Content Menu

● Introduction to Tungsten Carbide

● Challenges in Soldering Tungsten Carbide

>> Low Thermal Conductivity

>> Difficulty in Wetting

● Techniques for Soldering Tungsten Carbide

>> Brazing vs. Soldering

>>> Brazing Process

>> Specific Brazing Alloys for Tungsten Carbide

● Managing Stresses in Brazed Joints

● Inspection and Quality Control

● Advanced Techniques for Brazing Tungsten Carbide

>> Vacuum Brazing

>> Fluxless Brazing

>> Laser Brazing

● Applications of Brazed Tungsten Carbide

● Conclusion

● FAQs

>> 1. What is the best method for cleaning tungsten carbide before brazing?

>> 2. How do I choose the right brazing alloy for tungsten carbide?

>> 3. What are the common issues encountered during the brazing of tungsten carbide?

>> 4. Can I use soldering irons for tungsten carbide?

>> 5. How do I inspect the quality of a brazed tungsten carbide joint?

● Citations:

Tungsten carbide is a hard, dense material known for its exceptional wear resistance and high melting point, making it ideal for cutting tools, wear parts, and other industrial applications. However, soldering tungsten carbide can be challenging due to its low thermal conductivity and difficulty in wetting by solder alloys. This article will guide you through the process of soldering tungsten carbide, highlighting key considerations and techniques.

Introduction to Tungsten Carbide

Tungsten carbide is composed of tungsten carbide particles bonded together by a metal matrix, typically cobalt. Its hardness and durability make it suitable for applications where high wear resistance is required. However, these properties also make it difficult to solder, as the material does not easily form a strong bond with solder alloys.

Challenges in Soldering Tungsten Carbide

Low Thermal Conductivity

Tungsten carbide has a low thermal conductivity compared to metals, which means it does not efficiently conduct heat. This can lead to uneven heating during the soldering process, potentially causing thermal stresses that may crack the carbide.

Difficulty in Wetting

Wetting refers to the ability of a solder alloy to spread and adhere to the surface of the material being soldered. Tungsten carbide is difficult to wet due to its non-metallic nature and the presence of cobalt, which can inhibit the flow of solder alloys.

Techniques for Soldering Tungsten Carbide

Brazing vs. Soldering

While soldering typically involves lower temperatures (below 450°C), brazing uses higher temperatures (above 450°C) and is more commonly used for joining tungsten carbide due to its ability to form stronger bonds.

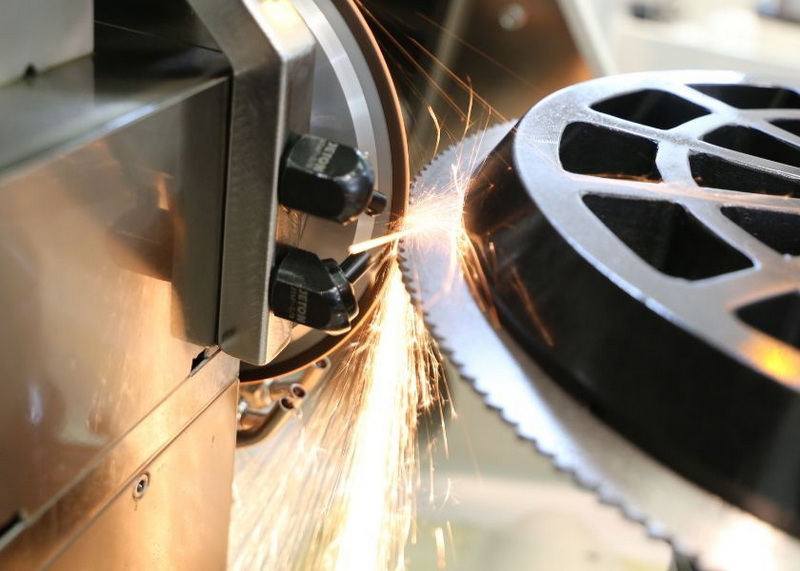

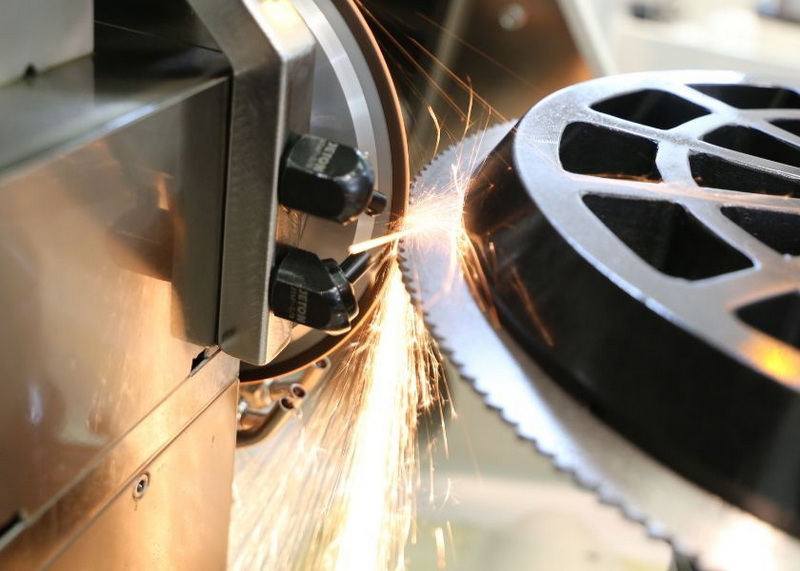

Brazing Process

1. Preparation: Clean the tungsten carbide surface thoroughly to remove any contaminants that might interfere with wetting. This can be done by grinding or using a chemical cleaner. For example, a mixture of nitric acid and hydrofluoric acid can be effective for removing oxides.

