Content Menu

● Introduction to Calcium Carbide and Acetylene Gas

● The Chemical Reaction Between Calcium Carbide and Water

>> The Fundamental Reaction

>> Reaction Mechanism

● Visual Representation of the Reaction

● Industrial Production of Acetylene Gas from Calcium Carbide and Water

>> Production Methods

>> Wet Process Details

>> Reaction Control and Safety

● Factors Affecting the Reaction Rate and Gas Yield

>> Experimental Data Example

● Applications of Acetylene Gas Produced from Calcium Carbide

>> Industrial Uses

>> Other Uses

● Safety Considerations in Acetylene Production

● Environmental Impact and Sustainability of Acetylene Production

● Innovations and Future Trends in Acetylene Production

● Troubleshooting Common Issues in Acetylene Production

● Summary of Key Points

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What safety precautions should be taken when handling calcium carbide and acetylene gas?

>> 2. Can acetylene gas be produced without calcium carbide?

>> 3. How is the purity of acetylene gas ensured?

>> 4. What happens to the calcium hydroxide produced in the reaction?

>> 5. Why is acetylene gas preferred for welding over other gases?

● Citations:

Calcium carbide (CaC₂) is a vital chemical compound widely used in various industrial applications, especially for the production of acetylene gas (C₂H₂). The reaction between calcium carbide and water is a classic and fundamental chemical process that produces acetylene gas and calcium hydroxide (Ca(OH)₂). This article provides a comprehensive explanation of how calcium carbide reacts with water, the chemical principles behind the reaction, the industrial production methods, safety considerations, and the applications of acetylene gas produced through this process.

Introduction to Calcium Carbide and Acetylene Gas

Calcium carbide is a solid, crystalline compound composed of calcium and carbon atoms. It is produced industrially by heating lime (CaO) and coke (carbon) in an electric arc furnace at extremely high temperatures (~2000 °C). This process yields calcium carbide, which is then cooled and crushed into various sizes for use in acetylene production.

Acetylene gas, with the chemical formula C₂H₂, is a colorless, highly flammable gas with a distinct garlic-like odor. It is known for its high flame temperature and is extensively used in welding, cutting, and chemical synthesis.

The Chemical Reaction Between Calcium Carbide and Water

The Fundamental Reaction

When calcium carbide comes into contact with water, it undergoes a hydrolysis reaction, producing acetylene gas and calcium hydroxide. The chemical equation is:

CaC2(s)+2H2O(l)→C2H2(g)+Ca(OH)2(aq)

- Calcium carbide (CaC₂) reacts with

- Water (H₂O) to produce

- Acetylene gas (C₂H₂) and

- Calcium hydroxide (Ca(OH)₂), also known as slaked lime.

Reaction Mechanism

Calcium carbide consists of calcium cations (Ca⊃2;⁺) and carbide anions (C₂⊃2;⁻). When water molecules contact calcium carbide, the carbide anion reacts with water, breaking down into acetylene gas and hydroxide ions (OH⁻). These hydroxide ions then combine with calcium ions to form calcium hydroxide.

This reaction is highly exothermic, releasing a significant amount of heat, which must be controlled in industrial settings to prevent hazards.

