Contentus menu

● Introductio ad molendum rotae

>> Genera molere rotarum pro Tungsten Carbide

● Characteres molere rotae

>> Grit magnitudine

>> Type

>> Rota durum

● Practical tips molere Tungsten carbide

● Advanced Techniques pro molere Tungsten Carbide

>> I. ElectroChemical (ECG)

>> II. Ultrasonic molere

>> III. Laser adiuvarent molere

● Latest innovations in molere rotas ad Tungsten carbide

>> Nano-Diamond Pectus

>> Ultra-denique Diamond Pectus Currus

● Specialis considerations

>> Forma molere

>> In ore gladii melius

● Applications molere rotae pro Tungsten Carbide

● Additional contentus in molere rotarum ad Tungsten carbide

>> Refrigerant Systems

>> Rota amicientes

● Conclusio

● Faq

>> I. Quid est optimum stridor rota pro Tungsten carbide?

>> II. Quid grit mole commendatur ad stridor Tungsten carbide?

>> III. Quod genus vinculi apta adamantino stridor rotarum?

>> IV. Quoties stridor rotis inspici?

>> V. Quid salus cautiones capiendum cum molere Tungsten carbide?

● Citations:

Tungsten carbide est clarus ad eius eximia duritia, gerunt resistentia, et summus temperatus resistentia, faciens illud crucial material in variis industriae applications, comprehendo secans instrumenta et gerunt partes. Sed haec proprietatibus etiam reddere provocantes ad apparatus. Inter varias machining processus, molere est discrimine gradus quod postulat ius tools ad consequi praecisione et efficientiam. Hoc articulum delve in lectio molere rotae Tungsten carbide , exploring genera rotarum praesto, sua sunt, et practica tips pro efficax stridor.

Introductio ad molendum rotae

Metalworking rotarum molere sunt essentiales sunt, usus est ad secans, acuit, et lenis metallum superficiebus. Sunt ex abrasive particulas religata una cum matrix materia. Et arbitrium est molere rota pendeat in materia esse terram, desideravit metam, et specifica application.

Genera molere rotarum pro Tungsten Carbide

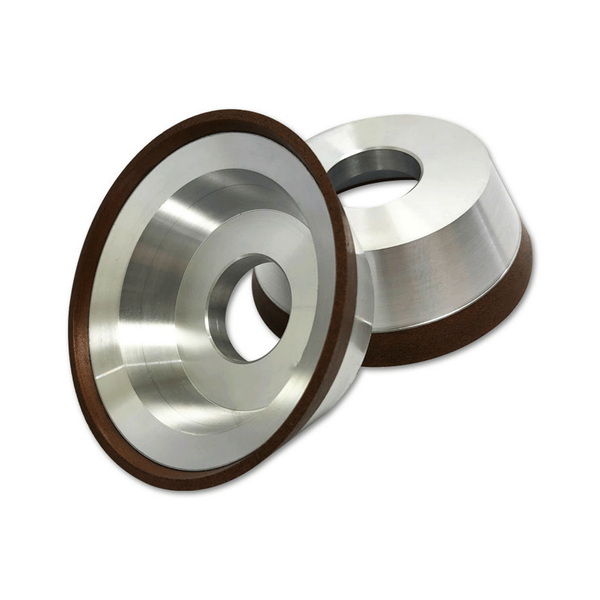

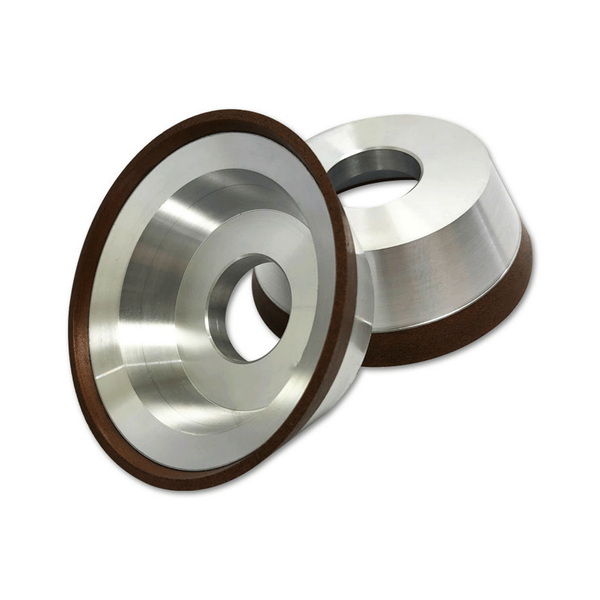

I. Diamond Pectus MOLLO rotae: Hi sunt maxime maluit arbitrium ad stridor Tungsten carbide ex superior duritia et gerunt resistentia. Diamond Pectus Currus offerre princeps efficientiam et praecisionem, faciens ea specimen ad altus-duritiam materiae sicut Tungsten carbide.

