Content Menu

● Methods for Cutting Tungsten Carbide

>> Diamond Saw Blades

>> Carbide Grit Blades

>> Dremel Tools with Carbide Wheels

>> Abrasion Wheels

>> Electric Discharge Machining (EDM)

>> Electrolytic Machining (ECM)

● Safety Precautions

● Applications of Tungsten Carbide Cutting Tools

● Challenges in Cutting Tungsten Carbide

● Conclusion

● FAQs

>> 1. How do I secure a tungsten carbide rod during cutting?

>> 2. What safety equipment is essential for cutting tungsten carbide?

>> 3. Can I use a standard hacksaw to cut tungsten carbide?

>> 4. Why is tungsten carbide difficult to cut?

>> 5. How do I maintain tungsten carbide cutting tools?

● Citations:

Tungsten carbide, renowned for its extreme hardness (8.5–9.5 on the Mohs scale) and wear resistance, poses significant challenges for cutting and shaping. Widely used in industrial tools, medical devices, and wear-resistant components, this material demands specialized techniques and equipment. Below, we explore the methods, tools, and safety measures required to cut tungsten carbide effectively.

Methods for Cutting Tungsten Carbide

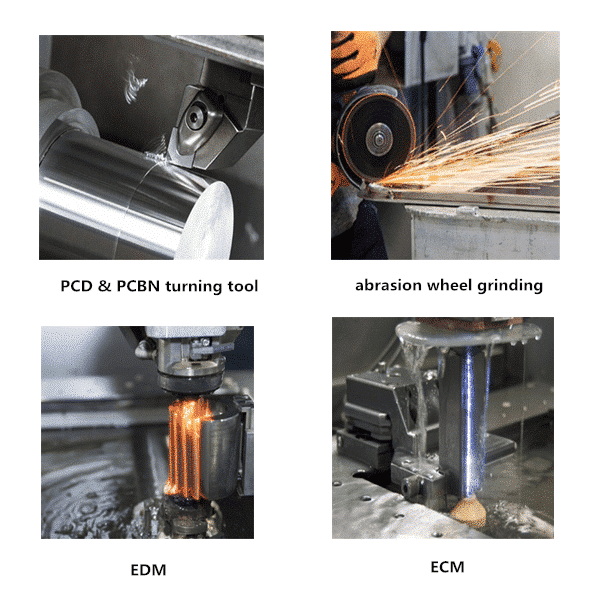

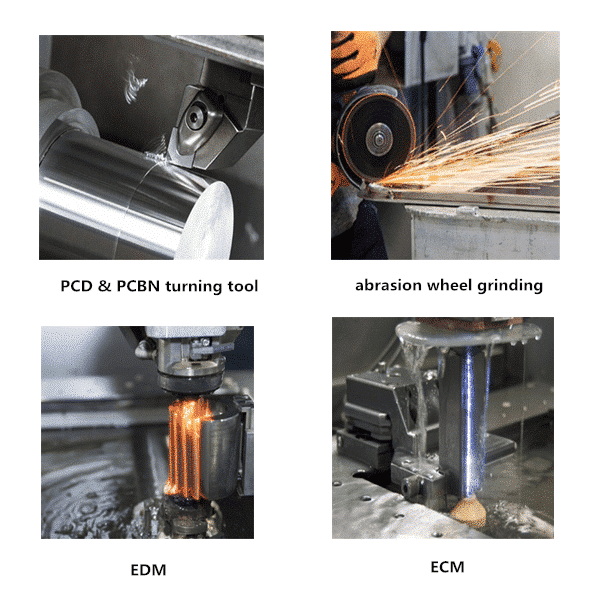

Diamond Saw Blades

Diamond saw blades, embedded with synthetic diamond particles, are the most common tool for precision cutting of tungsten carbide. The diamond's hardness (10 on the Mohs scale) allows it to grind through the carbide without significant wear. These blades are ideal for creating clean, straight cuts in rods, plates, or industrial components[3][6].

Applications:

- Cutting tungsten carbide rods for tool manufacturing.

- Trimming medical-grade carbide components[1][3].

Key Features:

- Wet or dry cutting capabilities.

- Available in diameters ranging from 4" to 16"[5].

