Content Menu

● Introduction to Tungsten Carbide

>> Tungsten Carbide vs. Stainless Steel

● Corrosion Resistance of Tungsten Carbide

>> Cobalt Binder and Corrosion

● Applications of Tungsten Carbide

● History of Tungsten Carbide

>> Early Industrial Applications

● Manufacturing Process of Tungsten Carbide

● Environmental Impact of Tungsten Carbide

>> Sustainable Practices

● Tungsten Carbide in Aerospace Applications

● Tungsten Carbide in Oil and Gas Industry

● Conclusion

● FAQs

>> 1. What is Tungsten Carbide?

>> 2. Is Tungsten Carbide Corrosion-Resistant?

>> 3. How Does Tungsten Carbide Compare to Stainless Steel?

>> 4. What Are the Common Applications of Tungsten Carbide?

>> 5. Can Tungsten Carbide Be Recycled?

● Citations:

Tungsten carbide is a compound made from tungsten and carbon, renowned for its exceptional hardness, wear resistance, and durability. It is widely used in industrial applications, including cutting tools, wear parts, and even jewelry. However, when considering its properties, a common question arises: Is tungsten carbide stainless? In this article, we will delve into the properties of tungsten carbide, its corrosion resistance, and compare it with stainless steel to provide a comprehensive understanding of its characteristics.

Introduction to Tungsten Carbide

Tungsten carbide is formed by combining tungsten and carbon atoms in a precise ratio. It is known for its high melting point, hardness, and resistance to deformation. These properties make it ideal for applications requiring high wear resistance and durability.

Tungsten Carbide Properties:

- Hardness: Tungsten carbide ranks about 9 on the Mohs scale, making it one of the hardest substances known, second only to diamond.

- Density: It is approximately twice as dense as steel, with a specific gravity of about 15.6.

- Thermal Conductivity: It has a thermal conductivity of about 110 W/(m·K), which is higher than many metals.

- Corrosion Resistance: While it is resistant to many acids and bases, it can react with hydrofluoric acid and fluorine gas.

Tungsten Carbide vs. Stainless Steel

Stainless steel is known for its corrosion resistance due to its chromium content, which forms a protective oxide layer on its surface. Tungsten carbide, on the other hand, offers superior hardness and wear resistance but lacks the same level of corrosion resistance as stainless steel.

Comparison Points:

| Property | Tungsten Carbide | Stainless Steel |

| Hardness | Extremely hard (Mohs 9) | Less hard than tungsten carbide |

| Corrosion Resistance | Resistant to many acids, but not hydrofluoric acid | Highly resistant to corrosion due to chromium content |

| Density | Twice as dense as steel | Less dense than tungsten carbide |

| Applications | Cutting tools, wear parts, jewelry | Medical instruments, kitchen appliances |

Corrosion Resistance of Tungsten Carbide

Tungsten carbide is generally resistant to corrosion, especially in normal environmental conditions. However, it can react with certain chemicals like hydrofluoric acid and fluorine gas. The addition of binders such as cobalt can affect its corrosion resistance, as cobalt can leach out in corrosive environments, leading to structural weakening.

Cobalt Binder and Corrosion

Cobalt is commonly used as a binder in cemented tungsten carbide to enhance its toughness and durability. However, cobalt can be susceptible to corrosion, particularly in acidic environments. This can lead to the deterioration of the tungsten carbide structure over time.

