Content Menu

● Understanding Tungsten Carbide and Diamond

>> Tungsten Carbide

>> Diamond

● Comparing Strength and Hardness

● Wear Resistance and Durability

>> Tungsten Carbide Wear Resistance

>> Diamond Wear Resistance

● Applications in Dremel Bits

>> Tungsten Carbide Dremel Bits

>> Diamond Dremel Bits

● Cost Considerations

>> Tungsten Carbide Cost

>> Diamond Cost

● Performance in Different Materials

>> Soft Materials

>> Hard Materials

● Heat Resistance and Thermal Properties

>> Tungsten Carbide Heat Resistance

>> Diamond Heat Resistance

● Longevity and Replacement Frequency

>> Tungsten Carbide Longevity

>> Diamond Longevity

● Environmental and Safety Considerations

>> Tungsten Carbide Environmental Impact

>> Diamond Environmental Impact

● Sharpening and Maintenance

>> Tungsten Carbide Maintenance

>> Diamond Maintenance

● Choosing the Right Bit for Your Project

● Conclusion

● FAQ

>> 1. Are diamond Dremel bits worth the extra cost?

>> 2. Can tungsten carbide bits cut glass effectively?

>> 3. How long do tungsten carbide Dremel bits typically last?

>> 4. Are there any materials that diamond bits can't cut?

>> 5. Can I use water cooling with both tungsten carbide and diamond Dremel bits?

● Citations:

Dremel tools are versatile and widely used for various DIY projects, crafts, and professional applications. When it comes to choosing the right bits for your Dremel, the strength and durability of the material are crucial factors to consider. Two popular materials for Dremel bits are tungsten carbide and diamond. In this article, we'll explore the properties of these materials, compare their strengths, and determine which one might be the better choice for your specific needs.

Understanding Tungsten Carbide and Diamond

Tungsten Carbide

Tungsten carbide is a compound made of tungsten and carbon atoms. It's known for its exceptional hardness and wear resistance, making it a popular choice for cutting tools, drill bits, and abrasives[1].

Key properties of tungsten carbide include:

