Content Menu

● The Role of Graphite in Cemented Carbide Manufacturing

● Types of Graphite Products Used in Cemented Carbide Production

>> 1. Graphite Sintering Boats

>> 2. Graphite Molds and Dies

>> 3. Graphite Crucibles

>> 4. Graphite Heating Elements

● Manufacturing Process of Cemented Carbide Using Graphite Products

● Advantages of Graphite Products in Carbide Production

● Challenges and Solutions

● Applications of Cemented Carbide Products

● Conclusion

● FAQ

>> 1. Why is graphite preferred over metals in carbide sintering?

>> 2. What types of graphite are used for sintering molds?

>> 3. How do graphite molds handle rapid temperature changes?

>> 4. What limits the lifespan of graphite sintering boats?

>> 5. Are graphite products recyclable after use?

● Citations:

Cemented carbide, a composite material renowned for its exceptional hardness, wear resistance, and durability, is widely used in industrial, military, metallurgical, and mining applications. At the heart of its production lies a critical component: graphite products. These specialized tools enable the high-temperature sintering, shaping, and precision manufacturing required to produce high-performance carbide components. This article explores the types, roles, and advantages of graphite products in cemented carbide production, supported by technical insights and industry applications.

The Role of Graphite in Cemented Carbide Manufacturing

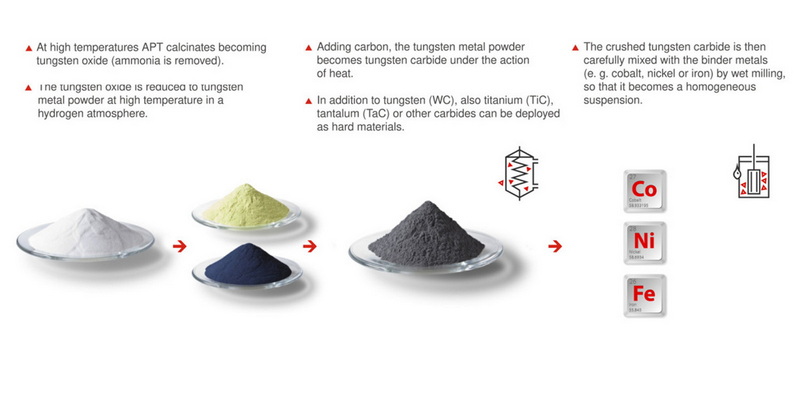

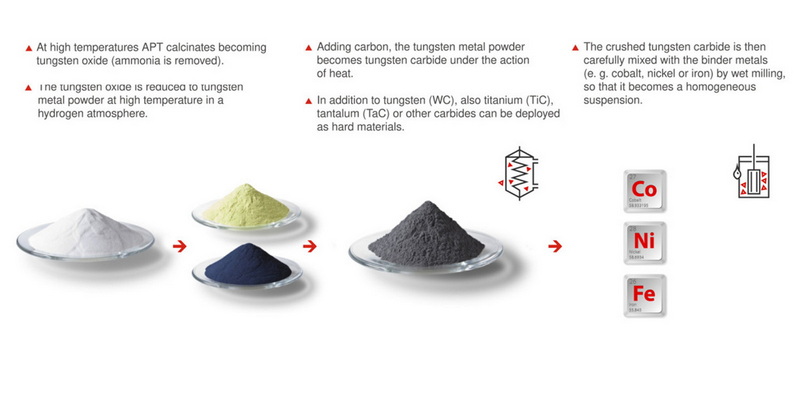

Cemented carbide production involves sintering a mixture of tungsten carbide powder and cobalt binder at temperatures exceeding 1,400°C. Graphite's unique properties make it indispensable for this process:

- High Thermal Conductivity: Ensures uniform heat distribution during sintering[6][10].

- Low Thermal Expansion: Maintains dimensional stability under extreme temperatures[5][11].

- Chemical Inertness: Resists reactions with molten metals or corrosive environments[1][6].

- Self-Lubrication: Reduces friction during demolding[9][11].

These characteristics allow graphite products to withstand the harsh conditions of carbide manufacturing while ensuring precision and repeatability.

