Content Menu

● What is Tungsten Carbide?

● Overview of the Production Process

● 1. Raw Material Preparation

>> Tungsten Powder and Carbon Source

>> Cleaning and Drying

● 2. Mixing and Carburization

>> Mixing

>> Carburization

● 3. Milling and Granulation

● 4. Pressing and Shaping

● 5. Sintering and Heat Treatment

>> Sintering

>> Heat Treatment

● 6. Machining and Finishing

● 7. Quality Inspection and Performance Testing

● Applications of Tungsten Carbide

● Environmental Considerations in Tungsten Carbide Production

● Innovations and Future Trends

● Safety Measures in Production

● Summary

● FAQ: Tungsten Carbide Production

>> 1. What raw materials are used in the production of tungsten carbide?

>> 2. What is carburization in tungsten carbide production?

>> 3. Why is sintering important in tungsten carbide manufacturing?

>> 4. How are tungsten carbide parts machined after sintering?

>> 5. What industries benefit most from tungsten carbide products?

● Citations:

Tungsten carbide is a remarkable material widely recognized for its exceptional hardness, wear resistance, and durability. It plays a crucial role in various industries including industrial manufacturing, military, metallurgy, oil drilling, mining, and construction. This article explores in detail the production process of tungsten carbide, highlighting the scientific and engineering craftsmanship behind this high-performance material.

What is Tungsten Carbide?

Tungsten carbide (WC) is a chemical compound consisting of tungsten and carbon atoms. It is known for being one of the hardest materials available, second only to diamond in hardness. This makes it ideal for applications requiring extreme durability and wear resistance. Tungsten carbide is often combined with a metallic binder such as cobalt to form cemented carbide, which is used to manufacture cutting tools, mining equipment, military hardware, and more.

Overview of the Production Process

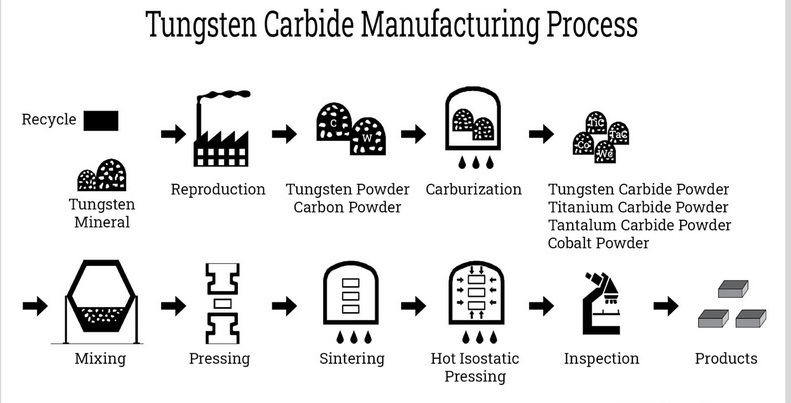

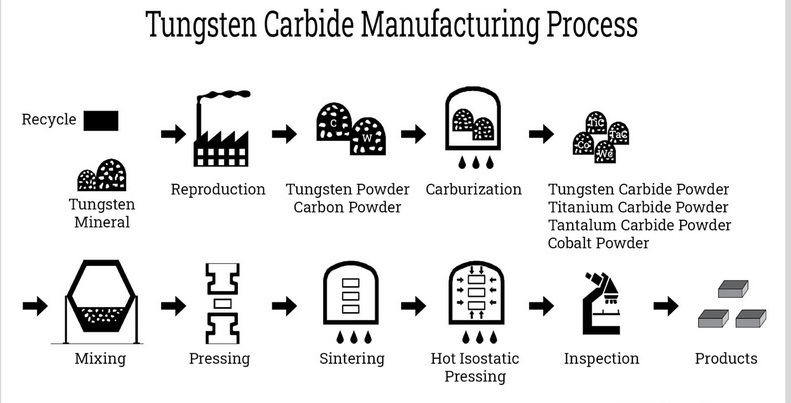

The production of tungsten carbide involves several key stages:

- Raw material preparation

- Mixing and carburization

- Milling and granulation

- Pressing and shaping

- Sintering and heat treatment

- Machining and finishing

- Quality inspection

Each stage is critical to ensure the final product meets the demanding specifications required for its various applications.

