Content Menu

● Introduction

● The Hardness Scale

>> Mohs Hardness Scale

>> Hardness Comparison Table

● Tungsten Carbide: Exceptional Properties

>> Characteristics of Tungsten Carbide

● Diamond: The Ultimate Hardness

>> Characteristics of Diamond

● Comparative Analysis of Hardness

>> Strength vs. Hardness

>> Cost Considerations

● Applications of Tungsten Carbide and Diamond

>> Industrial Applications

>>> Tungsten Carbide Applications

>>> Diamond Applications

>> Jewelry Applications

>>> Tungsten Carbide Jewelry

>>> Diamond Jewelry

● Advantages and Disadvantages of Each Material

>> Advantages of Tungsten Carbide

>> Disadvantages of Tungsten Carbide

>> Advantages of Diamond

>> Disadvantages of Diamond

● Future Trends in Material Science

>> Emerging Technologies for Tungsten Carbide

>> Synthetic Diamonds

● Conclusion

● FAQ

>> 1. What is harder, tungsten carbide or diamond?

>> 2. Can tungsten carbide be used in jewelry?

>> 3. Why is diamond so expensive?

>> 4. Is tungsten carbide brittle?

>> 5. What are common uses for diamond?

● Citations:

Introduction

Tungsten carbide and diamond are two of the hardest materials known to man, often compared in various industrial and commercial applications. Understanding their properties, strengths, and weaknesses is essential for selecting the right material for specific uses. This article delves into the hardness of tungsten carbide versus diamond, exploring their characteristics, applications, and implications in various fields.

The Hardness Scale

Mohs Hardness Scale

The Mohs hardness scale is a qualitative scale used to measure the hardness of minerals. It ranges from 1 (talc) to 10 (diamond), with each mineral able to scratch those below it on the scale.

- Diamond: 10 (the hardest known natural material)

- Tungsten Carbide: Approximately 9 (very hard but not as hard as diamond)

