Content Menu

● Introduction

● What is HVOF Tungsten Carbide Coating?

● How Does the HVOF Process Work?

>> 1. Combustion and Gas Generation

>> 2. Powder Injection

>> 3. Deposition

>> Key Parameters of the HVOF Process

● Properties of HVOF Tungsten Carbide Coatings

>> 1. Exceptional Hardness and Wear Resistance

>> 2. High Bond Strength

>> 3. Low Porosity

>> 4. Superior Corrosion and Chemical Resistance

>> 5. Customizable Thickness and Surface Finish

● Comparison: HVOF Tungsten Carbide vs. Chrome Plating

● Applications of HVOF Tungsten Carbide Coatings

>> 1. Aerospace

>> 2. Oil & Gas

>> 3. Automotive

>> 4. Power Generation

>> 5. Paper, Printing, and Steel Industries

● Advantages and Limitations

>> Advantages

>> Limitations

● Key Industries and Case Studies

>> Aerospace

>> Oil & Gas

>> Automotive

● Process Control, Quality Assurance, and Inspection

>> Process Control

>> Quality Assurance

>> Inspection and Certification

● Environmental and Economic Considerations

>> Environmental Benefits

>> Economic Impact

>> Sustainability

● Future Trends in HVOF Tungsten Carbide Coatings

● Conclusion

● FAQ

>> 1. What makes HVOF tungsten carbide coatings superior to chrome plating?

>> 2. What are the typical thicknesses achievable with HVOF tungsten carbide coatings?

>> 3. Which industries benefit most from HVOF tungsten carbide coatings?

>> 4. Can HVOF tungsten carbide coatings be applied to any substrate?

>> 5. What post-processing is needed after applying HVOF tungsten carbide coatings?

● Citations:

Introduction

High-Velocity Oxygen Fuel (HVOF) tungsten carbide coating is a cutting-edge surface engineering technology that has revolutionized the way industries protect and enhance the performance of critical components. This process combines the exceptional hardness of tungsten carbide with the advanced deposition capabilities of HVOF thermal spray, resulting in coatings that offer unmatched wear resistance, corrosion protection, and longevity. In this comprehensive guide, we will explore the science, process, applications, benefits, and future trends of HVOF tungsten carbide coatings, providing detailed insights for engineers, manufacturers, and decision-makers across various sectors.

What is HVOF Tungsten Carbide Coating?

HVOF tungsten carbide coating is a type of thermal spray process where tungsten carbide powder is propelled at supersonic speeds onto a substrate using a high-pressure, high-temperature gas jet. The result is a dense, tightly bonded coating that dramatically improves the surface properties of the underlying material.

- Tungsten carbide is a compound of tungsten and carbon, known for its extreme hardness and abrasion resistance.

- HVOF (High-Velocity Oxygen Fuel) is a thermal spray technique that combusts fuel and oxygen to create a high-temperature, high-velocity gas stream, which carries the tungsten carbide particles onto the workpiece.

How Does the HVOF Process Work?

