Content Menu

● Understanding Cemented Carbide Buttons

>> Key Properties of Cemented Carbide Buttons

● Applications of Cemented Carbide Buttons in Mining

>> Types of Cemented Carbide Buttons

● Enhancing Mining Efficiency with Cemented Carbide Buttons

>> 1. Increased Penetration Rates

>> 2. Reduced Downtime

>> 3. Cost-Effectiveness

● Technological Advancements in Cemented Carbide Buttons

>> Advanced Manufacturing Techniques

>> Customization Options

● Conclusion

● Related Questions

>> 1. What materials are used to make cemented carbide buttons?

>> 2. How do cemented carbide buttons compare to traditional drill bits?

>> 3. Can cemented carbide buttons be customized?

>> 4. What is the typical lifespan of a cemented carbide button?

>> 5. How do advancements in technology affect cemented carbide button performance?

Cemented carbide buttons are essential components in the mining industry, particularly in drilling and cutting applications. These buttons, made primarily from tungsten carbide, offer unmatched hardness and wear resistance, making them ideal for the harsh conditions of mining operations. In this article, we will explore how cemented carbide buttons enhance mining efficiency, their various applications, and the technological advancements that continue to improve their performance.

Understanding Cemented Carbide Buttons

Cemented carbide buttons are small, cylindrical inserts used in drilling tools. They are composed of tungsten carbide particles bonded together with a metallic binder, typically cobalt. This combination results in a material that is not only extremely hard but also tough enough to withstand the stresses encountered during drilling operations.

Key Properties of Cemented Carbide Buttons

1. Hardness: Cemented carbide buttons have a hardness that surpasses most metals, allowing them to cut through hard rock formations effectively.

2. Wear Resistance: The exceptional wear resistance of these buttons extends their operational life, reducing the frequency of tool replacements and maintenance.

3. Impact Resistance: Designed to absorb shock loads, cemented carbide buttons prevent premature failure during high-impact drilling tasks.

Applications of Cemented Carbide Buttons in Mining

Cemented carbide buttons are utilized in various mining applications, including:

- Coal Mining: In coal mining operations, these buttons are used on continuous miners and road headers. Their design allows for efficient cutting and material removal.

- Hard Rock Drilling: For hard rock formations, spherical and conical buttons are preferred due to their ability to penetrate tough materials.

- Tunneling: In tunneling applications, cemented carbide buttons provide the necessary durability and performance to navigate through challenging geological conditions.

Types of Cemented Carbide Buttons

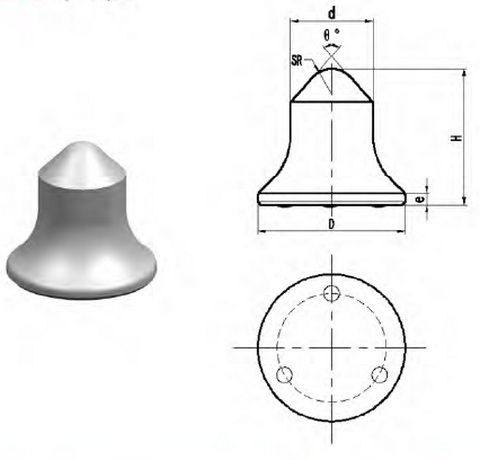

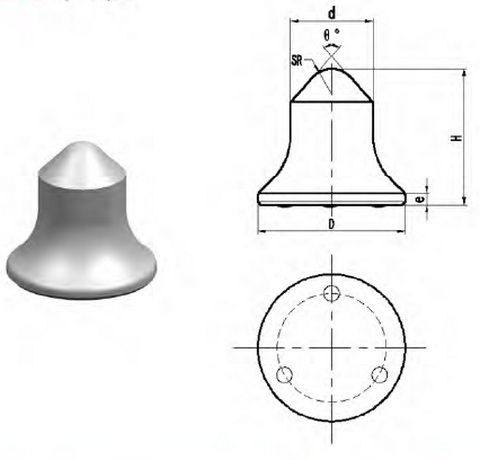

Different shapes and designs of cemented carbide buttons serve specific functions:

- Conical Buttons: Ideal for aggressive penetration in hard rock and coal seams.

- Mushroom-Shaped Buttons: Offer a balance between wear resistance and penetration capability.

- Spherical Buttons: Used for applications requiring high impact resistance.

Enhancing Mining Efficiency with Cemented Carbide Buttons

The efficiency of mining operations can be significantly improved through the use of cemented carbide buttons. Here are several ways they contribute to enhanced performance:

1. Increased Penetration Rates

Cemented carbide buttons allow for faster drilling speeds due to their superior hardness. This leads to increased penetration rates, enabling miners to extract resources more quickly and efficiently.

2. Reduced Downtime

With their extended wear life, cemented carbide buttons minimize downtime associated with tool changes. This reliability ensures that mining operations can run continuously without interruptions.

3. Cost-Effectiveness

Although the initial investment in cemented carbide buttons may be higher than traditional materials, their longevity and reduced maintenance needs result in lower overall costs over time.

Technological Advancements in Cemented Carbide Buttons

Recent innovations have further enhanced the performance of cemented carbide buttons. Manufacturers are continually researching new materials and manufacturing processes to improve the properties of these tools.

Advanced Manufacturing Techniques

1. Hot Isostatic Pressing (HIP): This technique enhances the density and strength of cemented carbides by applying high pressure and temperature during production.

2. Micro-Grain Technology: The use of finer tungsten carbide grains results in improved toughness and wear resistance.

Customization Options

Manufacturers now offer customized cemented carbide buttons tailored to specific mining conditions. These bespoke solutions ensure optimal performance based on geological factors such as rock hardness and mineral composition.

Conclusion

Cemented carbide buttons play a crucial role in enhancing mining efficiency through their superior hardness, wear resistance, and impact durability. By utilizing these advanced tools, mining operations can achieve faster drilling rates, reduced downtime, and overall cost savings. As technology continues to evolve, the effectiveness of cemented carbide buttons will only improve, further solidifying their importance in the industry.

Related Questions

1. What materials are used to make cemented carbide buttons?

Cemented carbide buttons are primarily made from tungsten carbide particles bonded with cobalt or other metallic binders.

2. How do cemented carbide buttons compare to traditional drill bits?

Cemented carbide buttons offer superior hardness and wear resistance compared to traditional steel drill bits, resulting in longer tool life and better performance in tough conditions.

3. Can cemented carbide buttons be customized?

Yes, manufacturers can customize cemented carbide buttons in terms of shape, size, and cutting geometry to meet specific application requirements.

4. What is the typical lifespan of a cemented carbide button?

The lifespan of a cemented carbide button varies based on application but is generally longer than that of traditional materials due to its exceptional wear resistance.

5. How do advancements in technology affect cemented carbide button performance?

Technological advancements such as micro-grain technology and hot isostatic pressing enhance the strength, toughness, and overall performance of cemented carbide buttons.