2. Joint Design: Ensure the joint is designed to minimize stress concentrations, which can lead to cracking during cooling. A machined pocket in the base material can help distribute stresses evenly.

3. Brazing Alloy Selection: Choose a brazing alloy that is compatible with tungsten carbide, such as silver-based alloys (e.g., BAg-3 or BAg-24). These alloys provide good wetting and strength.

4. Heating Method: Use a controlled heating method like induction or furnace brazing to achieve uniform heating. Avoid rapid heating or cooling to prevent thermal stresses.

5. Post-Brazing Operations: After brazing, inspect the joint for any defects and perform stress relief if necessary to prevent cracking.

Specific Brazing Alloys for Tungsten Carbide

- Meta-Braze 155 and 156: Suitable for small tungsten carbide tips (<10mm).

- Argo-braze 502: Recommended for small to medium-sized carbide pieces (10-20mm), contains nickel for improved wetting.

- BAg-3 and BAg-24: Common silver-based alloys used for brazing tungsten carbide.

Managing Stresses in Brazed Joints

Tungsten carbide expands and contracts less than steel during heating and cooling, leading to residual stresses in the joint. To manage these stresses:

- Slow Cooling: Avoid quenching; instead, use slow cooling methods like sand or insulation to reduce thermal shock.

- Joint Design: Ensure the carbide is under compressive stress during cooling by placing it in a machined pocket.

Inspection and Quality Control

After brazing, inspect the joint for:

- Cracks: Check for any visible cracks or defects.

- Wetting: Ensure the brazing alloy has properly wetted the carbide surface.

- Strength: Perform mechanical tests to ensure the joint strength meets requirements.

Advanced Techniques for Brazing Tungsten Carbide

Vacuum Brazing

Vacuum brazing is an advanced technique that involves brazing in a vacuum environment. This method helps prevent oxidation and ensures a clean, strong bond. It is particularly useful for complex geometries where atmospheric gases might interfere with the brazing process.

Fluxless Brazing

Fluxless brazing eliminates the need for flux by using a controlled atmosphere or vacuum. This method reduces contamination and is ideal for applications requiring high purity.

Laser Brazing

Laser brazing offers precise control over the heat input, allowing for localized heating and minimizing thermal stresses. This technique is beneficial for small or intricate parts.

Applications of Brazed Tungsten Carbide

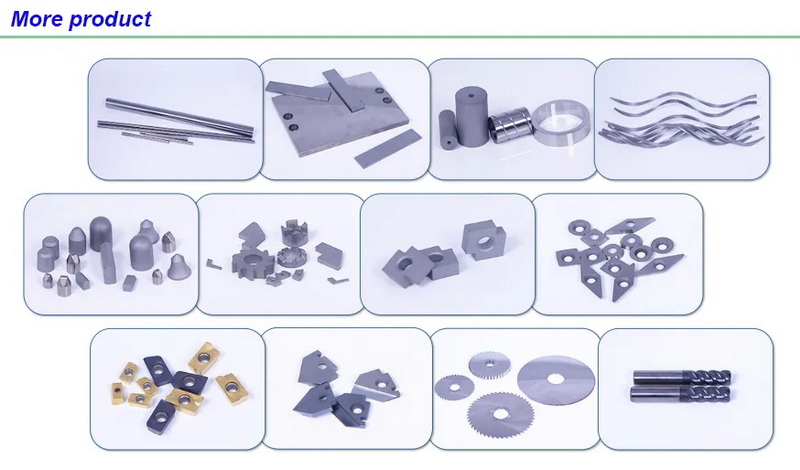

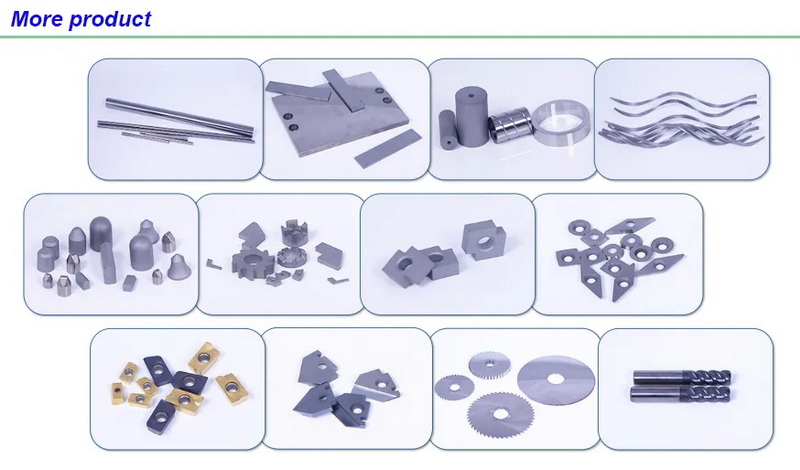

Brazed tungsten carbide is widely used in various industries:

- Cutting Tools: Carbide tips are brazed onto steel shanks to create durable cutting tools.

