Content Menu

● Hardness vs. Strength: A Technical Breakdown

● Applications: Industry-Specific Dominance

>> Diamond

>> Tungsten Carbide

● Cost, Ethics, and Sustainability

● Performance in Extreme Conditions

>> Thermal Stability

>> Chemical Resistance

● Specialized Tool Comparison: Dental Burs

● Innovation in Supermaterials

● Conclusion

● FAQ

>> 1. Can tungsten carbide drill through diamond?

>> 2. Which material is better for high-speed machining?

>> 3. Are there eco-friendly alternatives to cobalt-bound carbide?

>> 4. Why is synthetic diamond gaining traction in manufacturing?

>> 5. Can carbide jewelry be engraved?

● Citations:

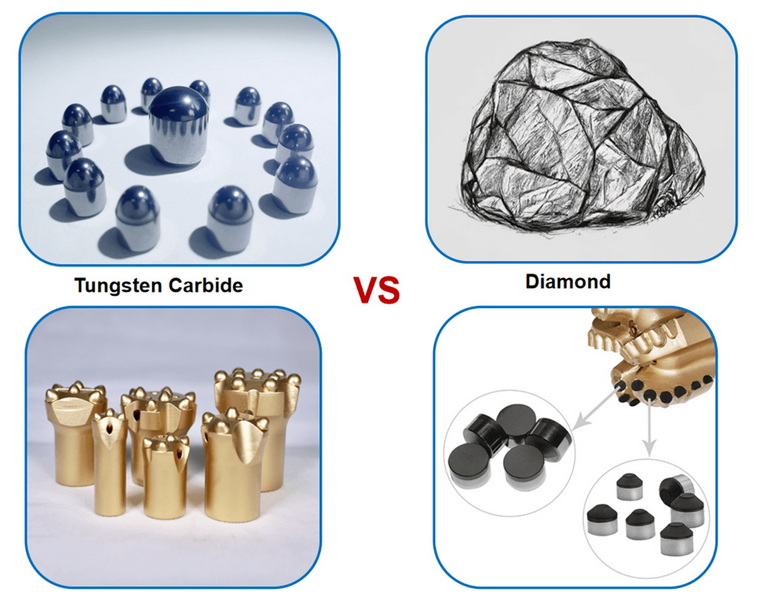

Tungsten carbide and diamond represent pinnacles of material science, each dominating specific domains of industrial and commercial applications. While diamond remains the hardest natural substance (Mohs 10), tungsten carbide (Mohs 9–9.5) excels in fracture toughness and practical durability. This article explores their properties, applications, cost dynamics, and industry-specific advantages, supported by technical comparisons and real-world use cases.

Hardness vs. Strength: A Technical Breakdown

- Diamond: A tetrahedral carbon lattice grants unparalleled scratch resistance (10 on Mohs scale), making it irreplaceable for precision cutting of ultra-hard materials like gemstones and ceramics[1][4].

- Tungsten Carbide: Composed of tungsten and carbon atoms in a hexagonal structure, it achieves a Mohs hardness of 9–9.5 and a Vickers hardness of 1,500–1,800 Hv[2][10]. Though softer than diamond, it resists deformation under extreme pressure.

- Fracture Toughness: Tungsten carbide (12 MPa·m⊃1;/⊃2;) surpasses diamond (5.5 MPa·m⊃1;/⊃2;), enabling it to withstand impact without shattering[4][13].

- Tensile Strength: At 750 MPa, carbide outperforms diamond (350 MPa) in load-bearing applications like industrial tooling[1][10].