Hardness Comparison Table

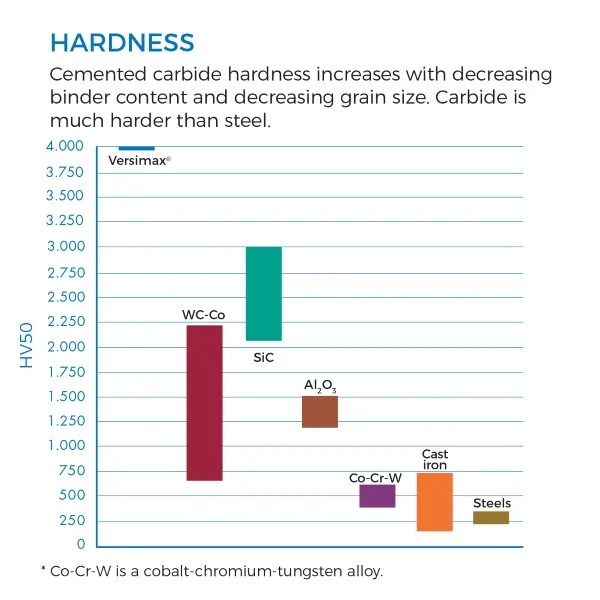

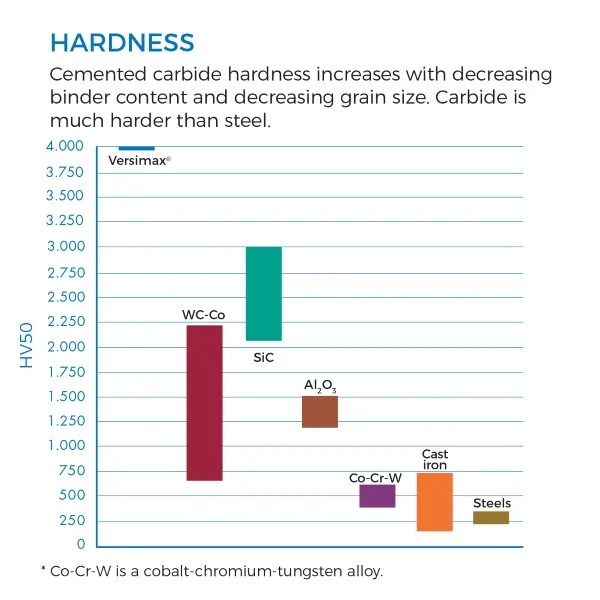

| Material | Mohs Hardness | Vickers Hardness (HV) |

| Diamond | 10 | ~10,000 |

| Tungsten Carbide | 9 | ~2,400 |

Tungsten Carbide: Exceptional Properties

Tungsten carbide is a composite material made from tungsten and carbon atoms. It is renowned for its hardness and durability, making it a popular choice for industrial applications.

Characteristics of Tungsten Carbide

- Hardness: Ranges between 7.5 and 9 on the Mohs scale.

- Durability: Highly resistant to wear and deformation.

- Density: Tungsten carbide has a high density, making it heavier than many other materials.

- Corrosion Resistance: It is resistant to corrosion and oxidation, which enhances its longevity in various environments.

- Applications: Widely used in cutting tools, mining equipment, and jewelry due to its strength and scratch resistance.

Diamond: The Ultimate Hardness

Diamond is composed of carbon atoms arranged in a crystal lattice structure, providing it with unparalleled hardness.

Characteristics of Diamond

- Hardness: Rated as a perfect 10 on the Mohs scale.

- Brittleness: While extremely hard, diamonds can be brittle and may shatter under high impact.

- Thermal Conductivity: Diamonds have excellent thermal conductivity, making them useful in electronics and heat sinks.

- Optical Properties: Diamonds are known for their brilliance and light dispersion, making them highly sought after in jewelry.

- Applications: Used in cutting tools, abrasives, and luxury jewelry due to its brilliance and durability.

Comparative Analysis of Hardness

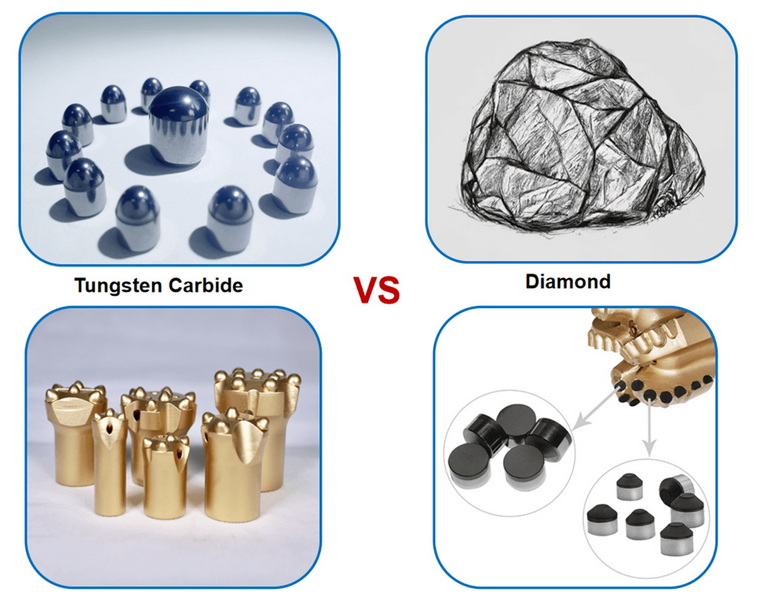

While both tungsten carbide and diamond are exceptionally hard materials, they differ significantly in their properties.

Strength vs. Hardness

- Tungsten Carbide: While it has a high hardness rating, it is more prone to chipping or breaking under extreme conditions compared to diamond. Its toughness makes it suitable for heavy-duty applications where impact resistance is crucial.

