Content Menu

● Introduction to Grinding Wheels

>> Types of Grinding Wheels for Tungsten Carbide

● Characteristics of Grinding Wheels

>> Grit Size

>> Bond Type

>> Wheel Hardness

● Practical Tips for Grinding Tungsten Carbide

● Advanced Techniques for Grinding Tungsten Carbide

>> 1. Electrochemical Grinding (ECG)

>> 2. Ultrasonic Grinding

>> 3. Laser-Assisted Grinding

● Latest Innovations in Grinding Wheels for Tungsten Carbide

>> Nano-Diamond Wheels

>> Ultra-Fine Diamond Wheels

● Special Considerations

>> Form Grinding

>> Edge Brightness Improvement

● Applications of Grinding Wheels for Tungsten Carbide

● Additional Content on Grinding Wheels for Tungsten Carbide

>> Cooling Systems

>> Wheel Dressing

● Conclusion

● FAQ

>> 1. What is the best grinding wheel for tungsten carbide?

>> 2. What grit size is recommended for grinding tungsten carbide?

>> 3. What type of bond is suitable for diamond grinding wheels?

>> 4. How often should grinding wheels be inspected?

>> 5. What safety precautions should be taken when grinding tungsten carbide?

● Citations:

Tungsten carbide is renowned for its exceptional hardness, wear resistance, and high-temperature resistance, making it a crucial material in various industrial applications, including cutting tools and wear parts. However, these properties also render it challenging to machine. Among the various machining processes, grinding is a critical step that requires the right tools to achieve precision and efficiency. This article will delve into the selection of grinding wheels for tungsten carbide, exploring the types of wheels available, their characteristics, and practical tips for effective grinding.

Introduction to Grinding Wheels

Grinding wheels are essential tools in metalworking, used for cutting, sharpening, and smoothing metal surfaces. They consist of abrasive particles bonded together with a matrix material. The choice of grinding wheel depends on the material being ground, the desired finish, and the specific application.

Types of Grinding Wheels for Tungsten Carbide

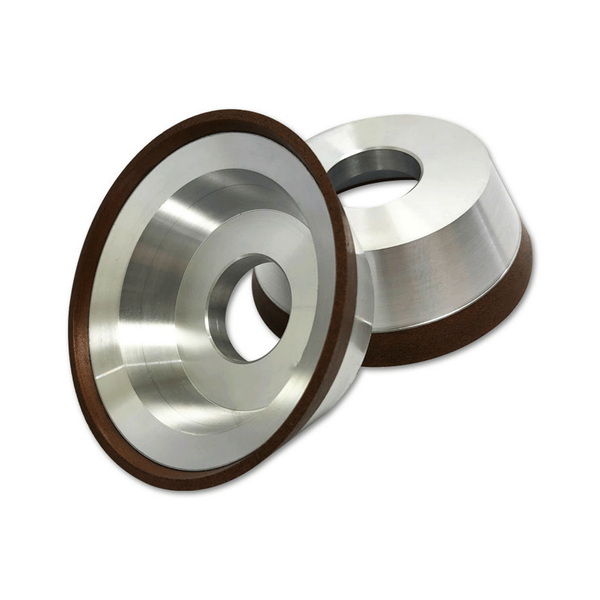

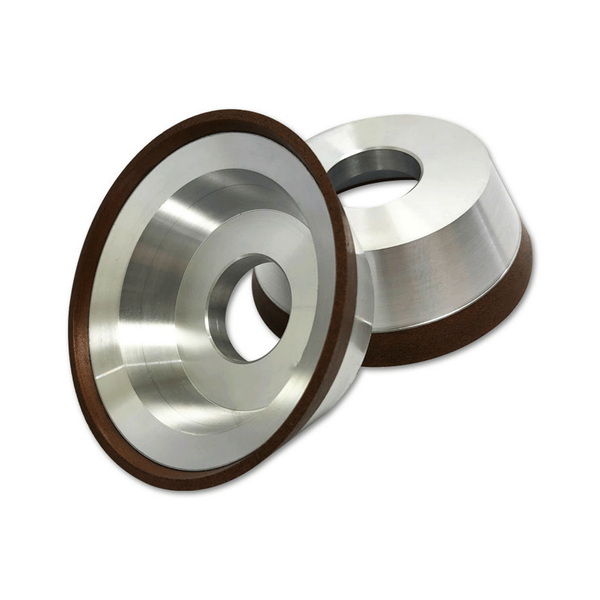

1. Diamond Grinding Wheels: These are the most preferred choice for grinding tungsten carbide due to their superior hardness and wear resistance. Diamond wheels offer high efficiency and precision, making them ideal for high-hardness materials like tungsten carbide.

Diamond grinding wheels are available in various grit sizes, typically ranging from 200 to 600, which are suitable for both rough and fine grinding operations. The bond type is crucial; resin or ceramic bonds are recommended for their good grinding force and shape retention, ideal for form grinding applications.

2. CBN (Cubic Boron Nitride) Grinding Wheels: While not as common for tungsten carbide, CBN wheels are used for grinding high-hardness materials. They are less expensive than diamond wheels but still offer good performance.

