Content Menu

● Introduction to Calcium Carbide

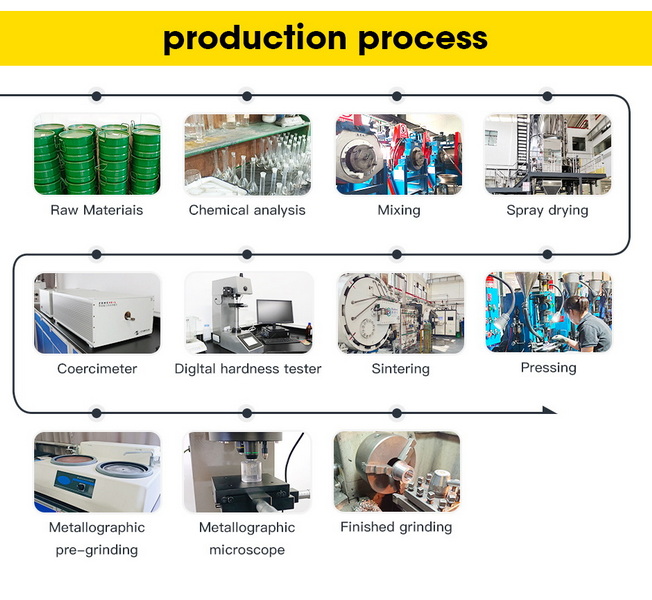

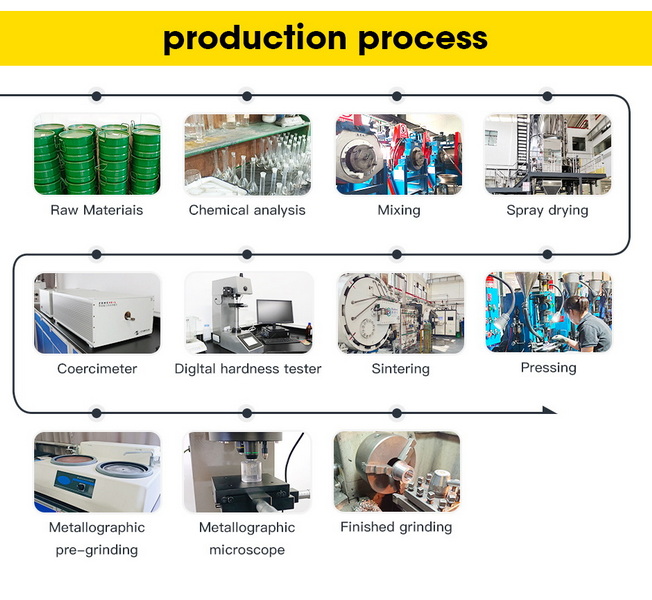

>> Production Process

● Cost Factors in Calcium Carbide Production

>> Raw Material Costs

>> Energy Costs

>> Labor Costs

>> Technological Advancements

>> Environmental and Regulatory Factors

● Market Dynamics and Demand

>> Market Price Fluctuations

● Technological Innovations and Sustainability

>> Environmental Challenges

>> Solutions and Strategies

● Market Outlook and Future Trends

● Conclusion

● FAQs

>> 1. What are the primary raw materials used in calcium carbide production?

>> 2. How does energy cost impact calcium carbide production?

>> 3. What are the main applications of calcium carbide?

>> 4. How do technological advancements influence calcium carbide production costs?

>> 5. What regulatory factors affect calcium carbide production costs?

● Citations:

Calcium carbide, with the chemical formula CaC₂, is a crucial industrial chemical used in various applications, including the production of acetylene gas, steel manufacturing, and the synthesis of other chemicals. The cost of producing calcium carbide is influenced by several factors, including raw material costs, energy consumption, labor expenses, and technological advancements. This article will delve into the economics of calcium carbide production, exploring the manufacturing process, cost factors, and market dynamics.

Introduction to Calcium Carbide

Calcium carbide is produced industrially by reacting lime (calcium oxide) and coke (carbon) in an electric arc furnace at high temperatures, typically around 2,200 °C (3,990 °F). This process is endothermic, requiring significant energy input to drive off the carbon monoxide byproduct. The resulting calcium carbide contains about 80% CaC₂ by weight, with the remainder consisting of impurities like calcium oxide, calcium phosphide, and silicon carbide.

