Content Menu

● Introduction to Carbides

>> Carbides Properties

● Production of Carbides

>> Tungsten Carbide Production

>> Silicon Carbide Production

>> Calcium Carbide Production

● Applications of Carbides

>> Industrial Applications

>> Military and Aerospace Applications

>> Metallurgy and Mining Applications

>> Oil and Gas Applications

>> Construction Applications

● Future Developments in Carbide Production

>> Nanotechnology in Carbide Production

>> Sustainable Production Methods

● Challenges and Opportunities

>> Environmental Impact

>> Economic Considerations

>> Technological Advancements

● Market Trends and Outlook

>> Emerging Applications

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary types of carbides?

>> 2. How is tungsten carbide produced?

>> 3. What are the applications of silicon carbide?

>> 4. How is calcium carbide used in industry?

>> 5. What are the benefits of using carbide hardfacing?

● Citations:

Carbides are a class of compounds consisting of carbon and metals or metalloids, known for their exceptional hardness, high melting points, and resistance to wear and corrosion. These properties make carbides invaluable in various industrial applications, including manufacturing, metallurgy, oil drilling, mining, and construction. This article delves into the production process, properties, and applications of carbides, highlighting their significance in modern industry.

Introduction to Carbides

Carbides are formed by combining carbon with metals or metalloids. The most common types include ionic carbides (like calcium carbide), covalent carbides (such as silicon carbide), and interstitial carbides (including tungsten carbide and titanium carbide). Each type has distinct properties and applications.

Carbides Properties

- Hardness and Wear Resistance: Carbides are renowned for their hardness, which makes them ideal for cutting tools and wear-resistant coatings.

- High Melting Points: Carbides generally have high melting points, contributing to their thermal stability in extreme environments.

- Corrosion Resistance: Many carbides exhibit excellent resistance to chemical corrosion, enhancing their durability in harsh conditions.

Production of Carbides

The production of carbides involves several steps, depending on the type of carbide being manufactured.