Visual Representation of the Reaction

Industrial Production of Acetylene Gas from Calcium Carbide and Water

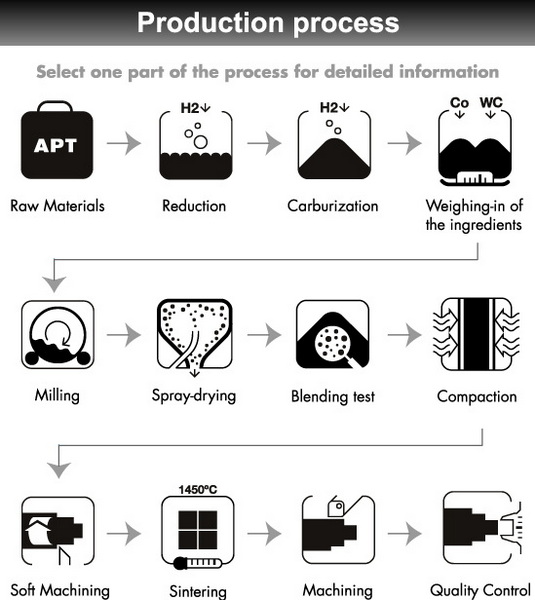

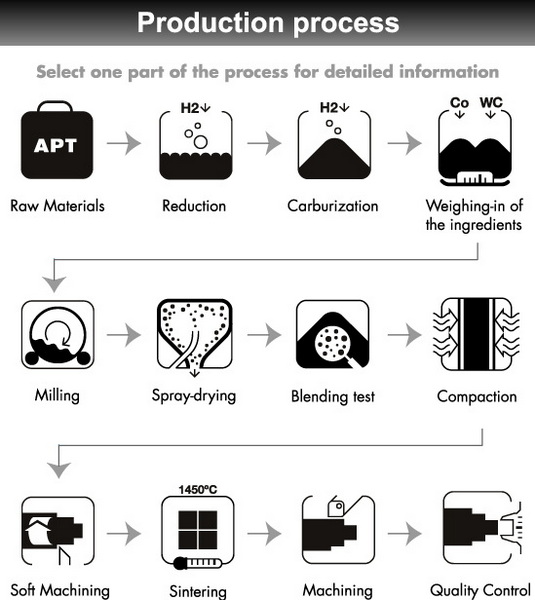

Production Methods

There are two main methods for producing acetylene gas from calcium carbide and water:

- Wet Process: Calcium carbide is added to water in a controlled reaction chamber. This is the most commonly used method due to its simplicity and controllability.

- Dry Process: A limited amount of water is added, often used in specific industries like pharmaceuticals and PVC manufacturing.

Wet Process Details

1. Feeding Calcium Carbide: Calcium carbide granules (typically 2mm x 8mm) are fed into a reaction chamber filled with water.

2. Reaction: The calcium carbide reacts with water, generating acetylene gas and calcium hydroxide slurry.

3. Gas Collection: The acetylene gas bubbles up and is collected through tubes.

4. Cooling and Purification: The gas passes through condensers, scrubbers, and dryers to remove impurities such as phosphine, arsine, and moisture.

5. Storage: Purified acetylene gas is compressed and stored in cylinders for industrial use.

Reaction Control and Safety

- Temperature Control: The exothermic nature of the reaction requires efficient cooling systems (water or air cooling) to maintain safe operating temperatures.

- Pressure Control: Pressure switches regulate the feed rate of calcium carbide to prevent excessive gas production.

- Safety Devices: Flash arrestors and automatic valves prevent explosions caused by the highly flammable acetylene gas.

- Quality Control: Impurities in calcium carbide (e.g., phosphorus, sulfur, iron) are minimized to ensure acetylene purity and process safety.

Factors Affecting the Reaction Rate and Gas Yield

- Surface Area of Calcium Carbide: Smaller particle size increases surface area, accelerating the reaction.

- Water Temperature: Higher temperatures increase kinetic energy, speeding up the reaction.

- Concentration of Reactants: Higher concentrations of calcium carbide or water increase reaction rate.

- Water-to-Carbide Ratio: Optimal water quantity ensures maximum acetylene yield without excessive dilution.

Experimental Data Example

| Weight of CaC₂ (g) | Volume of Water (ml) | Volume of Acetylene Gas (ml) |

| 3 | 15 | 540 |

| 3 | 30 | 620 |

| 3 | 55 | 730 |

Applications of Acetylene Gas Produced from Calcium Carbide

Industrial Uses

- Welding and Cutting: Acetylene produces the hottest flame among fuel gases (~3500 °C), ideal for oxy-acetylene welding and cutting.