Production Process

The production of calcium carbide involves several key steps:

1. Raw Material Preparation: Lime and coke are crushed and mixed in a specific ratio.

2. Heating in an Electric Arc Furnace: The mixture is heated to approximately 2,200 °C (3,990 °F) using graphite electrodes.

3. Reaction: The reaction between lime and coke produces calcium carbide and carbon monoxide.

4. Cooling and Crushing: The resulting calcium carbide is cooled and crushed into lumps.

A[Raw Material Preparation] --> B[Heating in Electric Arc Furnace]

B --> C[Reaction]

C --> D[Cooling and Crushing]

D --> E[Final Product: Calcium Carbide]

Cost Factors in Calcium Carbide Production

The cost of producing calcium carbide is influenced by several key factors:

Raw Material Costs

- Lime and Coke: The primary raw materials for calcium carbide production are lime (calcium oxide) and coke (carbon). Fluctuations in the prices of these materials directly impact the production cost. Lime is derived from limestone, while coke is typically obtained from coal or petroleum coke[1][2].

- Transportation Costs: The proximity of raw material sources to production facilities can affect transportation costs, further influencing overall production expenses.

Energy Costs

- Electricity Consumption: The electric arc furnace requires substantial electricity to achieve the high temperatures necessary for the reaction. Energy costs are a significant component of the production expenses. Fluctuations in energy prices can directly affect production costs[1][2].

- Energy Efficiency: Improving energy efficiency can help reduce production costs and enhance competitiveness.

Labor Costs

- Skilled Labor: The manufacturing process requires skilled operators and maintenance personnel, contributing to labor costs.

- Regulatory Compliance: Adherence to labor regulations and safety standards adds to these costs.

Technological Advancements

- Process Improvements: Innovations in production technology can enhance efficiency, reduce energy consumption, and optimize raw material use, potentially lowering costs[6].

- Initial Investment: Implementing new technologies often requires significant upfront investment, which can temporarily increase costs.

Environmental and Regulatory Factors

- Environmental Regulations: Compliance with environmental standards, such as emissions controls, can add to production costs. Stricter regulations may necessitate investments in pollution control equipment[8][14].

- Government Policies: Changes in government policies, such as energy taxes or subsidies, can impact production costs.

Market Dynamics and Demand

The demand for calcium carbide is driven by its applications in various industries:

- Steel Industry: Used for desulfurization and deoxidation in steel production.

- Chemical Industry: Essential for producing acetylene gas and other chemicals.

- Agricultural Sector: Used as a ripening agent and in fertilizer production.

Market Price Fluctuations

The market price of calcium carbide per ton typically ranges from $500 to $700, influenced by raw material costs, energy prices, and demand dynamics[14].

A[Raw Material Costs] --> B[Market Price]

C[Energy Prices] --> B

D[Demand Dynamics] --> B

Technological Innovations and Sustainability

The calcium carbide industry is witnessing significant technological advancements aimed at improving efficiency and reducing environmental impact:

- Clean Production Technologies: Innovations like enclosed conveyor systems and fully enclosed dust removal pipelines help minimize dust emissions and environmental pollution[6].

- Automated Production Lines: Automation enhances production efficiency and product consistency, reducing labor costs and improving quality control[6].

Environmental Challenges

Despite these advancements, calcium carbide production still poses environmental challenges:

- Dust Emissions: Crushing and handling processes generate significant dust, posing health risks and contributing to air pollution[12].

- Energy Consumption: The production process is energy-intensive, leading to substantial CO₂ emissions[12].

Solutions and Strategies

To address these challenges, manufacturers are adopting strategies such as:

- Advanced Dust Control Systems: Capturing over 95% of dust particles to meet environmental standards[12].

- Moisture Prevention Measures: Sealed equipment to prevent acetylene gas risks[12].

Market Outlook and Future Trends

The calcium carbide market is expected to grow, driven by increasing demand from the steel and chemical sectors. Technological innovations and environmental regulations will play crucial roles in shaping the industry's future:

- Market Growth: The global calcium carbide market is projected to expand due to rising demand for acetylene gas and steel production[5][7].

