Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide

● Applications of Tungsten Carbide

● Advantages of Tungsten Carbide

● Challenges and Limitations

● Environmental Impact

● Future Developments

● Innovations in Tungsten Carbide Production

● Market Trends

● Case Studies

● Conclusion

● Frequently Asked Questions

>> 1. What is Tungsten Carbide?

>> 2. How is Tungsten Carbide Manufactured?

>> 3. What are the Primary Applications of Tungsten Carbide?

>> 4. Can Tungsten Carbide Tools be Sharpened?

>> 5. Is Tungsten Carbide Recyclable?

● Citations:

Tungsten carbide, often simply referred to as "carbide," is a compound made from tungsten and carbon atoms. It is renowned for its exceptional hardness, wear resistance, and durability, making it an ideal material for various industrial applications. In this article, we will delve into the characteristics, advantages, and applications of tungsten carbide to assess whether it is indeed a "good metal" for different uses.

Introduction to Tungsten Carbide

Tungsten carbide is a chemical compound with the formula WC, consisting of equal parts of tungsten and carbon atoms. It is typically produced through a powder metallurgy process, where tungsten carbide powder is mixed with a metallic binder, such as cobalt, and then sintered at high temperatures to form a solid, hard composite.

Properties of Tungsten Carbide

- Hardness: Tungsten carbide is extremely hard, with a hardness rating of up to 90 HRA, second only to diamond. This makes it ideal for cutting and grinding operations.

- Wear Resistance: It excels in processing hard materials like stainless steel and cast iron, providing long tool life and reducing the need for frequent replacements.

- Corrosion Resistance: Tungsten carbide remains stable in acidic, alkaline, and other corrosive environments, making it suitable for the chemical and petroleum industries.

- Thermal Stability: It maintains high hardness and rigidity even at high temperatures (up to 900 to 1000°C), making it ideal for high-temperature operations.

Applications of Tungsten Carbide

Tungsten carbide is widely used across various industries due to its unique properties:

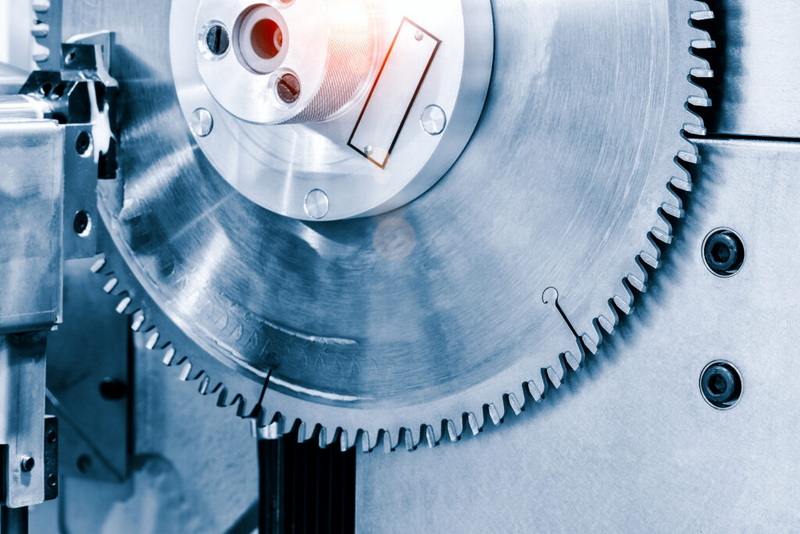

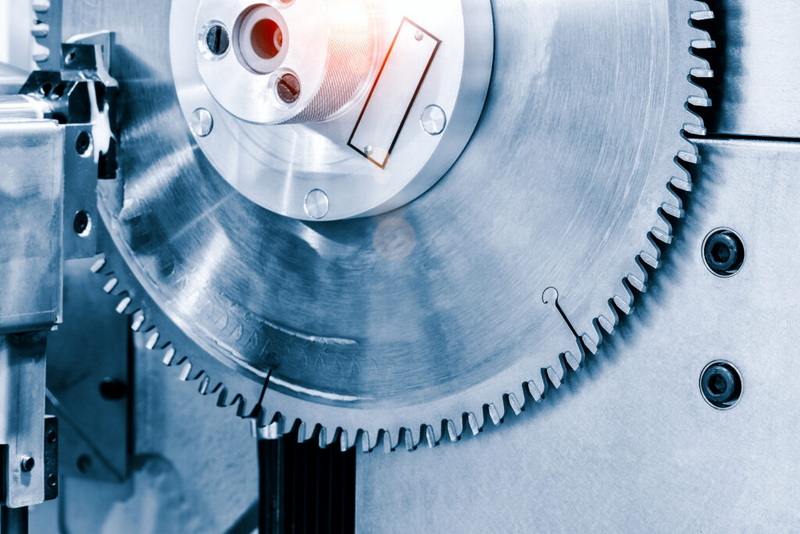

- Mechanical Processing: In the metal processing industry, tungsten carbide tools such as turning tools, milling cutters, and planing tools are preferred for their high hardness and wear resistance. These tools enable faster machining speeds and higher precision, crucial for high-speed machining applications.

- Mining and Metallurgy: Tungsten carbide drilling and mining tools are valued for their durability in harsh environments. They are used in extracting minerals and metals from the earth, where the tools must withstand abrasive and high-pressure conditions.

- Electronics and Telecommunications: Its high melting point and electrical conductivity make it suitable for precision electronic components and semiconductor devices. Tungsten carbide is used in the production of high-performance electronic components that require stability under extreme conditions.

- Construction Industry: Tungsten carbide is used to reinforce structures and manufacture explosion-proof doors, enhancing building safety and durability. Its hardness and wear resistance also make it useful in construction tools, such as drill bits and saw blades.

- Aerospace: It is used in aerospace engine components and spacecraft structural parts due to its stable performance under extreme conditions. Tungsten carbide components can withstand the high temperatures and stresses encountered during flight.

Advantages of Tungsten Carbide

The advantages of using tungsten carbide include:

- Extended Tool Life: Its superior hardness and wear resistance prevent rapid tool degradation, reducing the need for frequent replacements. This leads to cost savings over time, despite the initial higher cost of tungsten carbide tools.

- High-Speed Machining: Tungsten carbide allows for faster cutting speeds and higher precision, crucial for high-speed machining applications. This efficiency improves productivity and reduces production time.

- Corrosion Resistance: It remains stable in corrosive environments, providing reliable solutions for the chemical and petroleum industries. This property ensures that equipment lasts longer and requires less maintenance.

- Thermal Stability: Maintains high hardness at high temperatures, making it ideal for high-temperature operations. This stability is essential in applications where tools are exposed to extreme heat.

Challenges and Limitations

Despite its advantages, tungsten carbide also has some challenges:

- Cost: Tungsten carbide tools are generally more expensive than those made from other materials. This higher upfront cost can be a barrier for some businesses, especially small-scale operations.

- Machinability: While advancements have improved its machinability, it still requires specialized equipment and techniques for shaping and sharpening. This can add complexity and cost to the manufacturing process.

Environmental Impact

Tungsten carbide is generally considered environmentally friendly due to its recyclability and long lifespan, which reduces waste and the need for frequent replacements. However, the extraction of tungsten can have environmental impacts, such as deforestation and water pollution in some mining areas. Efforts are being made to improve mining practices and ensure more sustainable tungsten sourcing.

Future Developments

Research into improving the properties of tungsten carbide continues, focusing on enhancing its toughness and reducing production costs. New manufacturing techniques, such as 3D printing, are being explored to create complex shapes and structures that were previously difficult or impossible to produce. Additionally, there is a growing interest in developing sustainable tungsten carbide products by using recycled materials and reducing waste in the production process.

Innovations in Tungsten Carbide Production

Advancements in technology have led to more efficient production methods, allowing for the creation of complex geometries and customized tools. This flexibility is crucial for meeting the diverse needs of various industries. Furthermore, the integration of tungsten carbide with other materials to form composites is being explored to enhance its properties further.

Market Trends

The demand for tungsten carbide is expected to grow as industries seek more durable and efficient materials. The aerospace and defense sectors are particularly driving this demand due to their need for high-performance components. Additionally, the increasing focus on sustainability is pushing manufacturers to develop more environmentally friendly production processes.

