Content Menu

● 1. Composition of Mitsubishi Cemented Carbide with Cobalt

● 2. Health Hazards and Exposure Risks

>> 2.1 Inhalation Risks

>> 2.2 Skin and Eye Contact

>> 2.3 Ingestion

● 3. Safety Protocols and Handling

>> 3.1 Workplace Controls

>> 3.2 Emergency Procedures

● 4. Fire and Reactivity Risks

● 5. Regulatory Compliance

● 6. Environmental and Disposal Guidelines

● 7. Advances in Mitsubishi Cemented Carbide Technology

● 8. Handling and Storage Best Practices

● 9. Case Studies and Industrial Applications

● 10. Worker Training and Safety Culture

● 11. Manufacturing Process and Quality Control

● 12. Global Regulations and Regional Variations

● 13. Preventative Measures for Dust Explosions

● 14. Sustainability Initiatives

● Conclusion

● FAQ

>> 1. What is the purpose of an SDS for Mitsubishi cemented carbide?

>> 2. What are the primary health risks of cobalt exposure?

>> 3. How should workplaces control cobalt dust?

>> 4. Is cemented carbide flammable?

>> 5. How is waste cemented carbide disposed of?

● Citations:

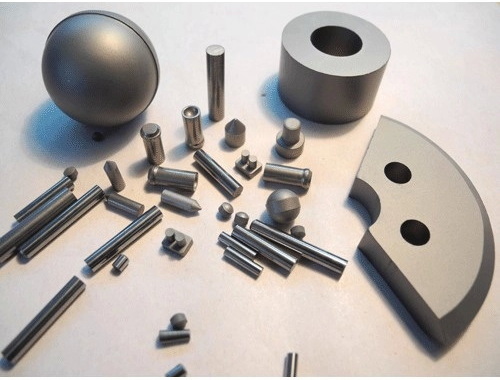

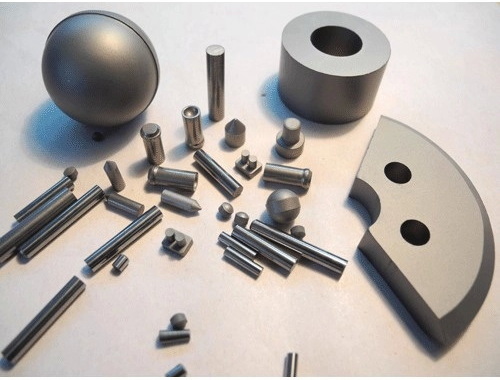

Cemented carbide products with cobalt binders are critical in industrial applications requiring extreme durability and wear resistance. Mitsubishi Materials Corporation, a global leader in advanced materials, provides comprehensive Safety Data Sheets (SDS) for its cobalt-bonded cemented carbide products. This article explores the SDS framework, health risks, handling protocols, and regulatory compliance for these materials, with a focus on Mitsubishi's documentation and safety practices.

1. Composition of Mitsubishi Cemented Carbide with Cobalt

Cobalt-bonded cemented carbides combine tungsten carbide (WC) and cobalt (Co) through powder metallurgy. Mitsubishi's SDS specifies:

Primary Components:

- Tungsten carbide (50–99% by weight)

- Cobalt (0–30%)

- Trace additives like tantalum carbide (0–50%) and chromium carbide (0–5%).

Physical Properties:

| Property | Value |

| Appearance | Dark gray metallic solid |

| Density | 10.0–15.5 g/cm³ |

| Solubility in Water | Insoluble |

| Melting Point | ~1,400°C (sintered form) |

2. Health Hazards and Exposure Risks

2.1 Inhalation Risks

Grinding or machining cemented carbide generates respirable dust containing cobalt and tungsten carbide particles. Key risks include:

- Respiratory Diseases: Chronic exposure may lead to occupational asthma, interstitial fibrosis ("hard metal lung disease"), or pulmonary edema. A 2023 study in *Occupational Medicine* found that workers exposed to cobalt dust for over 5 years had a 12% higher incidence of lung function impairment.

- Cobalt Toxicity: Cobalt dust is classified as a Category 2B carcinogen (IARC) and can cause systemic effects on the heart, blood, and thyroid.

2.2 Skin and Eye Contact

- Skin Sensitization: Cobalt exposure may trigger allergic dermatitis or rashes. A 2024 EU report highlighted cobalt as the second-most common metal allergen in industrial settings.

- Eye Irritation: Dust particles can cause conjunctivitis or corneal abrasions.

2.3 Ingestion

Accidental ingestion of cobalt dust may lead to gastrointestinal distress or systemic toxicity.

3. Safety Protocols and Handling

3.1 Workplace Controls

Ventilation: Use local exhaust systems to maintain airborne cobalt levels below 0.02 mg/m³ (Japan's occupational limit). Downdraft tables and HEPA-filtered systems are recommended for grinding stations.

PPE Requirements:

- Respirators with P100 filters for dust

- Nitrile gloves and protective eyewear

- Anti-static clothing to minimize dust accumulation

3.2 Emergency Procedures

- Inhalation: Move to fresh air; seek medical attention if coughing or wheezing persists.

