Content Menu

● Introduction to Tungsten Carbide

>> Tungsten Carbide Applications

● Testing Methods for Tungsten Carbide

>> Hardness Testing

>> Composition Testing

>> Performance Testing

● Standards and Specifications

● Advanced Testing Techniques

● Challenges in Testing Tungsten Carbide

● Future Developments

>> Emerging Trends in Tungsten Carbide Technology

● Economic and Environmental Considerations

● Conclusion

● FAQ

>> 1. What is the typical hardness range of tungsten carbide?

>> 2. How is the composition of tungsten carbide analyzed?

>> 3. What are the common applications of tungsten carbide?

>> 4. What is the purpose of wear resistance testing for tungsten carbide coatings?

>> 5. What standards are typically followed for testing tungsten carbide rods?

● Citations:

Tungsten carbide, known for its exceptional hardness and wear resistance, is widely used in industrial applications such as cutting tools, wear parts, and coatings. Ensuring the quality and performance of tungsten carbide products is crucial, and this involves rigorous testing procedures. In this article, we will delve into the methods and techniques used to test tungsten carbide, including hardness testing, composition analysis, and performance evaluation.

Introduction to Tungsten Carbide

Tungsten carbide is a composite material made from tungsten carbide grains bound together by a metallic matrix, typically cobalt. Its hardness ranges from 89 to 95 HRA, corresponding to approximately 69 to 81 HRC, making it one of the hardest materials available. The high hardness and wear resistance of tungsten carbide make it ideal for applications where durability is essential.

Tungsten Carbide Applications

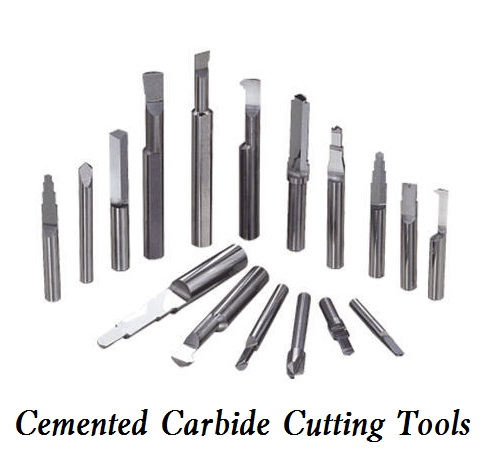

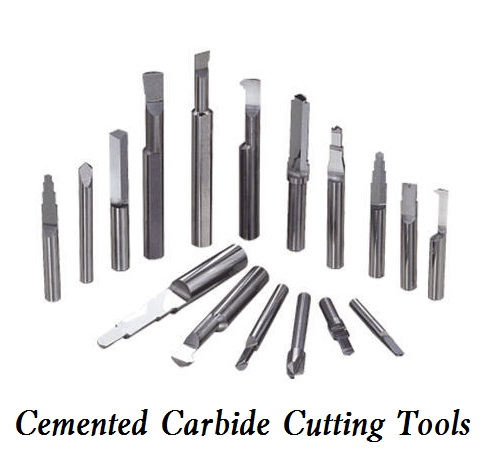

- Cutting Tools: Tungsten carbide is used in cutting tools due to its ability to withstand high wear and maintain sharp cutting edges. This is particularly important in machining operations where tool longevity directly impacts production efficiency.

- Wear Parts: It is used in wear parts such as nozzles and liners due to its resistance to abrasion. These components are often subjected to harsh environments where other materials would quickly degrade.

- Coatings: Tungsten carbide coatings are applied to surfaces to enhance wear resistance and extend the lifespan of components. This is especially beneficial in high-wear applications like drill bits and saw blades.

Testing Methods for Tungsten Carbide

Testing tungsten carbide involves evaluating its hardness, composition, and performance under various conditions. Here are some key testing methods:

Hardness Testing

Hardness is a critical property of tungsten carbide, reflecting its ability to resist wear and deformation. Common hardness testing methods include:

- Rockwell Hardness Test: Uses a diamond point to create an indentation in the material. The Rockwell hardness scale is commonly used for tungsten carbide, with HRA being the most relevant scale. This test is widely used due to its simplicity and speed.