- Sustainability Focus: There is a growing emphasis on sustainable production methods and energy efficiency, driving investments in advanced technologies[5][6].

Conclusion

The cost of calcium carbide production is complex, influenced by raw material availability and prices, energy consumption, labor costs, technological advancements, and regulatory compliance. Understanding these factors is crucial for manufacturers seeking to optimize production processes and remain competitive in the market.

FAQs

1. What are the primary raw materials used in calcium carbide production?

The primary raw materials for calcium carbide production are lime (calcium oxide) and coke (carbon), which are mixed and heated in an electric arc furnace.

2. How does energy cost impact calcium carbide production?

Energy costs significantly impact calcium carbide production due to the high electricity requirements of the electric arc furnace process. Fluctuations in energy prices can directly affect production costs.

3. What are the main applications of calcium carbide?

Calcium carbide is primarily used in the production of acetylene gas, steel manufacturing (for desulfurization and deoxidization), and the synthesis of other chemicals like calcium cyanamide.

4. How do technological advancements influence calcium carbide production costs?

Technological advancements can improve efficiency, reduce energy consumption, and optimize raw material use, potentially lowering production costs. However, implementing new technologies often requires significant initial investment.

5. What regulatory factors affect calcium carbide production costs?

Regulatory factors, including environmental regulations and labor standards, can add to production costs by requiring additional investments in pollution control equipment and compliance measures.

Citations:

[1] https://www.tjtywh.com/a-the-economics-of-calcium-carbide-analyzing-the-cost-factors.html

[2] https://www.tjtywh.com/a-understanding-the-factors-affecting-calcium-carbide-price-per-kg1.html

[3] https://www.procurementresource.com/cost-analysis/calcium-carbide-production-from-lime-and-coke

[4] https://www.ascconline.com/img/services/project_report/Calcium_Carbide_Project_Report_Sample.pdf

[5] https://www.mordorintelligence.com/industry-reports/calcium-carbide-market

[6] https://www.tjtywh.com/technological-innovations-in-calcium-carbide-clean-production-and-automated-production-lines.html

[7] https://www.openpr.com/news/3882742/calcium-carbide-market-forecast-2025-2034-evaluating-growth

[8] https://www.tjtywh.com/how-environmental-regulations-impact-global-calcium-carbide-production-and-supply-chains.html

[9] https://explosiveconsultant.com/calcium-carbide-rules-1987/

[10] https://www.procurementresource.com/production-cost-report-store/calcium-carbide

[11] https://www.imarcgroup.com/calcium-carbide-pricing-report

[12] https://www.tjtywh.com/environmental-challenges-in-calcium-carbide-production-and-tywh-s-solutions.html

[13] https://www.chemradar.com/lawinfo/detail/d1fqb4q9ujnk

[14] https://www.tjtywh.com/a-the-current-market-price-of-calcium-carbide-per-ton-a-detailed-analysis.html

[15] https://www.chemanalyst.com/Pricing-data/calcium-carbide-1145

[16] https://www.linkedin.com/pulse/calcium-carbide-production-cost-analysis-

[17] https://www.chemanalyst.com/industry-report/calcium-carbide-market-2850

[18] https://www.openpr.com/news/3678527/calcium-carbide-prices-monitor-demand-analysis-and-forecast

[19] https://www.einpresswire.com/article/615427259/calcium-carbide-production-costs-report-2023-2028-syndicated-analytics

[20] https://www.consegicbusinessintelligence.com/calcium-carbide-market

[21] https://www.linkedin.com/pulse/calcium-carbide-price-trend-analysis-suraj-jha-zxhgc

[22] https://www.einpresswire.com/article/686570177/calcium-carbide-market-statistics-2030-major-factors-that-can-increase-the-global-demand

[23] https://www.openpr.com/news/2947367/calcium-carbide-production-cost-an-in-depth-analysis

