Contentus menu

● I. Compositionem Mitsubishi cended carbide cum Cobalt

● II. Salutem discrimina et nuditate metus

>> 2.1 inspiratione metus

>> 2.2 cutis et oculus contactus

>> 2.3 ingestion

● III. Salus protocols et tractantem

>> 3,1 workplace controls

>> 3,2 subitis procedendi

● IV. Ignis et reactivity metus

● V. Regulatory obsequio

● VI. Environmental et dispositionum guidelines

● VII. Progredia in Mitsubishi cemented carbide technology

● VIII. Tractantem et repono optimum exercitia

● IX. Case Studies et Industrial Applications

● X. Habitatorem Training et Safety Culture

● XI. Vestibulum processus et qualis imperium

● XII. Global ordinationes et Regional Variations

● XIII. Praeventative mensurae enim pulvis explosions

● XIV. Sustainability initiatives

● Conclusio

● Faq

>> I. Quid est ad SDS ad Mitsubishi cemented carbide?

>> II. Quid sunt primaria salute metus de Cobalt nuditate?

>> III. Quomodo debet workplaces imperium Cobalt pulvis?

>> IV. Est cemented carbide flammabiles?

>> V. Quomodo desolata cemented carbide est?

● Citations:

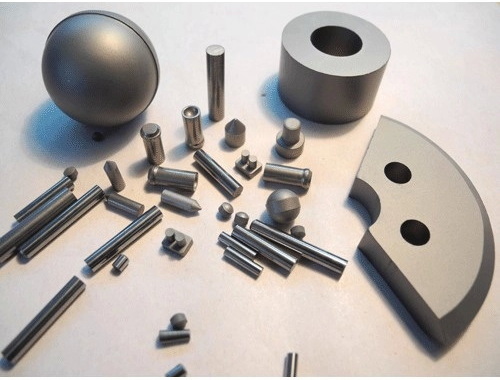

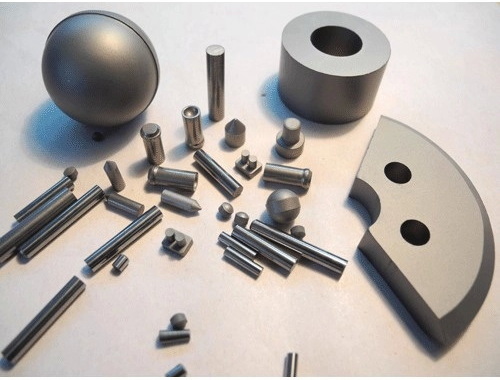

Celeratur carbide products cum Cobalt ligula sunt discrimine in Industrial Applications requiring Extremitate et Gerunt resistentia. Mitsubishi Materials Corporation, A Global Dux in Advanced materiae, providet comprehensive salutem notitia laminas (SDS) pro Cobalt-Bonded cender carbide products . Hoc articulum explorat SDS compage, salutem metus, tractantem protocols, et regulatory obsequium ob haec materiae, cum focus in Mitsubishi scriptor documenta et salus exercitia.

I. Compositionem Mitsubishi cended carbide cum Cobalt

Cobalt-Bonded cenderentur carbides miscere Tungsten Carbide (WC) et Cobalt (Co) per pulveris metallurgy. Mitsubishi scriptor SDs specificat:

Prima components:

- Tungsten Carbide (50-99% per pondus)

- Cobalt (0-30%)

- Vestigium additives sicut Tantalum carbide (0-50%) et Chromium carbide (0-5%).

Physica proprietatibus:

| Property |

valorem |

| Species |

Tenebris griseo metallicis solidum |

| Densitas |

10.0-15.5 g / cm³ |

| Solubility in aquam |

Insolubilis |

| Point liquescens |

~ 1,400 ° C (Sinaed Forma) |

II. Salutem discrimina et nuditate metus

2.1 inspiratione metus

Dulta aut machining cenderentur carbide generat respirable pulveris quibus Cobalt et Tungsten carbide particulas. Key metus includit:

- Respiratoriorum morbi: Chronic nuditate potest ducere ad occupational asthma, interstitial fibrosis ( 'difficile metallum pulmonis morbo '), aut pulmonalis OEDEMA. A MMXXIII studio in * occupational medicina * invenitur quod operarios patere Cobalt pulveris pro super V annorum habebat XII% superior incidentiae pulmonis munus opercionem.