3. Silicon Carbide (SiC) Grinding Wheels: These are often used for grinding non-ferrous metals and can be used for tungsten carbide, though they are less effective than diamond wheels. Green silicon carbide wheels are specifically noted for their use in grinding tungsten carbide.

Characteristics of Grinding Wheels

Grit Size

The grit size of a grinding wheel determines its coarseness. For tungsten carbide, a grit size between 200 to 600 is recommended for optimal burr removal and surface smoothing.

Bond Type

The bond type affects the wheel's durability and grinding performance. Resin bonds are common for diamond wheels, offering good grinding force and shape retention.

Wheel Hardness

The hardness of the grinding wheel should match the material being ground. For tungsten carbide, a wheel with sufficient hardness is crucial to prevent excessive wear.

Practical Tips for Grinding Tungsten Carbide

1. Wheel Inspection: Always inspect the grinding wheel for defects before use to avoid potential hazards.

2. Material Compatibility: Choose a wheel based on the hardness and properties of the material to ensure compatibility and efficiency.

3. Installation and Balance: Follow strict procedures for installing and checking the dynamic balance of the grinding wheel to maintain precision.

4. Operational Safety: Adhere to all operating procedures and monitor the grinding process for any abnormal conditions.

Advanced Techniques for Grinding Tungsten Carbide

1. Electrochemical Grinding (ECG)

ECG combines electrochemical dissolution with mechanical grinding, reducing the mechanical stress on the workpiece. This method is beneficial for complex shapes and can improve surface finish.

2. Ultrasonic Grinding

Ultrasonic grinding uses high-frequency vibrations to enhance the grinding process. It is particularly useful for grinding small or intricate parts with high precision.

3. Laser-Assisted Grinding

This technique involves using a laser to heat the workpiece locally, reducing its hardness and making it easier to grind. It is advantageous for reducing thermal damage and improving efficiency.

Latest Innovations in Grinding Wheels for Tungsten Carbide

Recent advancements in grinding wheel technology include the development of nano-diamond and ultra-fine diamond wheels. These wheels offer improved surface finish and reduced wear, making them ideal for high-precision applications.

Nano-Diamond Wheels

Nano-diamond wheels utilize diamond particles in the nanoscale, providing a smoother finish and better wear resistance. They are particularly beneficial for grinding small or delicate parts.

Ultra-Fine Diamond Wheels

These wheels feature diamond particles with very fine grit sizes, typically below 1 micron. They are used for achieving ultra-high surface finishes and are ideal for applications requiring minimal material removal.

Special Considerations

Form Grinding

Requires wheels that maintain form and deliver consistent grinding force. Resin or ceramic bonded diamond wheels are typically used for this application.

Edge Brightness Improvement

For applications requiring high finish quality, elastic diamond wheels are preferable. They help in removing tool marks and reducing cutting resistance, thereby extending the tool life.

Applications of Grinding Wheels for Tungsten Carbide

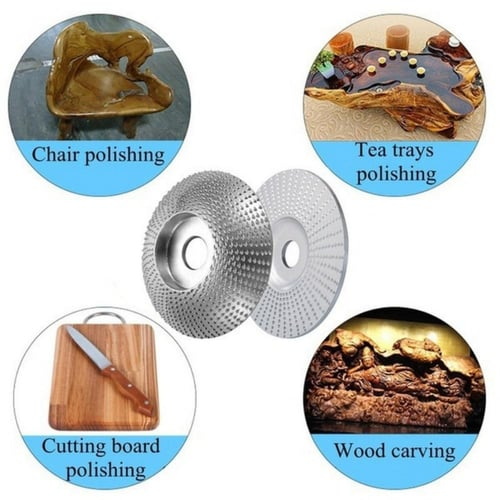

Grinding wheels for tungsten carbide are used in various industries, including:

- Tool Manufacturing: For sharpening and resharpening carbide tools.

- Aerospace: For grinding components that require high precision and durability.

- Automotive: For manufacturing wear-resistant parts.

Additional Content on Grinding Wheels for Tungsten Carbide

Cooling Systems

Effective cooling systems are essential during grinding to prevent overheating and thermal damage. Coolants like water or oil-based fluids are commonly used to maintain a stable temperature.

Wheel Dressing

Regular dressing of the grinding wheel is necessary to maintain its effectiveness. This process involves removing worn-out abrasive particles to expose new ones, ensuring consistent grinding performance.

Conclusion

Choosing the right grinding wheel for tungsten carbide is crucial for achieving efficient and precise machining. Diamond grinding wheels are the preferred choice due to their superior performance characteristics. However, understanding the specific requirements of the application, such as grit size and bond type, is essential for optimal results. Advanced techniques like electrochemical grinding and ultrasonic grinding offer additional benefits for complex applications.

FAQ

1. What is the best grinding wheel for tungsten carbide?

The best grinding wheel for tungsten carbide is a diamond grinding wheel due to its high hardness and wear resistance, which allows for efficient and precise grinding.