Carbide Grit Blades

For rough cuts and shaping, carbide grit blades provide an economical solution. These blades use tungsten carbide particles bonded to a steel core, offering a balance between durability and cost. While less precise than diamond blades, they excel in rapid material removal[3][46].

Applications:

- Initial shaping of carbide blanks.

- Trimming overlong planer blades[8][15].

Limitations:

- Higher risk of surface cracks due to thermal stress[3][7].

Dremel Tools with Carbide Wheels

For small-scale or intricate tasks, Dremel tools equipped with tungsten carbide wheels offer unmatched control. These handheld devices are perfect for detailed adjustments, such as cutting small sections or engraving[3][9][16].

Tips for Use:

- Operate at high speeds with gentle pressure.

- Cool the workpiece periodically to prevent overheating[3][9].

Abrasion Wheels

Diamond-coated abrasion wheels grind tungsten carbide gradually, enabling fine control over surface finish. They are indispensable for achieving polished edges or smoothing rough cuts[3][46].

Applications:

- Deburring machined carbide components.

- Preparing surfaces for coating or bonding[3][7].

Electric Discharge Machining (EDM)

EDM uses electrical discharges to erode tungsten carbide, making it ideal for complex geometries and fine details. This non-contact method minimizes mechanical stress, reducing the risk of cracking[7][36].

Advantages:

- No tool wear during cutting.

- Suitable for ultra-hard grades (HRA90+)[7][36].

Electrolytic Machining (ECM)

ECM dissolves tungsten carbide electrochemically, offering a non-thermal alternative. It's particularly effective for bulk material removal without inducing thermal damage[7][36].

Applications:

- Machining carbide components with tight tolerances.

- Creating intricate internal features[7].

Safety Precautions

- Protective Gear: Safety glasses, gloves, and dust masks are mandatory to shield against flying debris and fine particles[3][21].

- Workpiece Securing: Use a vise or clamp to prevent movement during cutting[3][8].

- Cooling: Regularly cool blades to avoid heat buildup, which can damage both the tool and workpiece[3][9].

- Ventilation: Ensure proper airflow to disperse hazardous dust[3][21].

Applications of Tungsten Carbide Cutting Tools

- Medical Devices: Precision-cut stents, catheters, and braided mesh[1].

- Industrial Tools: Drill bits, milling inserts, and wear-resistant components[6][46].

- Construction: Demolition blades for concrete, metal, and asphalt[5][46].

Challenges in Cutting Tungsten Carbide

1. Brittleness: Prone to chipping or shattering under improper techniques[3][9].

2. Heat Management: Excessive heat can warp tools or damage the carbide[3][21].

3. Tool Costs: Specialized equipment (e.g., EDM machines) requires significant investment[7][36].

Conclusion

Cutting tungsten carbide demands a strategic approach tailored to the material's properties. Diamond blades and advanced methods like EDM/ECM deliver precision, while abrasion wheels and carbide grit blades handle rougher tasks. Safety remains paramount to avoid injury and ensure optimal results. By selecting the right technique and adhering to best practices, manufacturers can harness tungsten carbide's full potential across industries.

FAQs

1. How do I secure a tungsten carbide rod during cutting?

Use a vise or clamp to hold the rod firmly, minimizing movement. Mark the cutting line beforehand for accuracy[3][8].

2. What safety equipment is essential for cutting tungsten carbide?

Wear safety glasses, gloves, and a dust mask. Ensure proper ventilation to avoid inhaling particles[3][21].

3. Can I use a standard hacksaw to cut tungsten carbide?

No—tungsten carbide's hardness will damage conventional blades. Diamond or carbide-grit tools are required[8][16].

4. Why is tungsten carbide difficult to cut?

Its extreme hardness and brittleness require specialized tools to avoid cracking or tool wear[3][9][36].

5. How do I maintain tungsten carbide cutting tools?

Inspect for wear, sharpen with diamond grinders, and store in dry conditions to prevent corrosion[6][44].