[24] https://en.wikipedia.org/wiki/Calcium_carbide

[25] https://www.alzchem.com/en/brands/calcium-carbide/

[26] https://www.industryarc.com/Report/17673/calcium-carbide-market.html

[27] https://sathee.prutor.ai/article/chemistry/chemistry-calcium-carbide/

[28] https://www.carbidellc.com/solutions.html

[29] https://www.alliedmarketresearch.com/calcium-carbide-market-A15002

[30] https://byjus.com/chemistry/calcium-carbide/

[31] https://www.transparencymarketresearch.com/calcium-carbide-market.html

[32] https://www.nature.com/articles/s41598-023-31075-z

[33] https://www.databridgemarketresearch.com/reports/global-calcium-carbide-market

[34] https://www.gminsights.com/industry-analysis/calcium-carbide-market

[35] https://www.innovations-report.com/engineering/materials-sciences/zelinsky-institute-of-organic-chemistry-russian-academy-of-sciences/

[36] https://pubs.acs.org/doi/10.1021/acssusresmgt.4c00164

[37] https://www.vpsatech.com/World-Class-Innovative-Projects/First-Calcium-Carbide-Furnace-Exhaust-to-MEG-Project.html

[38] https://www.linkedin.com/pulse/8-key-factors-setting-up-calcium-carbide-plant-khushbu-khan-nlvqc

[39] https://www.pyrometallurgy.co.za/InfaconXIV/149-McCaffrey.pdf

[40] https://blog.tbrc.info/2025/01/calcium-carbide-market-growth-2/

[41] https://www.carbidellc.com

[42] https://www.industryarc.com/PressRelease/3678/calcium-carbide-market

[43] http://jbb.xml-journal.net/article/doi/10.1016/j.jobab.2020.04.002

[44] https://www.promarketreports.com/reports/calcium-carbide-gas-44159

[45] https://www.skyquestt.com/report/calcium-carbide-market/market-news

[46] https://enterclimate.com/calcium-carbide-manufacturing-unit-setup

[47] https://peso.gov.in/web/sites/default/files/2019-12/calcium_carbide_rules_1987.pdf

[48] https://www.epa.gov/system/files/documents/2025-03/ghgrp-ry2024-extension-final-rule.pdf

[49] https://law.resource.org/pub/in/bis/S02/is.6819.1973.pdf

[50] https://ift.onlinelibrary.wiley.com/doi/10.1111/1541-4337.70140?af=R

[51] https://www.linkedin.com/pulse/calcium-carbide-market-set-experience-considerable-hyl8c

[52] https://health.economictimes.indiatimes.com/news/industry/fssai-alerts-traders-to-ensure-compliance-with-prohibition-of-calcium-carbide-in-fruit-ripening/110275491

[53] https://www.linkedin.com/pulse/calcium-carbide-price-trendlatest-news-market-analysis-suraj-jha-u8gjc

[54] https://www.imarcgroup.com/calcium-carbide-manufacturing-plant-project-report

[55] https://www.eiga.eu/uploads/documents/DOC196.pdf

[56] https://pmc.ncbi.nlm.nih.gov/articles/PMC9373447/

[57] https://www.datainsightsmarket.com/reports/calcium-carbide-market-2174

[58] https://www.syndicatedanalytics.com/calcium-carbide-production-cost-analysis-report

[59] https://www.tjtywh.com/a-the-current-market-price-of-calcium-carbide-per-ton-a-comprehensive-analysis.html

[60] https://www.tjtywh.com/a-the-role-of-calcium-carbide-in-industrial-applications.html

[61] https://www.tjtywh.com/a-the-role-of-calcium-carbide-in-industrial-processes-and-applications.html

[62] https://www.tjtywh.com/a-the-role-of-calcium-carbide-in-industrial-applications1.html

[63] https://www.tjtywh.com/a-exploring-the-practical-applications-of-calcium-carbide.html

[64] https://www.fortunebusinessinsights.com/industry-reports/calcium-carbide-market-101580

[65] https://www.aist.org/new-partnership-to-introduce-calcium-carbide-based-eaf-slag-technology

[66] https://www.niir.org/blog/launching-a-calcium-carbide-manufacturing-enterprise/

[67] https://www.thebusinessresearchcompany.com/report/calcium-carbide-global-market-report

[68] https://www.zkg.de/en/artikel/zkg_Application_technology_of_calcium_carbide_slag_a_case_study_concerning-3535204.html

[69] https://www.epa.gov/ghgreporting/subpart-xx-calcium-carbide-producers