Content Menu

● Understanding Hardness

>> Mohs Hardness Scale

>> Vickers and Rockwell Hardness

● Properties of Tungsten Carbide

>> Chemical Composition

>> Physical Properties

>> Mechanical Properties

● Comparative Hardness

● Applications of Tungsten Carbide

>> 1. Cutting Tools

>> 2. Mining Equipment

>> 3. Industrial Machinery

>> 4. Jewelry

>> 5. Aerospace Applications

>> 6. Medical Devices

● Manufacturing Process of Tungsten Carbide

>> 1. Powder Production

>> 2. Mixing

>> 3. Pressing

>> 4. Sintering

>> 5. Finishing Processes

● Advantages of Tungsten Carbide

● Challenges with Tungsten Carbide

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the Mohs hardness of tungsten carbide?

>> 2. How does tungsten carbide compare to diamond?

>> 3. What are common applications for tungsten carbide?

>> 4. Can tungsten carbide be machined easily?

>> 5. What is the Vickers hardness of tungsten carbide?

● Citations:

Tungsten carbide (WC) is a compound of tungsten and carbon that exhibits remarkable hardness, making it one of the toughest materials known. Its unique properties arise from its molecular structure and the bonding between tungsten and carbon atoms. This article explores the hardness of tungsten carbide, its comparisons with other materials, applications, and a comprehensive FAQ section.

Understanding Hardness

Hardness is a measure of a material's resistance to deformation, scratching, or indentation. It can be quantified using various scales, including the Mohs scale, Vickers hardness scale, and Rockwell hardness scale.

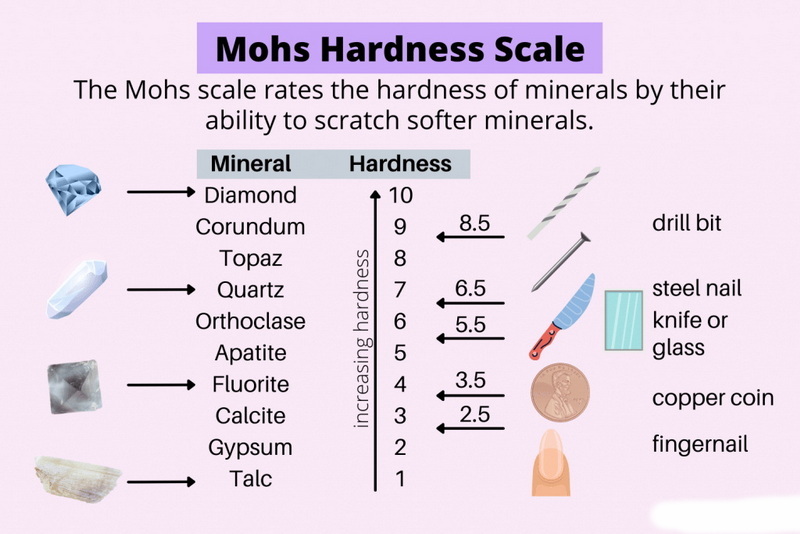

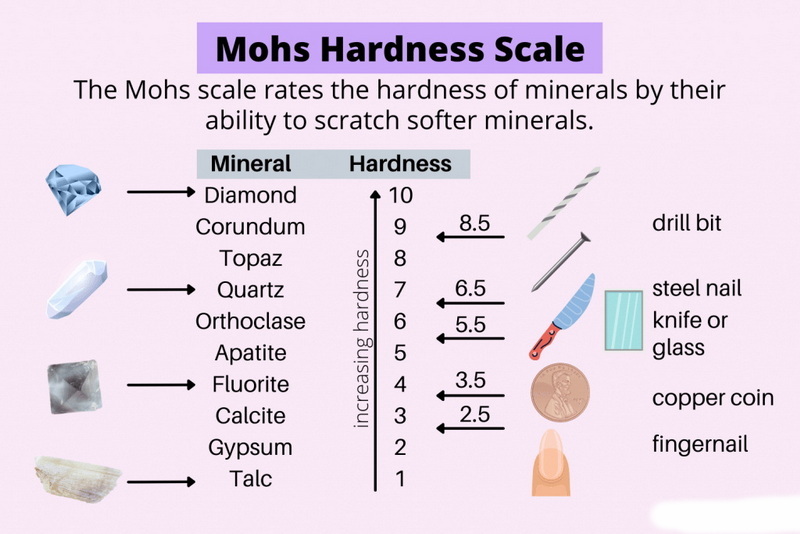

Mohs Hardness Scale

The Mohs hardness scale ranges from 1 (talc) to 10 (diamond). Tungsten carbide ranks between 9 and 9.5 on this scale, making it second only to diamond in terms of hardness. This exceptional hardness is one reason why tungsten carbide is widely used in industrial applications.

Vickers and Rockwell Hardness

- Vickers Hardness: Tungsten carbide has a Vickers hardness of approximately 2400 to 3000 HV, depending on its composition and processing methods.

- Rockwell Hardness: On the Rockwell A scale (HRA), tungsten carbide typically measures between 89 and 95 HRA, which corresponds to about 69 to 81 HRC on the C scale.

Properties of Tungsten Carbide

Chemical Composition

Tungsten carbide consists mainly of:

- Approximately 94% tungsten

- About 6% carbon

This composition can vary slightly based on specific applications and desired properties.

Physical Properties

- Density: Tungsten carbide has a density of around 15.6 g/cm³.

- Melting Point: The melting point is approximately 2870 °C (5198 °F).

- Thermal Conductivity: It has a thermal conductivity of about 110 W/m·K.

Mechanical Properties

Tungsten carbide exhibits:

- Exceptional wear resistance

- High compressive strength

- Minimal deflection under load

These properties make it suitable for high-stress applications.

