Content Menu

● Introduction to Carbide Wire Drawing Dies

● Understanding Wire Drawing Die Technology

● Manufacturing Process and Quality Control

● Applications and Industry Usage

● Technical Specifications and Performance

● Maintenance and Care

● Advanced Features and Innovations

● Selection and Optimization

● Future Trends and Developments

● Frequently Asked Questions

>> Q1: What is the typical lifespan of a carbide wire drawing die?

>> Q2: How do you determine the correct die size for wire drawing?

>> Q3: What maintenance practices extend die life?

>> Q4: Can carbide wire drawing dies be reconditioned?

>> Q5: What are the key factors affecting wire drawing die performance?

Introduction to Carbide Wire Drawing Dies

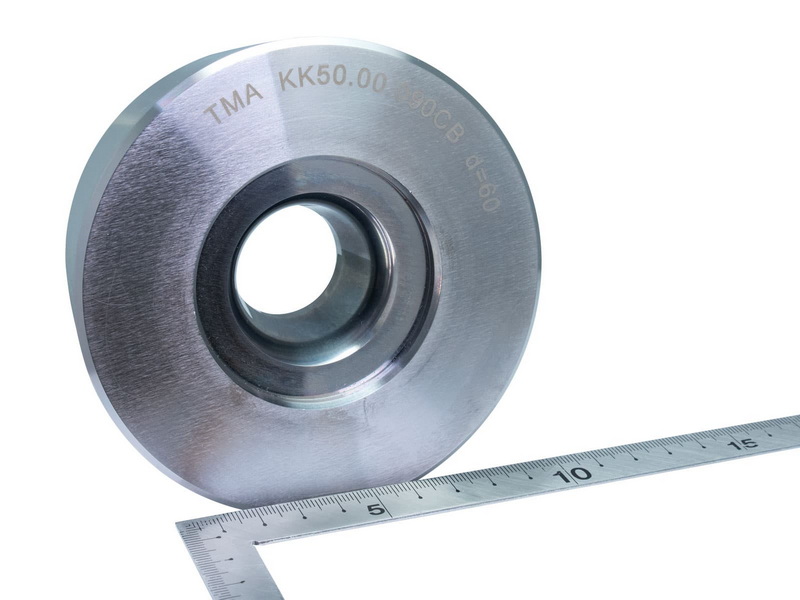

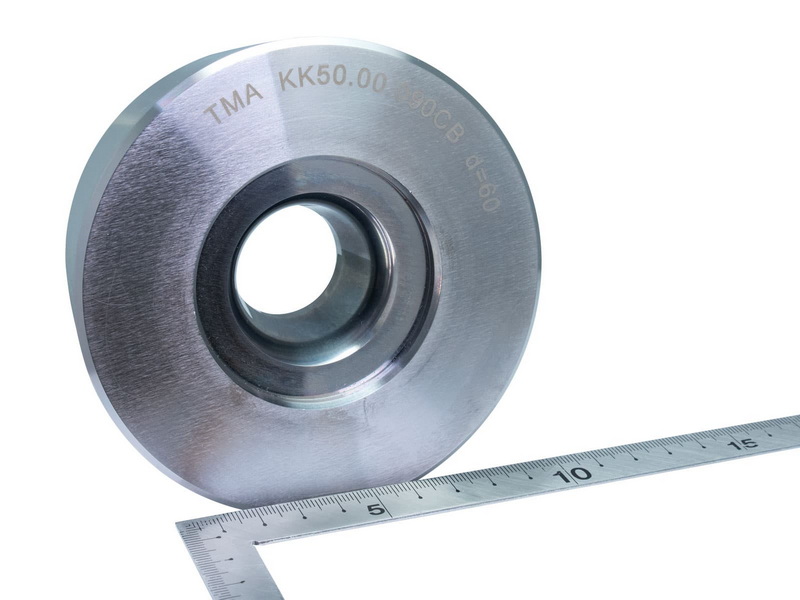

Carbide wire drawing dies represent a cornerstone technology in modern wire manufacturing processes. These precision-engineered tools are essential components in the wire drawing industry, enabling the production of high-quality wire products across various sectors.

Understanding Wire Drawing Die Technology

Carbide wire drawing dies are sophisticated tools designed to reduce wire diameter while improving its mechanical properties. These dies feature precisely engineered geometries, including carefully calculated approach angles, bearing lengths, and exit angles, all working together to ensure optimal wire drawing performance.

Manufacturing Process and Quality Control

The manufacturing of carbide wire drawing dies involves several critical steps:

1. Raw Material Selection

2. Core Formation

3. Precision Grinding

4. Surface Treatment

5. Quality Inspection

Applications and Industry Usage

Carbide wire drawing dies find extensive applications across multiple industries:

- Steel Wire Production

- Copper Wire Manufacturing

- Aluminum Wire Drawing

- Precious Metal Wire Formation

- Specialty Alloy Processing

Technical Specifications and Performance

Modern carbide wire drawing dies are characterized by:

- Superior Wear Resistance

- Excellent Surface Finish

- Precise Dimensional Control

- Extended Service Life

- Consistent Performance

Maintenance and Care

Proper maintenance of carbide wire drawing dies includes:

- Regular Cleaning

- Careful Handling

- Periodic Inspection

- Professional Reconditioning

- Proper Storage

Advanced Features and Innovations

Recent developments in carbide wire drawing die technology include:

- Enhanced Carbide Formulations

- Improved Geometry Designs

- Advanced Coating Technologies

- Optimized Performance Characteristics

- Innovative Manufacturing Processes

Selection and Optimization

Choosing the right carbide wire drawing die involves considering:

- Wire Material Properties

- Production Requirements

- Operating Conditions

- Quality Specifications

- Economic Factors

Future Trends and Developments

The future of carbide wire drawing dies points toward:

- Smart Manufacturing Integration

- Enhanced Material Science

- Improved Sustainability

- Advanced Process Control

- Greater Efficiency

Frequently Asked Questions

Q1: What is the typical lifespan of a carbide wire drawing die?

A1: The lifespan of a carbide wire drawing die varies depending on factors such as usage intensity, material being drawn, and maintenance practices. Under optimal conditions, these dies can process several tons of wire before requiring replacement or reconditioning.

Q2: How do you determine the correct die size for wire drawing?

A2: The selection of die size depends on the initial wire diameter, desired final diameter, material properties, and drawing sequence. Professional manufacturers typically provide detailed sizing charts and technical support for proper die selection.

Q3: What maintenance practices extend die life?

A3: Regular cleaning, proper lubrication, careful handling, and scheduled inspections are essential maintenance practices. Additionally, following manufacturer guidelines for speed and tension control helps maximize die life.

Q4: Can carbide wire drawing dies be reconditioned?

A4: Yes, carbide wire drawing dies can be reconditioned through professional services that include cleaning, polishing, and resizing of the drawing profile. This process can restore the die to near-original specifications.

Q5: What are the key factors affecting wire drawing die performance?

A5: Key performance factors include die material quality, geometry precision, surface finish, cooling conditions, lubrication effectiveness, and operational parameters such as drawing speed and reduction ratio.