Content Menu

● Introduction to Tungsten Carbide Tools

>> Benefits of Tungsten Carbide Tools

● Sharpening Techniques for Tungsten Carbide Tools

>> 1. Diamond Grinding Wheels

>> 2. Silicon Carbide Grinding Wheels

>> 3. EDM and Laser Sharpening

>>> EDM Sharpening

>>> Laser Sharpening

● Safety Precautions

● Common Mistakes to Avoid

● Maintenance and Storage

● Tips for Optimal Performance

● Troubleshooting Common Issues

● Conclusion

● FAQ

>> 1. What is the best method for sharpening tungsten carbide tools?

>> 2. Can silicon carbide wheels be used for sharpening tungsten carbide tools?

>> 3. How often should tungsten carbide tools be sharpened?

>> 4. What safety precautions should be taken when sharpening tungsten carbide tools?

>> 5. Can tungsten carbide tools be sharpened multiple times?

● Citations:

Tungsten carbide lathe tools are renowned for their exceptional hardness and durability, making them ideal for cutting through hard materials like steel and other metals. However, like all cutting tools, they eventually dull and require sharpening to maintain optimal performance. Sharpening tungsten carbide tools can be challenging due to their hardness, but with the right techniques and tools, it can be efficiently done.

Introduction to Tungsten Carbide Tools

Tungsten carbide tools are made from a combination of tungsten and carbon, which provides them with their remarkable strength and resistance to wear. These tools are widely used in metalworking and woodworking applications where precision and durability are crucial.

Benefits of Tungsten Carbide Tools

- Durability: Tungsten carbide tools can withstand high temperatures and maintain their cutting edge even when working with hard materials.

- Precision: They provide clean cuts and are essential for achieving precise dimensions in machining processes.

- Longevity: Despite their hardness, tungsten carbide tools can be sharpened multiple times, extending their lifespan.

Sharpening Techniques for Tungsten Carbide Tools

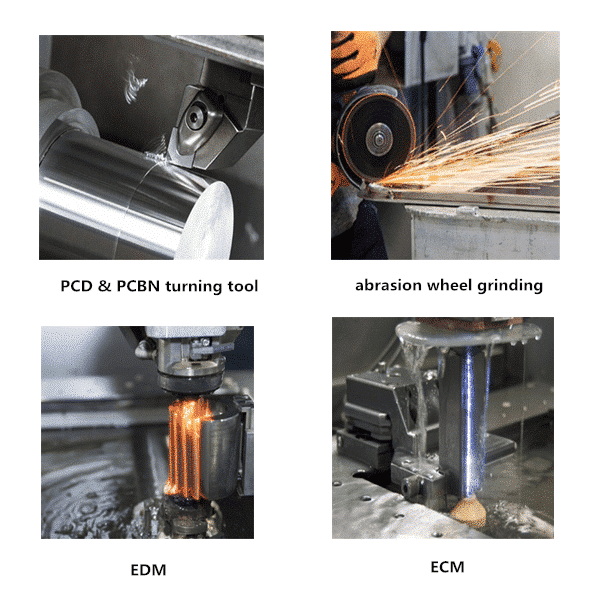

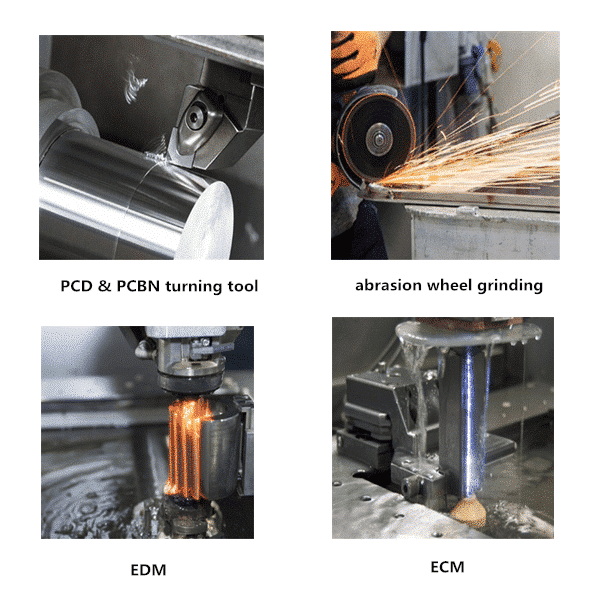

Sharpening tungsten carbide tools requires specialized equipment due to their hardness. The most effective methods include using diamond grinding wheels, silicon carbide wheels, EDM (Electrical Discharge Machining), and laser sharpening.

