Content Menu

● Introduction to Tungsten Carbide

>> Tungsten Carbide Properties

● Methods for Sharpening Tungsten Carbide Blades

>> 1. Diamond Grinding Wheels

>> 2. Silicon Carbide Grinding Wheels

>> 3. Electrical Discharge Machining (EDM)

>> 4. Laser Sharpening

● Factors to Consider When Sharpening Tungsten Carbide Blades

>> Cooling

>> Proper Angle

>> Sharpening Frequency

>> Quality of Sharpening Tools

● Common Mistakes to Avoid

● Advanced Techniques for Sharpening Tungsten Carbide Blades

>> Tool and Cutter Grinders

>> Custom Jigs for Small Blades

● Safety Precautions

● Cost Considerations

● Environmental Impact

● Conclusion

● FAQs

>> 1. What is the best method for sharpening tungsten carbide blades?

>> 2. Can silicon carbide wheels be used for sharpening tungsten carbide?

>> 3. What are the benefits of EDM in sharpening tungsten carbide blades?

>> 4. How often should tungsten carbide blades be sharpened?

>> 5. What safety precautions should be taken when sharpening tungsten carbide blades?

● Citations:

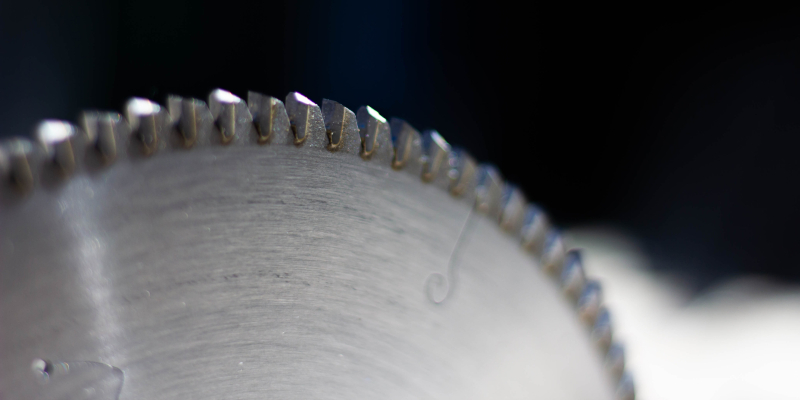

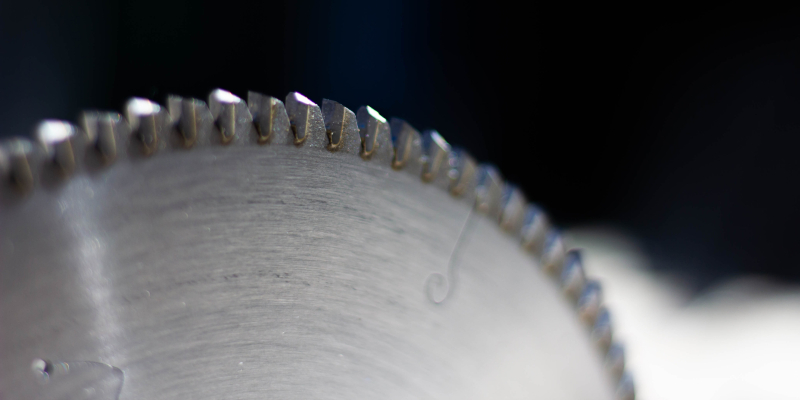

Tungsten carbide blades are renowned for their exceptional hardness and durability, making them indispensable in various industrial applications, including cutting tools, drill bits, and saw blades. However, like all cutting tools, they eventually dull and require sharpening to maintain optimal performance. Sharpening tungsten carbide blades can be challenging due to their hardness, but with the right techniques and tools, it is both feasible and cost-effective.

Introduction to Tungsten Carbide

Tungsten carbide is a composite material consisting of tungsten carbide particles bonded together by a metallic matrix, typically cobalt. This composition gives it superior hardness and wear resistance compared to steel, making it ideal for high-wear applications. However, its hardness also means that sharpening requires specialized equipment and methods.

Tungsten Carbide Properties

- Hardness: Tungsten carbide is significantly harder than steel, which makes it more resistant to wear but also more difficult to sharpen.

- Durability: It maintains its structural integrity under high stress and temperature conditions.

- Cost-Effectiveness: Despite being more expensive than steel tools initially, tungsten carbide tools can be sharpened multiple times, extending their lifespan and reducing overall costs.

Methods for Sharpening Tungsten Carbide Blades

Several methods are available for sharpening tungsten carbide blades, each with its advantages and limitations.

1. Diamond Grinding Wheels

Diamond grinding wheels are the most effective tool for sharpening tungsten carbide blades. Diamond is one of the few materials harder than tungsten carbide, allowing for precise grinding with minimal wear on the wheel.

Benefits:

- High Precision: Diamond wheels provide excellent control over the sharpening process, maintaining the blade's angle and sharpness.

- Long-Lasting: Diamond wheels are extremely durable and can be used repeatedly without significant wear.

- Fast Process: Sharpening with diamond wheels is efficient, restoring sharpness quickly.

