Content Menu

● Introduction to Tungsten Carbide TC850

● The Science Behind TC850

>> What Is Tungsten Carbide?

>> TC850: The Patented Formula

● Key Properties and Advantages

>> Unmatched Hardness and Strength

>> Hypoallergenic and Tarnish Resistant

>> Luxurious Weight and Feel

>> Color Versatility

● Color Variations and Coating Technologies

>> Classic Gray and Natural Finish

>> White, Yellow, and Rose Finishes

>> Black Finish

>> Advanced Coating Technologies

● Applications in Jewelry and Beyond

>> Men's Wedding Bands

>> Luxury Watches and Accessories

>> Other Uses

● Care, Maintenance, and Longevity

>> Low Maintenance

>> Scratch Resistance

>> Resizing and Engraving

>> Lifetime Warranty

● Comparison: Tungsten Carbide TC850 vs Other Metals

● History and Development of Tungsten Carbide

● Manufacturing Process of TC850

● Environmental Impact and Sustainability

● Future Trends and Innovations

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What does TC850 mean in tungsten carbide jewelry?

>> 2. How scratch-resistant is tungsten carbide TC850?

>> 3. Can TC850 rings be resized or repaired?

>> 4. Is tungsten carbide TC850 safe for sensitive skin?

>> 5. What color options are available for TC850 rings?

Tungsten carbide TC850 is a revolutionary material that has transformed the world of jewelry, especially men's wedding bands, with its unique blend of strength, durability, and contemporary style. This comprehensive article explores what tungsten carbide TC850 is, its scientific background, key properties, manufacturing process, environmental impact, and future trends. Whether you are considering a tungsten carbide ring or are simply curious about this advanced material, this guide will answer your questions and provide visual insights into its features and applications.

Introduction to Tungsten Carbide TC850

Tungsten carbide TC850 is a patented alloy, primarily used in high-end jewelry, that consists of approximately 85% tungsten carbide. This composition yields a material that is exceptionally strong, scratch-resistant, hypoallergenic, and tarnish-resistant. The “TC850” designation refers to the specific formulation and quality standard, ensuring a product that balances hardness, durability, and aesthetic appeal.

The Science Behind TC850

What Is Tungsten Carbide?

Tungsten carbide is an inorganic chemical compound formed by combining tungsten and carbon atoms at extremely high temperatures. The result is a dense, hard material that exhibits remarkable resistance to wear and corrosion. In its pure form, tungsten carbide is a deep gray powder that can be pressed and sintered into solid shapes for industrial and decorative use.

TC850: The Patented Formula

The “TC850” in tungsten carbide TC850 stands for a patented blend containing about 85% tungsten carbide. The remaining 15% typically includes a non-leaching nickel binder and small amounts of chromium. This precise ratio is critical for achieving the best balance between hardness and toughness. The use of a nickel binder, rather than cobalt, enhances the hypoallergenic properties and reduces the risk of oxidation, ensuring the jewelry remains safe and lustrous over time.

Key Properties and Advantages

Unmatched Hardness and Strength

One of the most significant advantages of TC850 is its exceptional hardness. On the Mohs scale, which measures mineral hardness, tungsten carbide TC850 rates over 8.5. This makes it the hardest material available for wedding bands, second only to diamonds. In practical terms, TC850 is:

- 10 times harder than 18K gold

- 5 times harder than steel

- 4 times harder than titanium

This hardness ensures that TC850 rings are highly resistant to scratches, dents, and everyday wear.

Hypoallergenic and Tarnish Resistant

The use of a nickel binder in TC850 makes it hypoallergenic, suitable for individuals with sensitive skin. Additionally, the inclusion of chromium reduces oxidation, preventing tarnishing and maintaining the ring's brilliance.

Luxurious Weight and Feel

TC850 rings have a substantial, luxurious weight similar to platinum, providing a sense of quality and permanence. Many wearers appreciate the solid feel, which distinguishes TC850 from lighter metals like titanium or stainless steel.

Color Versatility

TC850 is available in a range of colors, including classic gray, white, black, yellow, and rose. These variations are achieved through advanced coating and bonding technologies, allowing for a wide array of styles and finishes.

Color Variations and Coating Technologies

Classic Gray and Natural Finish

The natural color of tungsten carbide is a deep, lustrous gray. TC850 enhances this with a patented formula, providing a rich, metallic sheen that remains vibrant over time.

White, Yellow, and Rose Finishes

- White TC850: Achieved through a multi-layered nano-technology coating applied via physical vapor deposition (PVD). This process enhances color, durability, and scratch resistance.

