Contentus menu

● Introductio ad Tungsten Carbide

>> Applications of Tungsten Carbide

● Modi enim applicando Tungsten Carbide

>> I. Thermal RESPERSIO

>> II. Depositionem

>> III. Embedding

>> IV. Brazing

● Praeparatio et post-applicationem treatments

>> Praeparatio

>> Post-applicationem treatments

● Advanced artes et considerations

>> Laser Cladding

>> Environmental considerations

>> Sumptus et efficientiam

● Conclusio

● Faq

>> I. Quid est HVOf processus usus est applicando Tungsten carbide coatings?

>> II. Quomodo facit scintilla depositione adhibere Tungsten carbide?

>> III. Quid est ad nickel coating Tungsten carbide particulas?

>> IV. Quid est superficies praeparatio momenti ante applicando Tungsten carbide coatings?

>> V. Quid est quaedam communia de Tungsten carbide?

● Citations:

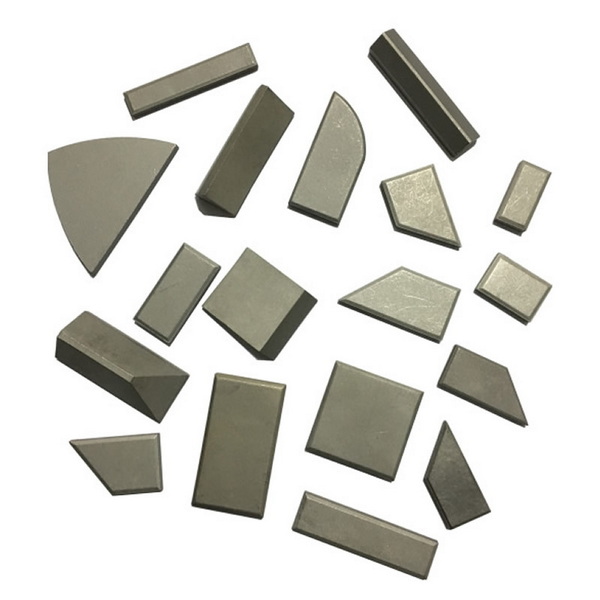

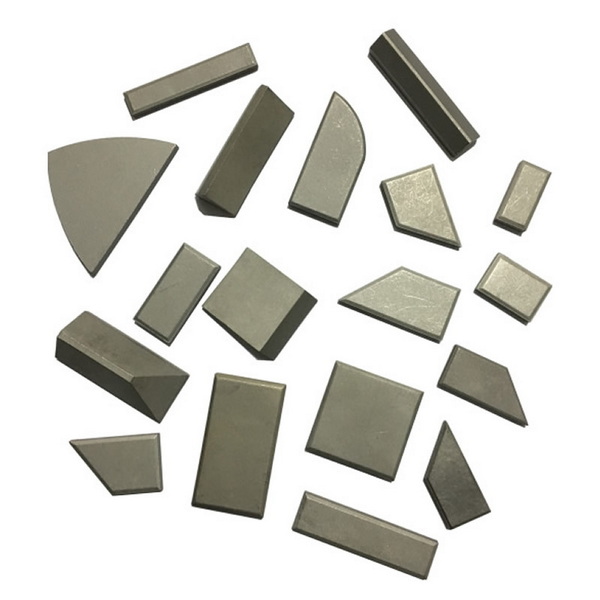

Tungsten carbide est clarus est eius eximia duritia et gerunt resistentia, faciens illud crucial materia in variis industriae applications, inter cutting instrumenta, exercitio machina, et gerunt, repugnans coatings. Applicatio Tungsten carbide effective requirit intellectus diversis modi et artes, quisque idonea ad specifica necessitates et materiae. Hic articulus erit dellve in processibus applicare Tungsten carbide, quatenus clavis modi ut scelerisque spargit, scintilla depositione et embedding.

Introductio ad Tungsten Carbide

Tungsten carbide est compositum materia constans Tungsten carbide particulas bonded simul per metallum matricem, typice Cobalt. Et duritia et diuturnitatem facere ideale pro applications ubi princeps gerunt resistentia necesse est. Processus applicandi Tungsten carbide potest variari signanter fretus in desideravit exitus et subiectum materia.

Applications of Tungsten Carbide

Antequam discussing applicationem modi, quod est essentialis intelligere diverse usus Tungsten Carbide:

- Cutting Tools: Tungsten carbide est late in secans instrumenta ob duritiam et facultatem ad sustinere altum temperaturis.

- EXERCITATIO Machinery, quod est in EXERCITATIO bits ad gerunt resistentia.

- Chirurgicam instrumenta: Tungsten Carbide Enhances ad perficientur et diuturnitatem de chirurgicam instrumenta.

- Jewelry: et duritia et diuturnitatem faciunt idoneam ad altus-finem jewelry.

- Aerospace Industry: usus est in components requiring princeps vires et resistentia ad induendum.

Modi enim applicando Tungsten Carbide

I. Thermal RESPERSIO

Thermal RESPERSIO est commune modum applicando Tungsten carbide coatings. Hoc processum involvit calefacit Tungsten carbide particulas ad altum caliditas et propellentes onto subiectum. In summa est thermal spraying ars enim Tungsten carbide est princeps velocitatem oxy-cibus (hvf) processus.