Comparative Hardness

To better understand tungsten carbide's position in terms of hardness, here's a comparison with other materials:

| Material | Mohs Hardness | Vickers Hardness (HV) | Rockwell Hardness (HRA) |

| Diamond | 10 | >3000 | N/A |

| Tungsten Carbide | 9 - 9.5 | 2400 - 3000 | 89 - 95 |

| Corundum (Aluminum Oxide) | 9 | ~2000 | ~80 |

| Steel | ~4 - 8 | ~150 - 600 | ~20 - 60 |

Applications of Tungsten Carbide

Due to its hardness and durability, tungsten carbide finds extensive use in various industries:

1. Cutting Tools

Tungsten carbide is commonly used in cutting tools such as drill bits, milling tools, and saw blades due to its wear resistance. The ability to maintain sharp edges over extended periods makes it ideal for machining hard materials like steel and other alloys.

2. Mining Equipment

In the mining industry, tungsten carbide is employed in drill bits for oil drilling and mining operations. Its toughness allows it to penetrate hard rock formations effectively, significantly enhancing productivity.

3. Industrial Machinery

Tungsten carbide is utilized in parts that experience high wear and tear, such as bearings, valves, and nozzles. Its ability to withstand extreme conditions makes it a preferred choice for manufacturing machinery components.

4. Jewelry

Increasingly popular for wedding bands and fashion jewelry, tungsten carbide offers a scratch-resistant surface that maintains its shine over time. Its weighty feel adds an element of luxury that many consumers appreciate.

5. Aerospace Applications

In aerospace engineering, tungsten carbide is used for various components due to its strength-to-weight ratio and resistance to wear at high temperatures. It is often found in turbine engines and other critical systems where reliability is paramount.

6. Medical Devices

Tungsten carbide is also making strides in the medical field. Its biocompatibility allows it to be used in surgical instruments and implants. The material's hardness ensures that surgical tools remain sharp longer than those made from softer metals.

Manufacturing Process of Tungsten Carbide

The manufacturing process of tungsten carbide involves several key steps:

1. Powder Production

The first step involves producing fine tungsten powder through chemical reduction processes or mechanical milling. Carbon black is also produced during this stage.

2. Mixing

The tungsten powder is then mixed with carbon in precise ratios to achieve the desired properties. This mixture is often referred to as "green" tungsten carbide powder.

3. Pressing

The mixed powder is pressed into molds under high pressure to form a compact shape known as a "green part." This part retains its shape but is not yet fully dense or hard.

4. Sintering

The green part undergoes sintering—a process where it is heated at high temperatures (typically around 1400 °C) in a controlled atmosphere without reaching its melting point. This step allows the particles to bond together tightly, resulting in a dense material.

5. Finishing Processes

After sintering, the tungsten carbide can be further processed through grinding or polishing to achieve precise dimensions or surface finishes required for specific applications.

Advantages of Tungsten Carbide

Tungsten carbide offers several advantages over other materials:

- Exceptional Durability: Its hardness ensures longevity and performance under extreme conditions.

- Corrosion Resistance: Tungsten carbide resists oxidation and corrosion better than many metals.

- Versatility: It can be manufactured into various shapes and sizes for different applications.

- Cost-Efficiency: Although initial costs may be higher than some alternatives, the long lifespan reduces overall costs over time.

Challenges with Tungsten Carbide

While tungsten carbide has numerous benefits, there are also challenges associated with its use:

- Brittleness: Despite its hardness, tungsten carbide can be brittle under certain conditions, leading to chipping or cracking if not handled properly.

- Machining Difficulty: Due to its extreme hardness, machining tungsten carbide requires specialized equipment and techniques.

- Weight: The density of tungsten carbide makes it heavier than many alternatives, which may not be suitable for all applications.

Conclusion

Tungsten carbide stands out as one of the hardest materials available, ranking just below diamond on the Mohs hardness scale. Its impressive mechanical properties make it invaluable across multiple industries, particularly where durability and wear resistance are crucial. Understanding its hardness not only highlights its significance in manufacturing but also emphasizes its role in enhancing performance across various applications.

Frequently Asked Questions (FAQ)

1. What is the Mohs hardness of tungsten carbide?

Tungsten carbide has a Mohs hardness ranging from 9 to 9.5.

2. How does tungsten carbide compare to diamond?

Tungsten carbide is second only to diamond in hardness; diamond ranks at 10 on the Mohs scale while tungsten carbide ranks between 9 and 9.5.

3. What are common applications for tungsten carbide?

Common applications include cutting tools, mining equipment, industrial machinery parts, jewelry, aerospace components, and medical devices.

4. Can tungsten carbide be machined easily?

No, due to its extreme hardness; traditional machining methods are ineffective; specialized tools are required for machining tungsten carbide.

5. What is the Vickers hardness of tungsten carbide?

The Vickers hardness of tungsten carbide typically ranges from approximately 2400 to over 3000 HV.

Citations:

[1] https://www.carbide-part.com/blog/tungsten-carbide-hardness-vs-diamond/

[2] https://www.dymetalloys.co.uk/what-is-tungsten-carbide/grade-chart

[3] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[4] https://en.wikipedia.org/wiki/Tungsten_carbide

[5] https://www.mitsubishicarbide.net/contents/mmus/enus/html/product/technical_information/information/hardness.html

[6] https://www.hit-tw.com/newsdetails.aspx?nid=298

[7] https://konecarbide.com/tungsten-vs-tungsten-carbide-differences-explained/

[8] http://www.tungsten-carbide.com.cn/tungsten-carbide-hardness-conversion-table.html