Diamond Pectus molere rotae sunt available in variis grit magnitudinum, typically vndique a CC ad DC, quae sunt idoneam ad utrumque aspera et denique molere operationes. Et vinculum genus est crucial; Resinae vel tellus vincula suadetur pro sua bona stridor vis et figura retention, specimen ad formam molere applications.

II. CBN (Cubic Boron Nitride) molere rotarum: dum non commune pro Tungsten carbide, cbn rotae sunt propter stridor altus-duritia materiae. Sunt minus pretiosa quam adamas rotae, sed tamen offer bonum perficientur.

III. Silicon carbide (microform) molere rotarum: Hi sunt plerumque usus est molere non-ferrea metalla et potest adhiberi Tungsten carbide, quamquam sunt minus effective quam adamas rotarum. Green Silicon Carbide rotae sunt specie attendendum pro usu in molere Tungsten carbide.

Characteres molere rotae

Grit magnitudine

ABRIT molentes rota determinat suavitas. Nam Tungsten Carbide, A GLAREA magnitudinem inter CC ad DC est suadetur pro optimal Burr remotionem et superficiem lenis.

Type

Quod vinculum genus afficit rotam scriptor diuturnitatem et molere perficientur. Resina vincula sunt communia adamas rotas, offering bonum molere vis et figura retention.

Rota durum

Durness molentes rota debet aequare materiam esse terram. Nam Tungsten carbide, rota satis duritia crucial ne nimia lapsum.

Practical tips molere Tungsten carbide

I. Rota inspectionem: Semper inspicere molere rota in defectibus ante usum vitare potential periculis.

II. Material Compatibility: Elige a rota fundatur in duritia et proprietatibus materiae ad ensure compatibility et efficientiam.

III. Installation et statera: sequimini stricte ratio installing et reprehendo in dynamic statera molere rota ad ponere praecisionem.

IV. Operational Salus: Adhere ad omnes operating ratio et Monitor molere processus pro aliquo abnormes conditionibus.

Advanced Techniques pro molere Tungsten Carbide

I. ElectroChemical (ECG)

ECG combines electrochemical dissolutio cum mechanica molere, reducendo mechanica accentus in workpiece. Hoc modus est utilis pro universa figuris et can amplio superficiem metam.

II. Ultrasonic molere

Ultrasonic molere utitur summus frequency vibrationum ad augendae molere processus. Praecipue utile molere parva vel intricatus partibus cum alta praecisione.

III. Laser adiuvarent molere

Hoc ars involves usura laser ad calefacere workpiece localiter, reducendo ad duritiam et faciens illud facilius ad tere. Est utile est reducendo scelerisque dampnum et meliorem efficientiam.

Latest innovations in molere rotas ad Tungsten carbide

Recens progressiones in molere rota technology includit in progressionem Nano-Diamond Pectus et ultra-denique Diamond Pectus rotae. Haec rotae offerre improved superficiem metam et reducitur lapsum, faciens ea specimen ad altus-praecisione applications.

Nano-Diamond Pectus

Nano-Diamond Pectus Currus utilitas Diamond Pectus particulas in Nanoscale, providing a levi metam et magis gerunt resistentia. Sunt praecipue expediunt molere parva vel delicata.

Ultra-denique Diamond Pectus Currus

Haec rotae pluma adamantino particulas cum valde denique Grit magnitudinum, typically infra I micron. Sunt enim propter consequi ultra-excelsum superficiem finiatur et sunt specimen pro applications requiring minimal materia remotionem.

Specialis considerations

Forma molere

Requires rotae, ut ponere formam et libera consistent molere vis. Resina aut Ceramic Bonded Diamond Pectus Currus sunt typice propter hoc application.

