Content Menu

● Key Properties of Silicon Carbide Beneficial for Mining

>> Extreme Hardness and Wear Resistance

>> Thermal Stability and Shock Resistance

>> Corrosion and Erosion Resistance

>> Lightweight and High Strength

● Applications of Silicon Carbide in Mining Equipment

>> 1. Valves and Pump Components

>> 2. Grinding and Crushing Tools

>> 3. Drilling Equipment

>> 4. Wear-Resistant Linings

>> 5. Sensors and Electronic Components

● Silicon Carbide Manufacturing and Production Processes

>> 1. Sintering

>> 2. Reaction Bonding

>> 3. Chemical Vapor Deposition (CVD)

>> 4. Nitride Bonding

● Environmental Benefits of Silicon Carbide in Mining

>> Reduced Waste and Resource Consumption

>> Energy Savings and Emission Reductions

● Innovations and Future Prospects in Silicon Carbide Technology

>> Additive Manufacturing and Customization

>> Enhanced Coatings and Surface Treatments

>> Integration with Smart Mining Technologies

● Case Studies: Real-World Impact of Silicon Carbide in Mining

>> Gold Mining Operations

>> Iron Ore Crushing Facilities

>> Underground Coal Mining

● Economic Advantages of Silicon Carbide Adoption

● Customization and Design Flexibility in Silicon Carbide Manufacturing Production

● Safety Improvements Enabled by Silicon Carbide

● Conclusion

● FAQs

>> 1. How does silicon carbide compare to tungsten carbide in mining tools?

>> 2. What are the challenges in silicon carbide manufacturing production?

>> 3. Can silicon carbide components be repaired or refurbished?

>> 4. How does SiC improve energy efficiency in mining operations?

>> 5. What future trends will shape silicon carbide use in mining?

Silicon carbide (SiC) has emerged as a revolutionary material in the mining industry, offering unparalleled performance in extreme operating conditions. Its unique combination of hardness, thermal stability, and corrosion resistance makes it an ideal choice for mining equipment subjected to abrasive environments, high pressures, and corrosive chemicals. This article explores the transformative role of silicon carbide in mining applications, its manufacturing processes, and the advantages it delivers to modern mining operations.

Key Properties of Silicon Carbide Beneficial for Mining

Silicon carbide's exceptional material properties address the toughest challenges faced by mining equipment. Below are the core characteristics that make it indispensable:

Extreme Hardness and Wear Resistance

Silicon carbide ranks among the hardest materials globally, second only to diamond. This hardness translates into superior abrasion resistance, critical for components like grinding media, cutting tools, and drill bits. In mining operations, where equipment constantly interacts with hard ores and rocks, SiC-based parts exhibit significantly longer lifespans compared to traditional steel or tungsten carbide.

Thermal Stability and Shock Resistance

Mining equipment often operates in high-temperature environments, such as ore processing furnaces or deep drilling systems. Silicon carbide retains its structural integrity at temperatures up to 1,750°C, far outperforming metals. Its low thermal expansion coefficient and high thermal conductivity prevent cracking under rapid temperature changes, ensuring reliability in thermal shock-prone applications.

Corrosion and Erosion Resistance

Exposure to acidic slurries, saline water, and corrosive chemicals is common in mining. Silicon carbide's inert chemical nature ensures resistance to oxidation and chemical attack, even in highly acidic or alkaline conditions. This property is vital for pumps, valves, and pipelines handling aggressive mining fluids.

Lightweight and High Strength

Despite its hardness, SiC is lighter than steel, reducing the overall weight of mining machinery. Its high strength-to-weight ratio enhances equipment efficiency, particularly in mobile drilling rigs and wearable components.

Applications of Silicon Carbide in Mining Equipment

The mining industry leverages silicon carbide's properties across diverse equipment types:

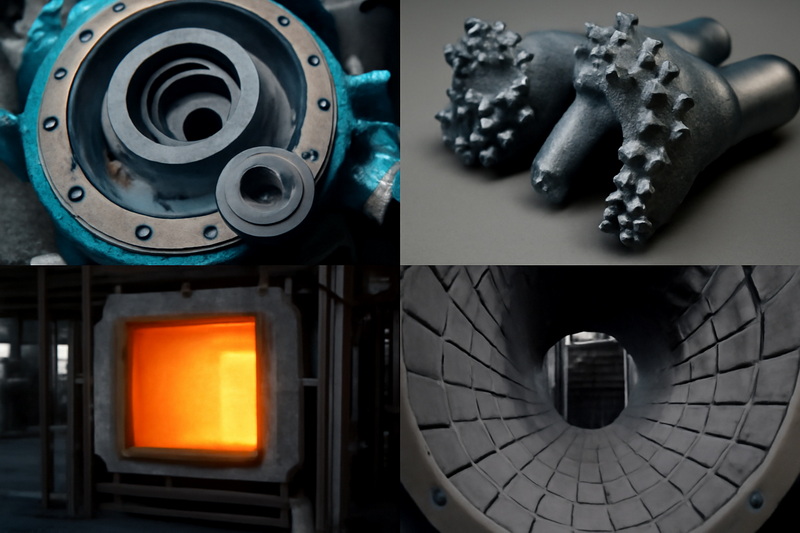

1. Valves and Pump Components

Silicon carbide valve trim and pump seals withstand erosive slurries and corrosive fluids. For example, Hexoloy® SA SiC valves are widely used in gold and nickel ore processing, offering leak-free performance under extreme pressures.

2. Grinding and Crushing Tools

SiC-based grinding media and crusher liners reduce wear in ball mills and crushers. Their hardness ensures consistent particle size reduction while minimizing contamination from worn debris.

3. Drilling Equipment

Drill bits coated with silicon carbide extend service life in hard-rock drilling. The material's thermal conductivity also helps dissipate heat generated during drilling, preventing premature failure.

4. Wear-Resistant Linings

Hopper liners, chutes, and conveyor systems lined with SiC tiles resist abrasion from ore movement, reducing downtime for maintenance.

5. Sensors and Electronic Components

SiC's semiconductor properties enable its use in high-temperature sensors for monitoring equipment health in harsh environments.

Silicon Carbide Manufacturing and Production Processes

The production of high-performance silicon carbide components involves advanced manufacturing techniques tailored to mining applications:

1. Sintering

Silicon carbide powder is sintered at high temperatures (2,000–2,500°C) to form dense, monolithic ceramics. This process ensures uniformity and eliminates porosity, enhancing mechanical strength.

2. Reaction Bonding

A mixture of SiC and carbon is infused with molten silicon, reacting to form additional SiC. This method produces complex shapes with near-net dimensions, ideal for custom mining components.

3. Chemical Vapor Deposition (CVD)

CVD-grown SiC offers ultra-pure layers for critical applications like sensor coatings. This process enables precise control over material properties, such as electrical conductivity.

4. Nitride Bonding

Nitride-bonded SiC incorporates silicon nitride as a binder, enhancing thermal shock resistance for components exposed to rapid temperature fluctuations.

Modern silicon carbide manufacturing production prioritizes scalability and cost-efficiency, enabling widespread adoption in mining. Innovations like ultrasonic-assisted machining further refine SiC components, reducing tool wear and improving surface finish.

Environmental Benefits of Silicon Carbide in Mining

Silicon carbide not only enhances the performance of mining equipment but also contributes positively to environmental sustainability. Its durability reduces the frequency of equipment replacement, thereby minimizing waste generation. Additionally, the energy efficiency improvements brought by SiC components lower the carbon footprint of mining operations.

Reduced Waste and Resource Consumption

The extended lifespan of SiC parts means fewer replacements and less scrap material. This reduction in waste helps mining companies meet environmental regulations and supports sustainable mining practices.

Energy Savings and Emission Reductions

SiC's high thermal conductivity and lightweight properties contribute to lower energy consumption in mining machinery. Reduced fuel and electricity use translate directly into decreased greenhouse gas emissions, aligning with global efforts to combat climate change.

Innovations and Future Prospects in Silicon Carbide Technology

The future of silicon carbide in mining looks promising with ongoing research and technological advancements.

Additive Manufacturing and Customization

Emerging additive manufacturing techniques allow for the production of complex SiC components with tailored properties. This customization enhances equipment performance and opens new possibilities for design innovation.

Enhanced Coatings and Surface Treatments

Advanced coating technologies improve the wear resistance and chemical stability of SiC parts, extending their service life even further.

Integration with Smart Mining Technologies

SiC-based sensors and electronic components are increasingly integrated into smart mining systems, enabling real-time monitoring and predictive maintenance, which improve operational efficiency and safety.