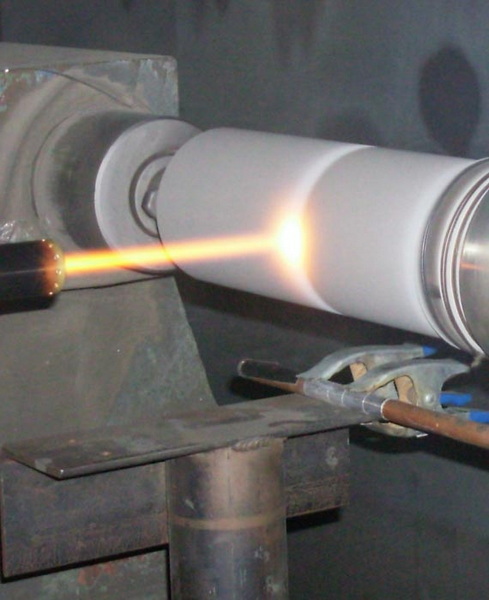

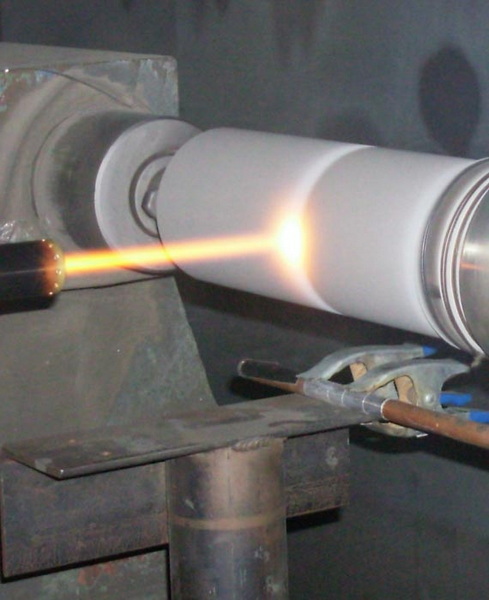

1. Combustion and Gas Generation

- Fuel (such as hydrogen or kerosene) and oxygen are mixed and ignited in a combustion chamber, generating a high-pressure, high-temperature gas (up to 5,600°F / 3,093°C).

- The gas is forced through a nozzle, accelerating to supersonic velocities.

2. Powder Injection

- Tungsten carbide powder is injected into the jet, where it is heated and accelerated to velocities up to 3,000 feet per second.

3. Deposition

- The high-velocity particles impact the substrate, flattening and bonding instantly due to their kinetic energy.

- Layers build up rapidly, forming a dense, cohesive coating with low porosity and high bond strength.

Key Parameters of the HVOF Process

| Parameter | Typical Value |

| Maximum Flame Temp | 5,600°F (3,093°C) |

| Particle Velocity | 2,000–3,000 ft/sec |

| Coating Thickness | 0.003" to 0.030" |

| Bond Strength | >10,000 psi |

| Porosity | <0.5% |

| Wear Resistance | Excellent |

| Corrosion Resistance | Very Good |

Properties of HVOF Tungsten Carbide Coatings

1. Exceptional Hardness and Wear Resistance

- Tungsten carbide coatings are among the hardest materials available, significantly outperforming steel and chrome plating in abrasive environments.

- Typical hardness values range from 1100 to 1600 HV (Vickers Hardness), depending on the specific formulation and binder content.

2. High Bond Strength

- The supersonic impact creates a mechanical bond exceeding 10,000 psi, ensuring the coating remains intact under severe stress.

- The strong adhesion is critical for components subject to high mechanical loads and cyclic stresses.

3. Low Porosity

- The process yields coatings with porosity typically below 0.5%, minimizing pathways for corrosive agents and enhancing durability.

- Low porosity is essential for applications exposed to corrosive or erosive environments, as it prevents the penetration of fluids and gases.

4. Superior Corrosion and Chemical Resistance

- Depending on the binder (cobalt, nickel, or chromium), tungsten carbide coatings resist a wide range of chemicals, making them suitable for aggressive environments.

- The choice of binder can be tailored to optimize performance against specific chemicals or corrosive media.

5. Customizable Thickness and Surface Finish

- Coatings can be tailored from a few microns up to several millimeters, with surface finishes ranging from rough to mirror-polished, depending on post-processing.

- This flexibility allows engineers to design coatings for both functional and aesthetic requirements.

Comparison: HVOF Tungsten Carbide vs. Chrome Plating

| Feature | HVOF Tungsten Carbide | Chrome Plating |

| Hardness | Superior (1100–1600 HV) | Good (800–1000 HV) |

| Wear Resistance | Excellent | Good |

| Corrosion Resistance | Very Good | Moderate |

| Environmental Impact | No hazardous Cr(VI) | Uses toxic hexavalent chromium |

| Bond Strength | Very High | Moderate |

| Thickness Range | 0.003"–0.030"+ | Typically <0.010" |

| Customization | Highly customizable | Limited |

| Cost | Higher initial, lower lifecycle | Lower initial, higher lifecycle |

| Typical Applications | Aerospace, Oil & Gas, Paper | Hydraulic rods, Rollers |

Key Takeaway: HVOF tungsten carbide coatings offer superior performance and are more environmentally friendly compared to chrome plating, making them the preferred choice for many critical applications.