- Yellow & Rose TC850: Created by blending the base alloy with precious metals like yellow and rose gold, then sealing with a semi-translucent nano-technology coating for longevity and vibrancy.

Black Finish

Black TC850 rings feature a durable titanium carbide deposit, applied using the PVD process. This results in a rich, luxurious black color that is both stylish and highly resistant to wear.

Advanced Coating Technologies

TC850 utilizes exclusive, patented nano-technology coatings for all its color variants. These coatings not only enhance appearance but also provide extra protection against scratches, tarnish, and fading.

Applications in Jewelry and Beyond

Men's Wedding Bands

TC850 is most commonly found in men's wedding bands, prized for its durability and modern aesthetic. These rings are ideal for active lifestyles, as they resist scratches and maintain their finish through daily wear.

Luxury Watches and Accessories

The strength and scratch resistance of TC850 make it suitable for luxury watch cases, bracelets, and other accessories, where maintaining a pristine appearance is essential.

Other Uses

While jewelry is the primary market, tungsten carbide alloys like TC850 are also used in industrial applications, such as cutting tools, bearings, and high-wear components, due to their exceptional hardness and toughness.

Care, Maintenance, and Longevity

Low Maintenance

TC850 rings require minimal care. They do not tarnish, fade, or lose their luster with normal use. Cleaning can be done with mild soapy water and a soft cloth.

Scratch Resistance

Thanks to their hardness, TC850 rings are virtually scratch-proof. However, they can shatter or crack if dropped onto a hard surface due to their brittleness. This is a trade-off of their extreme hardness.

Resizing and Engraving

TC850 rings cannot be resized due to their rigidity. However, they can be laser engraved, allowing for personalization without compromising durability.

Lifetime Warranty

Many TC850 rings come with a lifetime warranty, covering imperfections in design, materials, and workmanship, as well as size exchanges if your finger size changes.

Comparison: Tungsten Carbide TC850 vs Other Metals

| Feature | Tungsten Carbide TC850 | Gold | Platinum | Titanium | Stainless Steel |

| Hardness (Mohs) | 8.5+ | 2.5-3 | 4-4.5 | 6 | 5-6 |

| Scratch Resistance | Excellent | Poor | Good | Good | Good |

| Tarnish Resistance | Excellent | Fair | Excellent | Excellent | Excellent |

| Hypoallergenic | Yes (nickel binder) | Yes | Yes | Yes | Yes |

| Weight | Heavy | Medium | Heavy | Light | Medium |

| Color Options | Multiple | Yellow/White | White/Silver | Gray/Black | Silver |

| Resizing Possible | No | Yes | Yes | Limited | Limited |

| Price | Affordable | High | High | Moderate | Affordable |

History and Development of Tungsten Carbide

Tungsten carbide was first developed in the early 20th century as a material for industrial cutting tools due to its exceptional hardness and wear resistance. Over the decades, advancements in metallurgy and manufacturing techniques have allowed tungsten carbide to transition from purely industrial applications to consumer products such as jewelry. The development of the TC850 formula represents a significant milestone, combining traditional strength with modern hypoallergenic and aesthetic properties.