In HVOF processum, cibus Gas et oxygeni sunt conbustae in summus pressura cubiculum, perveniens temperaturis usque ad 5,600 ° (3,093 ° C). Et unde calida Gas est accelerated per COLLUM, ubi Tungsten carbide pulveris infusum. Partes miscere cum Gas et propellitur ad supersonicorum celeritatum onto subiectum formatam densa et gerunt repugnans coating.

II. Depositionem

Spars depositione est alius modus adhibetur adhibere Tungsten carbide, praecipue in die mittentem applications. Hoc processum involves depositing Tungsten carbide onto a metallum superficiem per electrica scintillas. Et rocklinizer est a fabrica, qui utitur hunc modum ad tangsten carbide in metallum superficiebus sine generating significant calor, ita servare ingenium workpiece.

III. Embedding

Embedding Tungsten carbide particulas in weld stagnum est ars solebat augendae ad induendum resistentia specifica areas in workpiece. Hoc modo involvit dirigens Tungsten carbide particulas in fusilia weld conlegio in welding. In particulas sunt typice intendebant ad ultimum dimidium de conlectus ut sint plene incorporatus in weld.

IV. Brazing

Brazing est modus ubi Nickel-iactaret Tungsten carbide particulas applicantur ad workpiece et tunc succensa ad conflandum ad conflandum ad conflandum ad conflandum in materia, securitate particulas in loco. Hoc modum est efficax quia nickel coating facit Tungsten carbide particulas intendentes, permittens eos adhaerere tam ad workpiece.

Praeparatio et post-applicationem treatments

Praeparatio

Antequam applicando Tungsten carbide coatings, subiectum superficiem praeparari ut bonum adhaesionem. Hoc saepius involves purgatio et roughening superficiem. Iaculat adficientes cum Tib2 particulas potest amplio superficiem crasse et compressive RELICTUM passes, enhancing ad vinculum inter coating et subiectum.

Post-applicationem treatments

Postquam applicando coating, additional treatments potest esse necessarium. Exempli gratia, stridor et adamantino rotae potest conflentur in coating superficies, reducendo porosity et meliorem microburness. Signatio cum epoxy resinae adhuc redigendum porositas et augendae corrosio resistentia.

Advanced artes et considerations

Laser Cladding

Laser Claddding est a modern ars quod involves uti a summus-nectunt laser ut conflandum et fuse Tungsten carbide particulis onto subiectum. Hoc modum offert praecise imperium super coating crassitudine et compositionem, faciens idealis ad complexu geometries et altus-praecisione applications.

Environmental considerations

Et applicationem Tungsten carbide coatings debet etiam considerans environmental factores. Nam exempli gratia, HVOF processu generat strepitu et postulat propriis evacuatione ut manage fumus. Praeterea, arbitrio Tungsten carbide vastum est adhaerere environmental ordinationes ne pollutio.

Sumptus et efficientiam

In sumptus-efficaciam applicando Tungsten carbide coatings pendeat in modum et scale application. Dum scelerisque RESPERSIO efficientem magnam officia operationes laser Cladding potest esse sumptus-efficax parva, praecisione applications.

Conclusio

Applicando Tungsten carbide efficacius requirit diligenter consideratione ad applicationem modum, subiectum praeparationem et post-applicationem treatments. Utrum per scelerisque spraying, scintilla depositione, embedding, aut atrio, singulis ars offert unicum commoda idonea ad diversas applications. Intelligentes haec processibus est crucial ad maximasing beneficia Tungsten carbide scriptor eximia duritia et gerunt resistentia.

Faq

I. Quid est HVOf processus usus est applicando Tungsten carbide coatings?

HVOF processus involves combusting fuel Gas et oxygeni propellit Tungsten carbide particulas ad altum velocitates onto subiectum creando densa et gerunt repugnans coating.

II. Quomodo facit scintilla depositione adhibere Tungsten carbide?

Scintilla depositione utitur electrica scintillas ad tellight tungsten carbide in metallum superficiebus sine generating significant calor, conservans workpiece scriptor ingenium.

III. Quid est ad nickel coating Tungsten carbide particulas?

Nickel coating facit tungsten carbide particulas, aliter, permittens eos adhaerere tam ad workpiece durante Brazing et Welding processibus.

IV. Quid est superficies praeparatio momenti ante applicando Tungsten carbide coatings?

Superficiem praeparatio, ut iaculat adficiendo, amplio superficiem crasse et RELICTUM passiones, enhancing adhaesionem inter coating et subiectum.

V. Quid est quaedam communia de Tungsten carbide?

Tungsten carbide adhibetur in cutting instrumenta, EXERCITATIO Machinery, chirurgicam instrumenta, jewelry, et aerospace industria ex duritia et gerunt resistentia.

Citations:

[I] https://www.thermalspray.com/preparation-tips-for-tungsten-carbide-coatings/

[II] https://www.asbindustries.com/coing-materials/carbide-coing-materials/tungsten-carbide-coatings

[III] https://patents.google.com/patent/us3049435a/en

[IV] https://rocklinmanufacturing.com/resources/files/yr/2020/die_casting_engineer_editorial_-_sept_20.pdf

[V] https://www.tungco.com/insights/blog/5-tungsten-carbide-applicsity/

[VI] https://www.youtube.com/watch?v=7O6Be6HyH0W

[VII] https://www.hardfaceretechnologies.com/zh/equipment-systen-operations-mbeding-system-operations-manual-2

[VIII] https://eurobalt.net/blog/2022/03/28/ALL-The-Application-Of-TungSten-carbide/