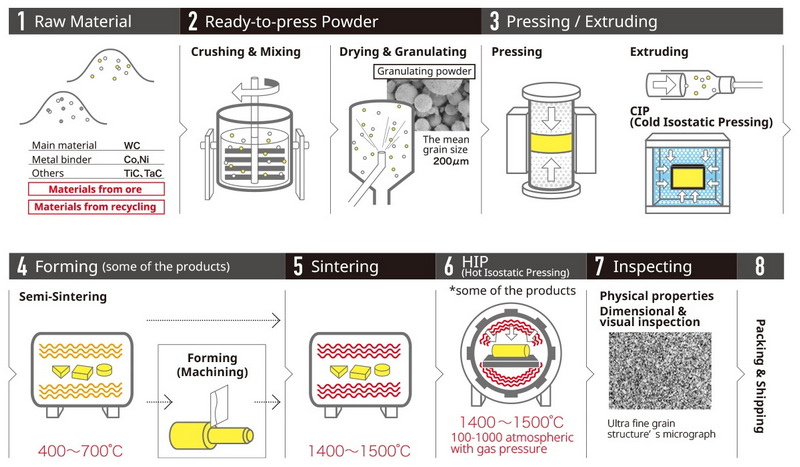

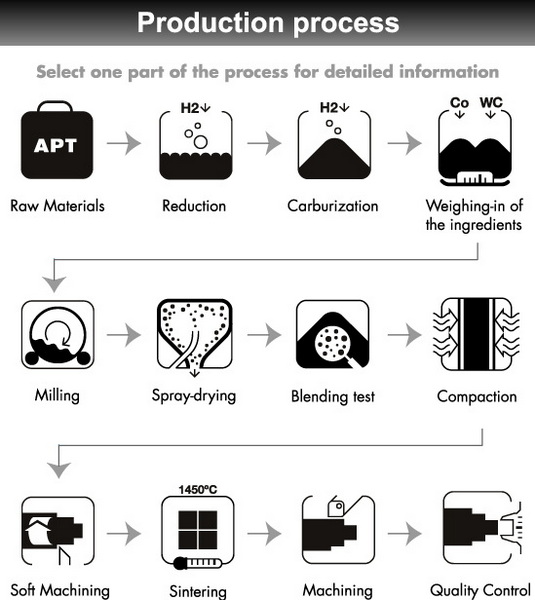

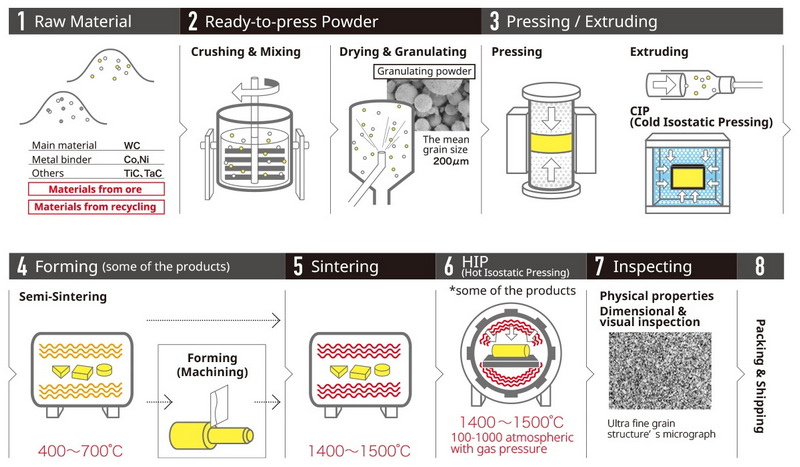

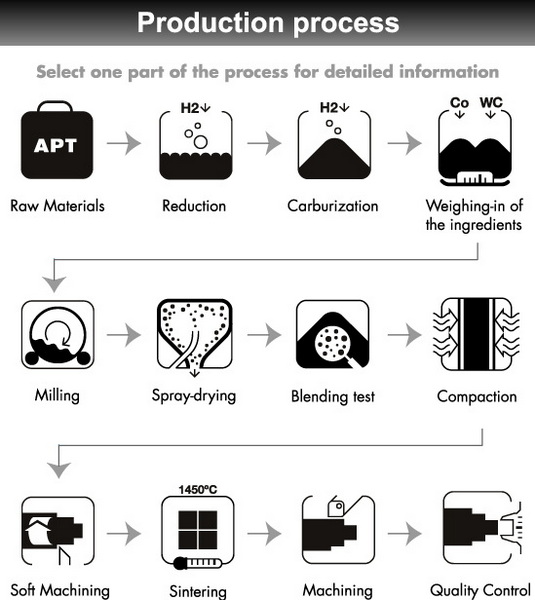

Tungsten Carbide Production

1. Raw Material Sourcing: Tungsten ore is extracted and refined to obtain tungsten oxide.

2. Reduction Process: Tungsten oxide is converted into pure tungsten powder by heating it in a hydrogen atmosphere.

3. Carbonization: The tungsten powder is mixed with carbon and heated at high temperatures (1,400°C to 2,000°C) to form tungsten carbide powder.

4. Sintering: The tungsten carbide powder is combined with a binder (usually cobalt) and pressed into molds. It is then sintered at high temperatures to create a dense, hard material.

Silicon Carbide Production

Silicon carbide (SiC) is produced by heating silicon dioxide (sand) with carbon at temperatures above 2,000°C. This process can be performed in an electric furnace.

Calcium Carbide Production

Calcium carbide is synthesized by heating calcium oxide (lime) with carbon in an electric furnace at about 2,200°C.

Applications of Carbides

Carbides are used in a wide range of industries due to their unique properties.

Industrial Applications

- Cutting Tools: Tungsten carbide is widely used in cutting tools due to its hardness and wear resistance.

- Abrasive Materials: Silicon carbide is used as an abrasive in grinding wheels and sandpapers.

- Hardfacing: Carbides are applied as coatings to enhance the wear resistance of machinery components.

Military and Aerospace Applications

- Armor-Piercing Ammunition: Tungsten carbide is used in armor-piercing ammunition due to its high density and hardness.

- Aerospace Components: Carbide coatings protect critical components from wear and erosion.