How to Use:

1. Set the blade at the correct angle against the grinding wheel.

2. Use a coolant to prevent overheating, which can damage the tungsten carbide.

3. Apply consistent pressure to achieve a sharp, even edge.

2. Silicon Carbide Grinding Wheels

Silicon carbide wheels are a more affordable alternative to diamond wheels, though less effective for heavy-duty sharpening.

Benefits:

- Affordable: Silicon carbide wheels are cheaper than diamond wheels.

- Accessible: Widely available for lighter sharpening needs.

How to Use:

1. Position the blade correctly.

2. Apply consistent pressure.

3. Ensure the blade remains cool during grinding.

3. Electrical Discharge Machining (EDM)

EDM uses electrical discharges to erode material from the blade's surface, ideal for intricate designs.

Benefits:

- High Precision: EDM is excellent for complex geometries without applying mechanical stress.

- No Mechanical Stress: Reduces the risk of deformation or damage.

How to Use:

1. Place the blade in an EDM machine.

2. Use electrical discharges to erode material from the blade's edge.

4. Laser Sharpening

Laser sharpening uses focused laser beams to sharpen blades without physical contact.

Benefits:

- Extreme Precision: Restores blades to their original sharpness with high accuracy.

- No Physical Wear: Eliminates the risk of mechanical wear or damage.

- Quick Process: Suitable for high-production environments.

How to Use:

1. Direct a concentrated laser beam at the blade's cutting edge.

2. Vaporize small amounts of material to restore sharpness.

Factors to Consider When Sharpening Tungsten Carbide Blades

Cooling

Overheating is a significant risk when sharpening tungsten carbide. Using a coolant is essential to prevent microcracks and maintain the blade's integrity.

Proper Angle

Maintaining the correct sharpening angle is crucial for achieving a sharp edge while preserving the blade's geometry. Using a guide can help ensure precision.

Sharpening Frequency

Regular maintenance is key. Sharpening before the blade becomes completely dull reduces efficiency loss and extends its lifespan.

Quality of Sharpening Tools

High-quality diamond or silicon carbide grinding wheels are necessary for effective sharpening. Using inappropriate abrasives can lead to poor results or damage the blade.

Common Mistakes to Avoid

- Overheating the Blade: Excessive heat can cause microfractures or break the tungsten carbide. Always use coolant.

- Using Inappropriate Abrasives: Only materials harder than tungsten carbide should be used.

- Incorrect Sharpening Angle: Results in uneven wear and poor performance.

- Neglecting Regular Maintenance: Leads to longer sharpening times and decreased efficiency.

Advanced Techniques for Sharpening Tungsten Carbide Blades

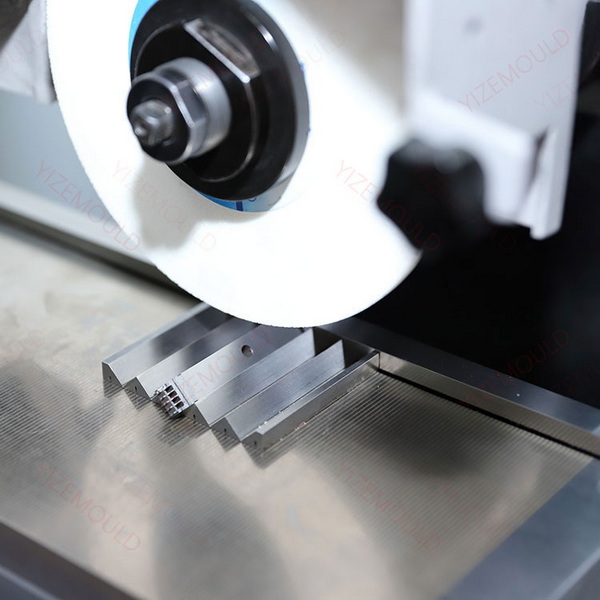

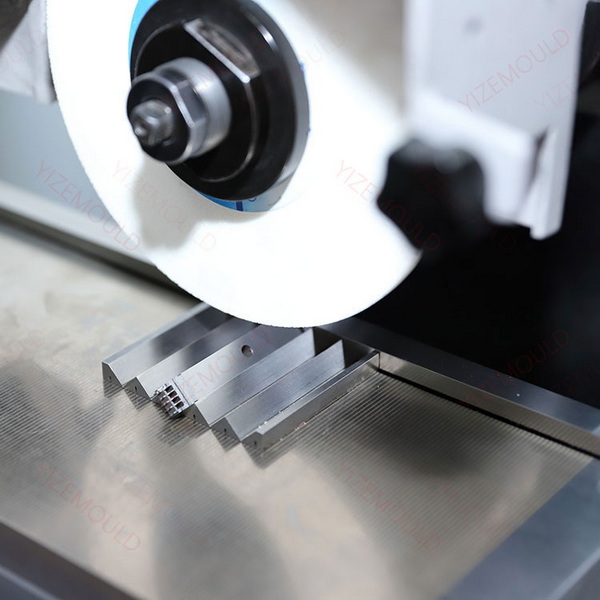

Tool and Cutter Grinders

These machines are designed for precision sharpening and can be equipped with diamond wheels for tungsten carbide blades. They offer high accuracy and efficiency, making them ideal for industrial settings where large quantities of blades need sharpening[2].