Applications: Industry-Specific Dominance

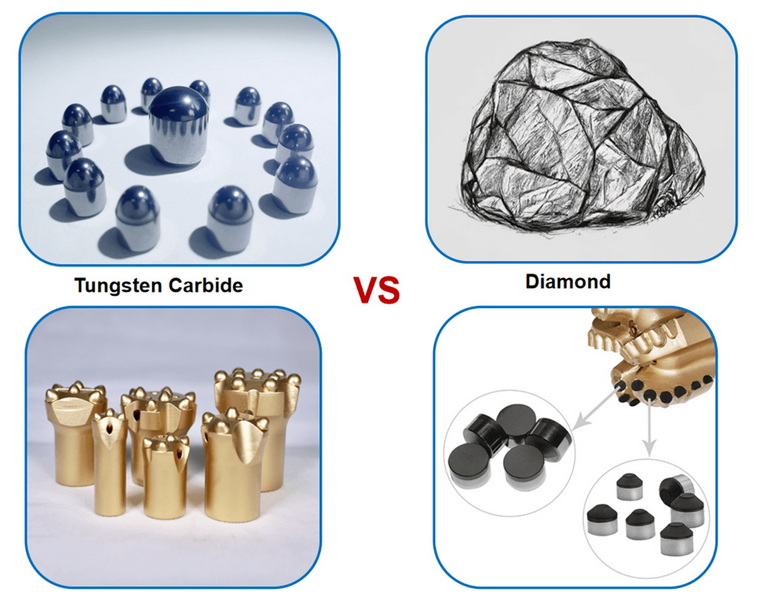

Diamond

1. Precision Cutting & Grinding

- Diamond-tipped blades cut glass, ceramics, and composite materials with micron-level accuracy[2][14].

- Polycrystalline diamond (PCD) drill bits dominate aerospace composite drilling, reducing delamination by 30% compared to carbide[2][6].

2. High-Performance Electronics

- Synthetic diamond heat sinks dissipate 2,200 W/m·K of thermal energy, critical for semiconductor and laser systems[6][16].

3. Luxury Jewelry

- Natural diamonds remain unmatched for brilliance and scratch resistance in engagement rings and watches[1][8].

Tungsten Carbide

1. Industrial Machinery

- Milling & Drilling: Carbide end mills grind metals, plastics, and wood at 3x the speed of steel tools, with 25x longer tool life than diamond-coated alternatives in non-abrasive materials[3][15].

- Construction: Carbide-tipped demolition blades cut reinforced concrete and asphalt without warping[8][9].

2. Medical & Dental Tools

- Carbide surgical burs remove bone and tissue efficiently, while dental burs prepare cavities 50% faster than diamond variants[5][8].

- Prosthetics: Carbide joints endure 10+ years of daily wear due to corrosion resistance[10][15].

3. Consumer Goods

- Jewelry: Polished tungsten rings retain their luster for decades, costing 90% less than diamond equivalents[1][8].

- Sporting Equipment: Trekking pole tips and fishing weights leverage carbide's density and abrasion resistance[3][8].

Cost, Ethics, and Sustainability

| Feature | Diamond Burs | Tungsten Carbide Burs |

| Hardness | 10 (Mohs) | 9.5 (Mohs) |

| Cutting Speed | Slower, precision-focused | 2x faster material removal |

| Lifespan | 50–100 uses | 200–300 uses |

| Cost | $5–$20 per bur | $15–$50 per bur |

- Diamond: Lab-grown alternatives reduce environmental harm but require high energy input (1,500°C and 55,000 atmospheres for HPHT synthesis)[6][13].

- Tungsten Carbide: Cobalt binders raise ethical concerns, but nickel-bound alternatives offer eco-friendly solutions[10][13].

Performance in Extreme Conditions

Thermal Stability

- Diamond: Degrades above 700°C in oxygen, limiting use in high-heat machining[6][13].

- Tungsten Carbide: Retains integrity up to 1,200°C, ideal for aerospace turbine coatings[10][16].

Chemical Resistance

- Carbide resists acids, alkalis, and saltwater corrosion, outperforming diamond in marine drilling[10][14].

- Diamond's inertness makes it ideal for chemical vapor deposition (CVD) processes[6][16].

