Content Menu

● Introduction to Carbide Products

● Tungsten Carbide Applications

>> Cutting Tools

>> Mold Materials

● Silicon Carbide Applications

>> Abrasive Materials

>> Power Electronics

● Industrial Applications of Carbide Products

>> Metalworking and Manufacturing

>> Aerospace and Defense

>> Medical Applications

>> Automotive Industry

>> Energy Applications

● Emerging Trends and Future Applications

>> Sustainable Manufacturing

>> Additive Manufacturing

>> Biomedical Applications

>> Advanced Materials Research

● Challenges and Opportunities

>> Cost Reduction Strategies

>> Environmental Impact Mitigation

● Conclusion

● FAQ

>> 1. What are the primary uses of tungsten carbide?

>> 2. What are the applications of silicon carbide?

>> 3. How are carbide strips used in metalworking?

>> 4. What role do carbide products play in aerospace?

>> 5. What are the emerging trends in carbide product manufacturing?

● Citations:

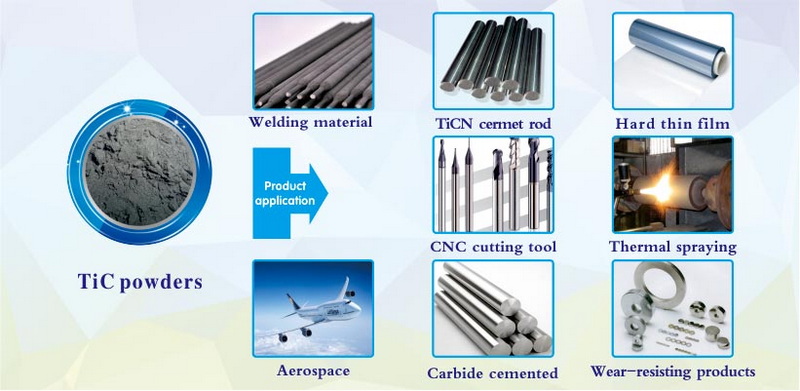

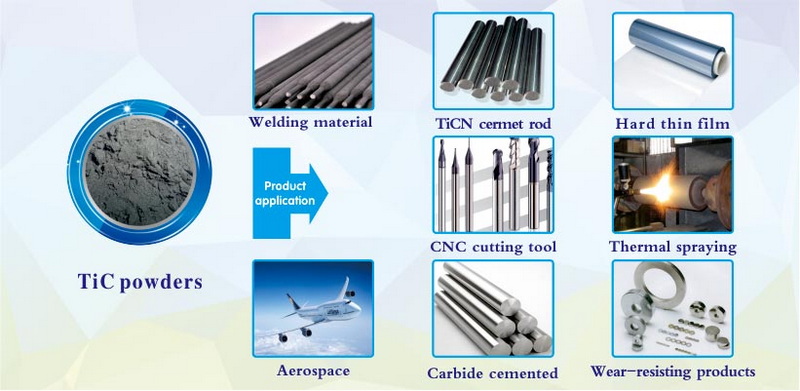

Carbide products, particularly those made from tungsten carbide and silicon carbide, are renowned for their exceptional hardness, wear resistance, and thermal stability. These properties make them invaluable across various industries, including manufacturing, aerospace, electronics, and more. In this article, we will delve into the diverse applications of carbide products, exploring their roles in cutting tools, mold-making, wear-resistant parts, and beyond.

Introduction to Carbide Products

Carbide products are typically composed of carbide materials combined with metals like tungsten and cobalt. Tungsten carbide, for instance, is a compound of tungsten and carbon, offering high density and hardness, making it ideal for applications requiring durability and precision.

Tungsten Carbide Applications

Tungsten carbide is widely used in the production of cutting tools such as drills, milling cutters, and saw blades. Its high hardness and wear resistance enable these tools to efficiently cut through difficult materials like steel and titanium.

Cutting Tools

- Turning Tools and Milling Cutters: These tools are essential for shaping and cutting operations on various materials.

- Drills and Planing Tools: Used for creating holes and shaping materials with precision.

- Specialty Cutting Applications: Variants like tungsten-cobalt carbide are effective for machining short chips from materials such as cast iron and brass.

Mold Materials

Tungsten carbide is also used in mold-making due to its robustness and wear resistance. It is ideal for applications like deep drawing dies and cold extrusion dies.