Custom Jigs for Small Blades

For small or irregularly shaped blades, creating a custom jig can help secure them during sharpening. This ensures consistent results and prevents damage to the blade or sharpening tool[2].

Safety Precautions

When sharpening tungsten carbide blades, safety is paramount. Carbide dust is carcinogenic, so it's essential to use good dust collection systems and personal protective equipment (PPE) to minimize exposure[2].

Cost Considerations

While diamond grinding wheels are more expensive upfront, they offer long-term cost savings by extending the lifespan of tungsten carbide blades. Silicon carbide wheels, though less effective, provide a more affordable option for lighter sharpening needs.

Environmental Impact

Sharpening tungsten carbide blades reduces waste by extending their lifespan, which can help minimize environmental impact. Additionally, using advanced methods like EDM and laser sharpening can reduce energy consumption compared to traditional grinding methods.

Conclusion

Sharpening tungsten carbide blades requires specialized tools and techniques due to their hardness and durability. Diamond grinding wheels offer the best combination of precision and efficiency, while silicon carbide wheels provide a cost-effective alternative for lighter sharpening needs. EDM and laser sharpening are ideal for high-precision applications. Regular maintenance and proper sharpening techniques are crucial for extending the lifespan of these blades.

FAQs

1. What is the best method for sharpening tungsten carbide blades?

The most effective method is using diamond grinding wheels due to their hardness and precision.

2. Can silicon carbide wheels be used for sharpening tungsten carbide?

Yes, silicon carbide wheels can be used, though they are less effective and wear faster than diamond wheels.

3. What are the benefits of EDM in sharpening tungsten carbide blades?

EDM offers high precision without mechanical stress, ideal for blades that require intricate geometries or tight tolerances.

4. How often should tungsten carbide blades be sharpened?

Blades should be sharpened regularly before they become completely dull to maintain efficiency and extend lifespan.

5. What safety precautions should be taken when sharpening tungsten carbide blades?

Always use proper dust collection and PPE, as carbide dust is carcinogenic. Ensure good ventilation and avoid overheating the blade.

Citations:

[1] https://passionblade.com/what-is-the-best-way-to-sharpen-tungsten-carbide-blade/

[2] https://www.reddit.com/r/sharpening/comments/1g6gq3h/how_to_sharpen_tungsten_carbide_cutting_tools/

[3] https://ibuildit.ca/tips/hand-sharpen-a-carbide-saw-blade/

[4] https://www.bladeforums.com/threads/tungsten-carbide-sharpening.1867146/page-2

[5] https://eternaltools.com/blogs/tutorials/tungsten-carbide-an-informative-guide

[6] https://www.linkedin.com/pulse/how-sharpen-tungsten-carbide-shijin-lei

[7] https://www.exchangeablade.com/blog/story/24/How-Can-I-Sharpen-My-Carbide-Saw-Blade/

[8] https://www.bladeforums.com/threads/tungsten-carbide-sharpening.1867146/

[9] https://www.youtube.com/watch?v=HHoQaPUbYOM

[10] https://forums.ybw.com/threads/sharpening-tungsten-carbide-chisels-and-scraper-blades.471030/

[11] https://knife.wickededgeusa.com/forums/topic/any-tips-on-sharpening-a-sandrin-tungsten-carbide-blade/

[12] https://www.youtube.com/watch?v=AuHQY300Aac

[13] https://knife.wickededgeusa.com/forums/forum/main-forum/techniques-and-sharpening-strategies/

[14] https://www.zhongbocarbide.com/news/How-To-Sharpen-Tungsten-Carbide-Blades.html

[15] https://www.istockphoto.com/photos/tool-sharpening

[16] https://generalcarbide.com/pdf/General-Carbide-Designers-Guide-Tungsten-Carbide.pdf

[17] https://rosi.bg/en/sharpening-of-saw-blades-with-tungsten-carbide-hw-tips-4253.html

[18] https://www.cadenceblades.com/materials-coatings/overview/tungsten-carbide

[19] https://www.passiontool.com/tungsten-carbide-machine-knives-manufacturer-zund-z20-z21-blade-sharpening-product/

[20] https://ezb2b.com/pdfimages/2018pdf_2792_9502267_6908061_5111.pdf

[21] https://rali-shop.com/1-blade-48mm-tungstene-carbide.html

[22] https://www.thesawcentre.co.uk/saw-blade-sharpening-tool-regrinding

[23] https://www.youtube.com/watch?v=UWrMPQn5zI8

[24] https://www.youtube.com/watch?v=ikCBVvZ7ZcA

[25] https://www.4x4community.co.za/forum/showthread.php/335502-Sharpening-a-tungsten-tipped-saw-blade

[26] https://www.fine-tools.com/pdf/sharpening-chisel-and-plane-blades.pdf

[27] https://www.reddit.com/r/sharpening/comments/zotngn/poly_hedral_tungsten_carbide_is_a_sharpening/