Content Menu

● Understanding Tungsten Carbide Tipped Chisels

>> Benefits of Tungsten Carbide Tipped Chisels

● Factors Influencing Lifespan

>> 1. Material Being Worked On

>> 2. Frequency of Use

>> 3. Quality of Manufacturing

>> 4. Maintenance Practices

● Maintenance Tips for Extending Lifespan

>> 1. Regular Cleaning

>> 2. Proper Sharpening Techniques

>> 3. Correct Storage

>> 4. Use Appropriate Cutting Techniques

● Comparing Lifespan with Other Materials

● Real-World Applications

● Conclusion

● Questions & Answers

>> 1. How often should I sharpen my tungsten carbide tipped chisels?

>> 2. Can I use tungsten carbide tipped chisels on soft materials?

>> 3. What is the best way to clean my chisels after use?

>> 4. Are there any specific storage requirements for these chisels?

>> 5. How do I know when it's time to replace my chisel?

Tungsten carbide tipped chisels have become a staple in various industries, particularly in construction and stoneworking, due to their exceptional durability and performance. Understanding the lifespan of these tools is crucial for professionals and DIY enthusiasts alike, as it can significantly affect project efficiency and costs. In this article, we will explore the factors that influence the lifespan of tungsten carbide tipped chisels, maintenance practices to extend their life, and comparisons with other materials.

Understanding Tungsten Carbide Tipped Chisels

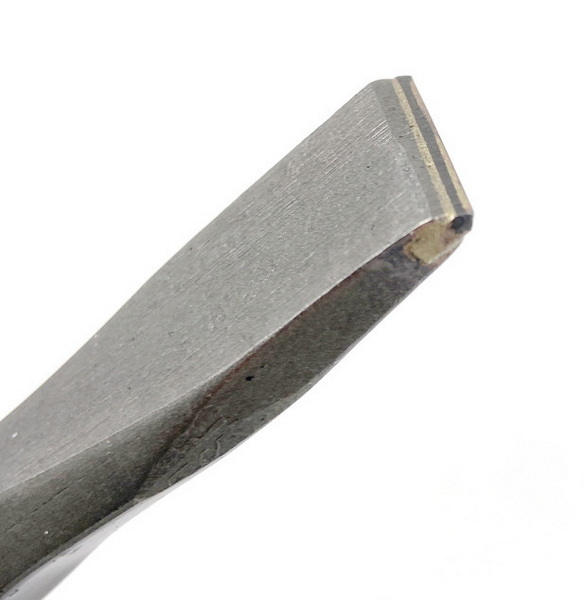

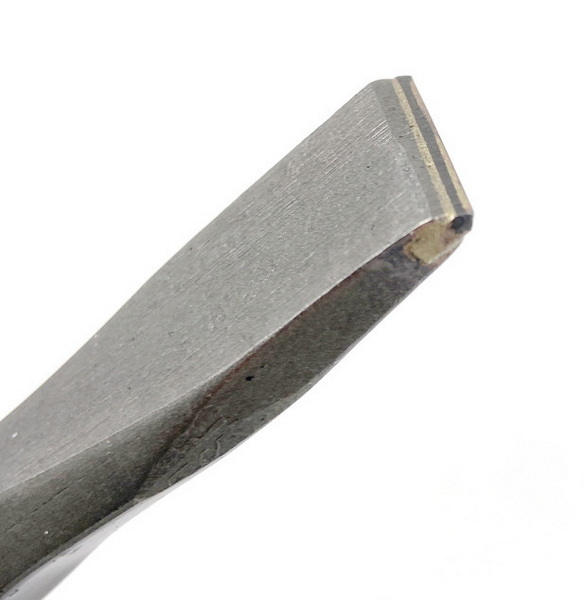

Tungsten carbide tipped chisels are designed with a high-carbon steel body and a tungsten carbide tip. This combination provides superior strength and longevity compared to traditional steel chisels. Tungsten carbide is renowned for its hardness, making it ideal for cutting through tough materials like granite, concrete, and other hard stones.