- Diamond: Offers superior strength due to its atomic structure, making it less likely to fracture under pressure. However, its brittleness can be a disadvantage in certain applications where shock resistance is necessary.

Cost Considerations

- Tungsten Carbide: Generally more affordable than diamond, making it a practical choice for many applications. Its cost-effectiveness is one reason why it has become popular in various industries.

- Diamond: More expensive due to its rarity and the complexity involved in mining and processing. The price of diamonds can vary significantly based on factors such as cut, clarity, color, and carat weight.

Applications of Tungsten Carbide and Diamond

Both materials have unique applications based on their properties.

Industrial Applications

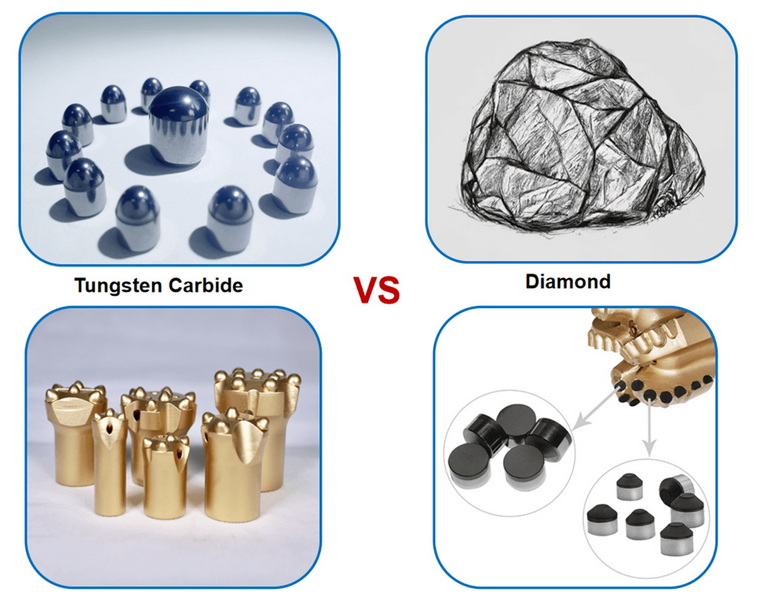

Tungsten Carbide Applications

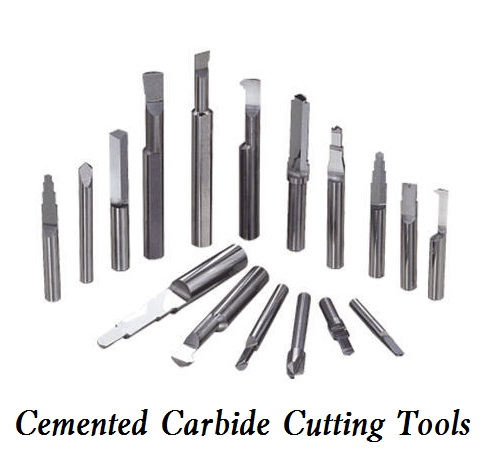

1. Cutting Tools: Tungsten carbide is extensively used in manufacturing cutting tools such as drills, saw blades, and milling tools due to its hardness and wear resistance.

2. Mining Equipment: Its durability makes it ideal for mining tools that endure extreme conditions.

3. Wear-resistant Surfaces: Used in machinery parts that require high wear resistance.

4. Aerospace Components: Its lightweight yet durable nature makes it suitable for aerospace applications.

Diamond Applications

1. Precision Cutting Tools: Diamonds are used in high-performance cutting tools for machining hard materials like metals and ceramics.

2. Abrasives: Due to their hardness, diamonds are used in grinding wheels and abrasive pastes.

3. Electronics: Diamonds are employed in electronic devices due to their excellent thermal conductivity.

4. Luxury Jewelry: Diamonds are traditionally used in engagement rings and other fine jewelry due to their brilliance.

Jewelry Applications

Tungsten Carbide Jewelry

Tungsten carbide has gained popularity as a material for wedding bands because of its scratch resistance and durability. Its modern aesthetic appeal makes it an attractive option for couples looking for something unique yet practical.