1. Raw Material Preparation

Tungsten Powder and Carbon Source

The primary raw materials for tungsten carbide are tungsten powder and a carbon source, usually carbon black or graphite. Tungsten powder is typically produced by reducing tungsten oxide (WO₃) in a hydrogen atmosphere at high temperatures (600–1000°C), resulting in high-purity tungsten metal powder with controlled particle size.

Cleaning and Drying

Before mixing, raw materials undergo rigorous cleaning to remove impurities such as oils, oxides, and moisture. Ultrasonic and chemical cleaning methods are used to ensure the powders are free from contaminants that could affect the quality of the final product. Drying is carefully controlled to prevent oxidation or agglomeration.

2. Mixing and Carburization

Mixing

Tungsten powder and carbon black are mixed thoroughly, often in a ball mill for 2–4 hours, to achieve a uniform blend. Uniformity is crucial to prevent unreacted cores and ensure consistent carbide formation.

Carburization

The mixed powders undergo carburization in a graphite carbon tube furnace at temperatures between 1300°C and 1600°C, depending on tungsten powder particle size. Fine tungsten powder typically requires 1300–1350°C, while coarser powder needs up to 1600°C. The process lasts 1–2 hours, during which tungsten reacts chemically with carbon to form tungsten carbide (WC).

This process can also be done by directly reacting tungsten oxide with carbon under controlled conditions to suppress grain growth and produce fine tungsten carbide particles.

3. Milling and Granulation

After carburization, the tungsten carbide powder is ball milled again to achieve the desired particle size distribution. The powder is then sieved through meshes of different sizes (e.g., 60-mesh for coarse, 200-mesh for fine particles) to classify the powder.

Granulation follows, where powders are mixed with binders like paraffin and alcohol to improve flowability and compactibility during pressing.

4. Pressing and Shaping

The granulated tungsten carbide powder, often mixed with a cobalt binder powder, is pressed into desired shapes using high-pressure presses. This forms a "green body," a fragile compact that holds the shape but lacks mechanical strength.

Pressing parameters such as pressure, speed, and temperature are carefully controlled to avoid defects like cracking, uneven density, or deformation.

5. Sintering and Heat Treatment

Sintering

Sintering is the critical step where the pressed green bodies are heated at high temperatures (around 1400–1600°C) in a vacuum or inert atmosphere. During sintering, the cobalt binder melts and flows, bonding the tungsten carbide grains into a dense, homogeneous structure known as cemented carbide.

The sintering atmosphere prevents oxidation and contamination, while controlled heating and cooling reduce internal stresses and prevent cracking.

Heat Treatment

Additional heat treatments like annealing, quenching, or tempering may be applied to optimize the microstructure, toughness, and mechanical properties of the tungsten carbide parts.

6. Machining and Finishing

Tungsten carbide parts, especially those with complex shapes, undergo various machining processes after sintering:

- Wire EDM cutting (rough and medium)

- Cylindrical grinding (internal and external)

- Surface grinding

- CNC machining for precision shaping

- Polishing for surface finish

These processes ensure the parts meet exact dimensional and surface quality requirements essential for their demanding applications.

7. Quality Inspection and Performance Testing

Comprehensive quality control is performed to verify chemical composition, microstructure, hardness, tensile strength, toughness, and wear resistance. Advanced analytical techniques and microstructure observations ensure the tungsten carbide products meet industry standards and client specifications.

Applications of Tungsten Carbide

Tungsten carbide's superior properties make it indispensable across many sectors:

- Industrial Manufacturing: Cutting tools, drills, milling cutters, saw blades.

- Military: Armor-piercing ammunition, firearm components, ordnance parts.

- Metallurgy: Inserts for metal cutting and forming.

- Oil and Gas: Drill bits and inserts for well drilling, resistant to abrasion and high pressure.

- Mining: Drill bits and wear-resistant parts for rock drilling and ore extraction.

- Construction: Tools for cutting and drilling hard materials like concrete and asphalt.

