Content Menu

● Introduction to Cemented Carbide

● Composition and Properties

>> Hardness and Toughness

>> High Temperature Resistance

● Applications of Cemented Carbide Products

>> Machining and Cutting Tools

>> Earth Boring and Mining

>> Wear Parts

● Future Developments and Innovations

>> Advanced Binders

>> Coatings and Surface Treatments

● Challenges and Limitations

>> Environmental Concerns

>> Health Concerns

● Economic Impact

● Case Studies

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary advantage of using cobalt as a binder in cemented carbide?

>> 2. What are the typical applications of cemented carbide products with cobalt binders?

>> 3. How does the cobalt content affect the properties of cemented carbide?

>> 4. What are some potential alternatives to cobalt binders in cemented carbide?

>> 5. What role does temperature resistance play in the application of cemented carbide products?

● Citations:

Cemented carbide products, particularly those with a cobalt binder, have become indispensable in various industrial applications due to their unique combination of hardness, toughness, and wear resistance. These materials are widely used in cutting tools, wear parts, and other components where high durability and performance are crucial. In this article, we will delve into the advantages of cemented carbide products with cobalt binders, exploring their properties, applications, and future developments.

Introduction to Cemented Carbide

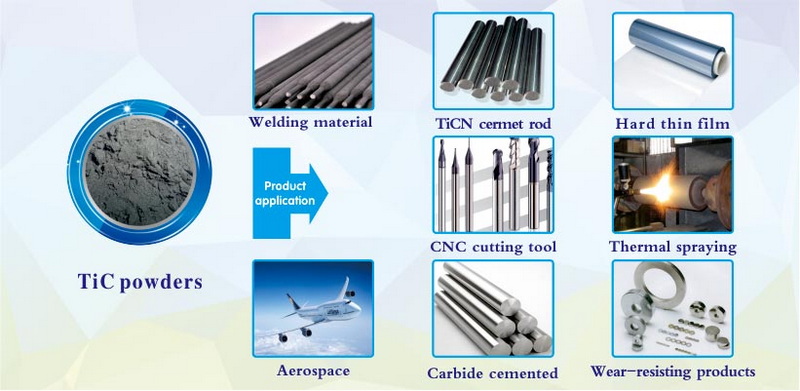

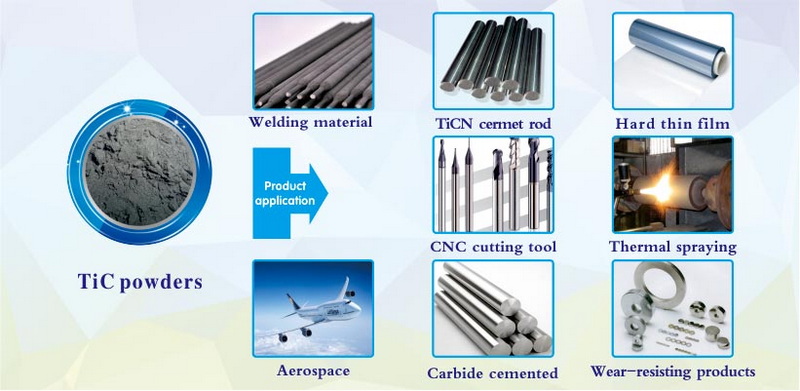

Cemented carbide is a type of powder metallurgy product primarily composed of tungsten carbide (WC) or titanium carbide (TiC) particles bonded together by a metallic phase, most commonly cobalt (Co). The addition of cobalt as a binder enhances the toughness of the material without significantly compromising its hardness, making it suitable for demanding applications such as machining and earth boring.

Composition and Properties

The composition of cemented carbide can vary, but the most common formulation includes tungsten carbide as the hard phase and cobalt as the binder. The cobalt content typically ranges from 3% to 25% by weight, depending on the desired balance of hardness and toughness. Other metals like nickel and chromium can be added to improve corrosion resistance or reduce magnetism.

Hardness and Toughness

Cemented carbide with a cobalt binder offers an excellent balance of hardness and toughness. The tungsten carbide particles provide high hardness, while the cobalt binder enhances the material's ability to absorb impact without cracking. This balance is crucial for applications where tools are subjected to both wear and impact.