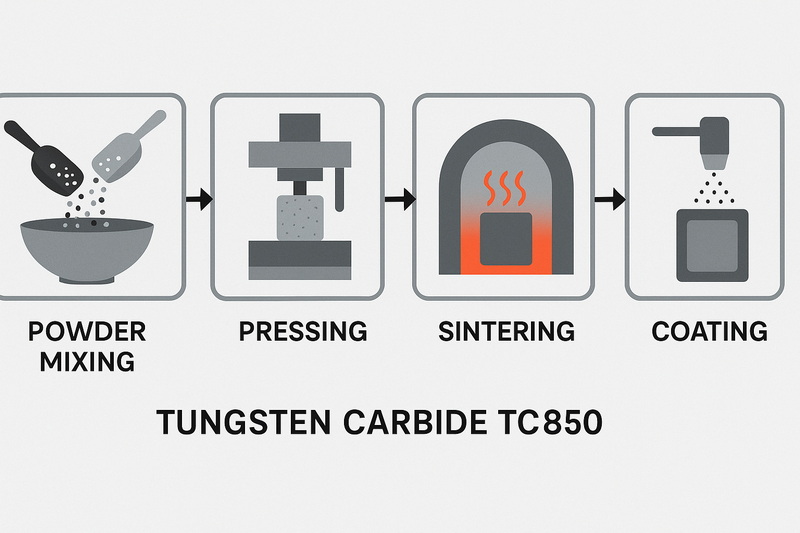

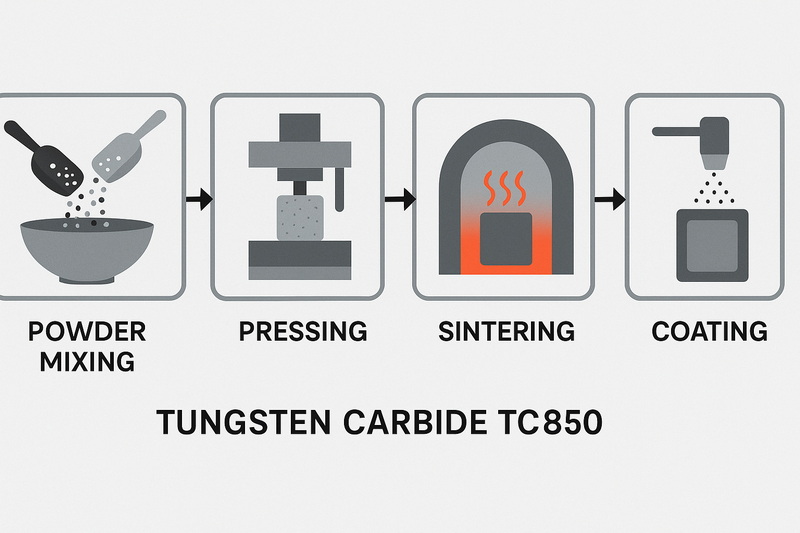

Manufacturing Process of TC850

The production of TC850 involves a complex process of powder metallurgy. Tungsten and carbon powders are precisely measured and mixed with a nickel binder and chromium additives. This mixture is then pressed into molds and sintered at extremely high temperatures to form a dense, solid alloy. Advanced coating techniques, such as physical vapor deposition, are applied to achieve the desired color and finish. Quality control at each stage ensures the final product meets the high standards associated with the TC850 brand.

Environmental Impact and Sustainability

While tungsten carbide is a durable and long-lasting material, its production involves mining and energy-intensive processes. Efforts are being made within the industry to improve sustainability by recycling tungsten carbide scrap and reducing the environmental footprint of manufacturing. The longevity of TC850 jewelry also contributes to sustainability by reducing the need for frequent replacements.

Future Trends and Innovations

The future of tungsten carbide TC850 looks promising, with ongoing research focused on enhancing its properties further. Innovations include developing even more scratch-resistant coatings, exploring alternative hypoallergenic binders, and expanding applications beyond jewelry into medical devices and aerospace components. As technology advances, TC850 is expected to maintain its position as a leading material in both consumer and industrial markets.

Conclusion

Tungsten carbide TC850 stands as a benchmark in contemporary jewelry, offering an unparalleled combination of strength, durability, and modern style. Its patented 85% tungsten carbide formula, enhanced with nickel and chromium, delivers a hypoallergenic, tarnish-resistant, and scratch-proof material that is perfect for active lifestyles and those seeking a lasting symbol of commitment. With a wide array of color options and finishes, TC850 rings cater to diverse tastes while maintaining their luxurious weight and luster for years to come. For anyone seeking a wedding band or accessory that truly endures, tungsten carbide TC850 is a choice that marries cutting-edge science with timeless elegance.

Frequently Asked Questions (FAQ)

1. What does TC850 mean in tungsten carbide jewelry?

TC850 refers to a patented alloy containing approximately 85% tungsten carbide, combined with a nickel binder and small amounts of chromium. This specific formula provides a strong, hypoallergenic, and tarnish-resistant material, ideal for jewelry that requires both durability and aesthetic appeal.

2. How scratch-resistant is tungsten carbide TC850?

TC850 is one of the most scratch-resistant materials used in jewelry, rating over 8.5 on the Mohs hardness scale. It is significantly harder than gold, platinum, titanium, and stainless steel, making it highly resistant to scratches from everyday wear.

3. Can TC850 rings be resized or repaired?

Due to their extreme hardness and rigidity, TC850 rings cannot be resized. If your finger size changes, many manufacturers offer a lifetime size exchange program. Repairs are generally limited to surface polishing or engraving.

4. Is tungsten carbide TC850 safe for sensitive skin?

Yes, TC850 uses a non-leaching nickel binder, making it hypoallergenic and suitable for most people with sensitive skin. It is also compliant with European standards for nickel release, minimizing the risk of allergic reactions.

5. What color options are available for TC850 rings?

TC850 rings are available in a variety of colors, including classic gray, white, black, yellow, and rose. These colors are achieved through advanced nano-technology coatings and proprietary metal blends, ensuring both beauty and durability.