Content Menu

● Introduction

● Understanding Tungsten Carbide

>> Tungsten Carbide Properties

>> Tungsten Carbide Structure

● Welding Methods for Tungsten Carbide

>> 1. Inertial Welding

>> 2. Induction Welding

>> 3. Laser Welding

>> 4. MIG Welding with Tungsten Carbide Feeders

● Considerations When Welding Tungsten Carbide

>> Surface Preparation

>> Heat Management

>> Material Compatibility

● Applications of Welded Tungsten Carbide

>> Cutting Tools

>> Mining Equipment

>> Manufacturing Components

>> Oil and Gas Industry

>> Aerospace Industry

● Challenges in Welding Tungsten Carbide

>> Brittleness Concerns

>> Equipment Limitations

>> Skill Level Required

● Future Trends in Tungsten Carbide Welding Technology

>> Automation of Welding Processes

>> Development of New Alloys

>> Enhanced Monitoring Techniques

● Conclusion

● FAQ

>> 1. Can you weld tungsten carbide directly to steel?

>> 2. What are the advantages of using inertial welding for tungsten carbide?

>> 3. Is it necessary to prepare the surface before welding tungsten carbide?

>> 4. What applications benefit from welded tungsten carbide?

>> 5. How does laser welding differ from other methods for tungsten carbide?

● Citations:

Introduction

Welding tungsten carbide is a specialized process that involves joining tungsten carbide materials to other substrates, typically steel. Tungsten carbide, known for its exceptional hardness and wear resistance, is widely used in various industrial applications, including cutting tools, mining equipment, and wear parts. However, the challenge lies in effectively welding this material due to its brittle nature and high melting point. This article explores the methods, techniques, and considerations involved in welding tungsten carbide.

Understanding Tungsten Carbide

Tungsten Carbide Properties

Tungsten carbide (WC) is a compound made from tungsten and carbon atoms. It is renowned for its hardness (approximately 9 on the Mohs scale), making it one of the hardest materials available. Its properties include:

- High Wear Resistance: Tungsten carbide can withstand significant wear and tear, making it ideal for cutting tools and industrial applications.

- Brittleness: Despite its hardness, tungsten carbide is brittle and can fracture under stress.

- High Melting Point: The melting point of tungsten carbide is around 2,600°C (4,700°F), complicating welding processes.

- Chemical Stability: Tungsten carbide exhibits excellent resistance to chemical corrosion, making it suitable for harsh environments.

Tungsten Carbide Structure

Tungsten carbide has a unique crystalline structure that contributes to its hardness and wear resistance. The material typically exists in two forms: hexagonal (WC) and cubic (W2C). The hexagonal form is more common in industrial applications due to its superior hardness characteristics.

Welding Methods for Tungsten Carbide

Welding tungsten carbide requires specialized techniques due to its unique properties. Here are the most common methods:

1. Inertial Welding

Inertial welding is a solid-state welding process that uses kinetic energy to generate heat at the weld interface. This method is particularly effective for joining tungsten carbide to steel.

Process Overview:

- Two workpieces are clamped in a machine.

- One piece (typically steel) is rotated at high speed.

- The other piece (tungsten carbide) is brought into contact with the rotating piece.

- Friction generates heat, allowing the materials to bond without melting.

Advantages of Inertial Welding:

- No Melting: Since the process does not involve melting the tungsten carbide, it prevents the formation of brittle phases that can occur during traditional welding.

- Strong Joints: The mechanical interlocking created during the process leads to strong joints capable of withstanding high stresses.

2. Induction Welding

Induction welding utilizes electromagnetic induction to heat the tungsten carbide and steel surfaces.

Benefits:

- Localized Heating: Induction welding provides localized heating, which reduces distortion and minimizes the heat-affected zone (HAZ).

- Versatility: This method can be adapted for various geometries and sizes of components.

Process Steps:

1. The components are positioned close together.

2. An induction coil generates an electromagnetic field that induces current in the workpieces.

3. The generated heat melts the interface, allowing for bonding.

3. Laser Welding

Laser welding employs a focused beam of light to melt the surfaces of tungsten carbide and steel.

Benefits:

- Precision: Laser welding offers high precision and control over heat input, which is critical when working with brittle materials like tungsten carbide.

- Minimal Distortion: Due to its rapid heating and cooling rates, laser welding minimizes thermal distortion in adjacent areas.

