Content Menu

● Introduction

● Understanding Chromium Carbide Overlay Plates

● Key Benefits of Chromium Carbide Overlay Plates

>> Wear Resistance

>> Impact Resistance

>> Cost-Effectiveness

● Applications of Chromium Carbide Overlay Plates

>> Mining

>> Construction

>> Energy

● Choosing the Right Overlay Plate

>> Thickness

>> Hardness

>> Backing Material

>> Customization Options

● Installation and Maintenance

>> Installation

>> Maintenance

● Conclusion

● Frequently Asked Questions

>> Q1. What is a chromium carbide overlay plate?

>> Q2. How does chromium carbide compare to other hardfacing materials?

>> Q3. In which industries are chromium carbide overlay plates commonly used?

>> Q4. How can I ensure the longevity of chromium carbide overlay plates?

>> Q5. Are chromium carbide overlay plates customizable?

Introduction

In the realm of industrial applications, the demand for materials that can withstand extreme wear and tear is ever-increasing. One such material that has gained significant attention is the chromium carbide overlay plate. These plates are engineered to provide exceptional durability and resistance to abrasion, making them ideal for various industries, including mining, construction, and energy. This article delves into the key benefits of using chromium carbide overlay plates, exploring their composition, applications, and the reasons behind their growing popularity.