Metallurgy and Mining Applications

- Steel Manufacturing: Acetylene gas from calcium carbide is used in welding and cutting processes.

- Mining Tools: Carbide hardfacing enhances the durability of drilling bits and excavator teeth.

Oil and Gas Applications

- Drilling Equipment: Tungsten carbide coatings protect drilling tools from abrasive wear.

Construction Applications

- Wear-Resistant Linings: Carbides are used to line pipes and chutes to prevent wear in construction and mining operations.

- High-Performance Concrete: Silicon carbide can be added to concrete to enhance its strength and durability.

Future Developments in Carbide Production

Advancements in nanotechnology and sustainable manufacturing processes are expected to enhance the performance and environmental impact of carbide production. Recycling of carbide materials is also gaining attention to reduce waste and conserve resources.

Nanotechnology in Carbide Production

Nanotechnology can improve the uniformity and purity of carbide powders, leading to better sintering properties and enhanced material performance. This can result in more efficient cutting tools and wear-resistant coatings.

Sustainable Production Methods

Efforts are being made to reduce energy consumption and emissions during carbide production. This includes the use of renewable energy sources and more efficient furnace designs.

Challenges and Opportunities

Despite the advantages of carbides, there are challenges associated with their production and use. These include high production costs, environmental concerns, and the need for advanced manufacturing technologies.

Environmental Impact

The production of carbides involves high-energy processes and can generate emissions. However, advancements in technology are helping to mitigate these impacts by improving efficiency and reducing waste.

Economic Considerations

The cost of raw materials and energy can fluctuate, affecting the economic viability of carbide production. Nonetheless, the demand for carbides remains strong due to their critical role in various industries.

Technological Advancements

Advancements in materials science and manufacturing technologies are opening new avenues for carbide applications. For instance, the development of composite materials that combine carbides with other materials can enhance performance in specific applications.

Market Trends and Outlook

The global carbide market is expected to grow due to increasing demand from industries such as aerospace, automotive, and construction. The development of new applications, such as in renewable energy systems, will further drive this growth.

Emerging Applications

Carbides are being explored for use in advanced technologies, including semiconductor manufacturing and high-performance ceramics. These emerging applications will expand the market for carbides and drive innovation in production processes.

Conclusion

Carbides are versatile materials with a wide range of applications across various industries. Their production involves complex processes that require precise control over temperature, pressure, and composition. As technology advances, carbides will continue to play a crucial role in enhancing the efficiency and durability of industrial components.

Frequently Asked Questions

1. What are the primary types of carbides?

Carbides are primarily classified into three types: ionic carbides (like calcium carbide), covalent carbides (such as silicon carbide), and interstitial carbides (including tungsten carbide and titanium carbide).

2. How is tungsten carbide produced?

Tungsten carbide is produced by first converting tungsten oxide into pure tungsten powder through a reduction process. The tungsten powder is then mixed with carbon and heated at high temperatures to form tungsten carbide powder, which is sintered with a binder like cobalt.

3. What are the applications of silicon carbide?

Silicon carbide is used as an abrasive material, in refractory components, and in power electronics due to its high thermal conductivity and hardness.

4. How is calcium carbide used in industry?

Calcium carbide is primarily used as a source of acetylene gas, which is essential in welding, cutting, and chemical synthesis processes.

5. What are the benefits of using carbide hardfacing?

Carbide hardfacing enhances the wear resistance and durability of machinery components, extending their lifespan and reducing maintenance costs in harsh industrial environments.

Citations:

[1] https://www.youtube.com/watch?v=zJkVi0cmtX0

[2] https://www.tjtywh.com/a-the-role-of-acetylene-calcium-carbide-in-industrial-applications.html

[3] https://www.britannica.com/science/carbide

[4] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[5] https://www.manufacturingtomorrow.com/article/2019/08/5-ways-carbide-metal-compound-is-used-in-the-manufacturing-industry/13794

[6] https://www.mmc-carbide.com/us/technical_information/tec_guide/tec_guide_carbide

[7] https://carbosystem.com/en/silicon-carbide-properties-applications/

[8] https://primatooling.co.uk/what-are-carbides/

[9] https://nanografi.com/blog/carbides-from-atomic-structure-to-industrial-applications-nanografi-/