Process Overview:

1. A laser beam is directed onto the joint area.

2. The intense heat generated melts the surfaces.

3. As the laser moves along the joint line, it creates a fusion bond as it cools.

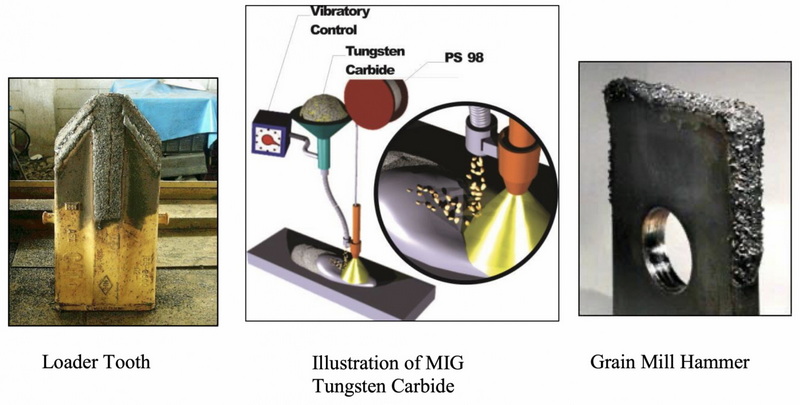

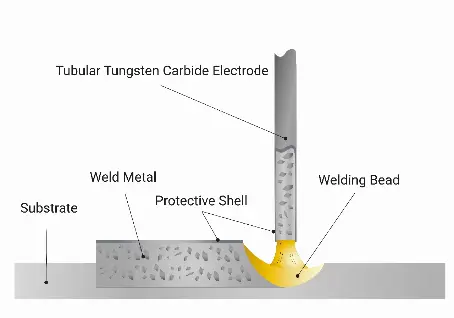

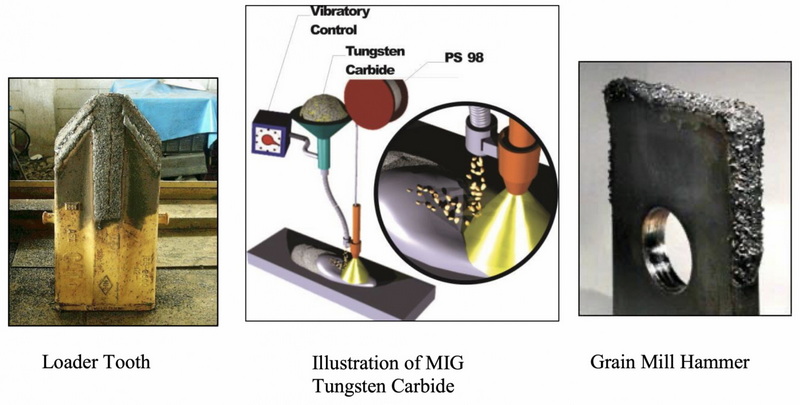

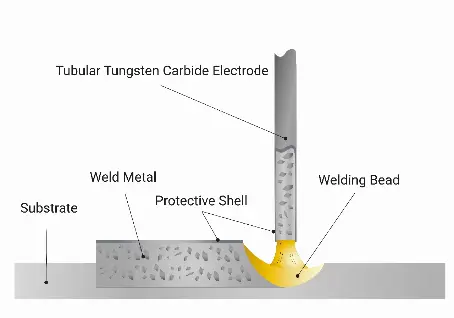

4. MIG Welding with Tungsten Carbide Feeders

Metal Inert Gas (MIG) welding can also be adapted for tungsten carbide applications by using specialized feeders that deliver tungsten carbide particles into the weld pool.

Equipment Required:

- MIG welder

- Tungsten carbide feeder system

- Appropriate shielding gas (usually argon or a mixture)

Advantages:

- Cost-Effective: MIG welding is generally more cost-effective than other methods while still providing good results when properly executed.

- Ease of Use: MIG welding equipment is widely available and relatively easy to operate compared to more complex systems.

Considerations When Welding Tungsten Carbide

When welding tungsten carbide, several factors must be considered to ensure successful bonding:

Surface Preparation

Proper surface preparation is crucial for achieving strong welds. Surfaces should be cleaned of contaminants such as rust, oil, or dirt. Techniques include:

- Mechanical Cleaning: Using grinders or sandblasters to remove surface impurities.

- Chemical Cleaning: Applying solvents or acid washes to eliminate oils or other residues.

Heat Management

Controlling heat input is essential to prevent overheating and cracking. Techniques such as preheating or using controlled cooling can help manage thermal effects.

Preheating:

Preheating involves warming up the base materials before welding to reduce thermal shock during the process. This technique helps in minimizing brittleness in tungsten carbide.

Material Compatibility

Ensure that the base materials are compatible with tungsten carbide. Using alloys with cobalt can enhance bonding strength. Cobalt acts as a binder in many tungsten carbide applications, improving toughness while maintaining hardness.