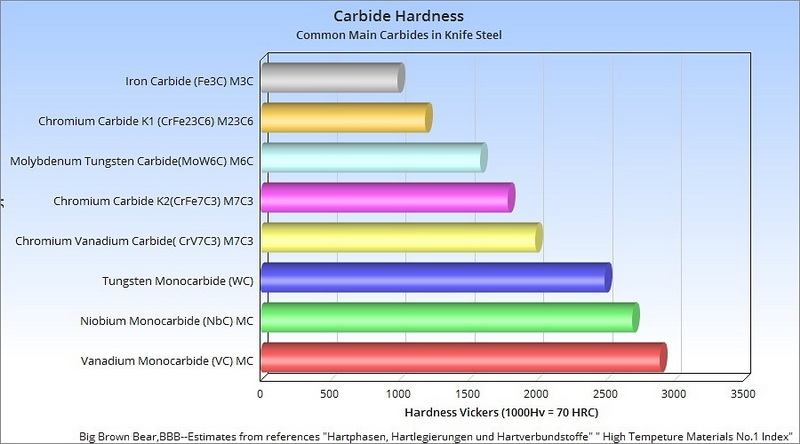

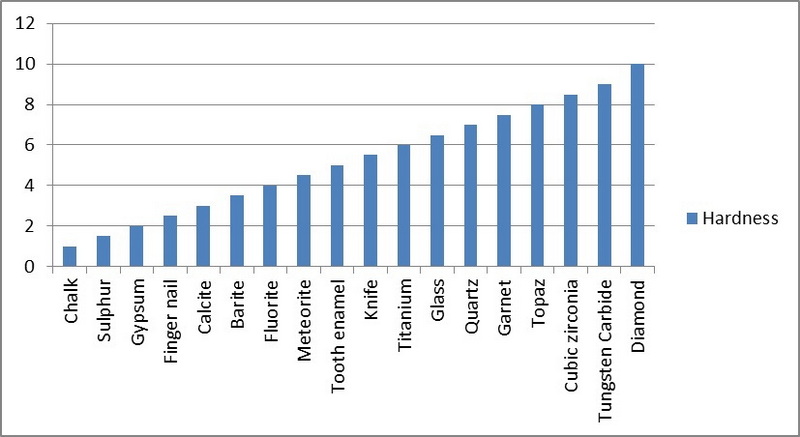

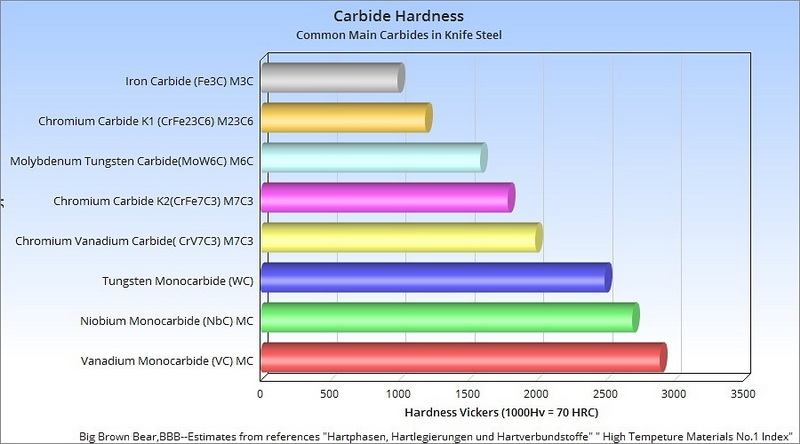

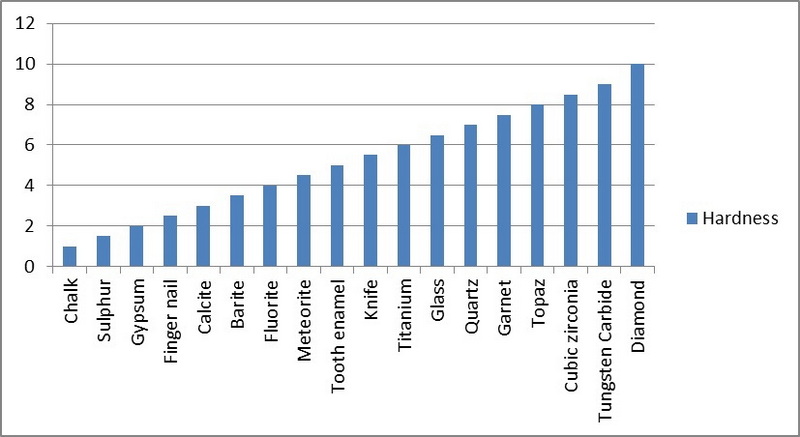

- Hardness: 8.5-9.5 on the Mohs scale

- High density

- Excellent wear resistance

- Good thermal conductivity

- High compressive strength

Diamond

Diamond is a naturally occurring form of carbon and is renowned for being the hardest known natural material. It's also synthesized for industrial applications, including cutting tools and abrasives[1].

Key properties of diamond include:

- Hardness: 10 on the Mohs scale (the highest)

- Excellent thermal conductivity

- High wear resistance

- Low coefficient of friction

- Chemical inertness

Comparing Strength and Hardness

When it comes to strength and hardness, diamond outperforms tungsten carbide. Diamond has a Mohs hardness of 10, while tungsten carbide ranges from 8.5 to 9.5[1][2]. This means that diamond is capable of scratching tungsten carbide, but not vice versa.

However, it's important to note that hardness is not the only factor determining a material's suitability for Dremel bits. Other properties such as toughness, wear resistance, and cost also play significant roles.