Specialized Tool Comparison: Dental Burs

| Feature | Diamond Burs | Tungsten Carbide Burs |

| Hardness | 10 (Mohs) | 9.5 (Mohs) |

| Cutting Speed | Slower, precision-focused | 2x faster material removal |

| Lifespan | 50–100 uses | 200–300 uses |

| Cost | $5–$20 per bur | $15–$50 per bur |

- Diamond: Ideal for enamel shaping and delicate procedures[5].

- Carbide: Preferred for root canals and metal crown adjustments[5][8].

Innovation in Supermaterials

1. Synthetic Diamond Composites

- Companies like Element Six combine diamond's hardness with carbide's toughness for drill bits that last 30% longer in granite mining[6][14].

2. Nano-Coated Carbide Tools

- CVD diamond coatings on carbide substrates reduce friction by 40%, enhancing lifespan in aluminum machining[6][16].

Conclusion

While diamond remains the hardest material, tungsten carbide's balanced strength, thermal resilience, and cost efficiency make it the stronger choice for most industrial applications. Innovations in hybrid materials continue to blur their roles, but the decision ultimately hinges on specific needs:

- Choose diamond for precision, luxury, or ultra-hard material processing.

- Opt for carbide for heavy-duty machinery, medical tools, and budget-conscious projects.

FAQ

1. Can tungsten carbide drill through diamond?

No. Diamond's hardness prevents carbide from scratching or cutting it, though diamond-coated carbide tools exist for specialized tasks[2][14].

2. Which material is better for high-speed machining?

Tungsten carbide handles high RPMs better due to its thermal stability, while diamond tools require coolant to prevent overheating[6][13].

3. Are there eco-friendly alternatives to cobalt-bound carbide?

Yes. Nickel and iron binders reduce reliance on conflict minerals, maintaining 90% of traditional carbide's performance[10][13].

4. Why is synthetic diamond gaining traction in manufacturing?

Lab-grown diamonds offer identical properties to natural ones at 30% lower cost, with ethical production benefits[6][16].

5. Can carbide jewelry be engraved?

Yes. Laser engraving works best, as carbide's hardness resists traditional mechanical engraving[8][10].

Citations:

[1] https://www.tungstenringsco.com/blog/2023/06/tungsten-vs-diamond/

[2] https://telconpcd.com/pcd-vs-carbide-who-has-better-tool-value/

[3] https://www.carbide-usa.com/top-5-uses-for-tungsten-carbide/

[4] https://www.carbide-part.com/blog/tungsten-carbide-hardness-vs-diamond/

[5] https://www.burdental.com/blog/comparison-of-dental-diamond-burs-and-tungsten-carbide-burs

[6] https://www.azom.com/article.aspx?ArticleID=18664

[7] https://letsemabd.co.za/Pages/Tungsten-vs-Diamond.asp

[8] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[9] https://triaticinc.com/blog/the-difference-between-diamond-core-bits-carbide/

[10] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[11] https://www.drillbitwarehouse.com/the-difference-between-carbide-and-diamond-burrs/

[12] https://www.reddit.com/r/metalworking/comments/cmjweu/can_tungsten_carbide_or_diamond_grit_cutting/

[13] https://www.carbide-products.com/blog/tungsten-carbide-hardness-vs-diamond/

[14] https://www.corediamtools.com/diamond-tools/diamond-core-bits-vs-carbide.html

[15] https://www.azom.com/article.aspx?ArticleID=1203

[16] https://www.johncrane.com/en/resources/blog/2022/john-crane-diamond-improves-operational-performance-on-tungsten-carbide-substrate

[17] https://www.cnczone.com/forums/metalwork-discussion/226048-quot-machine-quot-tungsten-carbide.html

[18] https://gdptooling.com/diamond-v-carbide-comparing-the-costs/

[19] https://www.reddit.com/r/Tools/comments/18yb0p4/whats_the_best_way_to_cut_into_granite_diamond_or/