Types of Graphite Products Used in Cemented Carbide Production

1. Graphite Sintering Boats

Graphite sintering boats are trays or containers that hold carbide powder during sintering. They are designed to:

- Withstand temperatures up to 2,000°C[5][13].

- Facilitate uniform heating and cooling to prevent warping[10][12].

- Enable batch processing of complex geometries[9].

Applications: Pressure sintering of tungsten carbide drills, cutting tools, and military armor components[10][13].

2. Graphite Molds and Dies

Graphite molds are used to form carbide powders into near-net shapes before sintering. Key features include:

- Precision machining (±0.05 mm tolerance)[6][11].

- High mechanical strength to withstand pressing forces up to 50 MPa[5][9].

- Reusability for 30–40 cycles before replacement[11][13].

Applications: Manufacturing of carbide inserts, drill bits, and wear-resistant components[6][12].

3. Graphite Crucibles

Graphite crucibles melt and mix cobalt binders with tungsten carbide powder. Advantages include:

- Resistance to thermal shock during rapid temperature changes[6][13].

- Non-contamination of molten metals[3][6].

- Long service life in vacuum or inert atmospheres[4][7].

Applications: Homogenizing binder mixtures for cemented carbide alloys[8][12].

4. Graphite Heating Elements

Graphite rods, tubes, and plates serve as heating elements in sintering furnaces. They provide:

- Rapid heating rates (up to 1,500°C/hour)[4][10].

- Consistent thermal output over thousands of cycles[7][13].

- Compatibility with vacuum and atmospheric furnaces[4][7].

Applications: Industrial-scale sintering of carbide tools and aerospace components[4][10].

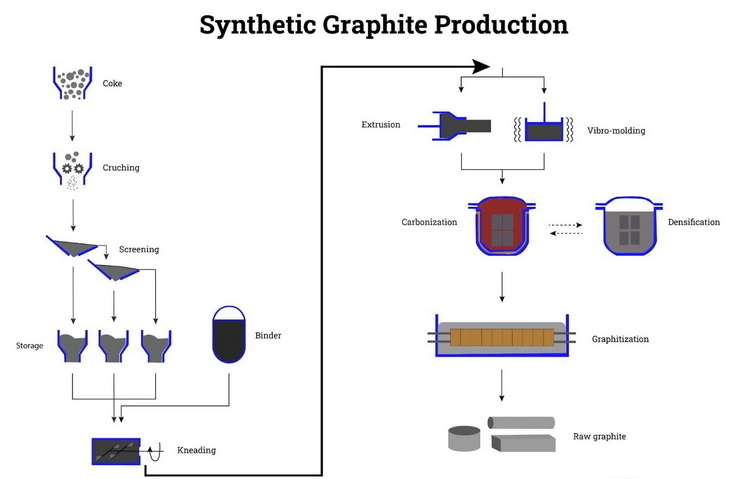

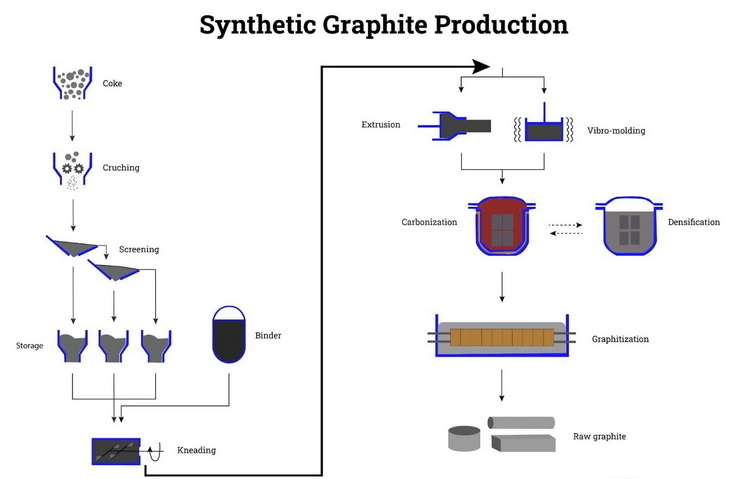

Manufacturing Process of Cemented Carbide Using Graphite Products

| Stage | Graphite Product Used | Function |

| Powder Preparation | Graphite Mixing Containers | Blend tungsten carbide and cobalt powders without contamination. |

| Pressing | Graphite Dies | Shape powder into green compacts under high pressure. |

| Sintering | Graphite Sintering Boats/Molds | Heat compacts to 1,400–1,500°C to form dense carbide. |

| Cooling | Graphite Trays | Ensure gradual cooling to prevent cracking. |

| Finishing | Graphite Grinding Tools | Polish sintered components to micron-level accuracy. |