Case Studies

Several companies have successfully integrated tungsten carbide into their operations, achieving significant improvements in tool life and productivity. For instance, a leading aerospace manufacturer reported a 30% reduction in tool replacement costs after switching to tungsten carbide tools. Similarly, a mining company extended the lifespan of its drilling equipment by using tungsten carbide components, resulting in substantial cost savings.

Conclusion

Tungsten carbide is indeed a "good metal" due to its exceptional hardness, wear resistance, and thermal stability, making it indispensable in various high-performance applications across different industries. Its ability to maintain sharpness under high-stress conditions and its long tool life justify its widespread use despite being more expensive than other materials. As technology advances, we can expect to see further improvements in its properties and applications.

Frequently Asked Questions

1. What is Tungsten Carbide?

Tungsten carbide is a hard, dense compound made from tungsten and carbon atoms, renowned for its exceptional hardness, wear resistance, and durability.

2. How is Tungsten Carbide Manufactured?

Tungsten carbide is typically produced through a powder metallurgy process, involving mixing tungsten carbide powder with a binder metal, compacting, and then sintering at high temperatures.

3. What are the Primary Applications of Tungsten Carbide?

Tungsten carbide is widely used in mechanical processing, mining, electronics, construction, and aerospace industries due to its unique properties.

4. Can Tungsten Carbide Tools be Sharpened?

Yes, tungsten carbide tools can be sharpened, but it requires specialized equipment and techniques due to their hardness.

5. Is Tungsten Carbide Recyclable?

Yes, tungsten carbide can be recycled. Worn-out tools and scrap material can be reclaimed and reused, reducing waste and conserving resources.

Citations:

[1] https://www.carbide-part.com/blog/tungsten-carbide-materials-characteristics-advantages-and-comprehensive-applications-analysis/

[2] https://en.wikipedia.org/wiki/Tungsten_carbide

[3] https://www.carbide-part.com/blog/tungsten-carbide-diverse-advantages-of-a-high-performance-material/

[4] https://www.istockphoto.com/photos/tungsten-carbide

[5] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[6] https://www.asbindustries.com/coating-materials/carbide-coating-materials/tungsten-carbide-coatings

[7] https://www.reddit.com/r/jewelers/comments/1gns2b1/is_tungsten_a_good_metal_for_wedding_rings/

[8] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[9] https://www.aemmetal.com/news/tungsten-vs-tungsten-carbide-guide.html

[10] https://www.freepik.com/free-photos-vectors/tungsten

[11] https://create.vista.com/photos/tungsten-carbide/

[12] https://www.shutterstock.com/search/tungsten-carbide

[13] https://www.gettyimages.hk/%E5%9C%96%E7%89%87/tungsten-carbide?page=3

[14] https://www.carbide-products.com/blog/tungsten-carbide-and-hss/

[15] https://www.tungstenrepublic.com/Tungsten-Carbide-Rings-FAQ.html

[16] https://www.tungco.com/insights/blog/frequently-asked-questions-used-tungsten-carbide-inserts/

[17] https://testbook.com/question-answer/identify-the-hardest-metal--5c2505b3f78a043402418c88

[18] https://unbreakableman.co.za/pages/all-about-tungsten-carbide-faq

[19] https://www.linkedin.com/pulse/what-advantages-tungsten-carbide-tooling-zzbettercarbide

[20] https://patrickadairdesigns.com/blogs/blog/the-pros-and-cons-of-tungsten-rings

[21] https://shop.machinemfg.com/the-pros-and-cons-of-tungsten-carbide-a-comprehensive-guide/

[22] https://grafhartmetall.com/en/the-advantages-of-tungsten-carbide-over-traditional-tools/

[23] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[24] https://www.alamy.com/stock-photo/tungsten-carbide.html

[25] https://periodictable.com/Elements/074/pictures.html

[26] https://www.alamy.com/stock-photo/tungsten-carbide-tool.html

[27] https://www.freepik.com/free-photos-vectors/tungsten-carbide

[28] http://picture.chinatungsten.com/list-18.html

[29] http://hardmetal-engineering.blogspot.com/2011/

[30] https://shop.machinemfg.com/tungsten-vs-tungsten-carbide-key-differences/

[31] https://tuncomfg.com/about/faq/

[32] https://www.thermalspray.com/questions-tungsten-carbide/