- Cobalt toxicity: Cobalt pulvis est genus sicut genus 2b carcinogen (iarc) et potest facere systemica effectus in corde, sanguinem et thyroideum.

2.2 cutis et oculus contactus

- Skid sensitization: Cobalt nuditate potest trigger allergic DERMATITIS aut rashes. A MMXXIV EU fama highlighted Cobalt sicut secunda-maxime commune metallum allergen in Industrial occasus.

- Oculus irritatio: pulvis particulas potest facere conjunctivitis aut cornea abrasions.

2.3 ingestion

Accidentales ingestion Cobalt pulvere ducere gastrointestinal angustia vel systemica toxicity.

III. Salus protocols et tractantem

3,1 workplace controls

VENTILATIO: Usus Locus exhauriunt systems ad ponere aerium Cobalt campester infra 0.02 mg / M⊃3; (Japan scriptor occupational terminum). Downdraft mensas et Hepa-percolantur systems sunt suadeo molere statio.

PPE Requisita:

- Respiratorum cum P100 Filtra in pulvis

- Nitrile caestus et tutela eyewear

- anti-stabilis vestimentum ad minimize pulveris cumulus

3,2 subitis procedendi

- Inhalatione: move ad recens aerem; Quaerite medical operam si tussis vel wheezing persistit.

- cutis contactus: lava penitus saponem et aquam; segregare contaminari indumentis.

IV. Ignis et reactivity metus

- combustibilis pulvis: denique particula generatur in molere potest ignitum sub alto dispersionem vel static missionem. Et NFPA DCLII Standard commendat pulvis aleam analyzes (DHA) omnis V annorum.

- Exstinguunt modos: Usus arena ABC ignis extinguishers, aut aqua caligo.

V. Regulatory obsequio

Mitsubishi scriptor SDS assistentes cum Global Signa:

- OSHA: Permissalis nuditate Low (PEL) ad Cobalt: 0,1 mg / M⊃3;.

- Semoto: Cobalt est enumerantur ut substantia valde alta de (SVHC).

- California propositionis LXV: Cobalt est intitulatum a nota Carcinogen.

- EU CLP ordinatione: Mandates Pellentesque (eg, salutem aleam, exclamation marcam) in packaging.

VI. Environmental et dispositionum guidelines

- Recycling: revocat Tungsten et Cobalt per specialized facilities. Mitsubishi sociis cum XV global redivivus centers, Achieving a XCII% materia recuperatio rate.

- vastum genus: non-ancipitia in solidum forma; ancipitia ut pulveris.

VII. Progredia in Mitsubishi cemented carbide technology

Mitsubishi continuously innovates ad augendae perficientur et salus Cobalt-Bonded Carbides:

- Nano-exstructa Carbides: Frumenti Refinement ad Nanometer squamis amplio duritiam et lenta.

- melior ligans formulations: Cobalt Alloys cum Nickel et ferrum reducere toxicity per XL% (Mitsubishi scriptor MMXXIV Sustainability Report).

- Superficiem coatings: Tialn aut Diamond Pectus, sicut ipsum (DLC) coatings extend tool vitae et obscuratis pulvere.

VIII. Tractantem et repono optimum exercitia

- PRAECLUSIO: ut in sicco, uentilandam areas a acida vel oxidizers.

- Transportation: Usus signati continentia ne pulvis release. ISO (X) CXXXI: MMXXIII Signa commendatae pro Internationalis Shipping.

- Machining DECAUTATIONS: uti molere molere ad supprimunt aerium particulas.

IX. Case Studies et Industrial Applications

- Mining: EXERCITATIO bits cum Mitsubishi carbides consequi XXX% iam officium in durum petra tere.

- Aerospace, summus praecisione incidendis Tools reducere machining tempore per XX% ad Titanium components.

- Medical: Chirurgicam Tools iactaret cum Mitsubishi scriptor carbide exhibent L% minus gerunt per iterari sterilizationem.