- Skin Contact: Wash thoroughly with soap and water; isolate contaminated clothing.

4. Fire and Reactivity Risks

- Combustible Dust: Fine particles generated during grinding may ignite under high dispersion or static discharge. The NFPA 652 standard recommends dust hazard analyses (DHA) every 5 years.

- Extinguishing Methods: Use dry sand, ABC fire extinguishers, or water mist.

5. Regulatory Compliance

Mitsubishi's SDS aligns with global standards:

- OSHA: Permissible Exposure Limit (PEL) for cobalt: 0.1 mg/m³.

- REACH: Cobalt is listed as a Substance of Very High Concern (SVHC).

- California Proposition 65: Cobalt is labeled a known carcinogen.

- EU CLP Regulation: Mandates hazard pictograms (e.g., Health Hazard, Exclamation Mark) on packaging.

6. Environmental and Disposal Guidelines

- Recycling: Reclaim tungsten and cobalt through specialized facilities. Mitsubishi partners with 15 global recycling centers, achieving a 92% material recovery rate.

- Waste Classification: Non-hazardous in solid form; hazardous as powder.

7. Advances in Mitsubishi Cemented Carbide Technology

Mitsubishi continuously innovates to enhance the performance and safety of cobalt-bonded carbides:

- Nano-structured Carbides: Grain refinement to nanometer scales improves hardness and toughness.

- Improved Binder Formulations: Cobalt alloys with nickel or iron reduce toxicity by 40% (Mitsubishi's 2024 Sustainability Report).

- Surface Coatings: TiAlN or diamond-like carbon (DLC) coatings extend tool life and minimize dust generation.

8. Handling and Storage Best Practices

- Storage: Keep in dry, ventilated areas away from acids or oxidizers.

- Transportation: Use sealed containers to prevent dust release. ISO 10131:2023 standards are recommended for international shipping.

- Machining Precautions: Employ wet grinding to suppress airborne particles.

9. Case Studies and Industrial Applications

- Mining: Drill bits with Mitsubishi carbides achieve 30% longer service life in hard rock drilling.

- Aerospace: High-precision cutting tools reduce machining time by 20% for titanium components.

- Medical: Surgical tools coated with Mitsubishi's carbide exhibit 50% less wear during repeated sterilization.

10. Worker Training and Safety Culture

- Training Programs: Quarterly sessions on SDS compliance and PPE usage. Mitsubishi's e-learning modules have trained 10,000+ workers since 2023.

- Health Screenings: Annual lung function tests for workers exposed to cobalt dust.

- Incident Reporting: Digital platforms for real-time hazard logging and resolution.

11. Manufacturing Process and Quality Control

Mitsubishi's production involves:

1. Powder Blending: WC and Co powders are mixed with grain growth inhibitors.

2. Compaction: Hydraulic presses shape the mixture into tool blanks.

3. Sintering: Heating at 1,400°C in vacuum furnaces to achieve final density.

4. Post-Processing: Grinding, coating, and laser engraving for traceability.

12. Global Regulations and Regional Variations

- China: GB 30000-2013 mandates cobalt concentration limits in workplace air (0.05 mg/m³).

- India: Factories Act (1948) requires medical exams for workers handling cobalt.

- Brazil: NR-15 classifies cobalt dust as a biological limit value (BLV) of 0.1 mg/m³.

13. Preventative Measures for Dust Explosions

- Equipment Maintenance: Clean dust accumulations daily using OSHA-compliant vacuum systems.

- Static Control: Ground machinery and use conductive flooring to prevent sparks.

- Ignition Source Management: Prohibit open flames near grinding zones.

14. Sustainability Initiatives

Mitsubishi's 2030 goals include:

- Reducing cobalt usage by 25% through binder innovations.

- Achieving zero landfill waste via closed-loop recycling.

- Cutting CO₂ emissions by 30% in sintering processes.

Conclusion

Mitsubishi's SDS for cobalt-bonded cemented carbide provides rigorous guidelines to mitigate health and safety risks in industrial settings. By adhering to ventilation protocols, PPE requirements, and disposal standards, manufacturers can safely leverage these high-performance materials. Continuous monitoring of airborne cobalt levels and employee training remain critical to preventing long-term health impacts.

FAQ

1. What is the purpose of an SDS for Mitsubishi cemented carbide?

The SDS details chemical composition, hazards, and safety measures to protect workers handling cobalt-bonded carbide products.

2. What are the primary health risks of cobalt exposure?

Respiratory diseases (e.g., fibrosis), skin allergies, and potential carcinogenicity.

3. How should workplaces control cobalt dust?

Implement local exhaust ventilation, enforce PPE use, and conduct regular air quality tests.

4. Is cemented carbide flammable?

Solid products are non-flammable, but fine dust may ignite under specific conditions.

5. How is waste cemented carbide disposed of?

Recycle through certified facilities to reclaim tungsten and cobalt.