Applications of HVOF Tungsten Carbide Coatings

1. Aerospace

- Landing gear, turbine blades, actuator rods, and pump components require high wear and corrosion resistance.

- HVOF tungsten carbide coatings help reduce maintenance intervals and ensure safety-critical performance.

2. Oil & Gas

- Downhole tools, valves, and drilling components are protected from abrasion and chemical attack.

- The coatings withstand abrasive slurries, high pressures, and corrosive fluids encountered in oilfield environments.

3. Automotive

- Engine valves, crankshafts, and piston rings benefit from extended service life and reduced maintenance.

- The low friction and high hardness of tungsten carbide coatings contribute to improved fuel efficiency and lower emissions.

4. Power Generation

- Turbine shafts, pump sleeves, and seals are coated to withstand harsh operational environments.

- The coatings provide protection against high-velocity steam, water, and particulate erosion.

5. Paper, Printing, and Steel Industries

- Rollers, cylinders, and cutting blades are coated for improved wear resistance and dimensional stability.

- HVOF coatings help maintain product quality and reduce downtime due to component failure.

Advantages and Limitations

Advantages

- Superior Wear and Abrasion Resistance: Extends component life in high-wear environments.

- Excellent Corrosion Protection: Ideal for chemically aggressive settings.

- High Bond Strength: Reduces risk of delamination or spalling.

- Low Porosity: Minimizes ingress of corrosive agents.

- Environmentally Friendly: No use of hazardous chromium compounds.

- Customizable: Thickness, finish, and composition can be tailored to application needs.

- Reduced Downtime: Longer component life leads to fewer replacements and less maintenance.

- Enhanced Surface Properties: Coatings can be engineered for specific friction, hardness, or thermal properties.

Limitations

- Higher Initial Cost: More expensive than some traditional coatings, but often offset by longer service life.

- Specialized Equipment Required: Not as widely available as electroplating.

- Post-Processing May Be Needed: Grinding or polishing may be required for tight tolerances or smooth finishes.

- Substrate Limitations: Some materials may not be suitable for the high temperatures and stresses of the HVOF process.

- Complex Geometries: Internal surfaces and intricate shapes can be challenging to coat uniformly.

Key Industries and Case Studies

Aerospace

- Landing gear components coated with HVOF tungsten carbide have demonstrated significantly increased life cycles, reducing maintenance intervals and costs.

- Example: Major airlines have reported a 2x to 3x increase in the service interval of landing gear struts after switching from chrome plating to HVOF tungsten carbide.

Oil & Gas

- Downhole drilling tools coated with tungsten carbide withstand abrasive slurries and corrosive fluids, outperforming traditional hardfacing methods.

- Example: Offshore drilling companies have extended the lifespan of mud motor rotors by over 50% using HVOF coatings.

Automotive

- Engine valves and camshafts coated with HVOF tungsten carbide show reduced wear and improved fuel efficiency due to lower friction.

- Example: High-performance racing teams use HVOF-coated components to gain a competitive edge in endurance and reliability.

Process Control, Quality Assurance, and Inspection

Process Control

- Modern HVOF systems use advanced process control to ensure consistent coating quality.

- Parameters such as gas flow, fuel-to-oxygen ratio, powder feed rate, and spray distance are monitored and adjusted in real time.

Quality Assurance

- Coating thickness, hardness, porosity, and bond strength are routinely tested to verify compliance with specifications.

- Non-destructive testing (NDT) methods, such as ultrasonic inspection and eddy current testing, are used to detect defects.

Inspection and Certification

- Finished components are inspected visually and with precision instruments to ensure surface finish and dimensional accuracy.

- Many industries require certification to international standards (e.g., ASTM, ISO) for critical parts.

Environmental and Economic Considerations

Environmental Benefits

- HVOF tungsten carbide coatings do not use toxic hexavalent chromium, a known carcinogen found in traditional chrome plating.

- The process generates minimal waste and can often be applied in facilities with advanced air filtration and recycling systems.

Economic Impact

- While the initial cost of HVOF tungsten carbide coating is higher than some alternatives, the total cost of ownership is often lower due to reduced downtime, longer component life, and less frequent replacement.