High Temperature Resistance

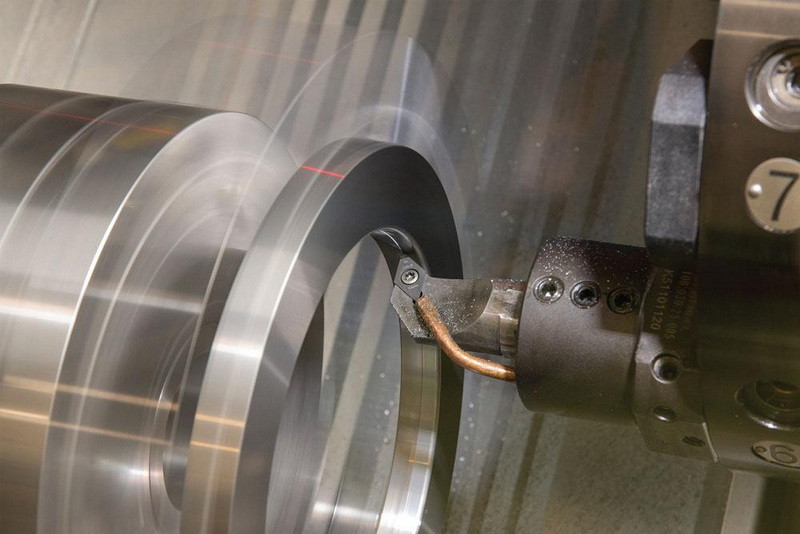

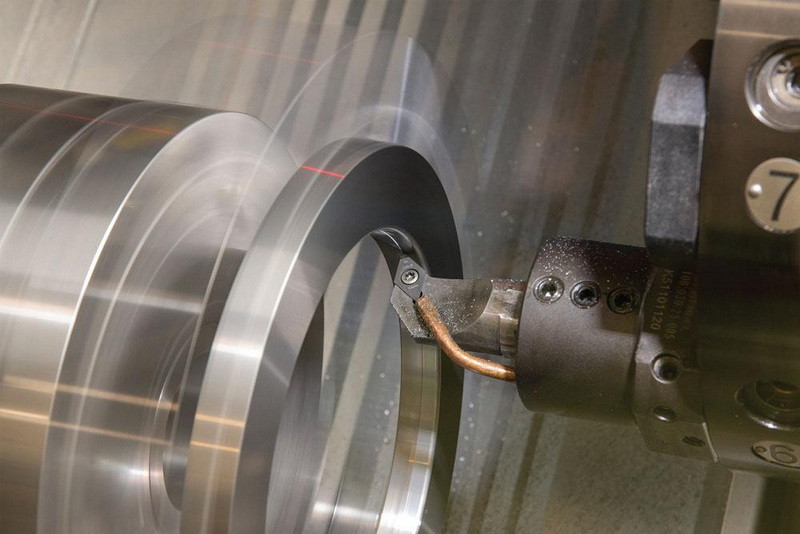

Cemented carbide products exhibit excellent resistance to high temperatures, making them suitable for high-speed cutting operations. The material's chemical stability and oxidation resistance are also enhanced by the presence of cobalt, which helps maintain its properties even under extreme conditions.

Applications of Cemented Carbide Products

Cemented carbide products with cobalt binders are used in a wide range of applications due to their superior mechanical properties.

Machining and Cutting Tools

These materials are extensively used in machining tools, such as drill bits, milling cutters, and turning tools. Their high hardness and wear resistance allow for efficient cutting of metals and alloys, while their toughness prevents tool breakage during operation.

Earth Boring and Mining

In earth boring and mining operations, cemented carbide tools are used for drilling and cutting through hard rock formations. The material's ability to withstand high pressures and temperatures makes it ideal for these applications.

Wear Parts

Cemented carbide is also used in wear parts, such as nozzles and liners, where its high wear resistance extends the lifespan of components exposed to abrasive environments.

Future Developments and Innovations

Researchers are continually exploring ways to enhance the properties of cemented carbide products. This includes the development of new binders, such as high entropy alloys, and the application of advanced coatings to improve wear resistance without compromising toughness.

