In the realm of manufacturing, efficiency, precision, and durability are paramount. Whether in automotive, aerospace, or any other industry, the components used in production processes must meet rigorous standards to ensure quality and consistency. One critical component that plays a significant role in manufacturing operations is the gripper. Grippers are essential for securely holding and manipulating workpieces during various stages of production. Among the various types of gripper inserts available, carbide grippers stand out for their exceptional performance and numerous benefits. In this comprehensive guide, we'll explore the key advantages of using carbide grippers in manufacturing processes, shedding light on their durability, versatility, and cost-effectiveness.

Understanding Gripper Inserts

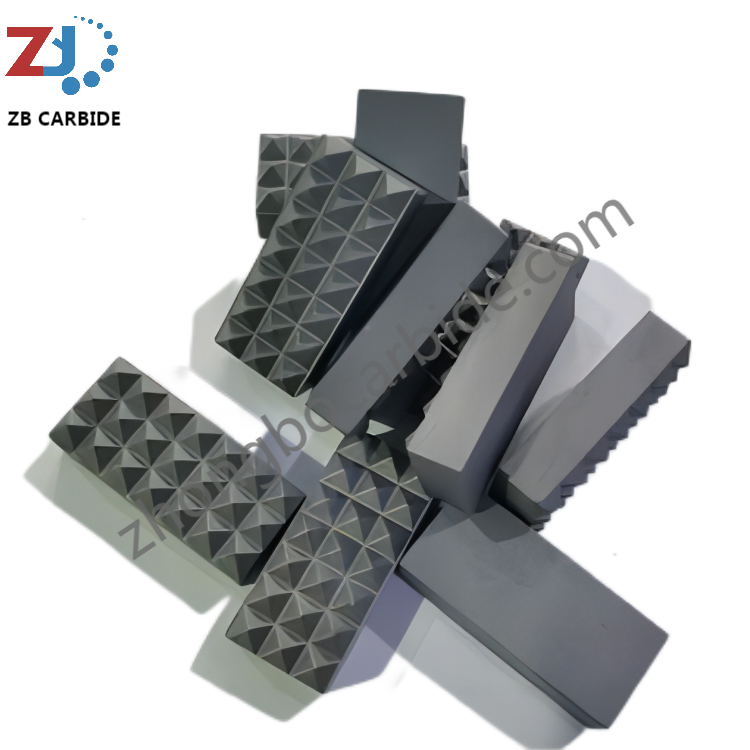

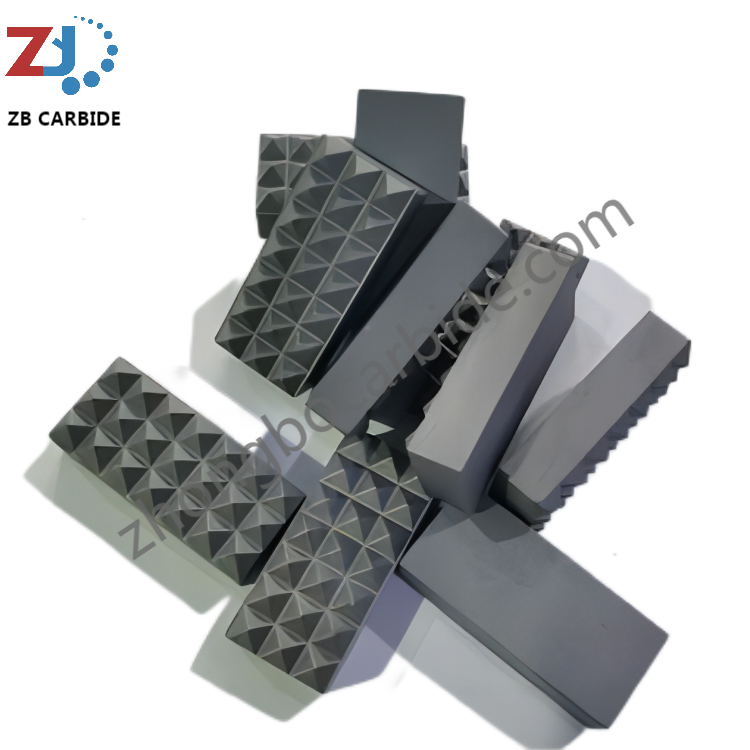

Before delving into the benefits of carbide grippers, let's first understand what gripper inserts are and their importance in manufacturing. Gripper inserts are components used in gripper systems to securely grasp and manipulate workpieces during machining, assembly, or handling operations. These inserts come in various shapes, sizes, and materials, each designed to meet specific application requirements. Among the materials commonly used for gripper inserts, carbide stands out for its exceptional hardness, wear resistance, and longevity.