Advantages of Graphite Products in Carbide Production

1. Thermal Stability

Graphite retains structural integrity at extreme temperatures, reducing mold deformation[6][11].

2. Cost Efficiency

Reusable molds and boats lower per-unit production costs compared to metal tools[9][13].

3. Precision

CNC-machined graphite molds achieve tolerances as tight as ±0.05 mm[6][11].

4. Versatility

Suitable for producing complex geometries, including internal cooling channels in cutting tools[5][9].

Challenges and Solutions

| Challenge | Solution |

| Oxidation at high temperatures | Use anti-oxidation coatings or inert atmospheres. |

| Machining complexity | Employ ultra-fine graphite grades (particle size <15 μm) for detailed molds. |

| Wear over cycles | Regular inspection and replacement after 30–40 uses. |

Applications of Cemented Carbide Products

- Industrial Tools: Cutting inserts, end mills, and lathe tools[8][12].

- Military Equipment: Armor-piercing projectiles and ceramic armor plates[10][13].

- Oil Drilling: Drill bits for deep-well exploration[9][12].

- Construction: Tunneling machinery components and wear plates[9][11].

Conclusion

Graphite products are the backbone of cemented carbide manufacturing, enabling high-precision, high-temperature processes that define the material's exceptional properties. From sintering boats to advanced CFRG molds, these tools ensure efficiency, durability, and cost-effectiveness across industries. As material science advances—such as silicon-impregnated grades and AI-driven mold optimization—graphite will continue to drive innovations in carbide technology, meeting demands from deep-earth drilling to space exploration.

FAQ

1. Why is graphite preferred over metals in carbide sintering?

Graphite outperforms metals due to its higher thermal stability, lower thermal expansion, and resistance to chemical reactions with molten binders[6][10][11].

2. What types of graphite are used for sintering molds?

Iso-molded graphite grades with fine particle sizes (<15 μm) are preferred for their mechanical strength and dimensional stability[10][13].

3. How do graphite molds handle rapid temperature changes?

Graphite's low thermal expansion coefficient minimizes stress fractures during heating/cooling cycles[5][11].

4. What limits the lifespan of graphite sintering boats?

Oxidation and mechanical wear after 30–40 cycles necessitate replacement, though coatings can extend longevity[9][13].

5. Are graphite products recyclable after use?

Yes, spent graphite tools can be crushed and reused in lower-grade applications or reprocessed[13].

Citations:

[1] https://www.alpapowder.com/115840/

[2] https://patents.google.com/patent/US5707567A/en

[3] https://www.whgraphitesupplier.com/graphite-electrodes-uses.html

[4] https://www.sglcarbon.com/en/markets-solutions/applications/high-temperature-furnaces/

[5] https://www.karssenmetal.com/Graphite-Sintering-Boat-p.html

[6] https://www.cdocast.com/graphite-mould/

[7] https://www.toyotanso.com/Products/catalog.en.full.pdf

[8] https://www.betalentcarbide.com/production-process-of-cemented-carbide-blade.html

[9] https://esgraf.com.mx/en/blog/graphite-molds-for-metal-sintering/

[10] https://www.mersen.com/en/products/isostatic-graphite-and-extruded-graphite/graphite-sintering

[11] https://www.thermalgraphite.com/news/technologynews/335.html

[12] https://www.zgcccarbide.com/news/The-Manufacturing-Process-of-Cemented-Carbide-Inserts:-A-Comprehensive-Guide-39.html

[13] https://www.jpgraphites.com/graphite-sintering-crucible-mould-for-power-metallurgy-and-hard-alloy.html

[14] https://www.nhdcarbon.com/Graphite-Products-For-Cemented-Carbide-pl40654147.html

