Content Menu

● Introduction to Tungsten Carbide

>> Applications of Tungsten Carbide

● Introduction to Tungsten Steel

>> Applications of Tungsten Steel

● Comparison of Tungsten Carbide and Tungsten Steel

● Advanced Applications and Developments

>> Tungsten Carbide in Aerospace

>> Tungsten Steel in Automotive

>> Nanotechnology and Composite Materials

>> Additive Manufacturing

● Environmental and Health Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What is the main difference between tungsten carbide and tungsten steel?

>> 2. Which material is harder, tungsten carbide or tungsten steel?

>> 3. What are the typical applications of tungsten carbide?

>> 4. Can tungsten steel be used in high-temperature applications?

>> 5. Is tungsten carbide more expensive than tungsten steel?

● Citations:

Tungsten carbide and tungsten steel are often confused with each other due to their similar names and properties, but they are distinct materials with different compositions and applications. In this article, we will delve into the differences between tungsten carbide and tungsten steel, exploring their compositions, properties, and uses.

Introduction to Tungsten Carbide

Tungsten carbide, with the chemical formula WC, is a compound made of equal parts tungsten and carbon atoms. It is renowned for its exceptional hardness, ranking between 9 and 9.5 on the Mohs hardness scale, making it one of the hardest substances known, second only to diamond. This hardness, combined with its high strength and resistance to wear and corrosion, makes tungsten carbide an ideal material for cutting tools, drilling bits, and wear-resistant parts.

Tungsten Carbide Composition and Structure

Tungsten carbide forms a hexagonal crystal structure, which contributes to its high stiffness and density. It is approximately three times as stiff as steel, with a Young's modulus of about 530–700 GPa. The high density of tungsten carbide, around 15.6 g/cm³, is nearly twice that of steel.

Applications of Tungsten Carbide

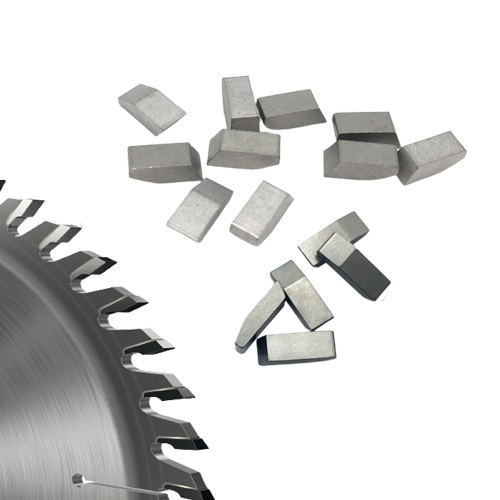

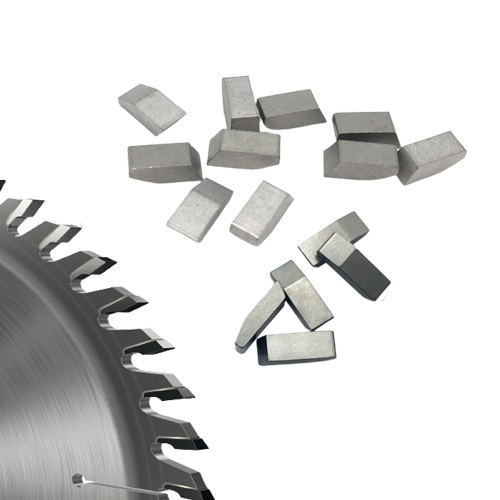

1. Cutting Tools: Tungsten carbide is widely used in the manufacture of cutting tools due to its high hardness and wear resistance. It allows for faster cutting speeds and longer tool life compared to high-speed steel.

2. Drilling Bits: In mining and drilling applications, tungsten carbide tips are used to drill through hard materials efficiently.

3. Armor-Piercing Ammunition: Its extreme hardness makes tungsten carbide suitable for producing armor-piercing rounds.

4. Jewelry and Surgical Instruments: Due to its corrosion resistance and hardness, tungsten carbide is used in making jewelry and surgical instruments.

5. Wear-Resistant Parts: Tungsten carbide is also used in components that require high wear resistance, such as nozzles and seals.

6. Aerospace and Defense: Its high density and strength make it suitable for applications in aerospace and defense, such as rocket nozzles and missile components.

Introduction to Tungsten Steel

Tungsten steel, often referred to as high-speed steel or tool steel, is an alloy that contains tungsten as a primary component. It is made by adding tungsten to molten steel during the steelmaking process, resulting in a material with a tungsten content typically ranging from 15% to 25%. Tungsten steel is known for its high hardness and wear resistance, although it is not as hard as tungsten carbide. It is commonly used in lathe tools, drill bits, and other cutting tools where high-speed operations are required.

Tungsten Steel Composition and Properties

Tungsten steel belongs to the category of cemented carbides but is distinct from tungsten carbide due to its lower tungsten content and different manufacturing process. It has a hardness of around HRC 85-92, which is lower than tungsten carbide but still very high compared to other steels.

Applications of Tungsten Steel

1. High-Speed Cutting Tools: Tungsten steel is used in high-speed cutting tools due to its ability to maintain hardness at high temperatures.

2. Drill Bits and Lathe Tools: It is commonly used in drill bits and lathe tools for its durability and resistance to wear.

3. Glass and Tile Cutters: Tungsten steel is also used in glass and tile cutters for its hardness and resistance to deformation.

4. Machining Tools: Its high wear resistance makes it suitable for machining tools that require precision and durability.