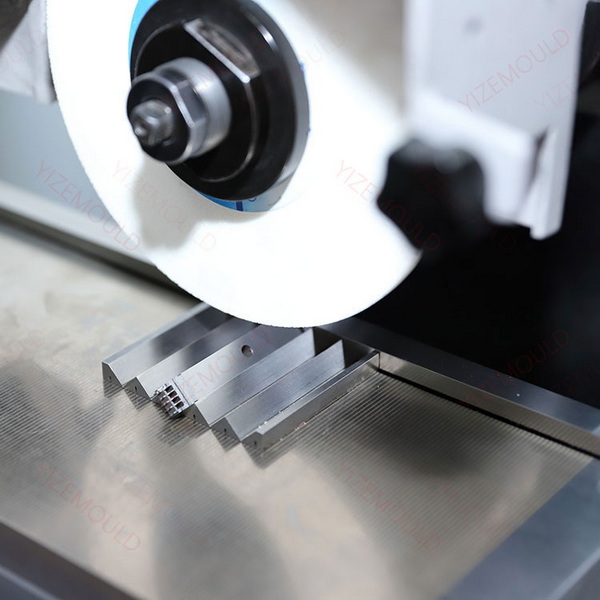

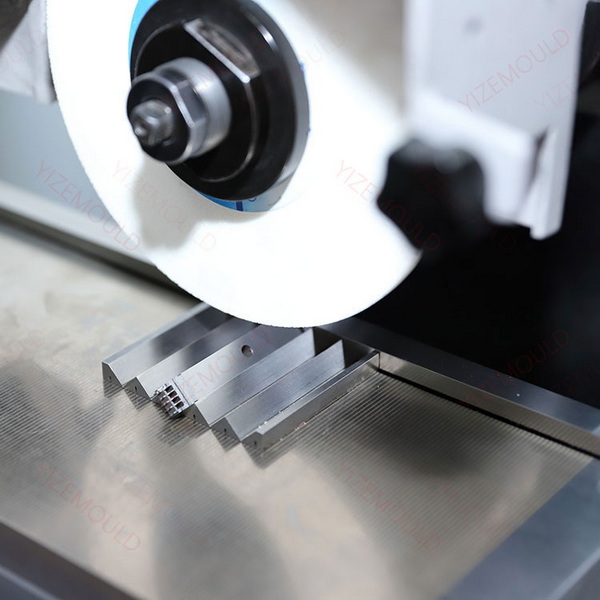

1. Diamond Grinding Wheels

Diamond grinding wheels are the most effective tool for sharpening tungsten carbide due to their superior hardness. They provide high precision, are long-lasting, and allow for a fast sharpening process.

Benefits:

- High Precision: Diamond wheels maintain the sharpness and angle of the blade's cutting edge.

- Long-Lasting: Diamond wheels are extremely durable and can be used repeatedly without noticeable wear.

- Fast Process: Sharpening with diamond wheels is efficient and effective, restoring sharpness quickly.

How to Use:

1. Positioning: Ensure the tool is correctly positioned against the wheel to maintain the desired angle.

2. Pressure: Apply consistent pressure to avoid uneven wear.

3. Cooling: Keep the tool cool during grinding to prevent overheating. Using a coolant is essential to maintain the blade's integrity by preventing heat buildup.

2. Silicon Carbide Grinding Wheels

Silicon carbide wheels are a more affordable alternative to diamond wheels but are less effective for heavy-duty sharpening. They are suitable for lighter or occasional sharpening needs.

Benefits:

- Affordable: Silicon carbide wheels are more cost-effective than diamond wheels.

- Accessible: They are widely available and can be used for lighter sharpening tasks.

How to Use:

1. Positioning: Similar to diamond wheels, ensure proper positioning.

2. Pressure: Apply consistent pressure but be aware that silicon carbide wheels may wear faster.

3. Cooling: Keep the tool cool to prevent overheating.

3. EDM and Laser Sharpening

EDM and laser sharpening are advanced methods that offer high precision but are typically used in industrial settings due to their complexity and cost.

EDM Sharpening

EDM uses electrical discharges to erode material from the blade's surface. This method is ideal for blades requiring intricate geometries or tight tolerances without applying mechanical force.

Laser Sharpening

Laser sharpening uses focused laser beams to sharpen tungsten carbide blades. This process is highly accurate and non-contact, eliminating the risk of mechanical wear.

Safety Precautions

When sharpening tungsten carbide tools, safety is paramount:

- Eye Protection: Always wear safety glasses to protect against debris.

- Dust Mask: Use a dust mask to prevent inhalation of dust particles.

- Proper Clothing: Wear protective clothing to avoid injury from flying particles.

Common Mistakes to Avoid

Sharpening tungsten carbide blades requires a careful approach. Here are some common mistakes to avoid:

- Overheating the Blade: Excessive heat can cause microfractures or even break the tungsten carbide. Always use coolant when sharpening to keep the blade cool.