- Chemical Synthesis: Used as a precursor for manufacturing plastics (PVC, polyethylene), synthetic rubber, acetic acid, and various organic chemicals.

- Lighting: Historically used in carbide lamps for mining and portable lighting.

- Heat Treating: Provides a controlled flame for metal heat treatment processes.

Other Uses

- Metal Desulfurization: Calcium carbide reacts with sulfur impurities in molten steel to improve steel quality.

- Laboratory Uses: Acetylene is used in organic chemistry for synthesizing acetylene derivatives.

Safety Considerations in Acetylene Production

- Heat Management: Excess heat from the reaction can cause equipment damage or explosions if not properly controlled.

- Impurities: Phosphine and arsine impurities are toxic; purification is critical.

- Storage: Acetylene cylinders must be stored in well-ventilated areas, away from ignition sources, and at controlled temperatures.

- Handling: Use of flash arrestors and pressure regulators is mandatory to prevent accidents.

Environmental Impact and Sustainability of Acetylene Production

The production of acetylene gas from calcium carbide and water has environmental considerations that industries must address. The process generates calcium hydroxide as a byproduct, which can be managed and utilized in various ways to minimize waste. Proper disposal or recycling of calcium hydroxide is essential to prevent environmental contamination.

Moreover, the energy-intensive production of calcium carbide itself, which requires high temperatures and significant electricity consumption, contributes to the carbon footprint of acetylene production. Advances in technology aim to improve energy efficiency and reduce emissions during calcium carbide manufacturing.

Industries are increasingly adopting greener technologies, such as using renewable energy sources to power electric arc furnaces and recycling calcium hydroxide byproducts in agriculture and construction, where it can serve as a soil conditioner or cement additive.

Innovations and Future Trends in Acetylene Production

Research continues to optimize the production of acetylene gas from calcium carbide and water. Innovations include the development of catalysts to enhance reaction rates, improved reactor designs for better heat management, and automation to increase safety and efficiency.

Additionally, alternative methods for acetylene production, such as from natural gas or biomass, are being explored to provide more sustainable and cost-effective options. However, the calcium carbide-water reaction remains a reliable and widely used method due to its simplicity and effectiveness.

Emerging technologies focus on miniaturized acetylene generators for on-site production, which reduce transportation risks and costs. Automation and digital monitoring systems also help maintain optimal reaction conditions, improving yield and safety.

Troubleshooting Common Issues in Acetylene Production

Operators often face challenges such as inconsistent gas yield, impurities in the gas, and equipment corrosion. Addressing these issues involves regular maintenance, quality control of raw materials, and monitoring reaction conditions closely.

For example, impurities like phosphine and arsine can be reduced by using high-purity calcium carbide and effective gas scrubbing systems. Corrosion caused by calcium hydroxide slurry requires corrosion-resistant materials in the reaction chamber.

Other common problems include clogging of feed systems due to moisture or carbide dust, which can be mitigated by proper storage and handling of calcium carbide. Monitoring reaction temperature and pressure helps prevent runaway reactions or incomplete gas generation.

Summary of Key Points

- Calcium carbide reacts with water to produce acetylene gas and calcium hydroxide.

- The reaction is exothermic and requires careful temperature and pressure control.

- Acetylene gas has diverse industrial applications, especially in welding and chemical synthesis.

- Environmental and safety considerations are critical in the production process.

- Ongoing innovations aim to improve efficiency and sustainability.

Conclusion

The reaction of calcium carbide with water to produce acetylene gas is a cornerstone chemical process with significant industrial importance. This exothermic hydrolysis reaction yields acetylene gas and calcium hydroxide, which are essential for welding, cutting, and chemical manufacturing industries.

Frequently Asked Questions (FAQ)

1. What safety precautions should be taken when handling calcium carbide and acetylene gas?

Handling calcium carbide requires dry storage to prevent premature reaction with moisture. During acetylene production, temperature and pressure must be controlled, and flash arrestors should be installed to prevent explosions. Acetylene gas cylinders must be stored upright in ventilated areas away from ignition sources.