In ore gladii melius

Nam applications requiring altum metam qualis, elastica adamas rotae sunt potior. Et auxilium in removendo instrumentum marcas et reducendo secare resistentia, ita extendens ad instrumentum vitae.

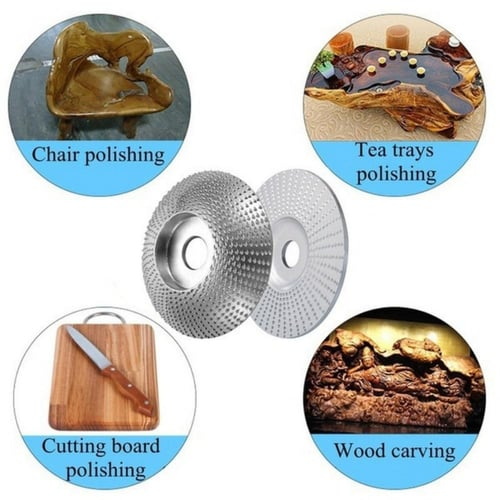

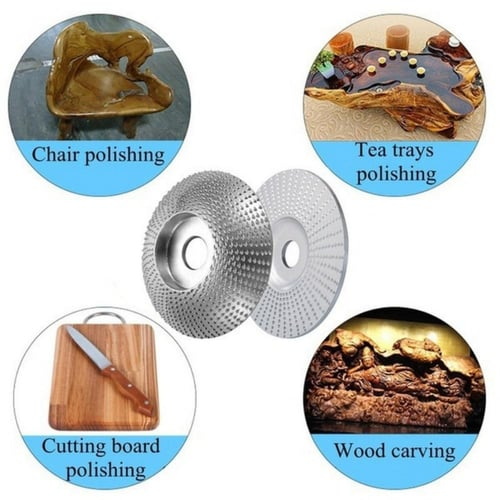

Applications molere rotae pro Tungsten Carbide

Tungsten carbide sunt in variis industrias in stridor rotarum, comprehendo:

- Tool vestibulum, quia acuit et resharpening carbide tools.

- Aerospace: nam molere components quod requirere altus praecisione et diuturnitatem.

- Automotive: nam vestibulum gere, repugnant.

Additional contentus in molere rotarum ad Tungsten carbide

Refrigerant Systems

Efficens refrigerationem systems sunt essentialis durante molere ne overheating et scelerisque damnum. Coolants quasi aqua aut oleum-fundatur fluidorum communiter solebant ponere firmum temperatus.

Rota amicientes

Ordinarius amicientes de molere rota est necessarium ponere sua efficaciam. Hoc processum involves removere trita, de abrasive particularum exponere novis, cursus consistent molere perficientur.

Conclusio

Eligendo ius stridor rotam in Tungsten carbide est crucial pro ashieving efficient et precise machining. Diamond Pectus MOLLIO rotae sunt malle arbitrium ex eorum superior perficientur characteres. Tamen intellectus specifica ad applicationem, ut grit magnitudinem et vinculum genus, est essentiale ad meliorem results. Advanced techniques sicut ElectroChemical molere et Ultrasonic molere offer additional beneficia ad complexu applications.

Faq

I. Quid est optimum stridor rota pro Tungsten carbide?

Optimus molere rota pro Tungsten carbide est adamantinas molere rota debitum ad altum duritiem et gerunt resistentia, quae concedit ad efficient et praecisam molere.

II. Quid grit mole commendatur ad stridor Tungsten carbide?

A GLAREA magnitudine inter CC ad DC commendatur ad meliorem Burr remotionem et superficiem lenis.

III. Quod genus vinculi apta adamantino stridor rotarum?

Resinae aut Ceramic vincula commendatur adamantino molere rotas quod providebit bonum molere vis et figura retention.

IV. Quoties stridor rotis inspici?

Molere rotarum inspiciendum regulariter defectus ante usum curare salutem efficientiam.

V. Quid salus cautiones capiendum cum molere Tungsten carbide?

Semper severus operational ratio et Monitor molere processus pro aliquo abnormes ad curare salutem.

