Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide

● Challenges in Making Tungsten Carbide Knives

>> Brittle Nature

>> Machining Difficulty

● Steps to Make a Tungsten Carbide Knife

>> 1. Material Preparation

>> 2. Design and Prototyping

>> 3. Machining

>> 4. Assembly and Finishing

● Examples of Tungsten Carbide Knives

>> Sandrin Knives

>> Industrial Applications

● Advanced Techniques in Tungsten Carbide Manufacturing

>> 3D Printing

>> Nanomaterials

● Economic Considerations

● Environmental Impact

● Conclusion

● FAQs

>> 1. What are the advantages of using tungsten carbide knives?

>> 2. How do you machine tungsten carbide?

>> 3. Can tungsten carbide knives be sharpened?

>> 4. Are tungsten carbide knives more expensive than steel knives?

>> 5. Can tungsten carbide be used for other tools besides knives?

● Citations:

Tungsten carbide knives are renowned for their exceptional hardness and durability, making them ideal for various cutting applications. However, crafting a tungsten carbide knife is a complex process due to the material's brittleness and difficulty in machining. In this article, we will explore the steps and challenges involved in making a tungsten carbide knife.

Introduction to Tungsten Carbide

Tungsten carbide is a composite material consisting of tungsten carbide particles bonded together by a metallic matrix, typically cobalt. It is known for its high hardness, wear resistance, and thermal conductivity, which make it superior to steel in many industrial cutting applications.

Properties of Tungsten Carbide

- Hardness: Tungsten carbide is extremely hard, with a Rockwell hardness rating that can reach up to 71, significantly higher than most steel alloys.

- Wear Resistance: It maintains sharp cutting edges longer than steel, reducing the need for frequent sharpening.

- Thermal Conductivity: Tungsten carbide can dissipate heat effectively, preventing thermal deformation during high-speed cutting operations.

Challenges in Making Tungsten Carbide Knives

Brittle Nature

Tungsten carbide is more brittle than steel, which can lead to cracking or breaking under impact. This brittleness poses a significant challenge in knife manufacturing, as knives are often subjected to various stresses during use.

Machining Difficulty

Standard machining tools cannot handle tungsten carbide due to its hardness. Specialized diamond abrasives are required for surface grinding, making the manufacturing process more complex and expensive.

Steps to Make a Tungsten Carbide Knife

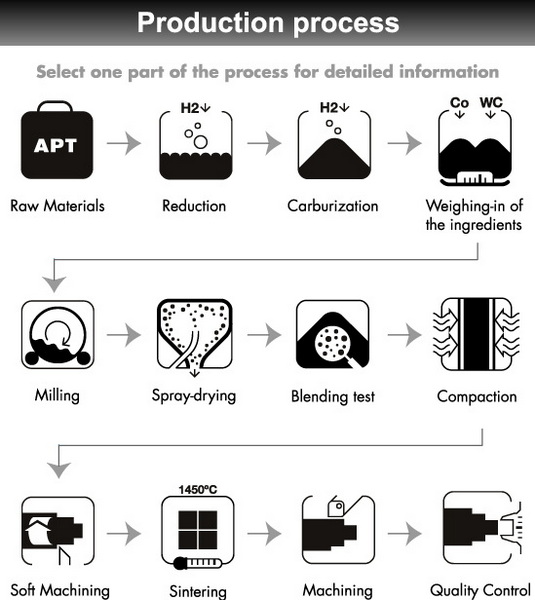

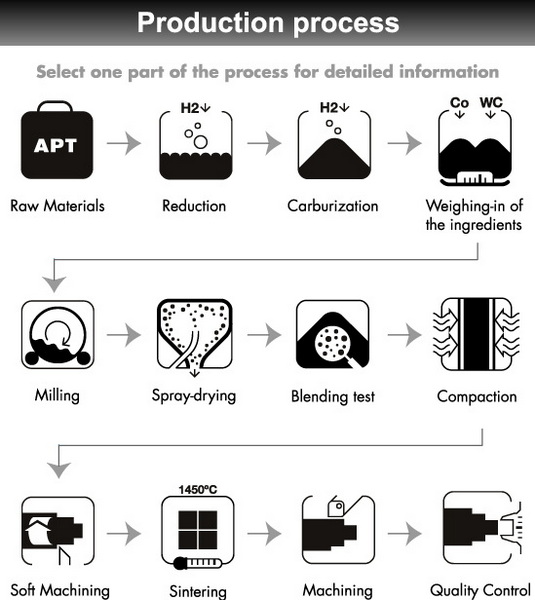

1. Material Preparation

The first step involves preparing the tungsten carbide material. This typically involves sintering tungsten carbide particles with a binder metal like cobalt to form a solid block. The composition and sintering process are crucial for achieving the desired hardness and strength.