- Using Inappropriate Abrasives: Only materials harder than tungsten carbide, such as diamond or silicon carbide, should be used for sharpening. Using softer abrasives will not sharpen the blade effectively.

- Incorrect Sharpening Angle: Applying the wrong angle can result in uneven wear and poor cutting performance. Use a sharpening guide to maintain consistency.

Maintenance and Storage

Proper maintenance and storage are crucial for extending the life of tungsten carbide tools:

- Regular Inspection: Check tools regularly for signs of wear or damage.

- Storage Conditions: Store tools in a dry environment away from corrosive atmospheres to prevent damage.

- Handling with Care: Handle tools carefully to avoid chipping or cracking due to their brittle nature.

Tips for Optimal Performance

To maximize the performance of tungsten carbide tools, consider the following tips:

- Select the Right Carbide Grade: Different applications require different carbide grades. For example, a tougher grade may be needed for hardened materials, while a more wear-resistant grade is suitable for high-speed operations[7].

- Implement Rigorous Maintenance: Regular cleaning and inspection can prevent premature tool failure and ensure consistent performance[7].

- Optimize Cutting Parameters: Adjusting cutting speeds, feed rates, and depths of cut can significantly reduce tool wear while maintaining efficiency[5].

Troubleshooting Common Issues

Common issues with tungsten carbide tools include inefficient cutting, which can be due to dull burrs, improper tool selection, or incorrect operating speeds. To troubleshoot:

- Inspect the Tool: Check for wear and replace if necessary.

- Adjust Operating Speeds: Follow manufacturer recommendations for optimal performance[6].

Conclusion

Sharpening tungsten carbide lathe tools requires careful consideration of the tools and techniques used. Diamond grinding wheels are the most effective method for sharpening these tools due to their hardness and precision. By following proper sharpening techniques and safety precautions, you can extend the life of your tungsten carbide tools and maintain optimal performance in your machining operations.

FAQ

1. What is the best method for sharpening tungsten carbide tools?

The best method for sharpening tungsten carbide tools is using diamond grinding wheels due to their superior hardness and precision.

2. Can silicon carbide wheels be used for sharpening tungsten carbide tools?

Yes, silicon carbide wheels can be used, but they are less effective and wear faster than diamond wheels. They are suitable for lighter sharpening tasks.

3. How often should tungsten carbide tools be sharpened?

Tungsten carbide tools should be sharpened when they begin to show signs of dulling, as continued use can lead to rapid deterioration and reduced tool life.

4. What safety precautions should be taken when sharpening tungsten carbide tools?

Always wear eye protection, a dust mask, and protective clothing to prevent injury from flying particles and dust.

5. Can tungsten carbide tools be sharpened multiple times?

Yes, tungsten carbide tools can be sharpened multiple times, but eventually, they may need to be replaced if the cutting edge becomes too small.

Citations:

[1] https://passionblade.com/what-is-the-best-way-to-sharpen-tungsten-carbide-blade/

[2] https://www.rennietool.co.uk/blogs/news/how-to-extend-the-lifespan-of-your-carbide-tools-maintenance-and-sharpening-tips

[3] https://www.linkedin.com/pulse/how-sharpen-tungsten-carbide-shijin-lei

[4] https://www.ihrcarbide.com/news/how-to-sharpen-tungsten-carbide-tools/

[5] https://primatooling.co.uk/essentials-of-solid-carbide-cutting-tools/

[6] https://www.empireabrasives.com/blog/guide-troubleshooting-tungsten-carbide-burrs-issues-solutions/

[7] https://www.rennietool.co.uk/blogs/news/maximising-productivity-with-carbide-tooling-tips-for-optimal-performance

[8] https://www.mtb2b.tw/en/company/articles/182

[9] http://conradhoffman.com/advancedsharp.htm

[10] https://www.hit-tw.com/newsdetails.aspx?nid=298

[11] https://hmaking.com/lathe-cutting-tools/

[12] https://carbideprocessors.com/pages/carbide-parts/carbide-defects.html

[13] https://www.youtube.com/watch?v=kUOuAPimjP4

[14] https://www.model-engineer.co.uk/forums/topic/tungsten-carbide-tipped-lathe-tools/

[15] http://chaski.org/homemachinist/viewtopic.php?t=37107

[16] https://www.homemodelenginemachinist.com/threads/sharpening-carbide-bits.8435/

[17] https://www.youtube.com/watch?v=RrttP9OfOH4

[18] https://int-enviroguard.com/blog/tungsten-carbide-exposure-are-your-workers-at-risk/

[19] https://www.practicalmachinist.com/forum/threads/sharpening-carbide-inserts.80378/

[20] https://mikedarlow.com/topics/articles/my-assessment-of-carbide-tipped-scrapers/