Environmental Considerations in Tungsten Carbide Production

The production of tungsten carbide, while technologically advanced, also poses environmental challenges. The extraction of tungsten ore and the chemical processes involved can generate waste and emissions that require careful management. Modern production facilities implement strict environmental controls to minimize the impact, including recycling of tungsten scrap, treatment of chemical effluents, and reduction of greenhouse gas emissions.

Sustainable practices are increasingly important as industries seek to balance performance with environmental responsibility. Innovations such as using alternative binders to reduce cobalt content and developing more energy-efficient sintering techniques are part of ongoing research efforts to reduce the environmental footprint of tungsten carbide production.

Innovations and Future Trends

The field of tungsten carbide production is continuously evolving. Researchers are exploring nanostructured tungsten carbide materials that offer enhanced hardness and toughness. These nanostructured carbides have grain sizes in the nanometer range, which can significantly improve mechanical properties beyond conventional materials.

Additive manufacturing (3D printing) techniques are also being developed to create complex tungsten carbide components with reduced waste and improved design flexibility. This allows for rapid prototyping and production of parts that were previously difficult or impossible to manufacture using traditional methods.

Furthermore, the integration of artificial intelligence and machine learning in production processes is helping optimize parameters for better quality control and cost efficiency. For example, AI can analyze sintering profiles and predict optimal heating and cooling rates to minimize defects and improve material properties.

These advancements promise to expand the applications and performance of tungsten carbide products in the future, making them even more versatile and cost-effective.

Safety Measures in Production

Due to the high temperatures and fine powders involved, safety is a critical concern in tungsten carbide production. Facilities enforce strict protocols to protect workers from inhalation of fine particles and exposure to hazardous chemicals. Protective equipment such as respirators, gloves, and protective clothing are mandatory.

Proper ventilation systems and dust collection units are installed to minimize airborne particles. Automated handling and processing systems reduce direct human contact with powders and high-temperature equipment, further enhancing workplace safety.

Regular training and monitoring ensure that safety standards are maintained, preventing accidents and health hazards associated with tungsten carbide manufacturing.

Summary

The production of tungsten carbide is a complex and multi-faceted process that combines raw material preparation, chemical reactions, mechanical processing, and quality control. With ongoing innovations and a focus on sustainability and safety, the industry continues to advance, meeting the growing demands of various high-performance applications.

From the initial reduction of tungsten oxide to fine tungsten powder, through carburization, pressing, sintering, and finishing, every step is engineered to produce a material that is exceptionally hard, tough, and wear-resistant. The future of tungsten carbide production lies in nanotechnology, additive manufacturing, and smart manufacturing processes, ensuring this material remains indispensable in cutting-edge industrial applications.

FAQ: Tungsten Carbide Production

1. What raw materials are used in the production of tungsten carbide?

Tungsten carbide is primarily produced from tungsten powder (derived from tungsten oxide) and carbon sources such as carbon black or graphite. Cobalt powder is often added as a binder to improve toughness in cemented carbide products.

2. What is carburization in tungsten carbide production?

Carburization is a high-temperature process where tungsten powder reacts chemically with carbon to form tungsten carbide. This typically occurs in a graphite carbon tube furnace at temperatures between 1300°C and 1600°C, depending on the particle size of tungsten powder.

3. Why is sintering important in tungsten carbide manufacturing?

Sintering bonds the compacted tungsten carbide and cobalt powders by heating them to high temperatures (around 1400–1600°C) in a controlled atmosphere. It creates a dense, homogeneous material with enhanced mechanical properties and wear resistance.

4. How are tungsten carbide parts machined after sintering?

After sintering, tungsten carbide parts are shaped using advanced machining techniques such as wire EDM cutting, cylindrical grinding, surface grinding, CNC machining, and polishing to achieve precise dimensions and surface finishes.

5. What industries benefit most from tungsten carbide products?

Tungsten carbide is extensively used in industrial manufacturing (cutting tools), military (armor-piercing ammunition), oil and gas (drill bits), mining (wear-resistant tools), metallurgy, aerospace, and construction due to its hardness and durability.