2. Design and Prototyping

Designing the knife involves creating a prototype that accounts for the material's brittleness. This may include reinforcing the knife with other materials or designing the knife to minimize stress concentrations. Computer-aided design (CAD) software can be used to simulate the knife's performance under different conditions.

3. Machining

Machining tungsten carbide requires specialized equipment and techniques. Diamond-coated tools are used for grinding and polishing to achieve the desired edge sharpness and finish. The process is slow and precise, as excessive heat or pressure can damage the material.

4. Assembly and Finishing

Once the blade is machined, it is assembled with the handle and other components. The final step involves polishing and testing the knife for sharpness and durability. The handle material should be durable and ergonomic to ensure comfortable grip and control.

Examples of Tungsten Carbide Knives

Sandrin Knives

Sandrin, a brand by Turmond, is known for producing solid tungsten carbide knives. These knives use a proprietary formulation to overcome the brittleness of tungsten carbide, resulting in blades with exceptional edge retention and durability.

Industrial Applications

Tungsten carbide is widely used in industrial cutting tools due to its ability to maintain sharp edges and resist wear. This makes it ideal for applications where high precision and efficiency are required, such as in woodworking, metal cutting, and mining.

Advanced Techniques in Tungsten Carbide Manufacturing

3D Printing

Recent advancements in 3D printing technology have allowed for the creation of complex tungsten carbide structures that cannot be produced through traditional machining methods. This technique offers greater design flexibility and can potentially reduce production costs.

Nanomaterials

Research into nanomaterials has shown promise in enhancing the properties of tungsten carbide. By controlling the size and distribution of tungsten carbide particles at the nanoscale, manufacturers can improve the material's strength and toughness.

Economic Considerations

While tungsten carbide knives are more expensive than their steel counterparts, their extended lifespan and reduced maintenance needs can make them a cost-effective option in the long term. Additionally, the high performance of tungsten carbide knives can increase productivity in industrial settings, further offsetting the initial investment.

Environmental Impact

The production of tungsten carbide involves the use of tungsten, a metal that is often mined under challenging environmental conditions. Efforts to improve mining practices and develop more sustainable manufacturing processes are crucial for reducing the environmental footprint of tungsten carbide products.

Conclusion

Making a tungsten carbide knife is a challenging but rewarding process that requires specialized materials and techniques. The benefits of tungsten carbide knives, including their exceptional hardness and wear resistance, make them valuable in both industrial and consumer applications. As technology continues to evolve, we can expect to see further innovations in the design and manufacturing of these remarkable tools.

FAQs

1. What are the advantages of using tungsten carbide knives?

Tungsten carbide knives offer superior edge retention, wear resistance, and thermal stability compared to steel knives. This results in longer tool life, reduced maintenance, and improved cutting efficiency.

2. How do you machine tungsten carbide?

Machining tungsten carbide requires the use of diamond-coated tools due to its extreme hardness. Standard abrasives are ineffective, and specialized equipment is necessary for grinding and polishing.

3. Can tungsten carbide knives be sharpened?

Yes, tungsten carbide knives can be sharpened, but they require specialized sharpening tools. Due to their hardness, they maintain their sharpness longer than steel knives, reducing the need for frequent sharpening.

4. Are tungsten carbide knives more expensive than steel knives?

Yes, tungsten carbide knives are generally more expensive than steel knives due to the higher cost of the material and the complexity of the manufacturing process. However, their longer lifespan and reduced maintenance needs can offset these costs over time.

5. Can tungsten carbide be used for other tools besides knives?

Yes, tungsten carbide is widely used in various industrial cutting tools, such as machine knives and drill bits, due to its hardness and wear resistance. It is also used in wear-resistant parts like saw blades and milling cutters.

Citations:

[1] https://knifenews.com/sandrin-tungsten-carbide-knives/

[2] https://www.retopz.com/industries/tungsten-carbide-knives/

[3] https://www.reddit.com/r/Blacksmith/comments/10pgv47/in_theory_is_it_possible_to_make_knives_or/

[4] https://www.linkedin.com/pulse/benefits-choosing-tungsten-carbide-blade-nancy-xia

[5] https://www.youtube.com/watch?v=Cytuz142KJs

[6] https://sheffieldgaugeplate.co.uk/blog/tungsten-blades/

[7] https://forum.spyderco.com/viewtopic.php?t=55785

[8] https://www.passiontool.com/news/what-are-the-advantages-of-tungsten-carbide-blades/