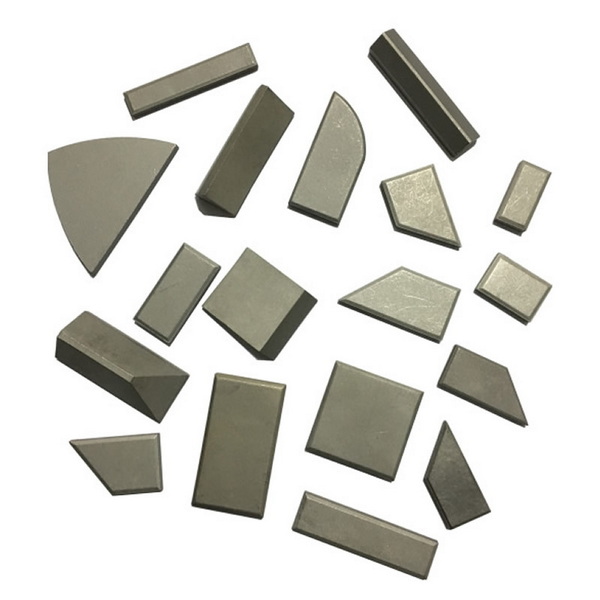

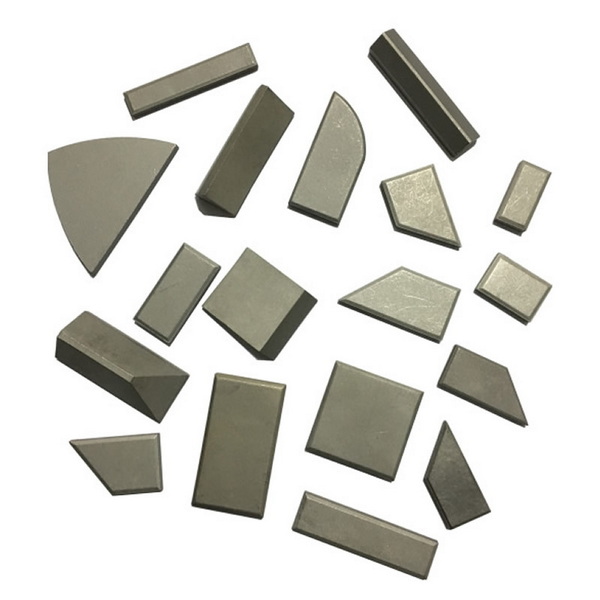

Applications of Tungsten Carbide

Tungsten carbide is used in a wide range of applications due to its unique properties:

1. Cutting Tools: Its hardness makes it ideal for cutting tools used in machining and drilling operations.

2. Wear Parts: It is used in components that require high wear resistance, such as nozzles and bearings.

3. Jewelry: Tungsten carbide rings are popular for their durability and scratch resistance.

History of Tungsten Carbide

The development of tungsten carbide dates back to the early 20th century. It was first synthesized in the 1920s by Friedrich Krupp AG in Germany, who discovered that by combining tungsten with carbon and a binder like cobalt, they could create a material with exceptional hardness and durability. This breakthrough led to its widespread use in industrial applications.

Early Industrial Applications

Initially, tungsten carbide was used primarily in the production of cutting tools. Its ability to withstand high temperatures and maintain its hardness made it ideal for machining operations. Over time, its applications expanded to include wear parts and other industrial components.

Manufacturing Process of Tungsten Carbide

The manufacturing process of tungsten carbide involves several steps:

1. Powder Production: Tungsten and carbon powders are mixed in a specific ratio.

2. Sintering: The mixture is then sintered at high temperatures with a binder, typically cobalt, to form a solid block.

3. Shaping: The block is then shaped into the desired form using various machining processes.

Environmental Impact of Tungsten Carbide

Tungsten carbide has a significant environmental impact due to the extraction of tungsten, which can lead to deforestation and water pollution. Additionally, the use of cobalt as a binder raises concerns due to cobalt mining's association with human rights issues and environmental degradation.

Sustainable Practices

Efforts are being made to improve the sustainability of tungsten carbide production. This includes recycling tungsten carbide scrap and implementing more environmentally friendly mining practices.

Tungsten Carbide in Aerospace Applications

In the aerospace industry, tungsten carbide is used for its high strength-to-weight ratio and resistance to extreme temperatures. It is often used in rocket nozzles and other components that require high durability.

Tungsten Carbide in Oil and Gas Industry

In the oil and gas industry, tungsten carbide is used in drilling tools due to its hardness and wear resistance. It helps in extending the lifespan of drilling equipment and improving drilling efficiency.

Conclusion

Tungsten carbide is not considered "stainless" in the same way as stainless steel, as it lacks the chromium oxide layer that provides stainless steel with its corrosion resistance. However, tungsten carbide offers superior hardness and wear resistance, making it invaluable in applications where these properties are critical.

FAQs

1. What is Tungsten Carbide?

Tungsten carbide is a compound made from tungsten and carbon, known for its exceptional hardness and wear resistance.

2. Is Tungsten Carbide Corrosion-Resistant?

Tungsten carbide is generally resistant to corrosion but can react with certain chemicals like hydrofluoric acid. Its corrosion resistance can be affected by the presence of binders like cobalt.

3. How Does Tungsten Carbide Compare to Stainless Steel?

Tungsten carbide is harder and more wear-resistant than stainless steel but lacks its corrosion resistance. Stainless steel is more versatile and cost-effective.

4. What Are the Common Applications of Tungsten Carbide?

Tungsten carbide is used in cutting tools, wear parts, and jewelry due to its hardness and durability.

5. Can Tungsten Carbide Be Recycled?

Yes, tungsten carbide can be recycled. Worn-out tools and scrap material can be reclaimed and reused.