Silicon Carbide Applications

Silicon carbide (SiC) is another prominent carbide material, known for its exceptional hardness, high melting point, and thermal conductivity. It is widely used in abrasives, refractory materials, power electronics, and the automotive industry.

Abrasive Materials

- Grinding Wheels and Sandpapers: SiC is used for its abrasive properties in grinding and polishing applications.

- Refractory Materials: It is used in kiln furniture and high-temperature furnace components due to its ability to withstand extreme temperatures.

Power Electronics

SiC is utilized in high-voltage devices and power semiconductors due to its high breakdown voltage and efficiency.

Industrial Applications of Carbide Products

Carbide products are integral to various industries, providing solutions for cutting tools, mold-making, wear-resistant parts, and more.

Metalworking and Manufacturing

In metalworking, carbide strips are used for cutting and drilling metals like steel and aluminum. Their hardness and durability make them ideal for these applications.

Aerospace and Defense

Carbide products are used in aerospace for their precision and ability to withstand high temperatures and pressures.

Medical Applications

In medical fields, carbide strips are used for cutting and shaping surgical instruments due to their precision and durability.

Automotive Industry

In the automotive sector, silicon carbide is used in brake pads and clutches for its frictional properties and durability.

Energy Applications

Tungsten carbide is used in nuclear reactors due to its high density and neutron absorption capabilities.

Emerging Trends and Future Applications

Carbide products are continuously evolving with advancements in materials science and manufacturing processes. New applications are emerging in fields like energy storage, aerospace, and biomedical industries.

Sustainable Manufacturing

Research is focused on developing sustainable production methods for carbide materials, aiming to reduce environmental impact while maintaining performance.

Additive Manufacturing

The use of additive manufacturing techniques is becoming more prevalent for creating customized carbide components, offering improved efficiency and precision.

Biomedical Applications

There is growing interest in using carbide materials in biomedical implants due to their biocompatibility and durability.

Advanced Materials Research

Scientists are exploring new carbide compounds with enhanced properties for future applications in fields like quantum computing and advanced electronics.

Challenges and Opportunities

Despite their numerous applications, carbide products face challenges such as high production costs and environmental concerns. However, these challenges also present opportunities for innovation and growth.

Cost Reduction Strategies

Efforts are being made to reduce production costs through more efficient manufacturing processes and recycling techniques.

Environmental Impact Mitigation

Research into sustainable production methods aims to minimize the environmental footprint of carbide products.

Conclusion

Carbide products, including those made from tungsten carbide and silicon carbide, play a crucial role in various industries due to their exceptional hardness, wear resistance, and thermal stability. From cutting tools and mold-making to aerospace and medical applications, carbide products contribute significantly to efficiency and precision in industrial operations.

FAQ

Here are some frequently asked questions about carbide products:

1. What are the primary uses of tungsten carbide?

- Tungsten carbide is primarily used in cutting tools, mold materials, and wear-resistant parts due to its hardness and durability.

2. What are the applications of silicon carbide?

- Silicon carbide is used in abrasives, refractory materials, power electronics, and the automotive industry for its thermal conductivity and hardness.

3. How are carbide strips used in metalworking?

- Carbide strips are used for cutting and drilling metals due to their hardness and ability to withstand wear.

4. What role do carbide products play in aerospace?

- Carbide products are used in aerospace for their precision and ability to withstand high temperatures and pressures.

5. What are the emerging trends in carbide product manufacturing?

- Emerging trends include sustainable manufacturing methods and the use of additive manufacturing for customized components.

Citations:

[1] https://www.sollex.se/en/blog/post/about-cemented-tungsten-carbide-applications-part-1

[2] https://nanografi.com/blog/carbides-from-atomic-structure-to-industrial-applications-nanografi-/

[3] https://jphe.amegroups.org/article/view/4265/10863

[4] https://www.carbide-products.com/blog/applications-of-carbide/

[5] https://www.scmtstool.com/blog/What-Are-the-Industrial-Applications-of_bid-316545588.html

[6] https://www.cnblogs.com/cloud-ken/p/9739282.html

[7] https://eurobalt.net/blog/2022/03/28/all-the-applications-of-tungsten-carbide/

[8] https://www.durit.com/industries