[10] https://www.vedantu.com/chemistry/carbide

[11] https://huanatools.com/cemented-carbide-grades-properties-and-uses/

[12] https://www.scmtstool.com/blog/What-Are-the-Industrial-Applications-of_bid-316545588.html

[13] https://www.psmindustries.com/yillik/tungsten-carbide-manufacturing-process

[14] https://www.allied-material.co.jp/en/techinfo/hard-metal/use.html

[15] https://www.samaterials.com/carbides-used-in-hardfacing-applications.html

[16] https://generalcarbide.com

[17] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/process.html

[18] https://www.defenseandmunitions.com/news/manufacturing-101-understanding-the-different-types-of-carbide-in-cutting-tools/

[19] https://www.linkedin.com/pulse/silicon-carbide-sic-industrial-production-methods-francois-xavier-xqf7e

[20] https://www.manufacturingtomorrow.com/article/2019/08/5-ways-carbide-metal-compound-is-used-in-the-manufacturing-industry/13794

[21] https://heegermaterials.com/blog/90_how-is-tungsten-carbide-made-.html

[22] https://pennunitedcarbide.com

[23] https://www.wolfspeed.com/knowledge-center/article/silicon-carbide-and-the-future-of-industrial-applications/

[24] https://www.practicalmachinist.com/forum/threads/need-a-clue-about-carbide-manuf.125345/

[25] https://en.wikipedia.org/wiki/Carbide

[26] https://www.fiven.com/world-of-silicon-carbide/sic-production-process/

[27] https://www.pennunited.com/carbide-manufacturing/

[28] https://www.youtube.com/watch?v=0QrynzJ_lZ4

[29] https://en.wikipedia.org/wiki/Tungsten_carbide

[30] https://www.osti.gov/biblio/4060816

[31] https://www.imetra.com/tungsten-carbide-material-properties/

[32] https://sv.rkriz.net/classes/MSE2094_NoteBook/96ClassProj/OLD/examples/si-c.html

[33] https://www.gwstoolgroup.com/understanding-the-different-types-of-carbide-in-cutting-tools/

[34] https://books.google.com/books/about/Carbides.html?id=6_HTBwAAQBAJ

[35] https://www.la-tools-service.com/en/news/was-ist-vollhartmetall-und-welche-eigenschaften-hat-es

[36] https://www.tungco.com/insights/blog/5-tungsten-carbide-applications/

[37] https://www.barnesandnoble.com/w/carbides-t-y-kosolapova/1117269705

[38] https://www.azom.com/properties.aspx?ArticleID=1203

[39] https://www.greenearthchem.com/important-carbide-chemicals-industrial-application.html

[40] https://www.abebooks.com/9781468480085/Carbides-Properties-Production-Applications-Kosolapova-1468480081/plp

[41] https://www.sciencedirect.com/topics/materials-science/carbide

[42] https://stock.adobe.com/search?k=carbide

[43] https://www.istockphoto.com/photos/carbide

[44] https://stock.adobe.com/search?k=%22calcium+carbide%22

[45] https://www.istockphoto.com/photos/tungsten-carbide

[46] https://www.everloy-cemented-carbide.com/en/process

[47] https://www.shutterstock.com/search/cemented-carbide

[48] https://www.shutterstock.com/search/production-carbide?image_type=photo&page=2

[49] https://stock.adobe.com/search?k=tungsten+carbide

[50] https://www.istockphoto.com/photos/cemented-carbide

[51] https://stock.adobe.com/search/images?k=carbide+cutting

[52] https://www.britannica.com/science/carbide

[53] https://www.tjtywh.com/a-the-role-of-calcium-carbide-in-industrial-processes-and-applications.html

[54] https://www.mmc-carbide.com/us/technical_information/tec_guide/tec_guide_carbide

[55] https://www.youtube.com/watch?v=L7nxS4AjRws

[56] https://precision-ceramics.com/materials/boron-carbide/

[57] https://www.alamy.com/stock-photo/tungsten-carbide.html

[58] https://www.youtube.com/watch?v=0QwfBueMjY4