Citations:

[1] https://en.wikipedia.org/wiki/Tungsten_carbide

[2] https://www.allied-material.co.jp/en/techinfo/tungsten_carbide/features.html

[3] https://www.jlsmoldparts.com/talking-corrosion-resistance-tungsten-carbide-grades/

[4] http://www.tungsten-carbide.com.cn

[5] https://www.alamy.com/stock-photo/tungsten-carbide.html

[6] https://www.vedantu.com/chemistry/tungsten-carbide

[7] https://www.thermalspray.com/questions-tungsten-carbide/

[8] https://carbideprocessors.com/pages/carbide-parts/tungsten-carbide-properties.html

[9] https://www.reekecarbide.com/tungsten-carbide/tungsten-carbide-and-stainless-steel-a-comparison-of-strengths-and-suitability.html

[10] https://www.linde-amt.com/resource-library/articles/tungsten-carbide

[11] https://www.boyiprototyping.com/materials-guide/does-tungsten-rust/

[12] https://www.retopz.com/57-frequently-asked-questions-faqs-about-tungsten-carbide/

[13] https://www.manufacturingtomorrow.com/news/2023/03/26/difference-between-tungsten-steel-and-stainless-steel/20331/

[14] https://brite.co/blog/tungsten-vs-stainless-steel/

[15] https://www.imetra.com/tungsten-carbide-material-properties/

[16] https://www.hyperionmt.com/en/Resources/materials/cemented-carbide/corrosion-resistance/

[17] https://www.azom.com/properties.aspx?ArticleID=1203

[18] https://www.hyperionmt.com/en/products/Wear-Parts/corrosion-resistant-carbide/

[19] https://www.reddit.com/r/AskReddit/comments/ag6ukl/what_are_the_differences_between_stainless_steel/

[20] https://www.carbideprobes.com/wp-content/uploads/2019/07/TungstenCarbideDataSheet.pdf

[21] https://www.metal-am.com/kennametal-offers-its-most-corrosion-resistant-tungsten-carbide-grade-for-am/

[22] https://www.makeitfrom.com/compare/AISI-304-S30400-Stainless-Steel/Tungsten-Carbide-WC

[23] https://www.dymetalloys.co.uk/what-is-tungsten-carbide

[24] https://htscoatings.com/blogs/our-craft-our-culture/three-tungsten-carbide-thermal-spray-coatings-and-their-uses

[25] https://www.wpiinc.com/blog/post/Why-Tungsten-Carbide-Surgical-Instruments-are-Preferred

[26] https://stock.adobe.com/search?k=tungsten+carbide

[27] https://www.istockphoto.com/photos/tungsten-carbide

[28] https://www.shutterstock.com/search/tungsten

[29] https://www.azom.com/article.aspx?ArticleID=1203

[30] https://stock.adobe.com/search?k=carbide

[31] https://cen.acs.org/materials/Chemistry-Pictures-Tungsten-carbide-slice/103/web/2025/02

[32] https://www.gettyimages.in/photos/tungsten

[33] https://www.aemmetal.com/news/tungsten-vs-tungsten-carbide-guide.html

[34] https://www.istockphoto.com/photos/tungsten-carbide-drill-bits

[35] https://www.kennametal.com/us/en/products/carbide-wear-parts/fluid-handling-and-flow-control/separation-solutions-for-centrifuge-machines/tungsten-carbide-materials.html

[36] https://periodictable.com/Elements/074/pictures.html

[37] https://www.shutterstock.com/search/tungsten-carbide

[38] https://www.freepik.com/free-photos-vectors/tungsten-carbide

[39] https://www.linkedin.com/pulse/7-questions-tungsten-carbide-burrs-shijin-lei

[40] https://www.tungstenworld.com/pages/tungsten-news-common-questions-about-tungsten

[41] https://www.linkedin.com/pulse/questions-composite-materials-tungsten-carbide-shijin-lei

[42] https://consolidatedresources.com/blog/10-facts-about-tungsten-carbide/

[43] https://www.linkedin.com/pulse/3-questions-tungsten-carbide-buttons-shijin-lei

[44] https://www.tungco.com/insights/blog/frequently-asked-questions-used-tungsten-carbide-inserts/

[45] https://www.britannica.com/science/tungsten-carbide

[46] http://www.carbidetechnologies.com/faqs/

[47] https://testbook.com/question-answer/abrasive-material-used-for-lapping-tungsten-carbid--6365d4f4f0a644c794ba74f9

[48] https://tuncomfg.com/about/faq/

[49] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[50] https://shop.machinemfg.com/the-pros-and-cons-of-tungsten-carbide-a-comprehensive-guide/

[51] https://www.ukowiretools.com/faq/

[52] https://create.vista.com/photos/tungsten-carbide/

[53] https://collegedunia.com/exams/tungsten-carbide-synthesis-properties-and-toxicity-chemistry-articleid-5537