Content Menu

● Understanding the Touch Plate

● Key Features to Look For

● Setting Up Your Touch Plate

● Maintenance Tips

● Common Issues and Troubleshooting

● Benefits of Using a Touch Plate

● Choosing the Right Touch Plate

● Conclusion

● Frequently Asked Questions

>> 1. What is a touch plate used for?

>> 2. How do I know if a touch plate is compatible with my CNC machine?

>> 3. Can I use a touch plate with any CNC software?

>> 4. What should I do if my touch plate is not working?

>> 5. How often should I clean my touch plate?

When it comes to CNC machining, precision is paramount. One of the essential tools that can help achieve this precision is a touch plate, specifically designed for machines like the Carbide 3D Shapeoko. If you're considering purchasing a Carbide 3D touch plate, there are several factors to consider to ensure you make an informed decision. This article will delve into the key aspects you should know before making your purchase, including functionality, compatibility, setup, and maintenance.

Understanding the Touch Plate

A touch plate is a device used to establish a reference point for your CNC machine. It allows the machine to accurately determine the position of the tool relative to the workpiece. This is crucial for ensuring that cuts are made at the correct depth and position, which can significantly affect the quality of the finished product.

Key Features to Look For

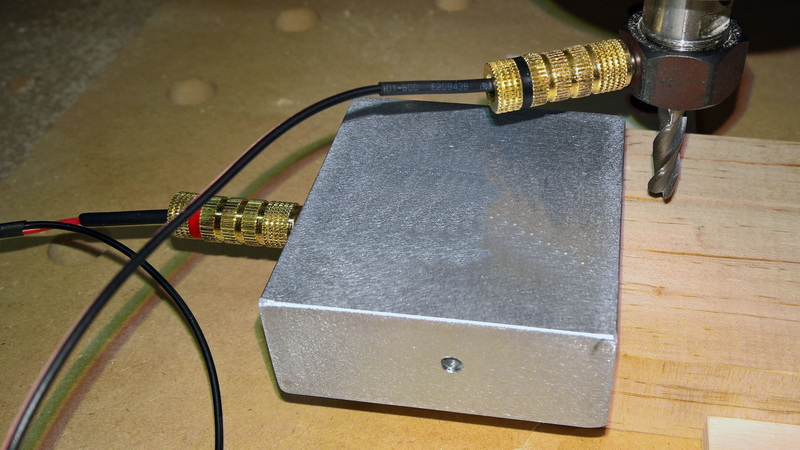

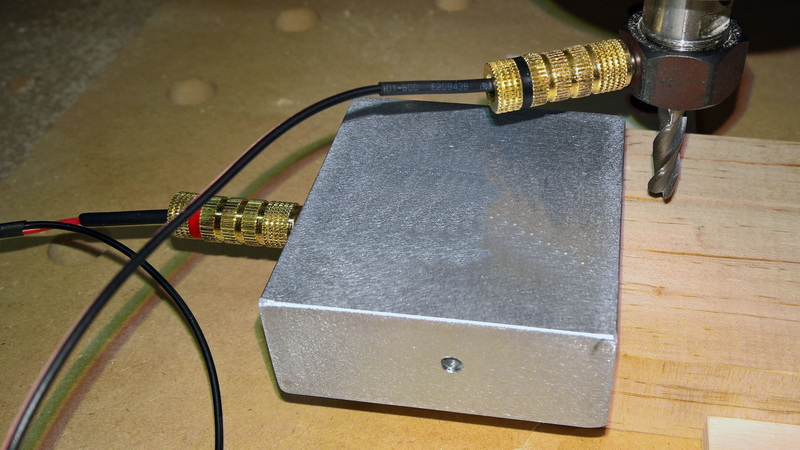

1. Material Quality: The touch plate should be made from durable materials that can withstand repeated use. Look for plates made from aluminum or other robust metals that resist wear and tear.

2. Size and Design: The size of the touch plate should be compatible with your CNC machine. A larger plate may offer more versatility, but it should still fit comfortably within the working area of your machine.