Citations:

[I] https://www.sparkyabrasives.com/camel-Grinding-Wheels-bench-wheels-green-silicon-carbide/

[II] https://www.carbide-products.com/blog/what-grinding-wheel-for-carbide/

[III] https://De.pferd.com/en/bench-grinding-oetdds-carbide?a%5BDiam-Outer-Tds%5D=250+MM&a%5bwidth-tds%5d=32+mm&a%5bdiam-bore-tds%5d=51+mm&a%5bgrit-size-tds%5d=80

[IV] https://www.passiontool.com/flaring-cup-diamond-grinding-wheels-for-tungsten-carbide-cutting-blades-product/

[V] https://chinagrindingwheel.en.made-in-china.com/product/ujjyixdgyd-bond-grinding-wheel-for-tung-carbide-ceramic-pdc-bits-strabilizer.html

[VI] https://www.axminstertools.com/us/silicon-carbide-green-grinding-wheels-ax222226

[VII] https://www.reddit.com/r/welding/coms/12876t5/best_type_of_grinding_wheels_for_tungsten/

[VIII] https://www.carbide-part.com/blog/what-grinding-wheel-for-carbide/

[IX] https://www.toolstores.com/toolstorecom/en/grinding-wheels-for-tungsten-carbide-grinding-norton-1

[X] https://www.superabrasivetools.com/diamond-grinding-wheel-for-tungsten-carbide-tools/

[XI] https://niolin-industrial.com/products/green-silicone-carbide-grinding-wheel-carbonatom

[XII] https://www.mcmaster.com/products/grinding-wheels/for-use-on~-carbide/

[XIII] https://www.elitestonetoo.co.uk/shop/p/tungsten-carbide-grinder-wheel-100mmm-amp-125mm

[XIV] https://ronixtools.com/en/blog/best-grinding-wheels/

[XV] https://www.elitestonetoo.co.uk/shop/p/tungsten-carbide-grinder-wheel-100mm-amp-125mm

[XVI] http://chaski.org/homemachinist/viewtopic.php?t=89068

[XVII] https://www.allied-material.co.jp/en/products/diamond/knowledge/Groding-wheel_spec.html

[XVIII] https://www.practalmachinist.com/forum/threads/What-Grinding-Wheel-For-Carbide-something-better-then-green-wheels.378924/

[XIX] https://www.cgwheels.com/bench-pedestal-grinding-wheels

[XX] https://www.erniestools.com/4-1-2-x-5-8-11-tungsten-carbide-sharpening-wheel-type-27/

[XXI] https://www.huvema.nl/en/bench-grinding-wheel-for-hard-materials-eg-tungsten-carbide-pf39009724

[XXII] https://www.superabrasivetools.com/diamond-grinding-wheel-for-tungsten-carbide-tools/

[XXIII] https://www.abtec4abrasives.com/125-x-13--x-31grinding-wheels-1250138018-1486-p.asp

[XXIV] https://diamondground.com/product-category/replace/2/

[XXV] https://www.taiwandiamond.com/en/product/Grinding-Wheels-For-Tung-Carbide-End-Mills-and-Drills/

[XXVI] https://www.unitedabrasives.com/mmi-family/green-silicon-carbide-bench-wheel/

[XXVII] https://www.ceisupply.com/virginia-abrasives-grinding-disc-tungsten-carbide

[XXVIII] https://www.pinterest.com/pin/4bt9-resinoid-diamond-grinding-wheel-for-tungsten-carbide--627689266804044705/

[XXIX] https://nikondia.com/n/product/grinding-stones-green-silicon-carbide/

[XXX] https://ausechsaw.com.au/abrasives-burrs/grinding-cut-off-wheels/grinding-wheels/grinding-wheels-for-tungsten-carbide

[XXXI] https://wwwalmart.com/c/kp/grinding-carbide-diamond-wheel

[XXXII] https://www.trvers.com/product/radiac-silicon-carbide-green-bench-grinding-wheels-133087

[XXXIII] https://www.pinterest.com/pin/672795631870701440/

[XXXIV] https://westterntree.biz/product/cgw-bench-gedestal-green-silicon-c80-greinding-wheels-gc80-iv/

[XXXV] https://ramweldingsupply.com/p/united-abrasives-sait-6-green-silicon-carbide-bench-grinding-wheel/

[XXXVI] https://htscoatings.com/blogs/our-Caose-OUDE-Culture/How-To-choose-UeTyGrinding-Wheel-Ue

[XXXVII] https://www.virginiaabrasives.com/products/grinding-discs/grinding-discs-for-tungsten-carbide-premium

[XXXVIII] https://www.aliexpress.com/i/1005004856681095.html