Understanding Chromium Carbide Overlay Plates

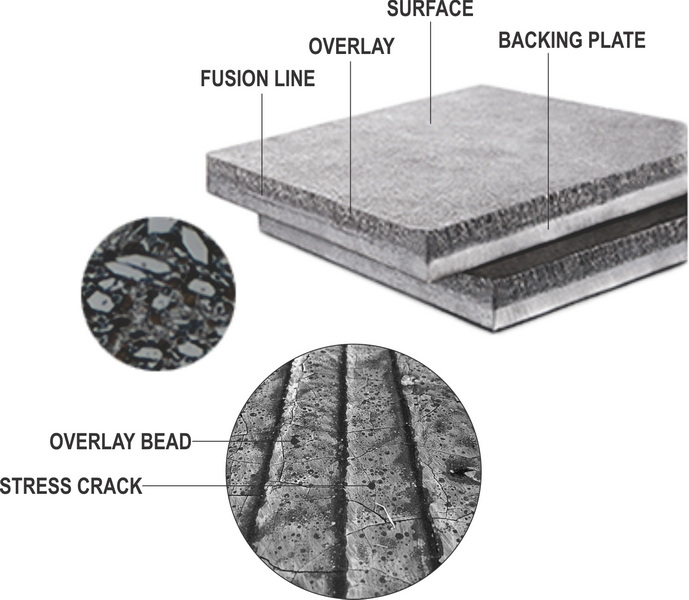

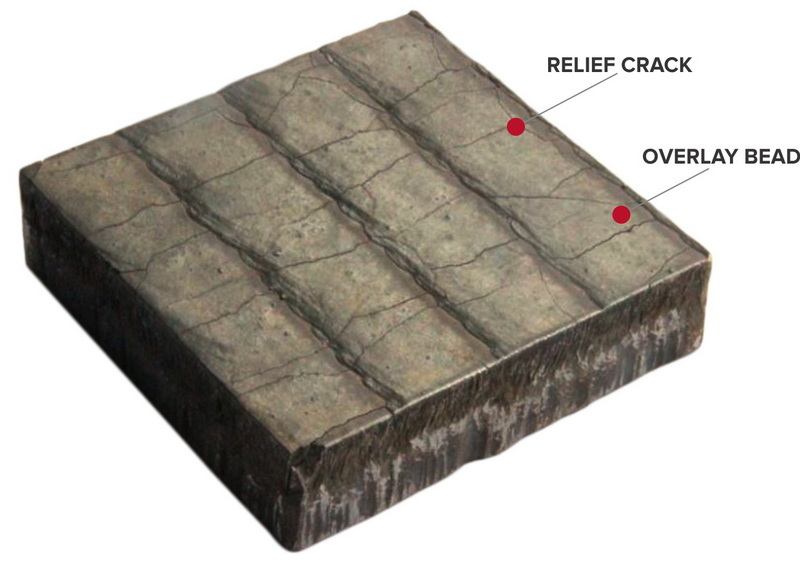

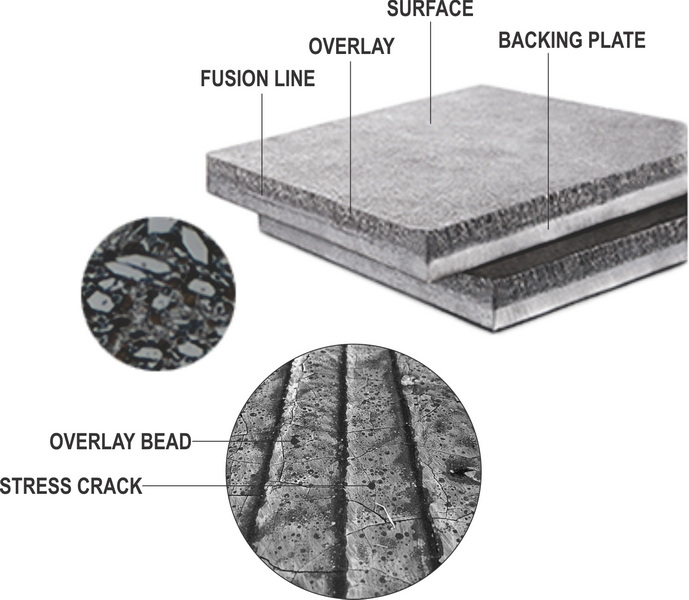

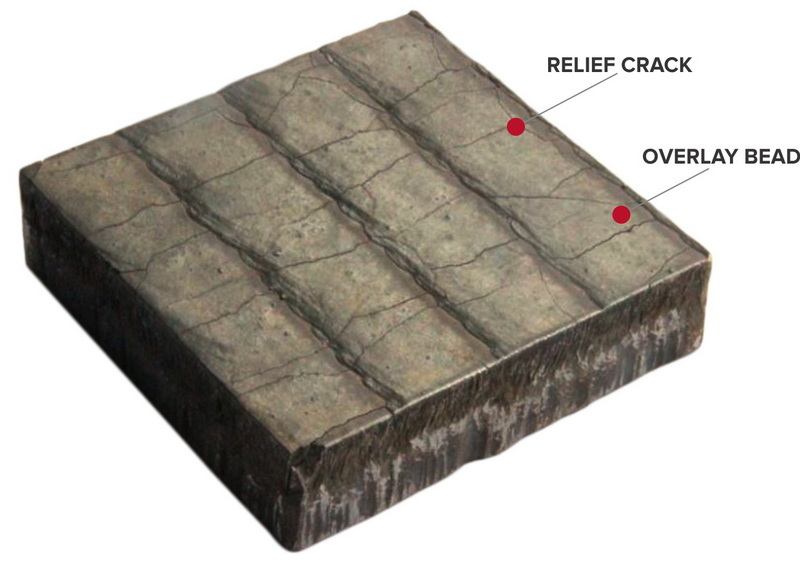

Chromium carbide overlay plates are composite materials that consist of a base plate, typically made of steel, which is coated with a layer of chromium carbide. This coating is achieved through a process known as hardfacing, where a mixture of chromium and carbon is applied to the surface of the base plate. The result is a hard, wear-resistant surface that can significantly extend the lifespan of the underlying material.

The manufacturing process of chromium carbide overlay plates involves several steps, including surface preparation, welding, and post-weld heat treatment. This meticulous process ensures that the overlay adheres properly to the base plate, providing a robust solution for industries that face harsh operating conditions.

Key Benefits of Chromium Carbide Overlay Plates

Wear Resistance

One of the most significant advantages of chromium carbide overlay plates is their exceptional wear resistance. The hardness of chromium carbide, which can reach up to 60 HRC (Rockwell Hardness Scale), makes these plates highly effective in resisting abrasion. This property is particularly beneficial in applications where materials are subjected to constant friction and wear, such as in conveyor systems, chutes, and hoppers.

The wear resistance of chromium carbide overlay plates is often compared to that of other materials, such as standard steel or even other hardfacing materials. In many cases, chromium carbide outperforms these alternatives, leading to reduced downtime and maintenance costs for industrial operations.

Impact Resistance

In addition to wear resistance, chromium carbide overlay plates also exhibit excellent impact resistance. This characteristic is crucial in environments where heavy materials are handled, and sudden impacts can occur. The toughness of the chromium carbide layer allows it to absorb shocks without cracking or breaking, ensuring the integrity of the underlying structure.

