace/

[51] https://www.gufancarbon.com/carbon-electrode-paste-anode-paste-product/

[52] https://patents.google.com/patent/CN102701205B/en