Diamond Jewelry

Diamonds remain the quintessential choice for engagement rings due to their unmatched brilliance and status symbol. The emotional significance attached to diamonds further elevates their value in the jewelry market.

Advantages and Disadvantages of Each Material

Advantages of Tungsten Carbide

- High durability

- Cost-effective

- Scratch-resistant

- Versatile applications

- Resistant to corrosion

Disadvantages of Tungsten Carbide

- Can be brittle under extreme impact

- Limited aesthetic appeal compared to diamond

- Not suitable for precision applications requiring extreme hardness

Advantages of Diamond

- Unmatched hardness

- Excellent thermal conductivity

- Exceptional optical properties

- Versatile applications across industries

Disadvantages of Diamond

- High cost

- Brittle nature can lead to shattering under stress

- Requires careful handling during manufacturing processes

Future Trends in Material Science

As technology advances, both tungsten carbide and diamond continue to see innovations that enhance their properties or expand their applications.

Emerging Technologies for Tungsten Carbide

Research is ongoing into improving tungsten carbide's toughness while maintaining its hardness. This could lead to even more durable cutting tools or components that can withstand higher impacts without chipping or breaking.

Synthetic Diamonds

Synthetic diamonds produced through High Pressure High Temperature (HPHT) or Chemical Vapor Deposition (CVD) methods are becoming increasingly popular. These lab-grown diamonds offer similar properties at a lower cost while addressing ethical concerns associated with natural diamond mining.

Conclusion

In conclusion, both tungsten carbide and diamond possess exceptional hardness but serve different purposes based on their unique properties. Tungsten carbide is an excellent choice for cost-effective industrial applications where durability is key. In contrast, diamond remains unmatched in hardness and brilliance, making it ideal for precision cutting tools and luxury items. Understanding these differences allows consumers and industries alike to make informed decisions regarding material selection.

FAQ

1. What is harder, tungsten carbide or diamond?

Diamond is harder than tungsten carbide, rated at 10 on the Mohs scale compared to tungsten carbide's rating of approximately 9.

2. Can tungsten carbide be used in jewelry?

Yes, tungsten carbide is commonly used in jewelry, particularly wedding bands, due to its scratch resistance and durability.

3. Why is diamond so expensive?

Diamonds are expensive due to their rarity, the intricate mining process involved in obtaining them, and their desirability in luxury markets.

4. Is tungsten carbide brittle?

While tungsten carbide is very hard, it can be brittle under extreme conditions or impacts compared to diamond.

5. What are common uses for diamond?

Diamonds are used in various applications including precision cutting tools, abrasives for grinding, electronics (due to thermal conductivity), and luxury jewelry items.

Citations:

[1] https://www.reekecarbide.com/blog/tungsten-carbide-vs-diamond-unveiling-the-test-of-strength.html

[2] https://www.mitsubishicarbide.net/contents/mmus/enus/html/product/technical_information/information/hardness.html

[3] https://www.tungstenringsco.com/blog/2023/06/tungsten-vs-diamond/

[4] https://www.sohu.com/a/150966204_489486

[5] https://www.zzcrcarbide.com/news/which-is-harder-compared-to-tungsten-carbide-and-diamond/

[6] https://gdptooling.com/diamond-v-carbide-comparing-the-costs/

[7] https://www.csulb.edu/sites/default/files/document/2019_mini_manuscript.pdf

[8] https://www.carbide-products.com/blog/tungsten-carbide-hardness-vs-diamond/

[9] https://blog.csdn.net/qq_34917728/article/details/125122327

[10] https://www.carbide-part.com/blog/tungsten-carbide-hardness-vs-diamond/

[11] https://jewelrydepotusa.com/metal-comparison/