- Wear Parts: Brazed carbide components are used in pumps, valves, and other machinery to enhance wear resistance.

- Aerospace: Brazed carbide parts are used in aerospace applications due to their high strength-to-weight ratio.

Conclusion

Soldering tungsten carbide requires careful consideration of the material's properties and the brazing process. By selecting the right brazing alloy, ensuring proper joint design, and managing thermal stresses, strong and reliable joints can be achieved. While soldering is less common for tungsten carbide, brazing offers a robust method for joining these components.

FAQs

1. What is the best method for cleaning tungsten carbide before brazing?

Cleaning tungsten carbide is crucial for successful brazing. Use a grinder or chemical cleaner to remove any contaminants. Ensure the surface is free from oil, grease, or oxides.

2. How do I choose the right brazing alloy for tungsten carbide?

Select a brazing alloy that provides good wetting and strength, such as silver-based alloys. Consider the size and application of the carbide piece when choosing between different alloys.

3. What are the common issues encountered during the brazing of tungsten carbide?

Common issues include cracking due to thermal stresses, poor wetting, and joint failure. These can be mitigated by proper joint design, slow cooling, and using appropriate brazing alloys.

4. Can I use soldering irons for tungsten carbide?

Soldering irons are generally not suitable for tungsten carbide due to the high temperatures required for brazing. Instead, use controlled heating methods like induction or furnace brazing.

5. How do I inspect the quality of a brazed tungsten carbide joint?

Inspect for cracks, ensure proper wetting, and perform mechanical tests to verify the joint strength. Use methods like striking the tool to check if the carbide insert remains firmly attached.

Citations:

[1] https://patents.google.com/patent/CN103949741A/en

[2] https://www.meta-braze.com/preventing-cracking-in-tungsten-carbide

[3] https://www.zzbetter.com/new/How-to-Braze-Tungsten-Carbide-Cutting-Tools.html

[4] https://blog.lucasmilhaupt.com/en-us/about/blog/carbide-brazing

[5] https://mat-tech.com/brazing-of-cemented-tungsten-carbide-to-din-1-2343-tool-steel-2/

[6] https://www.jmmetaljoining.com/pdfs-downloads/3493%20Argo-braze%20-%20Tungsten%20Carbide%20and%20PCD%20-%20En.pdf

[7] https://www.radyne.com/carbide_brazing/

[8] https://www.alibaba.com/showroom/tungsten-carbide-soldering-tips.html

[9] https://carbideprocessors.com/pages/brazing-carbide/brazing-tungsten-carbide.html

[10] https://www.eng-tips.com/threads/tungsten-carbide-and-tin-solder.294486/

[11] https://www.carbide-products.com/fr/blog/tungsten-carbide-products-wear-resistant-hardfacing/

[12] https://www.generalcarbide.com/wp-content/uploads/2019/04/GeneralCarbide-Designers_Guide_TungstenCarbide.pdf

[13] https://contenti.com/tungsten-carbide-soldering-pick

[14] https://www.istockphoto.com/photos/tungsten-carbide

[15] https://wenlijituan.en.made-in-china.com/product/kmiRJqebvgpz/China-Soldering-Tungsten-Carbide-Tip-Cemented-Carbide-Bit-Tipped.html

[16] https://stock.adobe.com/search?k=tungsten+carbide

[17] https://www.shutterstock.com/search/carbide-brazing

[18] https://www.etsy.com/listing/1536675165/titanium-tungsten-carbide-soldering

[19] https://www.practicalmachinist.com/forum/threads/questions-about-tungsten-copper.401578/

[20] https://www.allied-material.co.jp/en/faq.html

[21] https://jgcarbide.en.made-in-china.com/product/zSNEQmpuYqWy/China-Hip-Sintered-Tungsten-Carbide-Soldering-Tips-A430.html

[22] https://www.carbide-part.com/blog/how-to-machine-tungsten-carbide/

[23] https://www.practicalmachinist.com/forum/threads/silver-solder-carbide-blanks.279798/

[24] https://todaysmachiningworld.com/magazine/how-it-works-making-tungsten-carbide-cutting-tools/

[25] https://mat-tech.com/brazing-of-cemented-tungsten-carbide-to-din-1-2343-tool-steel/

[26] https://orchid.ganoksin.com/t/solder-pick-titanium-or-tungsten/40138

[27] https://www.silbraze.com.au/tiptungsten.html