Advanced Binders

High entropy alloys (HEAs) are being investigated as potential binders due to their unique properties, such as high strength and resistance to corrosion. These alloys can potentially improve the overall performance of cemented carbide by enhancing its mechanical properties and reducing environmental concerns associated with traditional binders.

Coatings and Surface Treatments

Advanced coatings and surface treatments are being developed to further enhance the wear resistance of cemented carbide products. Techniques like physical vapor deposition (PVD) and chemical vapor deposition (CVD) allow for the application of thin, wear-resistant layers that can significantly extend the tool life.

Challenges and Limitations

Despite its advantages, cemented carbide with cobalt binders faces challenges related to environmental and health concerns associated with cobalt. Efforts are being made to develop alternative binders that can maintain or improve the material's properties while reducing these risks.

Environmental Concerns

Cobalt mining has been linked to environmental degradation and health issues in some regions. As a result, there is a growing interest in finding sustainable alternatives to cobalt that can provide similar performance without the environmental drawbacks.

Health Concerns

Exposure to cobalt dust during manufacturing and recycling processes can pose health risks. Developing safer binders or improving manufacturing processes to minimize exposure are key areas of focus for the industry.

Economic Impact

The use of cemented carbide products with cobalt binders has a significant economic impact on industries that rely on these materials. By improving tool life and reducing downtime, companies can increase productivity and reduce costs associated with tool replacement and maintenance.

Case Studies

Several industries have seen substantial benefits from the use of cemented carbide products:

1. Automotive Industry: The use of cemented carbide cutting tools in the automotive sector has improved manufacturing efficiency by extending tool life and reducing production costs.

2. Aerospace Industry: High-performance cutting tools made from cemented carbide are crucial for machining complex aerospace components, where precision and durability are paramount.

3. Mining Sector: Cemented carbide drill bits have significantly increased drilling efficiency in mining operations, allowing for faster extraction of minerals and reduced operational costs.

Conclusion

Cemented carbide products with cobalt binders offer a unique combination of hardness, toughness, and wear resistance, making them indispensable in various industrial applications. Their versatility, high performance, and durability ensure their continued use in machining, earth boring, and wear parts. As research progresses, we can expect further innovations that address current challenges and expand the capabilities of these materials.

Frequently Asked Questions

1. What is the primary advantage of using cobalt as a binder in cemented carbide?

The primary advantage of using cobalt as a binder is that it enhances the toughness of the material without significantly reducing its hardness, making it suitable for applications where both wear resistance and impact resistance are required.

2. What are the typical applications of cemented carbide products with cobalt binders?

Cemented carbide products with cobalt binders are commonly used in machining tools, earth boring and mining operations, and wear parts due to their high hardness and toughness.

3. How does the cobalt content affect the properties of cemented carbide?

Increasing the cobalt content in cemented carbide enhances its toughness but reduces its hardness. The optimal cobalt content depends on the specific application requirements.

4. What are some potential alternatives to cobalt binders in cemented carbide?

Researchers are exploring alternatives such as high entropy alloys and nanoceramics to address environmental and health concerns associated with cobalt while maintaining or improving the material's properties.

5. What role does temperature resistance play in the application of cemented carbide products?

Temperature resistance is crucial for high-speed cutting operations, where cemented carbide products maintain their properties even under extreme heat conditions, ensuring efficient and durable performance.

Citations:

[1] https://www.sundicuttingtools.com/news/technology-articles/cemented-carbide-cutting-tool-material-basics-summary/

[2] https://patents.google.com/patent/US20170057878A1/en

[3] https://pmc.ncbi.nlm.nih.gov/articles/PMC9415848/

[4] https://www.aemmetal.com/cemented_carbide.html

[5] https://www.mdpi.com/2075-4701/13/1/171

[6] https://patents.google.com/patent/WO2017148885A1/en

[7] https://www.carbide-products.com/es/blog/cemented-carbide-product-with-cobalt-binder/

[8] https://ceramics.org/ceramic-tech-today/researchers-investigate-feasibility-of-nanoceramics-as-binder-in-cemented-carbide-tools/