X. Habitatorem Training et Safety Culture

- Disciplina Programs: Quarterly Sessionibus in SDS obsequio et PPE usus. Mitsubishi est E-Doctrina modules et docti 10,000+ operarios quia MMXXIII.

- Salutem Screenings: Annui pulmone munus probat pro opifices patere Cobalt pulvis.

- Incident Reporting: Digital Platforms pro Real-Time DISCIPULO logging et resolutio.

XI. Vestibulum processus et qualis imperium

Mitsubishi scriptor productio involves:

I. Pulveris miscent: WC et coque Pugders sunt mixta cum frumenti incrementum inhibitors.

II. Compaction: Hydrau premit figura mixtisque in instrumentum codicellos.

III. Sincering: calefactio ad 1,400 ° C in vacuo Furnorum ad consequi ultima density.

IV. Post-processus: molere, coating et laser sculptura ad vestigia.

XII. Global ordinationes et Regional Variations

- Sina: GB 30000-2013 mandates Cobalt concentration limits in workplace aere (0.05 mg / M⊃3;).

- India: Factories Act (MCMXLVIII) requirit Medical Examatibus pro opifices tractantem Cobalt.

- Brazil: NR-XV classifies Cobalt pulveris quasi biologicum limit (BLV) 0,1 MG / M⊃3;.

XIII. Praeventative mensurae enim pulvis explosions

- Equipment sustentationem: Pulvis cumulationibus cotidie usura OSHA-obsequi vacuo systems.

- Static imperium: terram machinery et usu PROLIXUS Tabulatum ne scintillae.

- Ignition Source Management: Prohibere aperta flammas prope molendum zonas.

XIV. Sustainability initiatives

Mitsubishi scriptor MMXXX proposita includit:

- Reducing Cobalt usus per XXV% per ligans innovations.

- Achieving nulla landfill deserta via clausa-loop redivivus.

- Cutting co ^ emissiones a XXX% in segregant processibus.

Conclusio

Mitsubishi s SDs ad Cobalt-Bonded cemented carbide praebet rigorous guidelines ad mitigare salutem et salutem metus in Industrial occasus. Per adhaerens ad VENTILATIO protocols, PPE requisitis, et dispositionum signa, manufacturers potest tuto leverage his princeps-perficientur materiae. Cogit et employee disciplina airborne Cobalt continuam et employee disciplina manere discrimine ad prohibendam diu terminus salutem confligant.

Faq

I. Quid est ad SDS ad Mitsubishi cemented carbide?

Et SDS Details eget compositionem, pericula et salus mensuras ad protegendum operarios tractantem Cobalt-bonded carbide products.

II. Quid sunt primaria salute metus de Cobalt nuditate?

Respiratoriorum morbi (eg, fibrosis), cutis allergies, et potential carcinogenicity.

III. Quomodo debet workplaces imperium Cobalt pulvis?

Effectum loci exhaurit evacuatione, urgeant ppe usu et mores iusto aere qualis probat.

IV. Est cemented carbide flammabiles?

Solidum products sunt non-flammabiles, sed denique pulvis ut ignitum in specifica conditionibus.

V. Quomodo desolata cemented carbide est?

Redivivus per certified facilities ut revocat Tungsten et Cobalt.

Citations:

[I] https://www.mcc-carbide.com/download_file/e1ddff69-1c32-4b83-a52d-bfc1ac1183/9519

[II] https://www1.cmdirect.com/msds/msds00057/61725982-20140924.pdf

[III] https://www.mmc-carbide.com/us/download/safety

[IV] https://us.ns-tool.com/en/download/pdf/sds-wc-ja20171_en.pdf

[V] https://www.carbide-products.com/blog/cemed-carbide-product-with-cobalt-binder/

[VI] https://www.mmc-carbide.com/download_file/d304f1ed-5157-4d20-8f3e-9c2e1e4b0134/6320

[VII] https://saturnmachineworks.com/wp-content/uploads/2020/11/20-07-03-saturn-safety-data-sheet-for-tungtten-carbide-with-cobalt.pdf

[VIII] https://sanally.co.jp/cn/img/top/sds_2018.pdf

[IX] https://data.mcc-carbide.com/5116/5837/2529/sds_pcd_en-gl.pdf

[X] https://wwwesternsupplies.com/admin/msds_pdfs/cementsed%20carbide%20Gradfs/Cemented%20GrBDS%20Carbide%20Wcobalt%20Filler)_Tv0Egn3l.pdf

