Content Menu

● Understanding Tungsten Carbide: The Material Behind the Tools

>> Key Properties of Tungsten Carbide

● How Tungsten Carbide Tooling Is Made

● Types of Tungsten Carbide Tooling

● Applications of Tungsten Carbide Tooling

>> Machining and Manufacturing

>> Construction and Mining

>> Woodworking and Composite Processing

>> Precision Molding and Injection Molding

>> Other Specialized Uses

● Advanced Applications of Tungsten Carbide Tooling

● Advantages of Tungsten Carbide Tooling

● Disadvantages and Limitations

● Maintenance and Care Tips

● Environmental Impact and Sustainability

● Innovations and Future Trends

● Comparing Tungsten Carbide Tooling with Other Tool Materials

● Summary of Key Points

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What types of tools are commonly made from tungsten carbide?

>> 2. How does tungsten carbide extend tool life?

>> 3. Can tungsten carbide tools be sharpened?

>> 4. Are tungsten carbide tools more expensive than other materials?

>> 5. What maintenance practices help extend the life of tungsten carbide tools?

Tungsten carbide tooling stands at the forefront of industrial machining, manufacturing, and engineering. Known for its extraordinary hardness, wear resistance, and ability to withstand extreme conditions, tungsten carbide has revolutionized the way materials are cut, shaped, and formed. In this comprehensive guide, we will explore the science behind tungsten carbide, its manufacturing process, key applications, advantages and disadvantages, maintenance tips, advanced uses, sustainability concerns, innovations, and frequently asked questions. This article is structured with clear headers and includes illustrative descriptions to help you visualize the concepts.

Understanding Tungsten Carbide: The Material Behind the Tools

Tungsten carbide is a compound formed by combining equal parts of tungsten and carbon atoms. In its basic state, it appears as a fine gray powder, but through a process called sintering, it is pressed and formed into solid shapes suitable for industrial use. The result is a material that is nearly as hard as diamond and significantly tougher than steel.

Key Properties of Tungsten Carbide

- Extreme Hardness: Only diamond is harder than tungsten carbide, making it ideal for cutting and shaping tough materials.

- High Density: It is almost twice as dense as steel.

- Wear Resistance: Maintains sharpness and structural integrity even under heavy use.

- Thermal Stability: Performs consistently at high temperatures, crucial for high-speed machining.

- Corrosion Resistance: Resists chemical attacks in harsh environments.

How Tungsten Carbide Tooling Is Made

The production of tungsten carbide tooling involves several critical steps:

1. Powder Preparation: Tungsten and carbon powders are mixed.

2. Sintering: The powder blend is heated to just below its melting point, causing the particles to bond and form a dense solid.

3. Shaping: The sintered material is pressed into the desired tool shapes, such as drills, end mills, or inserts.

4. Finishing: Tools are ground to precise dimensions and may be coated with materials like titanium nitride for enhanced performance.