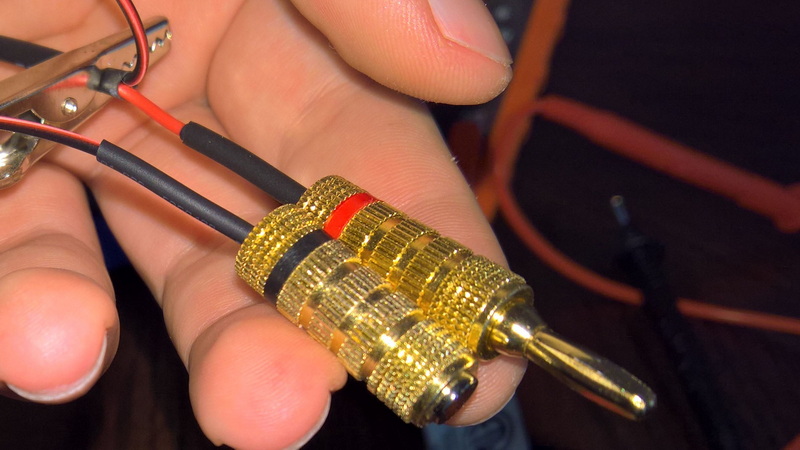

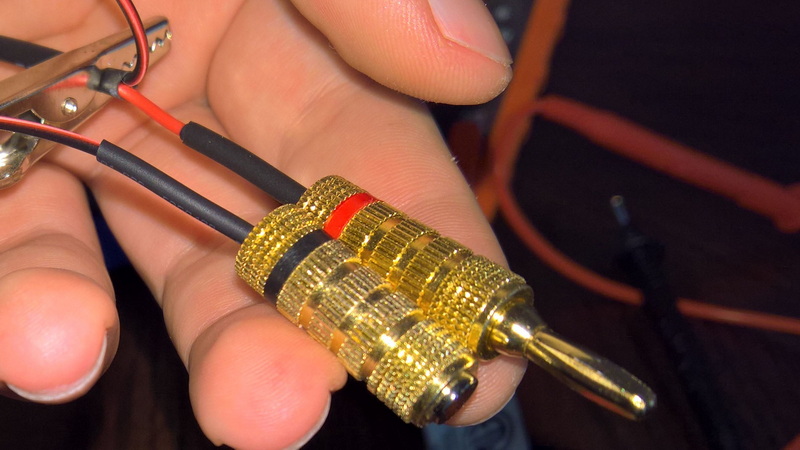

3. Electrical Components: Ensure that the touch plate has reliable electrical components. A good touch plate will have a clear LED indicator that shows when the probe is in contact with the workpiece, preventing potential damage to the tool.

4. Ease of Use: The setup process should be straightforward. Look for touch plates that come with clear instructions and are easy to connect to your CNC machine.

5. Compatibility: Make sure the touch plate is compatible with your specific model of the Carbide 3D machine. Some touch plates are designed for specific models, while others may be more universal.

Setting Up Your Touch Plate

Setting up a touch plate is generally a simple process, but it requires careful attention to detail. Here's a step-by-step guide to help you get started:

1. Connect the Wires: Most touch plates will have two wires: one for the plate itself and one for the tool. Connect these according to the manufacturer's instructions.

2. Position the Plate: Place the touch plate on your work surface where you intend to start your machining process. Ensure it is stable and won't move during operation.

3. Configure Your CNC Software: Open your CNC software and configure it to recognize the touch plate. This usually involves setting up the G-code commands that will instruct the machine to use the touch plate for zeroing.

4. Test the Setup: Before running a full job, perform a test run to ensure that the touch plate is functioning correctly. Check that the machine accurately detects the plate and zeros out the axes.

Maintenance Tips

To ensure longevity and accuracy, regular maintenance of your touch plate is essential:

- Clean Regularly: Dust and debris can affect the accuracy of the touch plate. Clean it regularly with a soft cloth to remove any particles.

- Check Connections: Periodically inspect the electrical connections for wear or damage. Replace any frayed wires to prevent malfunction.

- Store Properly: When not in use, store the touch plate in a safe place to prevent physical damage.

Common Issues and Troubleshooting

Even with proper care, you may encounter issues with your touch plate. Here are some common problems and their solutions:

- No LED Indicator: If the LED does not light up when the tool touches the plate, check the connections and ensure that the wires are securely attached.

- Inaccurate Readings: If the machine is not zeroing correctly, ensure that the touch plate is clean and free from debris. Also, verify that the G-code settings are correct.

- Physical Damage: If the touch plate is dented or scratched, it may affect its performance. Inspect it regularly and replace it if necessary.

Benefits of Using a Touch Plate

Using a touch plate offers several advantages that can enhance your CNC machining experience:

- Increased Accuracy: By providing a reliable reference point, touch plates help ensure that your cuts are precise, reducing the likelihood of errors.

- Time Efficiency: Setting up your machine with a touch plate can save time compared to manual zeroing methods, allowing you to focus on your projects.

- Reduced Wear on Tools: Accurate zeroing can help prevent tools from crashing into the workpiece, which can lead to damage and increased wear.

- Versatility: Many touch plates can be used with various materials and setups, making them a versatile addition to your CNC toolkit.

Choosing the Right Touch Plate

When selecting a touch plate, consider your specific needs and the types of projects you typically undertake. Here are some factors to keep in mind:

- Project Types: If you work with a variety of materials, look for a touch plate that can handle different thicknesses and densities.

- Budget: Touch plates come in a range of prices. Determine your budget and look for a quality product that fits within it.

- User Reviews: Research user reviews and testimonials to gauge the performance and reliability of different touch plates.

- Manufacturer Support: Consider purchasing from a manufacturer that offers good customer support and warranty options, as this can be invaluable if you encounter issues.

Conclusion

Purchasing a Carbide 3D touch plate can significantly enhance your CNC machining capabilities. By understanding the key features, setup process, and maintenance requirements, you can ensure that you select the right touch plate for your needs. Remember to consider compatibility with your machine, the quality of materials, and ease of use when making your decision.

Frequently Asked Questions

1. What is a touch plate used for?

A touch plate is used to establish a reference point for CNC machines, allowing for accurate positioning of tools relative to the workpiece.

2. How do I know if a touch plate is compatible with my CNC machine?

Check the manufacturer's specifications and ensure that the touch plate is designed for your specific model of CNC machine.

3. Can I use a touch plate with any CNC software?

Most touch plates are compatible with popular CNC software, but it's essential to verify compatibility with your specific software.

4. What should I do if my touch plate is not working?

Check the electrical connections, clean the plate, and ensure that the G-code settings are correct. If issues persist, consult the manufacturer.

5. How often should I clean my touch plate?

It's advisable to clean your touch plate after every use to ensure optimal performance and accuracy.