Benefits of Tungsten Carbide Tipped Chisels

- Durability: Tungsten carbide is one of the hardest materials available, second only to diamond. This hardness translates into longer-lasting tools that can withstand heavy use without dulling quickly.

- Resistance to Wear: The tips resist chipping and breaking, which is particularly important in demanding applications.

- Efficiency: These chisels maintain a sharp edge longer than traditional options, reducing the frequency of sharpening and replacement.

Factors Influencing Lifespan

The lifespan of tungsten carbide tipped chisels can vary based on several factors:

1. Material Being Worked On

The type of material being cut or shaped significantly impacts the wear on the chisel. For instance, working with softer materials will generally extend the chisel's life compared to harder materials like granite or concrete.

2. Frequency of Use

Regular use naturally leads to more wear. Professionals who use these chisels daily may find that they need to replace them more frequently than hobbyists who use them sporadically.

3. Quality of Manufacturing

Not all tungsten carbide tipped chisels are created equal. Higher-quality tools from reputable manufacturers tend to last longer due to better materials and construction techniques.

4. Maintenance Practices

Proper care can greatly enhance the lifespan of these tools. Regular cleaning, sharpening, and correct storage practices play a vital role in maintaining their effectiveness.

Maintenance Tips for Extending Lifespan

To maximize the lifespan of your tungsten carbide tipped chisels, consider the following maintenance tips:

1. Regular Cleaning

After each use, clean the chisels thoroughly to remove debris, dust, and any material residue. This prevents buildup that can dull the edge over time.

2. Proper Sharpening Techniques

While tungsten carbide tips maintain their edge longer than steel, they still require periodic sharpening. Use appropriate sharpening tools designed for carbide to avoid damaging the tip.

3. Correct Storage

Store chisels in a dry place away from moisture to prevent rusting on the steel body. Using protective cases or pouches can also help prevent accidental damage.

4. Use Appropriate Cutting Techniques

Applying too much pressure or using incorrect angles while cutting can lead to premature wear or breakage. Always follow best practices for cutting techniques specific to your material.

Comparing Lifespan with Other Materials

When comparing tungsten carbide tipped chisels with other types such as high carbon steel or high-speed steel chisels, tungsten carbide consistently shows superior longevity:

| Type of Chisel | Average Lifespan (Cuts) | Durability | Cost |

| High Carbon Steel | 500 - 1,000 | Moderate | Low |

| High-Speed Steel | 1,000 - 2,000 | High | Moderate |

| Tungsten Carbide Tipped | 3,000 - 5,000 | Very High | High |

As illustrated in this table, tungsten carbide tipped chisels provide a significant advantage in both durability and lifespan compared to their counterparts.

Real-World Applications

Tungsten carbide tipped chisels are used in various fields including:

- Stoneworking: Ideal for shaping and splitting hard stones.

- Construction: Essential for masonry work where precision is critical.

- Artisan Crafting: Used by sculptors and artisans for detailed work on stone and wood.

Conclusion

In conclusion, tungsten carbide tipped chisels are an investment worth making for anyone involved in heavy-duty cutting tasks. Their extended lifespan—often lasting up to five times longer than traditional steel options—makes them a cost-effective choice over time despite their higher initial price. By adhering to proper maintenance practices and selecting quality tools suited for specific tasks, users can maximize their performance and longevity.

Questions & Answers

1. How often should I sharpen my tungsten carbide tipped chisels?

Sharpening frequency depends on usage; however, it's advisable to check the edge after every few uses and sharpen as needed.

2. Can I use tungsten carbide tipped chisels on soft materials?

Yes, they can be used on soft materials but are primarily designed for harder substances where their durability shines.

3. What is the best way to clean my chisels after use?

Use a soft brush or cloth to remove debris followed by a gentle wash with soap and water if necessary; ensure they are dried thoroughly afterward.

4. Are there any specific storage requirements for these chisels?

Store them in a dry environment away from moisture; using protective cases can help prevent damage during storage.

5. How do I know when it's time to replace my chisel?

If you notice significant chipping or if sharpening no longer restores the edge effectively, it may be time to replace your chisel.