Types of Tungsten Carbide Tooling

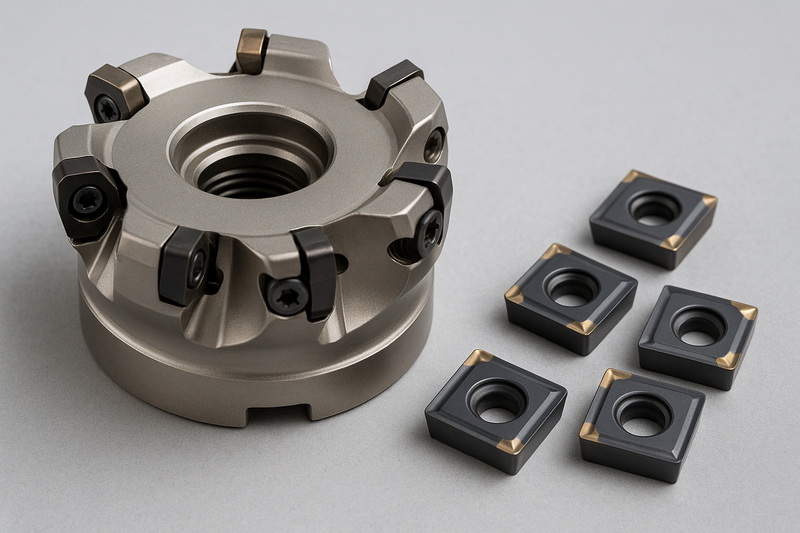

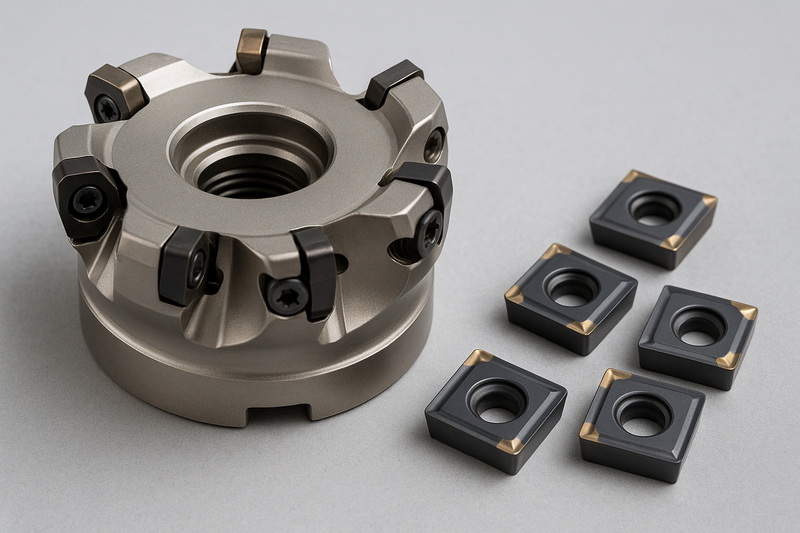

Tungsten carbide tooling comes in various forms, each designed for specific tasks:

- Drills: For creating precise holes in metals, composites, and other hard materials.

- End Mills: Used in milling operations to shape and finish surfaces.

- Inserts: Replaceable cutting edges for turning, milling, and drilling.

- Reamers: For finishing and sizing holes to tight tolerances.

- Saw Blades: For cutting wood, metals, and composites with minimal wear.

- Specialty Tools: Including router bits, slitting cutters, and keyseat cutters.

Applications of Tungsten Carbide Tooling

Tungsten carbide tooling is indispensable across numerous industries due to its versatility and performance.

Machining and Manufacturing

- Milling: Carbide end mills remove material quickly and provide smooth finishes on metals and composites.

- Drilling: Carbide drills excel in high-speed, high-precision drilling of steel, aluminum, and cast iron.

- Turning: Carbide inserts are used in lathes for shaping rotating workpieces.

- Reaming: Achieve precise hole dimensions and finishes.

Construction and Mining

- Rock Drills: Carbide-tipped bits penetrate hard rock and concrete.

- Trenching Tools: Used in road construction and mining for their durability.

Woodworking and Composite Processing

- Router Bits and Saw Blades: Provide clean cuts and extended tool life in wood and composite materials.

Precision Molding and Injection Molding

- Mold Tools: Carbide molds maintain accuracy and resist wear during high-volume plastic part production.

Other Specialized Uses

- Jewelry: Used for its scratch resistance and high polish.

- Medical Instruments: Scissors, forceps, and other surgical tools benefit from carbide's durability.

- Ammunition: Armor-piercing rounds utilize carbide for its density and hardness.

Advanced Applications of Tungsten Carbide Tooling

Beyond the common industrial uses, tungsten carbide tooling finds applications in cutting-edge fields that demand exceptional precision and durability.

In aerospace engineering, tungsten carbide tools are used to machine high-strength alloys and composites that form aircraft components. The ability to maintain sharpness and resist wear under extreme conditions ensures the safety and performance of these critical parts.

In the electronics industry, tungsten carbide tooling is employed to manufacture micro-components and circuit boards. The precision and fine edge retention allow for intricate designs and high-volume production without frequent tool changes.

In the medical device field, micro-scale carbide tools are used to fabricate implants and surgical instruments that require exacting tolerances and biocompatibility. The hardness and wear resistance of carbide enable repeated use in demanding environments.

In the energy sector, such as oil and gas extraction, tungsten carbide is used for downhole drilling tools, valves, and flow control components that must withstand abrasive slurries, high pressures, and corrosive fluids.

Advantages of Tungsten Carbide Tooling

- Long Tool Life: Outlasts high-speed steel and other tool materials, reducing replacement frequency.

- High Cutting Speeds: Maintains sharpness and effectiveness at higher speeds, boosting productivity.

- Superior Finish Quality: Produces cleaner, more precise cuts with less material deformation.

- Versatility: Suitable for metals, composites, plastics, and wood.

- Reduced Downtime: Fewer tool changes and maintenance interruptions.

Disadvantages and Limitations

- Higher Initial Cost: More expensive upfront than steel tools, though cost-effective over time due to longevity.

- Brittleness: While hard, tungsten carbide is less ductile and can chip or shatter under extreme impact.