Applications of Welded Tungsten Carbide

Welded tungsten carbide has various applications across industries:

Cutting Tools

Welded tungsten carbide is extensively used in manufacturing cutting tools such as saw blades, drill bits, and milling cutters due to its exceptional hardness and wear resistance.

Mining Equipment

In mining operations, welded tungsten carbide components are utilized in excavators, drills, and other machinery that require high durability against abrasive materials.

Manufacturing Components

Welded tungsten carbide finds application in parts that require high durability against abrasion, such as nozzles in spray equipment or wear plates in conveyor systems.

Oil and Gas Industry

In oil drilling operations, welded tungsten carbide tools are employed for their ability to withstand extreme conditions while maintaining performance efficiency.

Aerospace Industry

The aerospace sector utilizes welded tungsten carbide components in applications where lightweight yet durable materials are essential for performance optimization.

Challenges in Welding Tungsten Carbide

While there are effective methods for welding tungsten carbide, several challenges persist:

Brittleness Concerns

The inherent brittleness of tungsten carbide means that improper welding techniques can lead to cracks or failures at the joint interface. It's crucial to select appropriate methods that minimize stress concentrations during fabrication.

Equipment Limitations

Specialized equipment may be required for certain welding processes like laser or inertial welding. This can lead to increased costs and longer lead times for production compared to conventional welding techniques.

Skill Level Required

Welding tungsten carbide requires skilled operators familiar with advanced techniques and equipment settings. Training may be necessary to ensure quality outcomes consistently.

Future Trends in Tungsten Carbide Welding Technology

As technology advances, several trends are emerging in the field of tungsten carbide welding:

Automation of Welding Processes

Automation is becoming increasingly prevalent in industrial settings. Automated systems can enhance precision and repeatability while reducing human error during the welding process.

Development of New Alloys

Research into new alloy compositions may yield improved bonding characteristics when joining tungsten carbide with other metals, leading to enhanced performance in demanding applications.

Enhanced Monitoring Techniques

The integration of advanced monitoring technologies during the welding process allows real-time assessment of parameters such as temperature and pressure, ensuring optimal conditions throughout fabrication.

Conclusion

Welding tungsten carbide presents unique challenges due to its hardness and brittleness; however, with appropriate techniques such as inertial welding, induction welding, laser welding, and MIG welding with specialized feeders, it is possible to achieve strong bonds between tungsten carbide and other materials. Proper surface preparation, heat management, and material compatibility are vital for successful outcomes in this specialized field. As industries continue to evolve and demand more durable materials capable of withstanding extreme conditions, mastering these advanced welding techniques will be essential for manufacturers aiming for excellence in performance and longevity.

FAQ

1. Can you weld tungsten carbide directly to steel?

Yes, you can weld tungsten carbide directly to steel using methods like inertial welding or MIG welding with specialized feeders designed for this purpose.

2. What are the advantages of using inertial welding for tungsten carbide?

Inertial welding allows for solid-state bonding without melting the materials involved; this minimizes thermal distortion while providing strong joints capable of withstanding high stresses.

3. Is it necessary to prepare the surface before welding tungsten carbide?

Yes! Surface preparation is crucial as it removes contaminants that could weaken the weld joint; mechanical cleaning or chemical cleaning methods are commonly employed before starting any weld operation on tungsten carbide components.

4. What applications benefit from welded tungsten carbide?

Welded tungsten carbide finds extensive use across various sectors including cutting tools manufacturing (like saw blades), mining equipment (for excavators), manufacturing components requiring high durability against abrasion (like nozzles), oil drilling operations (due to extreme conditions), aerospace industry applications needing lightweight yet durable solutions among others!

5. How does laser welding differ from other methods for tungsten carbide?

Laser welding provides precise control over heat input compared to traditional methods; this precision minimizes thermal distortion significantly while allowing intricate designs—making it ideal when working with brittle materials like Tungsten Carbide!

Citations:

[1] https://patents.google.com/patent/US3497942A/en

[2] https://www.hardfacetechnologies.com/products/mig-tungsten-carbide-feeder

[3] https://carbideprocessors.com/pages/brazing-carbide/welding-tungsten-carbide.html

[4] https://www.metalspraysupplies.com/metal-spray-thermal-spray-equipment/spray-weld-equipment/tungsten-feeder?showall=1

[5] https://lineagemet.com/welding/

[6] https://www.weldingandwelder.com/category/welding-consumables/mma-arc-welding-supplies/mma-stick-electrodes/tungsten-carbide-welding-electrodes/

[7] https://hup-pietz.de/en/beschichtungen/wolfram-karbid-schweissung/

[8] https://www.alibaba.com/showroom/carbide-welding-machine.html