Content Menu

● Introduction to Tungsten Carbide

● Benefits of Tungsten Carbide Saw Tips

>> 1. Extreme Hardness

>> 2. Wear Resistance

>> 3. Heat Resistance

>> 4. High Cutting Speeds

>> 5. Precision and Accuracy

>> 6. Reduced Maintenance

>> 7. Versatility

● Applications of Tungsten Carbide Saw Tips

● Maintenance Tips for Tungsten Carbide Saw Tips

● Conclusion

● Frequently Asked Questions

>> 1. What are tungsten carbide saw tips made of?

>> 2. How long do tungsten carbide saw tips last?

>> 3. Can tungsten carbide saw tips be sharpened?

>> 4. Are tungsten carbide saw tips suitable for all materials?

>> 5. What maintenance do tungsten carbide saw tips require?

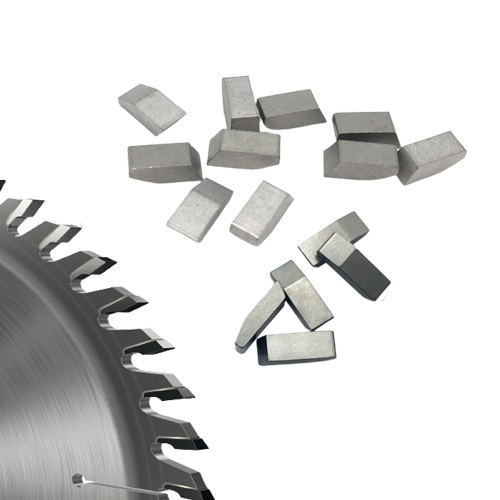

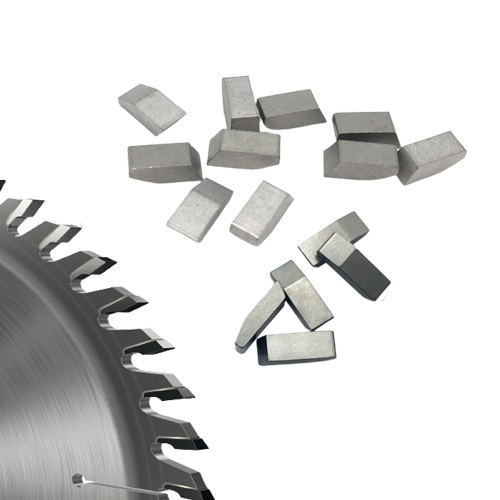

Tungsten carbide saw tips are increasingly becoming the preferred choice for various cutting applications due to their exceptional properties. This article delves into why tungsten carbide is considered the best material for saw tips, exploring its benefits, applications, and maintenance tips to maximize performance.

Introduction to Tungsten Carbide

Tungsten carbide is a composite material made from tungsten and carbon. It is known for its extreme hardness and durability, making it an ideal choice for cutting tools. The manufacturing process involves mixing tungsten powder with carbon at high temperatures, resulting in a material that is harder than most steels.

Benefits of Tungsten Carbide Saw Tips

1. Extreme Hardness

One of the most significant advantages of tungsten carbide saw tips is their hardness. On the Rockwell scale, tungsten carbide rates between 89 and 93, compared to tool steel, which typically rates between 60 and 65. This hardness allows tungsten carbide saw tips to maintain sharp cutting edges for longer periods, resulting in fewer interruptions for sharpening or replacing blades.

2. Wear Resistance

Tungsten carbide is highly resistant to wear and abrasion. This characteristic makes it suitable for cutting hard materials such as metals, plastics, and composites. Unlike traditional steel blades that can quickly dull when cutting abrasive materials, tungsten carbide saw tips retain their sharpness over extended use.

3. Heat Resistance

Cutting generates heat, which can lead to tool deformation and loss of cutting ability. Tungsten carbide can withstand high temperatures without losing its structural integrity or cutting performance. This property is particularly important in industrial applications where high-speed cutting generates significant heat.

4. High Cutting Speeds

The design of tungsten carbide saw tips allows for faster cutting speeds compared to traditional steel or high-speed steel (HSS) tools. This capability enhances productivity and efficiency in various applications, reducing overall project time.

5. Precision and Accuracy

Tungsten carbide saw tips are engineered to provide clean and precise cuts. Their ability to maintain a sharp edge ensures that cuts are accurate, which is crucial in industries like woodworking and metalworking where precision is paramount.

6. Reduced Maintenance

Due to their durability and wear resistance, tungsten carbide saw tips require less frequent maintenance than other types of saw tips. This reduction in maintenance translates into lower operational costs and less downtime.

7. Versatility

Tungsten carbide saw tips are versatile and can be used across various industries and applications, including woodworking, metalworking, construction, and more. They can effectively cut through a wide range of materials without needing multiple types of blades.

Applications of Tungsten Carbide Saw Tips

Tungsten carbide saw tips are utilized in numerous applications due to their superior properties:

- Woodworking: Used for cutting lumber, plywood, MDF, and making precision cuts in furniture.

- Metalworking: Ideal for cutting sheet metal, pipes, tubing, and making precise cuts in metal components.

- Construction: Effective in cutting concrete, brick, marble, drywall, and other building materials.

Maintenance Tips for Tungsten Carbide Saw Tips

To ensure the longevity and optimal performance of tungsten carbide saw tips, follow these maintenance guidelines:

1. Regular Inspection: Check for wear or damage regularly to ensure the tips remain effective.

2. Cleaning: Use a soft brush or compressed air to remove debris and resin buildup from the tips.

3. Lubrication: Lubricate the saw blade to reduce friction during use.

4. Sharpening: When dull, sharpen the tips with a diamond wheel.

5. Proper Storage: Store blades in a dry environment to prevent corrosion.

Conclusion

Tungsten carbide saw tips offer unparalleled advantages over traditional materials due to their hardness, wear resistance, heat resistance, precision, and versatility. These features make them an excellent choice for various cutting applications across multiple industries. By following proper maintenance practices, users can maximize the lifespan and effectiveness of their tungsten carbide saw tips.

Frequently Asked Questions

1. What are tungsten carbide saw tips made of?

Tungsten carbide saw tips are made from a composite of tungsten powder and carbon that is sintered at high temperatures.

2. How long do tungsten carbide saw tips last?

Tungsten carbide saw tips typically last significantly longer than steel blades due to their hardness and wear resistance.

3. Can tungsten carbide saw tips be sharpened?

Yes, tungsten carbide saw tips can be sharpened using specialized equipment such as diamond wheels.

4. Are tungsten carbide saw tips suitable for all materials?

While they are versatile and can cut many materials effectively, they are particularly suited for hard or abrasive materials like metals and concrete.

5. What maintenance do tungsten carbide saw tips require?

Maintenance includes regular inspection for wear, cleaning debris buildup, lubricating the blade, sharpening when dull, and proper storage.