Citations:

[1] https://www.ideal-tek.com/catalogue/1/cutters-and-pliers/tungsten-carbide-cutters

[2] https://www.gwstoolgroup.com/understanding-the-different-types-of-carbide-in-cutting-tools/

[3] https://shop.machinemfg.com/how-to-cut-tungsten-carbide-rods-an-overview/

[4] https://www.alamy.com/stock-photo/tungsten-carbide.html

[5] https://globaldiamondpros.com/products/4-1-2

[6] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[7] https://www.linkedin.com/pulse/carbiderod-how-cut-tungsten-carbide-rod-shijin-lei

[8] https://www.model-engineer.co.uk/forums/topic/how-to-cut-tungsten-carbide/

[9] http://derbytalk.com/viewtopic.php?t=2378

[10] https://www.stepcraft-systems.com/forum/milling/4349-cutting-tungsten-carbide

[11] https://www.betalentcarbide.com/products/carbide-cutting-tools/

[12] https://www.youtube.com/watch?v=zk3ZiVOvwFg

[13] https://www.larsonjewelers.com/pages/can-tungsten-rings-be-cutoff

[14] https://sawfish-endive-kgks.squarespace.com/shop/tungsten-carbide-loop-tools

[15] https://www.model-engineer.co.uk/forums/topic/how-to-cut-tungsten-carbide/

[16] https://www.reddit.com/r/metalworking/comments/1e9xttj/cutting_tungsten/

[17] https://www.walmart.com/c/kp/tungsten-carbide-cutters

[18] http://derbytalk.com/viewtopic.php?t=2378

[19] https://www.lowes.com/pl/power-tools/rotary-tools-oscillating-tools/rotary-tool-bits-wheels/tungsten-carbide/cutting/4294607819-4294838287-4294963906

[20] https://www.practicalmachinist.com/forum/threads/machining-tungsten-carbide-advice-needed.351332/

[21] https://www.ringrescue.com/blog/cutting-tungsten-rings-are-there-risks

[22] https://stock.adobe.com/search?k=tungsten+carbide

[23] https://www.istockphoto.com/de/bot-wall?returnUrl=%2Fde%2Fphotos%2Ftungsten-carbide

[24] https://www.shutterstock.com/search/carbide-tools

[25] https://www.shutterstock.com/search/tungsten-carbide

[26] https://www.istockphoto.com/de/bot-wall?returnUrl=%2Fde%2Fphotos%2Fcarbide-cutter-insert

[27] https://stock.adobe.com/search/images?k=carbide+cutting

[28] https://www.homedepot.com/b/Tools-Power-Tool-Accessories-Saw-Blades-Diamond-Blades/Tungsten-Carbide/N-5yc1vZc5v1Z1z1czwy

[29] https://www.istockphoto.com/de/bot-wall?returnUrl=%2Fde%2Fphotos%2Ftungsten-carbide-drill-bits

[30] https://www.doallsaws.com/406-476158-000

[31] https://www.shutterstock.com/search/%22tungsten-carbide%22?page=3

[32] https://www.technologylk.com/__162/tungsten-carbide-and-diamond-wire-saw-blades.html

[33] https://create.vista.com/photos/tungsten-carbide/

[34] https://bosondia.en.made-in-china.com/product/pdVmzlIjnYhy/China-Diamond-Cutting-Disc-for-Tungsten-Carbide.html

[35] https://www.cnczone.com/forums/cnc-plasma-oxy-fuel-cutting-machines/261594-cnc.html

[36] https://www.cnczone.com/forums/metalwork-discussion/226048-quot-machine-quot-tungsten-carbide.html

[37] https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-Designers_Guide_TungstenCarbide.pdf

[38] https://www.linkedin.com/pulse/7-questions-tungsten-carbide-burrs-shijin-lei

[39] https://www.iforgeiron.com/topic/23670-forging-tungsten-carbide/

[40] https://www.practicalmachinist.com/forum/threads/turning-tungsten.84677/

[41] https://tuncomfg.com/about/faq/

[42] https://www.reddit.com/r/Pottery/comments/18t3wap/tungsten_carbide_trimming_tools_anyone_know_how/

[43] http://www.titaniumkay.com/tungsten-rings/can-you-cut-a-tungsten-carbide-ring/

[44] https://tronex-tools.com/products/carbide-hard-wire-taper-head-cutters-medium-long-ergonomic-handle

[45] https://www.alamy.com/stock-photo/tungsten-carbide-tool.html

[46] https://benchmarkabrasives.com/collections/cutting-tools-tct-blades-for-metal

[47] https://bladesdirect.net/collections/blades-metal-blades/diamond-blade-9

[48] https://www.toptechdiamond.com/all-about-saw-blade/