The Benefits of Carbide Grippers

Carbide grippers offer several advantages over traditional materials such as steel or aluminum. Here are some key benefits of using carbide grippers in manufacturing:

●Exceptional Hardness: Carbide, often in the form of tungsten carbide, is renowned for its exceptional hardness. This property allows carbide grippers to withstand high levels of wear and abrasion, making them ideal for demanding manufacturing environments where precision and durability are essential.

●Superior Wear Resistance: In manufacturing operations involving repetitive gripping and releasing of workpieces, wear and tear are inevitable. Carbide grippers excel in such environments due to their superior wear resistance. They maintain their sharp edges and gripping surfaces for extended periods, reducing the frequency of replacements and downtime.

●Enhanced Grip Strength: The hardness and surface finish of carbide grippers contribute to enhanced grip strength, ensuring secure and stable holding of workpieces during machining or handling. This superior grip strength minimizes the risk of slippage or misalignment, leading to improved machining accuracy and productivity.

●Chemical Resistance: Carbide grippers exhibit excellent resistance to chemical corrosion, making them suitable for use in harsh manufacturing environments where exposure to chemicals or coolant fluids is common. This resistance ensures long-term performance and reliability, even in challenging operating conditions.

●Versatility: Carbide grippers are highly versatile and can be customized to suit specific application requirements. Whether for holding delicate electronic components or heavy-duty machining operations, carbide grippers can be tailored to provide optimal gripping solutions across a wide range of industries and applications.

●Cost-Effectiveness: While carbide grippers may have a higher initial cost compared to grippers made from other materials, their exceptional durability and longevity translate to long-term cost savings. Reduced maintenance, fewer replacements, and increased productivity contribute to a lower total cost of ownership over the lifespan of the grippers.

Applications of Carbide Grippers

Carbide grippers find applications in various manufacturing processes across different industries. Some common applications include:

●Machining: Carbide grippers are used in CNC machining centers, lathes, and milling machines to securely hold workpieces during cutting, drilling, and milling operations.

●Assembly: In assembly lines, carbide grippers are employed to manipulate and position components during the assembly of products, ensuring precise alignment and fit.

●Handling: Carbide grippers are used in material handling systems to grip and transport workpieces between different stages of production, optimizing workflow efficiency and minimizing manual labor.

●Electronics: In the electronics industry, carbide grippers are utilized for handling and assembly of delicate electronic components, ensuring gentle yet secure gripping without causing damage.

Maintenance and Care

To maximize the benefits of carbide grippers and prolong their lifespan, proper maintenance and care are essential. Here are some tips for maintaining carbide grippers:

●Regular Inspection: Routinely inspect carbide grippers for signs of wear, damage, or contamination. Replace worn or damaged gripper inserts promptly to prevent quality issues or production downtime.

●Cleaning: Clean carbide grippers regularly to remove dirt, debris, and coolant residues that may accumulate during operation. Use mild detergent solutions and soft brushes to avoid scratching or damaging the gripper surfaces.

●Lubrication: Apply lubricants or anti-seize compounds to moving parts and contact surfaces of carbide grippers to reduce friction and wear. Be sure to use lubricants compatible with carbide materials to avoid degradation or damage.

●Proper Storage: Store carbide grippers in a clean, dry environment away from moisture, chemicals, and excessive heat or cold. Use protective covers or containers to prevent damage during storage or transportation.

Conclusion

Carbide grippers play a vital role in modern manufacturing, offering unparalleled durability, precision, and versatility. From machining and assembly to material handling and electronics, carbide grippers provide secure and reliable gripping solutions across a wide range of applications. By leveraging the benefits of carbide grippers and adopting proper maintenance practices, manufacturers can enhance productivity, minimize downtime, and achieve consistent quality in their production processes. So, the next time you're considering gripper inserts for your manufacturing operation, remember the numerous advantages that carbide grippers bring to the table.