Case Studies: Real-World Impact of Silicon Carbide in Mining

Examining real-world examples highlights the tangible benefits of silicon carbide in mining environments:

Gold Mining Operations

In gold ore processing plants, silicon carbide pump seals and valves have dramatically reduced maintenance intervals. Equipment downtime has decreased, and the need for frequent part replacements has been virtually eliminated, resulting in significant cost savings.

Iron Ore Crushing Facilities

SiC-lined chutes and hoppers in iron ore crushing plants have demonstrated superior resistance to abrasion, leading to longer operational periods between scheduled maintenance. This reliability is crucial for maintaining continuous production flows in large-scale mining operations.

Underground Coal Mining

SiC drill bits and cutting tools have improved penetration rates and tool longevity in underground coal mines, where abrasive rock and high temperatures are common challenges. The enhanced performance translates to higher productivity and lower operational costs.

Economic Advantages of Silicon Carbide Adoption

Mining companies adopting silicon carbide components realize substantial economic benefits:

- Lower Maintenance Costs: The exceptional durability of SiC reduces the frequency and cost of repairs and part replacements.

- Increased Equipment Uptime: With fewer breakdowns and longer-lasting components, mining operations experience less downtime and higher productivity.

- Reduced Inventory Requirements: The extended service life of SiC parts means that companies can maintain smaller inventories of spare parts, optimizing warehouse space and reducing capital tied up in inventory.

- Enhanced Return on Investment: Although the initial cost of SiC components may be higher, the long-term savings in maintenance, energy, and downtime quickly offset the upfront expense.

Customization and Design Flexibility in Silicon Carbide Manufacturing Production

One of the most significant advantages of modern silicon carbide manufacturing production is the ability to customize components for specific mining applications. Manufacturers can tailor SiC products to meet unique operational requirements, such as:

- Complex Geometries: Advanced molding and machining techniques allow for the creation of intricate shapes and internal channels, optimizing fluid flow and wear resistance in pumps and valves.

- Property Optimization: By adjusting the composition and processing parameters, manufacturers can fine-tune properties like hardness, toughness, and thermal conductivity to suit different mining environments.

- Surface Engineering: Specialized coatings and treatments further enhance the performance of SiC components, providing additional protection against extreme conditions.

Safety Improvements Enabled by Silicon Carbide

Safety is a paramount concern in mining, and silicon carbide plays a vital role in mitigating risks:

- Reduced Equipment Failure: The reliability of SiC components minimizes the risk of sudden equipment failures that could endanger workers.

- Enhanced Monitoring: SiC-based sensors provide real-time data on equipment condition, allowing for proactive maintenance and reducing the likelihood of hazardous incidents.

- Lower Exposure to Hazardous Materials: Longer-lasting SiC parts mean less frequent maintenance in dangerous environments, reducing worker exposure to dust, chemicals, and mechanical hazards.

Conclusion

Silicon carbide has redefined durability and efficiency in mining equipment. Its unmatched hardness, thermal stability, and corrosion resistance address the industry's most pressing challenges, from abrasive wear to chemical degradation. As silicon carbide manufacturing production advances, mining operations will continue to benefit from longer equipment lifespans, reduced maintenance costs, and enhanced productivity. The environmental and economic advantages, coupled with ongoing innovations in manufacturing and smart mining integration, position silicon carbide as a cornerstone material for the future of mining.

FAQs

1. How does silicon carbide compare to tungsten carbide in mining tools?

Silicon carbide outperforms tungsten carbide in hardness and thermal stability, making it suitable for high-temperature applications. However, tungsten carbide remains preferable for high-impact scenarios due to its fracture toughness.

2. What are the challenges in silicon carbide manufacturing production?

Producing defect-free SiC components requires precise control over sintering temperatures and raw material purity. Machining SiC is also labor-intensive due to its extreme hardness.

3. Can silicon carbide components be repaired or refurbished?

Due to their monolithic structure, damaged SiC parts are typically replaced rather than repaired. Their long lifespan offsets replacement costs.

4. How does SiC improve energy efficiency in mining operations?

SiC's lightweight nature reduces energy consumption in mobile equipment, while its thermal conductivity minimizes cooling requirements in high-temperature systems.

5. What future trends will shape silicon carbide use in mining?

Advances in additive manufacturing and coating technologies will enable more complex SiC geometries, while cost reductions will expand its adoption in small-scale mining.