- Vickers Hardness Test: Also uses indentation but with a square-based pyramid indenter. It provides a more precise measurement of hardness, especially for materials with complex microstructures. The Vickers test is preferred when detailed hardness profiles are needed.

- Brinell Hardness Test: Uses a tungsten carbide ball to create an indentation. It is suitable for larger samples with coarse grain structures. Although less common for tungsten carbide, it remains useful for certain applications.

Composition Testing

Composition testing is essential to verify the chemical makeup of tungsten carbide, ensuring it meets specifications:

- X-ray Fluorescence Spectroscopy (XRF): A non-destructive method that analyzes the elemental composition by detecting the fluorescence emitted when the material is exposed to X-rays. XRF is quick and does not damage the sample, making it ideal for quality control.

- Chemical Analysis: Provides detailed information on the content of alloy elements but is more time-consuming and often destructive. This method is used when precise composition data is required.

Performance Testing

Performance tests evaluate how tungsten carbide behaves under operational conditions:

- Wear Resistance Test: Assesses the material's ability to withstand abrasion and wear. Genuine tungsten carbide coatings exhibit minimal wear under high friction. This test is critical for ensuring that the material will perform well in its intended application.

- Corrosion Resistance Test: Evaluates the material's resistance to chemical corrosion by exposing it to corrosive environments. While tungsten carbide is generally resistant to corrosion, this test ensures that the material will not degrade in harsh chemical conditions.

Standards and Specifications

Testing tungsten carbide must adhere to relevant standards to ensure consistency and reliability:

- GB/T 4162-2008: Chinese standard for tungsten carbide rods.

- ASTM A600: American standard for tungsten carbide materials.

- JIS G 4403: Japanese standard for tungsten carbide tools.

These standards provide guidelines for testing procedures, ensuring that materials meet international quality benchmarks.

Advanced Testing Techniques

In addition to traditional testing methods, advanced techniques are being developed to further evaluate the properties of tungsten carbide:

- Nanoindentation: This method allows for precise hardness measurements at the nanoscale, providing insights into the material's microstructure.

- Scanning Electron Microscopy (SEM): Used to examine the surface morphology and microstructure of tungsten carbide, helping to identify defects or irregularities.

These advanced techniques offer deeper insights into the material's properties, enabling the development of more sophisticated applications.

Challenges in Testing Tungsten Carbide

Testing tungsten carbide poses several challenges due to its hardness and brittleness:

- Sample Preparation: Preparing samples for testing can be difficult due to the material's hardness. Specialized equipment is often required to ensure accurate results.

- Interpretation of Results: The interpretation of test results requires expertise, as the material's properties can vary significantly depending on its composition and processing conditions.

Addressing these challenges involves investing in specialized equipment and training personnel to handle the unique demands of testing tungsten carbide.

Future Developments

As technology advances, new methods and materials are being developed to enhance the performance of tungsten carbide. For instance, nanotechnology is being explored to create composites with improved mechanical properties. Additionally, advancements in coating technologies are allowing for more efficient application of tungsten carbide coatings, expanding their use in various industries.

Emerging Trends in Tungsten Carbide Technology

- Nanocomposites: Researchers are focusing on developing nanocomposites that combine tungsten carbide with other materials to achieve enhanced properties such as improved toughness or thermal resistance.

- 3D Printing: The application of 3D printing technology to produce complex tungsten carbide components is gaining attention. This allows for the creation of parts with intricate geometries that cannot be produced using traditional manufacturing methods.

These emerging trends are expected to significantly impact the future of tungsten carbide applications, enabling its use in more complex and demanding environments.