2. What grit size is recommended for grinding tungsten carbide?

A grit size between 200 to 600 is recommended for optimal burr removal and surface smoothing.

3. What type of bond is suitable for diamond grinding wheels?

Resin or ceramic bonds are recommended for diamond grinding wheels as they provide good grinding force and shape retention.

4. How often should grinding wheels be inspected?

Grinding wheels should be inspected regularly for defects before use to ensure safety and efficiency.

5. What safety precautions should be taken when grinding tungsten carbide?

Always follow strict operational procedures and monitor the grinding process for any abnormal conditions to ensure safety.

Citations:

[1] https://www.sparkyabrasives.com/camel-grinding-wheels-bench-wheels-green-silicon-carbide/

[2] https://www.carbide-products.com/blog/what-grinding-wheel-for-carbide/

[3] https://de.pferd.com/en/bench-grinding-wheels-carbide?a%5Bdiam-outer-tds%5D=250+mm&a%5Bwidth-tds%5D=32+mm&a%5Bdiam-bore-tds%5D=51+mm&a%5Bgrit-size-tds%5D=80

[4] https://www.passiontool.com/flaring-cup-diamond-grinding-wheels-for-tungsten-carbide-cutting-blades-product/

[5] https://chinagrindingwheel.en.made-in-china.com/product/UJjYIxDGsvVk/China-1A1-Resin-Diamond-Bond-Grinding-Wheel-for-Tungsten-Carbide-Ceramic-PDC-Bits-Stabilizer.html

[6] https://www.axminstertools.com/us/silicon-carbide-green-grinding-wheels-ax22226

[7] https://www.reddit.com/r/Welding/comments/12876t5/best_type_of_grinding_wheels_for_tungsten/

[8] https://www.carbide-part.com/blog/what-grinding-wheel-for-carbide/

[9] https://www.toolstore.com/toolstorecom/en/grinding-wheels-for-tungsten-carbide-grinding-norton-1

[10] https://www.superabrasivetools.com/diamond-grinding-wheel-for-tungsten-carbide-tools/

[11] https://niolin-industrial.com/products/green-silicone-carbide-grinding-wheel-carbonatom

[12] https://www.mcmaster.com/products/grinding-wheels/for-use-on~carbide/

[13] https://www.elitestonetools.co.uk/shop/p/tungsten-carbide-grinder-wheel-100mm-amp-125mm

[14] https://ronixtools.com/en/blog/best-grinding-wheels/

[15] https://www.elitestonetools.co.uk/shop/p/tungsten-carbide-grinder-wheel-100mm-amp-125mm

[16] http://chaski.org/homemachinist/viewtopic.php?t=89068

[17] https://www.allied-material.co.jp/en/products/diamond/knowledge/grinding-wheel_spec.html

[18] https://www.practicalmachinist.com/forum/threads/what-grinding-wheel-for-carbide-something-better-then-green-wheels.378924/

[19] https://www.cgwheels.com/bench-pedestal-grinding-wheels

[20] https://www.erniestools.com/4-1-2-x-5-8-11-tungsten-carbide-sharpening-wheel-type-27/

[21] https://www.huvema.nl/en/bench-grinding-wheel-for-hard-materials-e-g-tungsten-carbide-pf39009724

[22] https://www.superabrasivetools.com/diamond-grinding-wheel-for-tungsten-carbide-tools/

[23] https://www.abtec4abrasives.com/125-x-13--x-3175mm-gc-80-kv-grinding-wheels-1250138018-1486-p.asp

[24] https://diamondground.com/product-category/replacement-grinder-wheels/page/2/

[25] https://www.taiwandiamond.com/en/product/grinding-wheels-for-tungsten-carbide-end-mills-and-drills/

[26] https://www.unitedabrasives.com/mmi-family/green-silicon-carbide-bench-wheel/

[27] https://www.ceisupply.com/virginia-abrasives-grinding-disc-tungsten-carbide

[28] https://www.pinterest.com/pin/4bt9-resinoid-diamond-grinding-wheel-for-tungsten-carbide--627689266804044705/

[29] https://nikondia.com/n/product/grinding-stones-green-silicon-carbide/

[30] https://austechsaw.com.au/abrasives-burrs/grinding-cut-off-wheels/grinding-wheels/Grinding-Wheels-for-Tungsten-Carbide

[31] https://www.walmart.com/c/kp/grinding-carbide-diamond-wheel

[32] https://www.travers.com/product/radiac-silicon-carbide-green-bench-grinding-wheels-133087

[33] https://www.pinterest.com/pin/672795631870701440/

[34] https://westerntree.biz/product/cgw-bench-pedestal-green-silicon-carbide-grinding-wheels-gc80-i-v/

[35] https://ramweldingsupply.com/p/united-abrasives-sait-6-green-silicon-carbide-bench-grinding-wheel/

[36] https://htscoatings.com/blogs/our-craft-our-culture/how-to-choose-which-grinding-wheel-to-use

[37] https://www.virginiaabrasives.com/products/grinding-discs/grinding-discs-for-tungsten-carbide-premium

[38] https://www.aliexpress.com/i/1005004856681095.html