- Companies report significant savings in maintenance, labor, and replacement parts over the lifecycle of coated components.

Sustainability

- The durability and longevity of HVOF tungsten carbide coatings contribute to sustainability by reducing material consumption and waste.

- Many organizations are adopting HVOF coatings as part of their green manufacturing initiatives.

Future Trends in HVOF Tungsten Carbide Coatings

- Increased Adoption: As environmental regulations tighten and performance demands rise, more industries are transitioning from chrome plating to HVOF tungsten carbide coatings.

- Advanced Materials: New binder chemistries (e.g., WC/Co/Cr) are being developed to further enhance corrosion resistance and toughness.

- Robotic Application: Automation and robotics are making the HVOF process more consistent and cost-effective.

- Digital Process Control: Real-time monitoring and control of spray parameters are improving coating quality and repeatability.

- Hybrid Coatings: Research is ongoing into combining HVOF with other surface technologies, such as laser cladding or PVD, to create multi-functional surfaces.

- Additive Manufacturing Integration: Some manufacturers are exploring the integration of HVOF coatings into additive manufacturing processes for next-generation components.

Conclusion

HVOF tungsten carbide coating is a transformative technology for industries seeking to maximize the performance and longevity of critical components. By combining the exceptional hardness of tungsten carbide with the advanced deposition capabilities of HVOF, this process delivers coatings that are harder, tougher, and more corrosion-resistant than traditional alternatives like chrome plating. The result is reduced downtime, lower maintenance costs, and improved sustainability across a wide range of applications.

As industries continue to evolve, the demand for high-performance, environmentally friendly surface treatments will only increase. HVOF tungsten carbide coatings are poised to play a pivotal role in this future, offering a compelling solution for the most demanding engineering challenges.

FAQ

1. What makes HVOF tungsten carbide coatings superior to chrome plating?

HVOF tungsten carbide coatings offer higher hardness, better wear and corrosion resistance, and superior bond strength compared to chrome plating. They also eliminate the use of hazardous hexavalent chromium, making them more environmentally friendly.

2. What are the typical thicknesses achievable with HVOF tungsten carbide coatings?

HVOF tungsten carbide coatings can be applied in thicknesses ranging from 0.003 inches to over 0.030 inches, depending on application requirements.

3. Which industries benefit most from HVOF tungsten carbide coatings?

Industries such as aerospace, oil & gas, automotive, power generation, and manufacturing (including paper, printing, and steel) benefit significantly from the enhanced wear and corrosion protection provided by HVOF tungsten carbide coatings.

4. Can HVOF tungsten carbide coatings be applied to any substrate?

While HVOF tungsten carbide coatings can be applied to a wide range of substrates, including steel, aluminum, and titanium, the substrate must be able to withstand the thermal and mechanical stresses of the process.

5. What post-processing is needed after applying HVOF tungsten carbide coatings?

Depending on the application, post-processing such as grinding or polishing may be required to achieve the desired surface finish or tight tolerances. Tungsten carbide coatings are extremely hard and require diamond or cubic boron nitride abrasives for finishing.

Citations:

[1] https://www.alphatek.co.uk/what-is-hvof-tungsten-carbide-coating/

[2] https://htscoatings.com/pages/hvof-spray

[3] https://flamespray.org/newsEN-17-HVOF-Tungsten-Carbide-Coatings-A-Superior-Alternative-to-Chrome-Plating

[4] https://blog.indianaprecisiongrinding.com/trends-in-the-hvof-tungsten-carbide-coating

[5] https://www.asbindustries.com/coating-materials/carbide-coating-materials/tungsten-carbide-coatings

[6] https://www.thermalspray.com/4-popular-hvof-coating-materials/

[7] https://flamespray.org/newsEN-15-Tungsten-Carbide-Based-HVOF-Coatings-WC-coatings-WC-Co-Cr-and-WC-Co-Introduction

[8] https://kermetico.com/coating-materials/tungsten-carbide-wc-co-coatings

[9] https://www.sciencedirect.com/science/article/abs/pii/S0257897200011488

[10] https://www.alphatek.co.uk/how-long-does-hvof-tungsten-carbide-coating-last/