Wear Resistance and Durability

Both tungsten carbide and diamond exhibit excellent wear resistance, but they perform differently under various conditions.

Tungsten Carbide Wear Resistance

Tungsten carbide is known for its outstanding wear resistance, especially in applications involving abrasive materials. It maintains its sharp edge for extended periods, making it ideal for cutting and grinding applications[2].

Diamond Wear Resistance

Diamond, being the hardest natural material, offers superior wear resistance compared to tungsten carbide. Diamond-coated or diamond-impregnated tools can maintain their cutting edge for much longer periods, especially when working with hard materials[2].

Applications in Dremel Bits

Tungsten Carbide Dremel Bits

Tungsten carbide Dremel bits are versatile and suitable for a wide range of applications, including:

- Carving and engraving wood

- Cutting and shaping soft metals

- Grinding and sharpening tools

- Removing rust and corrosion

Diamond Dremel Bits

Diamond Dremel bits are typically used for more specialized applications, such as:

- Cutting and grinding glass

- Working with ceramics and porcelain

- Shaping and polishing gemstones

- Engraving hard metals

Cost Considerations

When comparing tungsten carbide and diamond Dremel bits, cost is an important factor to consider.

Tungsten Carbide Cost

Tungsten carbide bits are generally more affordable than diamond bits. They offer a good balance between performance and cost, making them a popular choice for many DIY enthusiasts and professionals[7].

Diamond Cost

Diamond bits are typically more expensive due to the higher cost of the material and the manufacturing process. However, their longer lifespan and superior performance in certain applications can justify the higher initial investment[7].

Performance in Different Materials

The performance of tungsten carbide and diamond Dremel bits can vary significantly depending on the material being worked on.

Soft Materials

For softer materials like wood, plastic, and soft metals, tungsten carbide bits often provide sufficient hardness and durability. They can maintain a sharp edge and deliver clean cuts without the need for the extreme hardness of diamond[2].

Hard Materials

When working with harder materials such as glass, ceramics, or hardened steel, diamond bits generally outperform tungsten carbide. The superior hardness of diamond allows it to cut and grind these materials more effectively and with less wear[2].

Heat Resistance and Thermal Properties

The thermal properties of Dremel bits can affect their performance and longevity, especially in high-speed applications.

Tungsten Carbide Heat Resistance

Tungsten carbide has good thermal conductivity and can withstand high temperatures. However, extreme heat can cause the binder material (usually cobalt) to soften, potentially leading to bit failure[1].

Diamond Heat Resistance

Diamond has excellent thermal conductivity, which helps dissipate heat quickly during use. This property, combined with its chemical stability at high temperatures, makes diamond bits less prone to heat-related degradation[1].

Longevity and Replacement Frequency

The lifespan of Dremel bits is an important consideration, as it affects both cost-effectiveness and convenience.

Tungsten Carbide Longevity

Tungsten carbide bits typically have a shorter lifespan compared to diamond bits, especially when used on harder materials. However, they still offer good durability for most general-purpose applications[7].

Diamond Longevity

Diamond bits generally last longer than tungsten carbide bits, particularly when used on hard materials. Their superior wear resistance means they require less frequent replacement, which can offset their higher initial cost over time[7].

Environmental and Safety Considerations

When choosing between tungsten carbide and diamond Dremel bits, it's important to consider environmental and safety factors.

Tungsten Carbide Environmental Impact

The production of tungsten carbide involves mining and processing, which can have environmental impacts. However, tungsten carbide is recyclable, which can help mitigate some of these concerns[1].

Diamond Environmental Impact

While natural diamonds have been associated with ethical and environmental concerns, most industrial diamonds used in tools are synthetic. The production of synthetic diamonds generally has a lower environmental impact compared to mining natural diamonds[1].

Sharpening and Maintenance

The ability to sharpen and maintain Dremel bits can affect their overall lifespan and performance.

