Content Menu

● Introduction

● What Are Large Tungsten Carbide Balls?

>> Properties of Large Tungsten Carbide Balls

● Applications of Large Tungsten Carbide Balls

>> 1. Aerospace Industry

>> 2. Automotive Manufacturing

>> 3. Mining Operations

>> 4. Oil and Gas Industry

● Advantages of Investing in Large Tungsten Carbide Balls

>> 1. Enhanced Durability

>> 2. Improved Performance

>> 3. Cost-Effectiveness

>> 4. Versatility

● Considerations When Choosing Large Tungsten Carbide Balls

>> 1. Cost vs. Benefit Analysis

>> 2. Sourcing Quality Products

>> 3. Application-Specific Requirements

● Conclusion

● Related Questions

>> 1. What industries primarily use large tungsten carbide balls?

>> 2. How do I choose the right size of large tungsten carbide ball for my application?

>> 3. Are there alternatives to large tungsten carbide balls?

>> 4. What is the typical lifespan of large tungsten carbide balls?

>> 5. Can large tungsten carbide balls be recycled?

Introduction

In the realm of industrial manufacturing and engineering, the choice of materials can significantly impact the performance, durability, and overall efficiency of machinery and components. Among the various materials available, large tungsten carbide balls have emerged as a preferred option for many applications due to their exceptional hardness, wear resistance, and versatility. This article delves into the benefits of investing in large tungsten carbide balls, exploring their applications, advantages, and considerations for businesses.

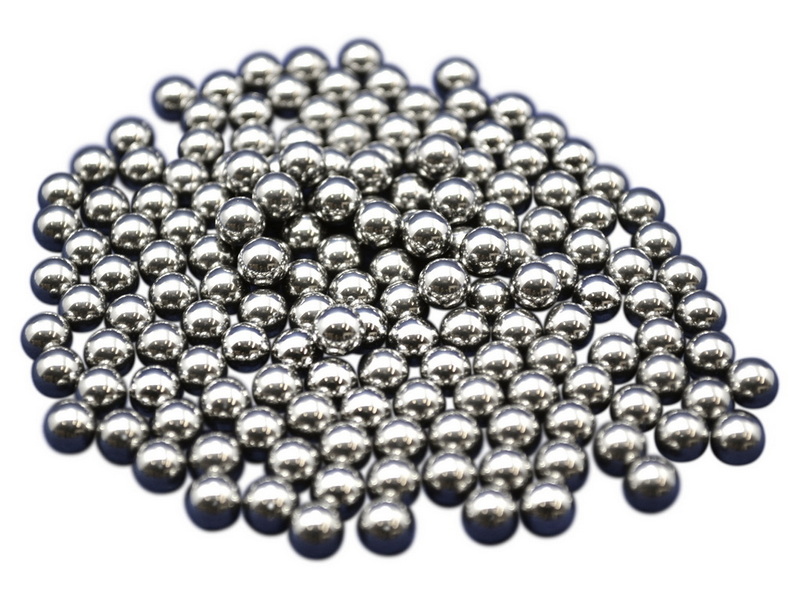

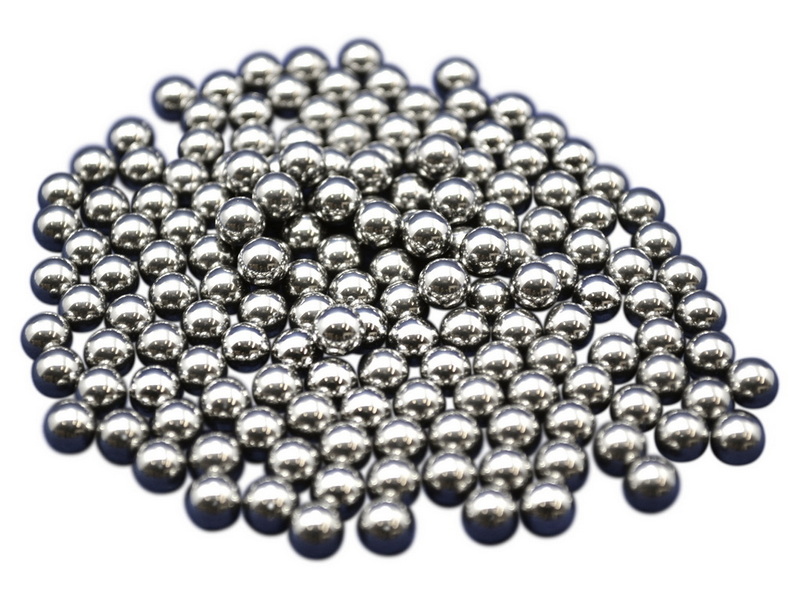

What Are Large Tungsten Carbide Balls?