- Special Handling Required: Needs careful maintenance and specialized sharpening equipment.

Maintenance and Care Tips

To maximize the lifespan and performance of tungsten carbide tooling, follow these best practices:

- Regular Inspection: Check for chipping, cracks, or uneven wear.

- Proper Cleaning: Remove debris and residues after each use.

- Lubrication: Apply rust inhibitors or specialized lubricants to prevent corrosion.

- Safe Storage: Store in dry, cool environments, ideally in individual cases to avoid tool contact.

- Professional Sharpening: Use specialized equipment or services for resharpening.

Environmental Impact and Sustainability

While tungsten carbide tooling offers many industrial benefits, it is also important to consider its environmental footprint. The production process involves mining tungsten and carbon sources, which can have ecological impacts. However, the long lifespan and durability of tungsten carbide tools reduce waste and the frequency of replacements, contributing to sustainability.

Recycling programs for tungsten carbide scrap are increasingly common, allowing manufacturers to reclaim valuable materials and reduce environmental harm. Advances in green manufacturing techniques are also being explored to minimize energy consumption and emissions during tool production.

Innovations and Future Trends

Research and development in tungsten carbide tooling continue to push the boundaries of performance. Nanostructured coatings and composite materials are being developed to enhance toughness and reduce brittleness. These innovations aim to extend tool life even further and enable machining of new, advanced materials.

Additive manufacturing techniques, such as 3D printing with tungsten carbide powders, are also emerging. These methods could revolutionize tool design by allowing complex geometries and customized tooling solutions that were previously impossible to produce.

The integration of smart sensors into carbide tools is another promising trend. These sensors can monitor tool wear, temperature, and cutting forces in real time, enabling predictive maintenance and optimizing machining processes for efficiency and safety.

Comparing Tungsten Carbide Tooling with Other Tool Materials

| Property | Tungsten Carbide | High-Speed Steel (HSS) | Ceramic Tools |

| Hardness | Very High | Moderate | Very High |

| Wear Resistance | Excellent | Good | Excellent |

| Toughness | Good | Excellent | Low (Brittle) |

| Thermal Stability | Excellent | Moderate | Excellent |

| Cost | High | Low | High |

| Sharpening Difficulty | Difficult | Easy | Very Difficult |

| Typical Applications | High-speed, precision machining, abrasive materials | General machining, softer materials | High-speed, non-ferrous, finishing |

Summary of Key Points

- Tungsten carbide tooling is essential in high-precision and high-durability applications across various industries.

- Its environmental impact is mitigated by long tool life and recycling efforts.

- Ongoing innovations promise to improve performance and expand the range of applications.

Conclusion

Tungsten carbide tooling is a cornerstone of modern manufacturing, offering unmatched hardness, wear resistance, and thermal stability. Its ability to perform under extreme conditions makes it indispensable for industries ranging from machining and construction to precision molding and medical device manufacturing. While the initial investment is higher, the extended tool life, superior performance, and reduced downtime provide significant long-term benefits. Proper maintenance and handling ensure that these tools continue to deliver optimal results, making tungsten carbide tooling a wise choice for professionals seeking reliability and efficiency. As advancements in material science and manufacturing processes continue, the future of tungsten carbide tooling promises even greater performance, sustainability, and application possibilities.

Frequently Asked Questions (FAQ)

1. What types of tools are commonly made from tungsten carbide?

Tungsten carbide is used to manufacture a wide range of tools, including cutting tools (drills, end mills, inserts), dies, punches, grinding wheels, slitting blades, pump components, valve seats, and liners. Its versatility makes it valuable in machining, mining, construction, and many other industries.

2. How does tungsten carbide extend tool life?

The superior hardness and wear resistance of tungsten carbide prevent rapid tool degradation. Tools maintain sharpness and structural integrity for longer periods, reducing the need for frequent replacements and minimizing downtime.

3. Can tungsten carbide tools be sharpened?

Yes, tungsten carbide tools can be sharpened, but this requires specialized equipment and techniques due to their extreme hardness. Professional sharpening services or diamond grinding wheels are typically used for this purpose.

4. Are tungsten carbide tools more expensive than other materials?

Tungsten carbide tools generally have a higher initial cost compared to materials like high-speed steel. However, their longer lifespan and reduced maintenance needs often result in significant cost savings over time.

5. What maintenance practices help extend the life of tungsten carbide tools?

Regular cleaning, proper handling to prevent chipping, timely sharpening or reconditioning, and following manufacturer guidelines for use and storage all contribute to extending the life of tungsten carbide tools. Storing tools individually and keeping them dry also helps prevent corrosion and accidental damage.