[XI] https://www.kyocera.co.jp/prdct/tool/wp-content/uploads/2020/12/Cemented-carbide.pdf

[XII] https://www1.mscdirect.com/msds/msds0015/09906199-20109.pdf

[XIII] http://www.carbidecechnologies.com/wp-contenthts/2018/12/sds-carbidetechnologies.pdf

[XIV] http://www.carbidechnologies.com/msds/

[XV] https://www.eng.uwo.ca/files/department-units/student-shop/2015/sds-cemented-scarbide-mitsubishi.pdf

[XVI] https://www1.cmdirect.com/msds/msds00022/48667018-20160507.pdf

[XVII] https://www.moldino.com/sea/support/safety/

[XVIII] https://www.mitsubishicarbide.net/products/MHG/PL/HTML/Poduct/Product_Guide/SAFely/Safely.html

[XIX] https://view.publitia.com/mitsubishi-materials/sds_wc_en/page/1

[XX] https://www1.cmdirect.com/msds/msds00045/44839843-20170210.pdf

[XXI] https://www.mitsubishicarbide.net/products/Mmus/enus/Safely/Safely.html

[XXII] https://www.ryotec.co.jp/en/company/environment.html

[XXIII] https://www.moldino.com/en/support/safety/

[XXIV] https://www.mitsubisicarbide.net/contents/mhg/de/html/product/product_guide/Introduction/Introduction.html

[XXV] https://www.mcc-carbide.com/permanent/courseses/91/cemented-carbides.html

[XXVI] https://www.mmc-carbide.com/in/products/rotating_tools/solid_end_mills/smart-vq

[XXVII] https://www.mcc.co.jp/corprate/en/ir/pdf/roadshow_document2018_0903.pdf

[XXVIII] https://www.mitsubishicarbide.net/mht/enuk/drilling/30000007/30002416?hskzi_ini=10000001

[XXIX] https://www.mcc-carbide.com/download_file/e1ddff69-1c32-4b83-a52d-bfc1ac1183/9519

[XXX] https://th.misumi-ec.com/en/vona2/maker/mitsubishi-material/fs_machined/t0101000000/

[XXXI] https://www.ryotec.co.jp/en/products/Material/plate.html

[XXXII] https://www.moldino.com/usa/support/safety/

[XXXIII] https://www.mitsubishicarbide.net/products/mhg/enuk/html/product/technical_information/grade/milling/f_carbide.html

[XXXIV] http://www.mt.co.html http://www.mmct.co.html

[XXXV] https://www.mmc-carbide.com/us/technical_information/tec_guide/tec_Guide_Safely

[XXXVI] httpsshstercuttool.com/wp-content/uploads/202/09/sds-r3-2022.pdf

[XXXVII] http://www.carbidechnologies.com/wp-contenthts/2018/12/sds-carbideteteterechnologies.pdf

[XXXVIII] https://fyburtoolety.com/images/wybur%20Toolsfety%20data%20sheet-carbide%20burs.pdf

[XXXIX] https://www.justdial.com/jdmart/pune/mitsubishi-hob-cutter/pl20567395/020pxx20-xx20- 17010210300 I-T1w2

[XL] https://data.mcc-carbide.com/5116/5837/2529/sds_pcd_en-gl.pdf

[XLI] https://www.icscuttingtools.com/pdfsdsds-2-carbide.pdf

[XLII] https://www.techmet-carbide.com/customer/content%20pages/resources%20page/sds.pdf

[XLIII] http://www.mcct.co.th/sds/

[XLIV] https://www.sadot-sy.com/uploaded/catalog350.pdf

[XLV] https://patents.google.com/patent/us3451791a/un

[XLVI] https://www.toyotool.co.jp/eng/product/superhard_1.html

[XLVII] https://www.zhongbocarbide.com/zh-tw/how-safe-are-cemed-carbide-products-containing-cobalt.html

[XLVIII] https://us.ns-tool.com/en/download/pdf/sds-wc-ja20171_en.pdf