This impact resistance makes chromium carbide overlay plates suitable for use in high-impact applications, such as mining equipment, where the risk of damage from falling rocks or heavy machinery is prevalent.

Cost-Effectiveness

Investing in chromium carbide overlay plates can lead to significant cost savings over time. While the initial cost may be higher than that of standard materials, the longevity and durability of these plates often result in lower overall maintenance and replacement costs. Industries that utilize chromium carbide overlay plates frequently report extended service life, which translates to reduced downtime and increased productivity.

Moreover, the ability of these plates to withstand harsh conditions means that companies can avoid the frequent replacement of components, further enhancing their cost-effectiveness.

Applications of Chromium Carbide Overlay Plates

Chromium carbide overlay plates find applications across various industries due to their unique properties. Some of the key sectors that benefit from their use include:

Mining

In the mining industry, equipment is constantly exposed to abrasive materials, making wear resistance a top priority. Chromium carbide overlay plates are commonly used in components such as chutes, hoppers, and conveyor systems to protect against wear and extend the lifespan of critical machinery.

Construction

The construction industry also relies on chromium carbide overlay plates for their durability. These plates are used in equipment such as excavators, bulldozers, and other heavy machinery that encounter abrasive materials like soil, gravel, and concrete.

Energy

In the energy sector, particularly in coal and biomass power plants, chromium carbide overlay plates are utilized in various applications, including ash handling systems and coal pulverizers. Their ability to withstand high temperatures and abrasive materials makes them an ideal choice for these demanding environments.

Choosing the Right Overlay Plate

When selecting a chromium carbide overlay plate, several factors must be considered to ensure optimal performance. These factors include:

Thickness

The thickness of the overlay plate is crucial, as it directly impacts the wear resistance and longevity of the material. Thicker plates generally offer better protection against wear, but they may also be heavier and more challenging to install.

Hardness

The hardness of the chromium carbide layer is another essential consideration. Higher hardness levels typically correlate with better wear resistance, but it is essential to balance hardness with toughness to avoid brittleness.

Backing Material

The choice of backing material is also vital. Steel is the most common backing material, but other options may be available depending on the specific application and environmental conditions.

Customization Options

Many manufacturers offer customization options for chromium carbide overlay plates, allowing companies to tailor the plates to their specific needs. This customization can include variations in thickness, hardness, and even the shape of the plates to fit particular equipment.

Installation and Maintenance

Proper installation and maintenance of chromium carbide overlay plates are critical to maximizing their lifespan and performance. Here are some best practices:

Installation

- Surface Preparation: Ensure that the surface of the base plate is clean and free of contaminants before applying the overlay.

- Welding Techniques: Use appropriate welding techniques to ensure a strong bond between the overlay and the base plate.

- Alignment: Properly align the plates during installation to avoid misalignment issues that could lead to premature wear.

Maintenance

- Regular Inspections: Conduct regular inspections of the overlay plates to identify any signs of wear or damage early.

- Cleaning: Keep the plates clean to prevent the buildup of abrasive materials that could accelerate wear.

- Repairs: Address any damage promptly to prevent further deterioration of the plates.

Conclusion

Chromium carbide overlay plates offer a multitude of benefits for industrial applications, including exceptional wear and impact resistance, cost-effectiveness, and versatility across various sectors. Their unique properties make them an ideal choice for industries that require durable materials capable of withstanding harsh conditions. By understanding the key benefits and considerations associated with chromium carbide overlay plates, companies can make informed decisions that enhance their operational efficiency and reduce costs.

Frequently Asked Questions

Q1. What is a chromium carbide overlay plate?

A chromium carbide overlay plate is a composite material made of a steel base plate coated with a layer of chromium carbide, designed to provide exceptional wear and impact resistance.

Q2. How does chromium carbide compare to other hardfacing materials?

Chromium carbide typically offers superior wear resistance compared to other hardfacing materials, making it a preferred choice for applications involving high abrasion.

Q3. In which industries are chromium carbide overlay plates commonly used?

These plates are commonly used in industries such as mining, construction, and energy, where equipment is exposed to abrasive materials and harsh conditions.

Q4. How can I ensure the longevity of chromium carbide overlay plates?

To ensure longevity, proper installation and regular maintenance, including inspections and cleaning, are essential.

Q5. Are chromium carbide overlay plates customizable?

Yes, many manufacturers offer customization options for chromium carbide overlay plates, allowing for variations in thickness, hardness, and shape to meet specific application needs.