2. Can acetylene gas be produced without calcium carbide?

Yes, acetylene can also be produced by the partial combustion of methane or by cracking hydrocarbons in petrochemical processes. However, the calcium carbide-water reaction remains a simple and cost-effective method, especially where calcium carbide is readily available.

3. How is the purity of acetylene gas ensured?

Purity is ensured by using high-quality calcium carbide, controlling reaction parameters, and passing the gas through scrubbers and dryers to remove impurities such as phosphine, arsine, and moisture.

4. What happens to the calcium hydroxide produced in the reaction?

Calcium hydroxide, also known as slaked lime, can be disposed of safely or recycled. It is used in agriculture to neutralize acidic soils, in construction as a component of cement, and in water treatment.

5. Why is acetylene gas preferred for welding over other gases?

Acetylene produces the hottest flame among commonly used fuel gases, reaching temperatures around 3500 °C when combined with oxygen. This high temperature allows efficient cutting and welding of metals.

Citations:

[1] https://melscience.com/US-en/articles/chemical-characteristics-calcium-carbide-and-its-r/

[2] https://www.ijsrd.com/articles/IJSRDV8I30699.pdf

[3] https://www.acetyleneplant.net/technology/applications-of-acetylene-gas/

[4] https://www.tjtywh.com/how-to-ensure-safety-in-acetylene-production-using-calcium-carbide.html

[5] http://enggyd.blogspot.com/2012/03/acetylene-production-process-using.html

[6] https://www.alzchem.com/en/company/news/calcium-carbide-for-acetylene-production/

[7] https://www.doubtnut.com/qna/452591445

[8] https://www.tjtywh.com/a-understanding-the-role-of-calcium-carbide-in-acetylene-production.html

[9] https://rexarc.com/blog/know-how-acetylene-is-produced-in-acetylene-plant/

[10] https://www.tjtywh.com/a-the-reaction-of-calcium-carbide-with-water-understanding-the-chemistry-behind-it.html

[11] http://www.crecompany.com/company_news_en/calcium-carbide278.html

[12] https://www.tjtywh.com/a-the-uses-and-production-of-acetylene-calcium-carbide.html

[13] https://www.tjtywh.com/a-understanding-the-reaction-of-calcium-carbide-in-water.html

[14] https://www.kviconline.gov.in/pmegp/pmegpweb/docs/commonprojectprofile/AcetyleneGas.pdf

[15] https://www.tjtywh.com/a-understanding-the-reaction-of-calcium-carbide-in-water-the-science-behind-the-reaction.html

[16] https://www.youtube.com/watch?v=RcTb0L7uUlI

[17] https://www.tiktok.com/@chemicalkim/video/7010169654291320070

[18] https://www.youtube.com/watch?v=JGB4-rDYPyM

[19] https://rexarc.com/blog/calcium-carbide-for-acetylene-production/

[20] https://www.acetylenegasplant.com/applications.php

[21] https://www.tjtywh.com/how-to-safely-transport-and-store-calcium-carbide.html

[22] https://www.sciencesource.com/2418691-calcium-carbide-reacts-with-water-stock-video-rights-managed.html

[23] https://chemed.chem.purdue.edu/demos/demosheets/24.9.html

[24] https://www.acs.org/education/whatischemistry/landmarks/calciumcarbideacetylene.html

[25] https://air-source.com/blog/8-interesting-uses-for-acetylene/

[26] https://nj.gov/health/eoh/rtkweb/documents/fs/0312.pdf

[27] https://melscience.com/US-en/articles/hydrolysis-calcium-carbide-and-characteristics-sub/

[28] https://www.alamy.com/stock-photo/calcium-carbide-and-water.html

[29] https://www.shutterstock.com/search/calcium-carbide

[30] https://sciencesource.com/2449645-calcium-carbide-reacts-with-water-3-of-3-stock-image-rights-managed.html