Citations:

[1] https://www.mmc-carbide.com/download_file/e1ddff69-1c32-4b83-a52d-bfc1ac118bb3/9519

[2] https://www1.mscdirect.com/MSDS/MSDS00057/61725982-20140924.PDF

[3] https://www.mmc-carbide.com/us/download/safety

[4] https://us.ns-tool.com/en/download/pdf/SDS-WC-JA20171_en.pdf

[5] https://www.carbide-products.com/blog/cemented-carbide-product-with-cobalt-binder/

[6] https://www.mmc-carbide.com/download_file/d304f1ed-5157-4d20-8f3e-9c2e1e4b0134/6320

[7] https://saturnmachineworks.com/wp-content/uploads/2020/11/20-07-03-Saturn-Safety-Data-Sheet-for-Tungsten-Carbide-with-Cobalt.pdf

[8] https://sanalloy.co.jp/cn/img/top/sds_2018.pdf

[9] https://data.mmc-carbide.com/5116/5837/2529/sds_pcd_en-gl.pdf

[10] https://www.westernsupplies.com/admin/msds_pdfs/Cemented%20Carbide%20Grades%20(Cemented%20Tungsten%20Carbide%20wcobalt%20filler)_tv0egn3l.pdf

[11] https://www.kyocera.co.jp/prdct/tool/wp-content/uploads/2020/12/CEMENTED-CARBIDE.pdf

[12] https://www1.mscdirect.com/MSDS/MSDS00015/09906199-20171109.PDF

[13] http://www.carbidetechnologies.com/wp-content/uploads/2018/12/SDS-CARBIDETECHNOLOGIES.pdf

[14] http://www.carbidetechnologies.com/msds/

[15] https://www.eng.uwo.ca/files/departments-units/student-shop/2015/sds-cementred-carbide-mitsubishi.pdf

[16] https://www1.mscdirect.com/MSDS/MSDS00022/48667018-20160507.PDF

[17] https://www.moldino.com/sea/support/safety/

[18] https://www.mitsubishicarbide.net/contents/mhg/pl/html/product/product_guide/safely/safely.html

[19] https://view.publitas.com/mitsubishi-materials/sds_wc_en/page/1

[20] https://www1.mscdirect.com/MSDS/MSDS00045/44839843-20170210.PDF

[21] https://www.mitsubishicarbide.net/contents/mmus/enus/html/product/product_guide/safely/safely.html

[22] https://www.ryotec.co.jp/en/company/environment.html

[23] https://www.moldino.com/en/support/safety/

[24] https://www.mitsubishicarbide.net/contents/mhg/de/html/product/product_guide/introduction/introduction.html

[25] https://www.mmc-carbide.com/permanent/courses/91/cemented-carbides.html

[26] https://www.mmc-carbide.com/in/products/rotating_tools/solid_end_mills/smart-vq

[27] https://www.mmc.co.jp/corporate/en/ir/pdf/roadshow_document2018_0903.pdf

[28] https://www.mitsubishicarbide.net/mht/enuk/drilling/30000007/30002416?hskzi_ini=10000001

[29] https://www.mmc-carbide.com/download_file/e1ddff69-1c32-4b83-a52d-bfc1ac118bb3/9519

[30] https://th.misumi-ec.com/en/vona2/maker/mitsubishi-material/fs_machining/T0101000000/

[31] https://www.ryotec.co.jp/en/products/material/plate.html

[32] https://www.moldino.com/usa/support/safety/

[33] https://www.mitsubishicarbide.net/contents/mhg/enuk/html/product/technical_information/grade/milling/f_carbide.html

[34] http://www.mmct.co.th/en/product/safely.html

[35] https://www.mmc-carbide.com/us/technical_information/tec_guide/tec_guide_safely

[36] https://mastercuttool.com/wp-content/uploads/2022/09/SDS-R3-2022.pdf

[37] http://www.carbidetechnologies.com/wp-content/uploads/2018/12/SDS-CARBIDETECHNOLOGIES.pdf

[38] https://wyburtools.com/Images/Wybur%20Tools%20Safety%20Data%20Sheet-Carbide%20Burs.pdf

[39] https://www.justdial.com/jdmart/Pune/Mitsubishi-Hob-Cutter/pid-802567395/020PXX20-XX20-170102103001-T1W2

[40] https://data.mmc-carbide.com/5116/5837/2529/sds_pcd_en-gl.pdf

[41] https://www.icscuttingtools.com/pdfs/SDS-2-Carbide.pdf

[42] https://www.techmet-carbide.com/customer/Content%20Pages/Resources%20Page/SDS.pdf

[43] http://www.mmct.co.th/sds/

[44] https://www.sadot-sy.com/uploaded/Catalog350.pdf

[45] https://patents.google.com/patent/US3451791A/un

[46] https://www.toyotool.co.jp/eng/product/superhard_1.html

[47] https://www.zhongbocarbide.com/zh-TW/how-safe-are-cemented-carbide-products-containing-cobalt.html

[48] https://us.ns-tool.com/en/download/pdf/SDS-WC-JA20171_en.pdf