[15] https://www.sciencedirect.com/science/article/pii/S026343681830533X

[16] https://ningheda.en.made-in-china.com/product/UFNakHycArhp/China-Hip-ED-Graphite-Sinter-Tray-for-Cemented-Carbide.html

[17] https://ningheda.en.made-in-china.com/product/kwptIrhUOPcA/China-Graphite-Box-for-Cemented-Carbide-Industry-From-Ningheda.html

[18] https://www.ceratizit.com/int/en/sustainability/blog/2021/blogposting-cemented-carbide.html

[19] https://www.sciencedirect.com/science/article/abs/pii/S0925838825018729

[20] https://www.saar-hartmetall.de/en/products/cemented-carbide/process/

[21] https://www.iqsdirectory.com/articles/graphite-machining.html

[22] https://www.samaterials.com/cemented-carbide-rod.html

[23] https://patents.google.com/patent/US20160122250A1/en

[24] http://en.ykdsts.com/news/219.html

[25] https://www.ceratizit.com/int/en/company/passion-for-cemented-carbide-/production.html

[26] https://ningheda.en.made-in-china.com/product/dsoJXVIELWce/China-Graphite-Plate-for-Cemented-Carbide-Sintering.html

[27] https://www.nhdgraphite.com/fixed-competitive-price-graphite-box-for-cemented-carbide-special-design-for-china-high-quality-clay-graphite-crucible-for-heating-induction-furnace-graphite-crucibles-for-aluminium-with-good-heat-product/

[28] https://www.toyotanso.com/Products/catalog.en.full.pdf

[29] https://www.ipsceramics.com/graphite-products/

[30] https://www.sciencedirect.com/science/article/pii/S2238785423027643

[31] https://ningheda.en.made-in-china.com/product/kdcalumUOIVG/China-Graphite-Groove-Plate-for-Cemented-Carbide-Tungsten-Carbide-Sintered-Graphite-Plate.html

[32] https://www.sumitool.com/en/downloads/assets/mt-catalog/carbide_blanks.pdf

[33] https://www.s-s-alloy.com/en/product/mold.html

[34] https://www.sciencedirect.com/science/article/abs/pii/S0032591099002107

[35] https://www.sciencedirect.com/science/article/abs/pii/S1526612518306303

[36] https://www.made-in-china.com/products-search/hot-china-products/Graphite_Sintering_Mould_Graphite.html

[37] https://hangcarbon.en.made-in-china.com/product/eAFpHirzYGcW/China-Hot-Pressed-Sps-Graphite-Mold.html

[38] https://www.sanalloy.co.jp/en/q_a/

[39] https://www.rydmetcarbide.com/faq/

[40] https://www.linkedin.com/pulse/25-frequently-asked-questions-field-mold-plastic-mould-ivy-cao-

[41] https://www.zgcccarbide.com/news/The-Manufacturing-Process-of-Cemented-Carbide-Inserts:-A-Comprehensive-Guide-39.html

[42] https://ask.okorder.com/graphite-mold/ql119013003.html

[43] https://www.mmc-carbide.com/us/technical_information/tec_guide/tec_guide_safely

[44] https://www.betalentcarbide.com/production-process-of-cemented-carbide-blade.html

[45] https://www.sciencedirect.com/science/article/abs/pii/S0925838823041269

[46] https://www.whgraphitesupplier.com/graphite-electrodes-uses.html

[47] https://www.reddit.com/r/CNC/comments/18vrjwo/graphite_mold_dill_bits/

[48] https://www.linkedin.com/pulse/advantages-using-graphite-molds-copper-alloy-casting-process-%E5%AD%A6%E6%9D%91-%E8%8C%83

[49] https://www.fujidie.co.jp/assets/pdf/en/products/materials/E050-07-16_FUJILLOY_EN_201611.pdf

[50] https://patents.google.com/patent/US5993970A/en

[51] https://www.karssenmetal.com/Graphite-mold-p.html

[52] https://www.allied-material.co.jp/en/techinfo/hard-metal/features.html

[53] https://www.aemmetal.com/cemented_carbide.html

[54] https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-Designers_Guide_TungstenCarbide.pdf