Content Menu

● Introduction

● What is Silicon Carbide?

● Key Benefits of Silicon Carbide Sandpaper Rolls

>> Versatility

>> Durability

>> Fine Finish

>> Wet and Dry Use

● Choosing the Right Grit Size

>> Fine Grit

>> Medium Grit

>> Coarse Grit

● Tips for Effective Wet Sanding with Silicon Carbide Sandpaper Rolls

>> Use Plenty of Water

>> Keep the Surface Clean

>> Sand in a Circular Motion

>> Change Sandpaper Regularly

>> Rinse the Surface Frequently

● Conclusion

● Related Questions

>> 1. What materials can I use silicon carbide sandpaper rolls on?

>> 2. How do I know which grit size to choose for my project?

>> 3. Can I use silicon carbide sandpaper rolls for dry sanding?

>> 4. How often should I change my sandpaper when wet sanding?

>> 5. What is the advantage of wet sanding over dry sanding?

Introduction

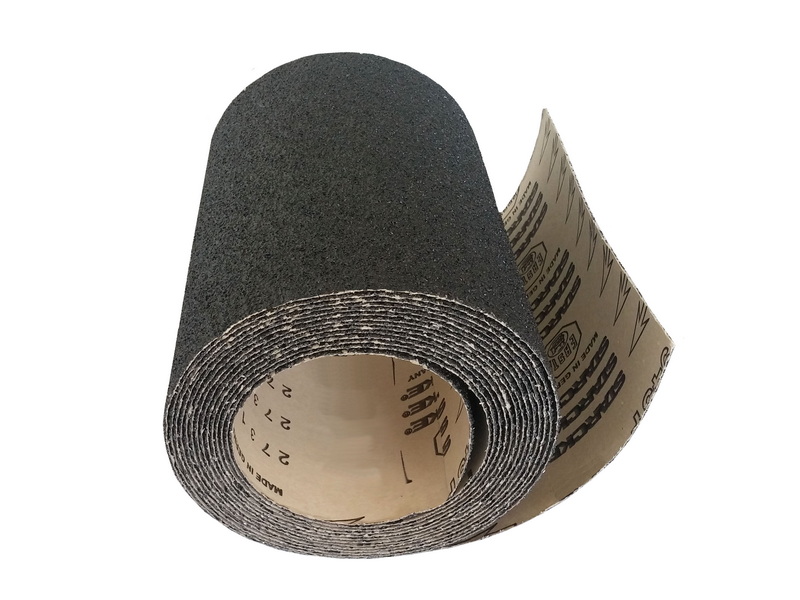

Silicon carbide sandpaper rolls are a popular choice among professionals and DIY enthusiasts alike due to their versatility and effectiveness. These rolls are made from silicon carbide, a synthetic abrasive that is known for its sharpness and durability. One of the most significant advantages of silicon carbide sandpaper rolls is their ability to be used for wet sanding, a technique that can enhance the finish of various materials. In this article, we will explore the benefits of using silicon carbide sandpaper rolls for wet sanding, how to choose the right grit size, and tips for effective use.

What is Silicon Carbide?

Silicon carbide (SiC) is a compound made of silicon and carbon. It is known for its hardness and thermal conductivity, making it an ideal material for abrasives. Unlike aluminum oxide, which is commonly used in sandpaper, silicon carbide is sharper and more brittle. This characteristic allows it to cut through materials more effectively, producing a finer finish. Silicon carbide sandpaper rolls are particularly effective for sanding hard materials such as glass, ceramics, and metals, as well as softer materials like wood and plastic.

Key Benefits of Silicon Carbide Sandpaper Rolls

Versatility

One of the primary benefits of silicon carbide sandpaper rolls is their versatility. They can be used on a wide range of materials, including wood, metal, plastic, and even glass. This makes them an excellent choice for various projects, from woodworking to automotive refinishing. The ability to use the same type of sandpaper for different materials simplifies the sanding process and reduces the need for multiple products.

Durability

Silicon carbide sandpaper rolls are known for their durability. The abrasive particles are tightly bonded to the backing material, allowing them to withstand heavy use without breaking down quickly. This durability means that users can complete more sanding tasks with a single roll, making it a cost-effective option in the long run. Additionally, silicon carbide is resistant to heat, which helps maintain its cutting ability even during extended use.