Tungsten Carbide Maintenance

Tungsten carbide bits can be resharpened, although this requires specialized equipment and skills. Regular cleaning and proper storage can help maintain their performance[2].

Diamond Maintenance

Diamond bits generally cannot be resharpened once worn. However, their longer lifespan often compensates for this limitation. Proper cleaning and storage are essential to maintain their performance[2].

Choosing the Right Bit for Your Project

Selecting the appropriate Dremel bit depends on various factors, including:

1. The material you're working with

2. The precision required

3. The frequency of use

4. Your budget

5. The specific application (cutting, grinding, engraving, etc.)

Consider these factors when deciding between tungsten carbide and diamond bits for your project.

Conclusion

While diamond is indeed stronger and harder than tungsten carbide, the choice between tungsten carbide and diamond Dremel bits depends on various factors beyond just strength. Tungsten carbide bits offer a good balance of performance and cost for many general-purpose applications, especially when working with softer materials. Diamond bits, on the other hand, excel in applications involving hard materials and where long-term durability is crucial.

Ultimately, the best choice depends on your specific needs, the materials you're working with, and your budget. For many DIY enthusiasts and professionals, having a combination of both tungsten carbide and diamond bits in their toolkit provides the versatility to tackle a wide range of projects effectively.

FAQ

1. Are diamond Dremel bits worth the extra cost?

Diamond Dremel bits can be worth the extra cost if you frequently work with hard materials like glass, ceramics, or hardened metals. Their superior hardness and wear resistance can lead to longer-lasting performance and potentially better results in these applications. However, for general-purpose use or working with softer materials, tungsten carbide bits often provide sufficient performance at a lower cost.

2. Can tungsten carbide bits cut glass effectively?

While tungsten carbide bits can cut glass, they are not as effective as diamond bits for this purpose. Tungsten carbide may wear down more quickly when cutting glass, leading to less precise cuts and shorter bit life. For frequent or precision glass cutting, diamond bits are generally recommended.

3. How long do tungsten carbide Dremel bits typically last?

The lifespan of tungsten carbide Dremel bits can vary significantly depending on usage, materials worked on, and maintenance. With proper use and care, tungsten carbide bits can last for several hours of continuous use or several months of occasional use. However, when used on harder materials or at high speeds, their lifespan may be reduced.

4. Are there any materials that diamond bits can't cut?

While diamond is extremely hard and can cut most materials, it's not effective for cutting ferrous metals (those containing iron) at high speeds. The carbon in the diamond can diffuse into the hot iron, causing the diamond to degrade. For cutting steel and other ferrous metals, tungsten carbide or other specialized bits are often more suitable.

5. Can I use water cooling with both tungsten carbide and diamond Dremel bits?

Yes, water cooling can be used with both tungsten carbide and diamond Dremel bits. Water cooling helps reduce heat buildup, which can extend the life of the bit and improve cutting performance. However, it's important to ensure that your Dremel tool is designed for wet use or properly protected from water ingress when using this technique.

Citations:

[1] https://www.reekecarbide.com/blog/tungsten-carbide-vs-diamond-unveiling-the-test-of-strength.html

[2] https://telconpcd.com/pcd-vs-carbide-who-has-better-tool-value/

[3] https://graduate.buaa.edu.cn/2020nianyanjiushengfabiaoyouxiuxueshulunwenjianggongshimingdan.pdf

[4] https://www.makeitfrom.com/compare/Polycrystalline-CVD-Diamond/Tungsten-Carbide-WC

[5] https://www.reddit.com/r/metalworking/comments/cmjweu/can_tungsten_carbide_or_diamond_grit_cutting/

[6] https://www.tek.com.cn/-/media/china-marketing-documents/material-science/mtsc_cailiaodianxuetexing.pdf

[7] https://www.carbide-part.com/blog/tungsten-carbide-hardness-vs-diamond/

[8] https://gdptooling.com/diamond-v-carbide-comparing-the-costs/