5. Automotive Components: Tungsten steel is used in the automotive industry for components that require high strength and durability.

Comparison of Tungsten Carbide and Tungsten Steel

| Property | Tungsten Carbide | Tungsten Steel |

| Composition | Tungsten and Carbon (WC) | Tungsten alloyed with steel (15-25% Tungsten) |

| Hardness | Mohs hardness: 9-9.5, Vickers hardness: around 2600 | Vickers hardness: around 10K, HRC 85-92 |

| Manufacturing Process | Powder metallurgy with cobalt binder | Steelmaking process with tungsten addition |

| Applications | Cutting tools, drilling bits, wear-resistant parts, jewelry, surgical instruments | High-speed cutting tools, drill bits, lathe tools, glass and tile cutters |

| Density | Approximately 15.6 g/cm³ | Lower than tungsten carbide, similar to steel |

| Thermal Conductivity | High thermal conductivity (around 110 W/(m·K)) | Lower thermal conductivity compared to tungsten carbide |

Advanced Applications and Developments

Tungsten Carbide in Aerospace

Tungsten carbide is used in aerospace for its high strength-to-weight ratio and resistance to extreme temperatures. It is often used in rocket nozzles and other components that require high durability.

Tungsten Steel in Automotive

In the automotive industry, tungsten steel is used for making high-performance engine components due to its ability to withstand high temperatures and wear.

Nanotechnology and Composite Materials

Recent advancements in nanotechnology have led to the development of composite materials that combine tungsten carbide with other materials to enhance its properties further. These composites are being explored for advanced applications in fields like energy storage and biomedical devices.

Additive Manufacturing

Additive manufacturing technologies, such as 3D printing, are being developed to produce complex tungsten carbide parts with improved efficiency and reduced waste. This technology has significant potential to disrupt traditional manufacturing methods by allowing for the creation of complex geometries that cannot be achieved through conventional machining techniques[5].

Environmental and Health Considerations

Both tungsten carbide and tungsten steel have environmental and health implications. Tungsten mining can have environmental impacts, and exposure to tungsten carbide dust during manufacturing can pose health risks. Therefore, manufacturers must adhere to strict safety protocols and environmental regulations. The recycling of tungsten carbide is also crucial, as it helps reduce waste and conserve resources. Approximately 30 to 35% of tungsten is recycled globally[8].

Conclusion

In conclusion, while both tungsten carbide and tungsten steel are known for their hardness and wear resistance, they are distinct materials with different compositions and applications. Tungsten carbide is a compound of tungsten and carbon, renowned for its extreme hardness and use in cutting tools and wear-resistant parts. Tungsten steel, on the other hand, is an alloy containing tungsten and is used in high-speed cutting tools and other applications where high hardness is required but not to the extent of tungsten carbide.

Frequently Asked Questions

1. What is the main difference between tungsten carbide and tungsten steel?

The main difference lies in their composition and manufacturing process. Tungsten carbide is a compound of tungsten and carbon, made through powder metallurgy, while tungsten steel is an alloy of tungsten with steel, produced through the steelmaking process.

2. Which material is harder, tungsten carbide or tungsten steel?

Tungsten carbide is significantly harder than tungsten steel, with a Mohs hardness of 9-9.5 compared to tungsten steel's HRC 85-92.

3. What are the typical applications of tungsten carbide?

Tungsten carbide is commonly used in cutting tools, drilling bits, wear-resistant parts, jewelry, and surgical instruments due to its exceptional hardness and wear resistance.

4. Can tungsten steel be used in high-temperature applications?

Yes, tungsten steel can maintain its hardness at high temperatures, making it suitable for high-speed cutting tools and other applications where heat resistance is important.

5. Is tungsten carbide more expensive than tungsten steel?

Generally, tungsten carbide is more expensive than tungsten steel due to its complex manufacturing process and higher tungsten content.

Citations:

[1] https://shop.machinemfg.com/tungsten-vs-steel-a-comprehensive-analysis/

[2] https://cncpartsxtj.com/cnc-materials/difference-tungsten-and-tungsten-carbide/

[3] https://www.kovametalli-in.com/manufacturing.html

[4] https://www.lepuseal.com/a-news-the-environmental-impact-of-tungsten-carbide-seals-in-industrial-processes

[5] https://www.coherentmarketinsights.com/industry-reports/tungsten-carbide-market

[6] https://www.iqsdirectory.com/articles/tungsten/tungsten-metal.html

[7] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[8] https://tungstencarbide42.wordpress.com/environmental-impact-and-sustainability/

[9] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/process.html

[10] https://www.skyquestt.com/report/tungsten-carbide-market

[11] https://be-cu.com/blog/tungsten-steel-vs-tungsten-carbide/

[12] https://en.wikipedia.org/wiki/Tungsten_carbide

[13] https://www.psmindustries.com/yillik/tungsten-carbide-manufacturing-process

[14] https://pubmed.ncbi.nlm.nih.gov/16168748/

[15] https://www.industryarc.com/Research/Global-Tungsten-Carbide-Market-Research-507803

[16] https://konecarbide.com/tungsten-vs-tungsten-carbide-differences-explained/

[17] https://www.imetra.com/tungsten-carbide-material-properties/

[18] https://www.linkedin.com/pulse/different-manufacturing-methods-tungsten-carbide-hss-shijin-lei

[19] https://www.itia.info/health-environment/

[20] https://www.linkedin.com/pulse/tungsten-carbide-market-future-trends-solutions-industry-fib5f