Fine Finish

When it comes to achieving a smooth surface finish, silicon carbide sandpaper rolls excel. The sharpness of the silicon carbide particles allows for a finer cut, resulting in a smoother surface compared to other types of sandpaper. This is particularly important in applications where a high-quality finish is required, such as in automotive painting or fine woodworking. The ability to achieve a fine finish makes silicon carbide sandpaper rolls a preferred choice for professionals who demand the best results.

Wet and Dry Use

One of the standout features of silicon carbide sandpaper rolls is their ability to be used for wet sanding. Wet sanding involves using water or another lubricant during the sanding process, which helps to reduce dust and prevent clogging of the sandpaper. This technique is especially beneficial when working with softer materials, as it minimizes the risk of scratching or damaging the surface. Wet sanding also helps to achieve a smoother finish by allowing the abrasive particles to glide over the surface more easily.

Choosing the Right Grit Size

When selecting a silicon carbide sandpaper roll for wet sanding, it is essential to choose the right grit size for your project. Grit size refers to the size of the abrasive particles on the sandpaper, and it plays a crucial role in determining the finish of the material being sanded.

Fine Grit

Fine grit sandpaper rolls, typically ranging from 400 to 600 grit, are ideal for finishing work. They are perfect for smoothing surfaces and preparing them for painting or sealing. Fine grit is often used in the final stages of sanding to achieve a polished look.

Medium Grit

Medium grit sandpaper rolls, usually between 220 and 400 grit, are suitable for general sanding tasks. They can effectively remove material while still providing a relatively smooth finish. Medium grit is often used for initial sanding of surfaces that require significant material removal.

Coarse Grit

Coarse grit sandpaper rolls, ranging from 60 to 120 grit, are designed for heavy material removal. They are ideal for shaping and leveling surfaces before moving on to finer grits. Coarse grit is typically used in the early stages of sanding when working with rough materials or when significant surface imperfections need to be addressed.

Tips for Effective Wet Sanding with Silicon Carbide Sandpaper Rolls

To achieve the best results when wet sanding with silicon carbide sandpaper rolls, consider the following tips:

Use Plenty of Water

When wet sanding, it is crucial to use an adequate amount of water to lubricate the surface. This helps to reduce friction and prevents the sandpaper from clogging. A spray bottle can be an effective tool for applying water evenly to the surface being sanded.

Keep the Surface Clean

Before starting the wet sanding process, ensure that the surface is clean and free of debris. Any dirt or dust can scratch the surface and compromise the finish. Wipe down the area with a damp cloth to remove any contaminants before sanding.

Sand in a Circular Motion

When using silicon carbide sandpaper rolls for wet sanding, it is best to sand in a circular motion. This technique helps to distribute the pressure evenly across the surface and reduces the risk of creating flat spots or uneven areas.

Change Sandpaper Regularly

As the sandpaper becomes worn or clogged, it is essential to change it regularly to maintain optimal performance. Using worn sandpaper can lead to poor results and may require additional sanding to achieve the desired finish.

Rinse the Surface Frequently

During the wet sanding process, rinse the surface frequently to remove any debris and excess abrasive particles. This helps to keep the surface clean and allows for a smoother sanding experience.

Conclusion

Silicon carbide sandpaper rolls are an excellent choice for wet sanding due to their versatility, durability, and ability to produce a fine finish. Whether you are working on wood, metal, or plastic, these rolls can help you achieve the desired results. By choosing the right grit size and following effective wet sanding techniques, you can enhance the quality of your projects and ensure a professional finish.

Related Questions

1. What materials can I use silicon carbide sandpaper rolls on?

Silicon carbide sandpaper rolls can be used on a variety of materials, including wood, metal, plastic, and glass.

2. How do I know which grit size to choose for my project?

Choose fine grit (400-600) for finishing, medium grit (220-400) for general sanding, and coarse grit (60-120) for heavy material removal.

3. Can I use silicon carbide sandpaper rolls for dry sanding?

Yes, silicon carbide sandpaper rolls can be used for both wet and dry sanding applications.

4. How often should I change my sandpaper when wet sanding?

Change your sandpaper regularly, especially when it becomes worn or clogged, to maintain optimal performance and achieve the best results.

5. What is the advantage of wet sanding over dry sanding?

Wet sanding reduces dust, prevents clogging of the sandpaper, and helps achieve a smoother finish by allowing the abrasive particles to glide over the surface more easily.