[31] https://ocw.mit.edu/courses/22-033-nuclear-systems-design-project-fall-2011/4a2d1059fade1cce993afc566d35e42d_MIT22_033F11_lec07_note.pdf

[32] https://www.acetylenegasplant.com/photo-gallery.php

[33] https://www.gettyimages.com/photos/calcium-carbide

[34] https://www.shutterstock.com/image-photo/calcium-carbide-cac2-water-reacts-on-2041401479

[35] https://rexarc.com/blog/know-how-acetylene-is-produced-in-acetylene-plant/

[36] https://en.wikipedia.org/wiki/Calcium_carbide

[37] https://www.istockphoto.com/photos/metal-gas-cutting-with-acetylene-torch

[38] https://www.istockphoto.com/photos/calcium-carbide

[39] https://stock.adobe.com/search?k=%22calcium+carbide%22

[40] https://www.tjtywh.com/common-faqs-about-calcium-carbide-10-key-questions-customers-care-about.html

[41] https://camachem.com/es/blog/post/frequently-asked-question-about-calcium-carbide

[42] https://www.labour.gov.hk/eng/public/os/B/welding2.pdf

[43] https://sathee.prutor.ai/article/chemistry/chemistry-calcium-carbide/

[44] https://www.nexair.com/learning-center/industrial-uses-of-acetylene/

[45] https://www.eiga.eu/uploads/documents/DOC226.pdf

[46] https://www.vedantu.com/question-answer/calcium-carbide-reacts-with-water-to-produce-a-class-11-chemistry-cbse-5f087ebf832a2662986672f0

[47] https://www.energy.virginia.gov/mineral-mining/documents/TRAINING/REFRESHER/MaintenanceRepairTopics/AR-oxygen-acetyleneuseandsafety.pdf

[48] https://www.hse.gov.uk/fireandexplosion/acetylene.htm

[49] https://www.sciencedirect.com/science/article/abs/pii/S0959652621032443

[50] https://cdn.intratec.us/docs/reports/previews/acetylene-e31a-b.pdf

[51] https://www.sciencedirect.com/science/article/pii/S2369969820300608

[52] https://iigas.com/uses-of-acetylene-gas/

[53] https://www.youtube.com/watch?v=AiHksObCLuU

[54] https://www.studocu.com/en-za/messages/question/8961294/a-conclusion-for-experiment-of-preparation-and-testing-of-acetylene-from-calcium-carbide-and-water

[55] https://cdn.intratec.us/docs/reports/previews/acetylene-e11a-b.pdf

[56] https://melscience.com/US-en/articles/chemical-characteristics-calcium-carbide-and-its-r/

[57] https://www.sciencedirect.com/science/article/pii/S2468025722001820

[58] https://www.youtube.com/watch?v=ovcYzWvyKVo

[59] https://www.tjtywh.com/a-understanding-the-reaction-of-calcium-carbide-in-water.html

[60] https://www.alamy.com/stock-photo/calcium-reaction-water.html

[61] https://www.acetyleneplant.net/technology/process-description-of-acetylene-plant/

[62] https://www.istockphoto.com/photos/acetylene-cylinder

[63] https://www.cdhfinechemical.com/images/product/msds/51_130617646_CalciumCarbide-CASNO-75-20-7-MSDS.pdf

[64] https://www.bocgases.co.uk/files/Facts_about_acetylene.pdf

[65] https://www.flinnsci.ca/api/library/Download/877039d923ef426f961d5438aae85eb6

[66] https://eg.airliquide.com/Oxygen-and-Acetylene-Essentials

[67] https://www.airproducts.com.hk/gases/acetylene

[68] https://testbook.com/question-answer/which-gas-is-evolved-when-water-is-added-to-calciu--612cb8db1c0d7fc68e81669b