Economic and Environmental Considerations

The production and testing of tungsten carbide also involve economic and environmental considerations:

- Cost Efficiency: The cost of testing and manufacturing tungsten carbide products can be high due to the specialized equipment and expertise required. Efforts to streamline processes and reduce costs are ongoing.

- Sustainability: There is a growing focus on ensuring that tungsten carbide production is sustainable and environmentally friendly. This includes sourcing raw materials responsibly and minimizing waste during manufacturing.

Balancing these factors is crucial for maintaining the viability of tungsten carbide in various industries.

Conclusion

Testing tungsten carbide is a comprehensive process that involves evaluating its hardness, composition, and performance. By using methods such as hardness testing, composition analysis, and performance evaluation, manufacturers can ensure that their products meet the required standards and specifications. As technology advances, testing techniques continue to evolve, providing more accurate and efficient ways to assess the quality of tungsten carbide materials.

FAQ

1. What is the typical hardness range of tungsten carbide?

Tungsten carbide typically has a hardness range from 89 to 95 HRA, which corresponds to approximately 69 to 81 HRC.

2. How is the composition of tungsten carbide analyzed?

The composition of tungsten carbide can be analyzed using X-ray fluorescence spectroscopy (XRF) for rapid elemental analysis or chemical analysis for detailed composition.

3. What are the common applications of tungsten carbide?

Tungsten carbide is commonly used in cutting tools, wear parts, and coatings due to its high hardness and wear resistance.

4. What is the purpose of wear resistance testing for tungsten carbide coatings?

Wear resistance testing evaluates how well tungsten carbide coatings withstand abrasion and wear, ensuring they meet performance standards.

5. What standards are typically followed for testing tungsten carbide rods?

Testing tungsten carbide rods typically follows standards such as GB/T 4162-2008, ASTM A600, and JIS G 4403 to ensure quality and consistency.

Citations:

[1] https://www.carbide-part.com/blog/comprehensive-guide-to-testing-tungsten-carbide-rods-key-steps-to-ensure-quality-and-performance/

[2] https://www.jinhangmachinery.com/news/how-to-tell-if-the-tungsten-carbide-coating-of-industrial-rollers-is-real

[3] https://www.carbide-part.com/blog/tungsten-carbide-hardness-vs-diamond/

[4] https://nvlpubs.nist.gov/nistpubs/jres/5/jresv5n2p365_A2b.pdf

[5] https://foundrax.co.uk/the-brinell-hardness-tester-explained/

[6] https://blog.carbideprocessors.com/saw-blades/carbide-tips/testing-the-hardness-of-carbide/

[7] https://konecarbide.com/quality-control/

[8] https://www.ostoncarbide.com/info-detail/the-hardness-testing-of-tungsten-carbide

[9] https://gaotek.com/product/leeb-hardness-tester-with-tungsten-carbide-bluetooth-usb/

[10] https://www.elcometerusa.com/Laboratory/Elcometer-3092-Sclerometer-Hardness-Tester/

[11] https://www.struers.com/en/Knowledge/Hardness-testing/Brinell

[12] https://www.carbide-products.com/blog/hardness-testing-of-carbide/

[13] https://www.thermalspray.com/how-to-distinguish-real-tungsten-carbide-from-fakes/

[14] https://eprints.soton.ac.uk/424554/1/Fletcher_Pierron2018_Article_AnImage_BasedInertialImpactIBI.pdf

[15] https://www.carbide-usa.com/tungsten-carbide-testing-resources/

[16] https://scispace.com/pdf/the-wear-properties-of-tungsten-carbide-cobalt-hardmetals-3p0rgkhmil.pdf

[17] https://www.shutterstock.com/search/tungsten-metal

[18] http://ltu.diva-portal.org/smash/get/diva2:1326264/FULLTEXT03.pdf

[19] https://www.youtube.com/watch?v=TMT6T40yD1Y

[20] https://www.youtube.com/watch?v=cT1uKBo8lSA

[21] https://www.imeko.org/publications/tc5-2004/IMEKO-TC5-2004-016.pdf