Large tungsten carbide balls are spherical components made from tungsten carbide, a composite material consisting of tungsten and carbon. Known for their remarkable hardness—second only to diamonds—these balls are utilized in various industries, including aerospace, automotive, mining, and manufacturing.

Properties of Large Tungsten Carbide Balls

- Hardness: The hardness of tungsten carbide is one of its most significant attributes. It allows large tungsten carbide balls to withstand high levels of wear and tear.

- Toughness: Despite their hardness, these balls exhibit excellent toughness, which helps them resist chipping and breaking under stress.

- Corrosion Resistance: Tungsten carbide is inherently resistant to corrosion, making it suitable for use in harsh environments.

- Thermal Stability: Large tungsten carbide balls maintain their properties even at elevated temperatures, ensuring consistent performance.

Applications of Large Tungsten Carbide Balls

Large tungsten carbide balls are employed across various sectors due to their unique properties. Here are some notable applications:

1. Aerospace Industry

In aerospace applications, large tungsten carbide balls are used in bearings and valve components where high precision and reliability are crucial. Their ability to withstand extreme conditions makes them ideal for aircraft engines and landing gear systems.

2. Automotive Manufacturing

The automotive industry utilizes large tungsten carbide balls in various components such as bearings, valves, and pumps. Their durability ensures that vehicles operate smoothly over extended periods without frequent maintenance.

3. Mining Operations

In mining operations, large tungsten carbide balls are used in grinding mills and crushers. Their hardness allows them to break down tough materials efficiently while minimizing wear on machinery.

4. Oil and Gas Industry

The oil and gas sector benefits from large tungsten carbide balls in drilling equipment and downhole tools. Their resistance to abrasion and corrosion enhances the longevity of these critical components.

Advantages of Investing in Large Tungsten Carbide Balls

Investing in large tungsten carbide balls can yield numerous benefits for businesses:

1. Enhanced Durability

The exceptional hardness of large tungsten carbide balls translates into longer service life for machinery and components. This durability reduces downtime and maintenance costs over time.

2. Improved Performance

With their ability to withstand high loads and resist wear, large tungsten carbide balls contribute to improved performance in various applications. This enhancement can lead to increased productivity and efficiency.

3. Cost-Effectiveness

While the initial investment in large tungsten carbide balls may be higher than alternative materials, their longevity and reduced maintenance needs often result in lower overall costs for businesses.

4. Versatility

Large tungsten carbide balls can be customized for specific applications, making them suitable for a wide range of industries. This versatility allows businesses to tailor solutions to meet their unique needs.

Considerations When Choosing Large Tungsten Carbide Balls

While there are many advantages to using large tungsten carbide balls, businesses should consider several factors when making their investment:

1. Cost vs. Benefit Analysis

Conducting a thorough cost-benefit analysis is essential before investing in large tungsten carbide balls. While they may have a higher upfront cost, evaluating potential savings on maintenance and replacement can provide clarity on their value.

2. Sourcing Quality Products

Not all suppliers offer the same quality when it comes to large tungsten carbide balls. It's crucial to source from reputable manufacturers who adhere to strict quality control standards.

3. Application-Specific Requirements

Different applications may require specific grades or sizes of large tungsten carbide balls. Understanding these requirements will ensure optimal performance.

Conclusion

In conclusion, large tungsten carbide balls represent a valuable investment for businesses across various industries. Their unmatched hardness, durability, and versatility make them an ideal choice for critical applications where performance is paramount. By understanding the benefits and considerations associated with these components, businesses can make informed decisions that enhance operational efficiency and reduce long-term costs.

Related Questions

1. What industries primarily use large tungsten carbide balls?

Large tungsten carbide balls are commonly used in aerospace, automotive manufacturing, mining operations, and the oil and gas industry due to their durability and performance characteristics.

2. How do I choose the right size of large tungsten carbide ball for my application?

Choosing the right size involves understanding your specific application requirements, including load capacity, space constraints, and compatibility with other components.

3. Are there alternatives to large tungsten carbide balls?

Yes, alternatives include steel or ceramic balls; however, they may not offer the same level of hardness or wear resistance as tungsten carbide.

4. What is the typical lifespan of large tungsten carbide balls?

The lifespan varies based on application conditions but can significantly exceed that of traditional materials due to their superior wear resistance.

5. Can large tungsten carbide balls be recycled?

Yes, large tungsten carbide balls can be recycled; however, it requires specialized processes due to the material's composition.