Content Menu

● Introduction to Tungsten Carbide

>> Properties of Tungsten Carbide

● Methods for Removing Oxidation or Contamination

>> 1. Hydrogen Peroxide Solution

>> 2. Mechanical Cleaning

>> 3. Ultrasonic Cleaning

>> 4. Chemical Etching

>> 5. Electrochemical Cleaning

● Preventing Oxidation

● Advanced Techniques for Specific Applications

>> 1. Aerospace Industry

>> 2. Medical Industry

>> 3. Industrial Manufacturing

● Safety Considerations

● Conclusion

● Frequently Asked Questions

>> 1. What is the best method for removing rust from tungsten carbide?

>> 2. Can I use acid to clean tungsten carbide?

>> 3. How do I prevent oxidation on tungsten carbide parts?

>> 4. Is ultrasonic cleaning safe for tungsten carbide?

>> 5. Can I use household items to clean tungsten carbide?

● Citations:

Tungsten carbide is a highly durable material used in various industrial and consumer applications due to its hardness and resistance to wear. However, like many metals, it can be susceptible to oxidation or contamination, which may resemble rust, although true rust is specific to iron and its alloys. Removing oxidation or contaminants from tungsten carbide requires careful methods to preserve its integrity. This article will explore effective techniques for cleaning tungsten carbide surfaces.

Introduction to Tungsten Carbide

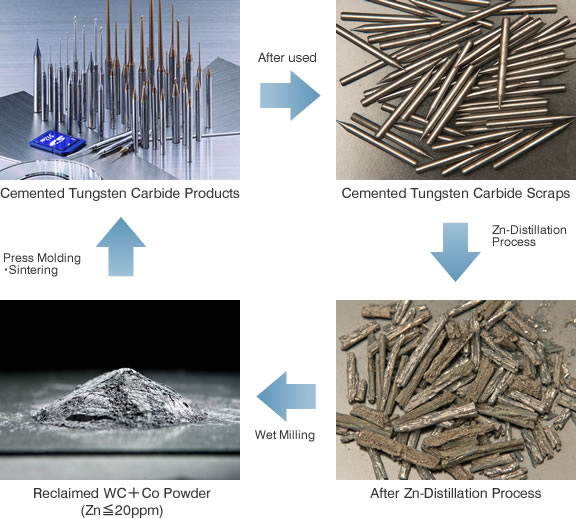

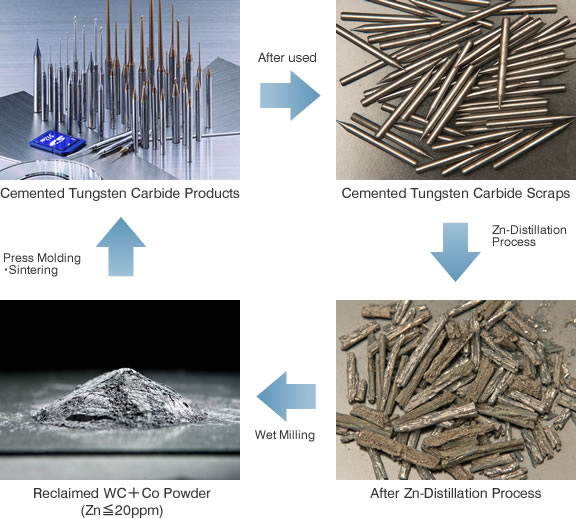

Tungsten carbide is a composite material made from tungsten carbide particles bonded together by a metal matrix, often cobalt. It is renowned for its exceptional hardness and resistance to abrasion, making it ideal for cutting tools, wear parts, and jewelry.

Properties of Tungsten Carbide

- Hardness: Tungsten carbide is significantly harder than most metals, which makes it resistant to wear but also challenging to machine or clean.

- Corrosion Resistance: While it is not prone to rust like iron, tungsten carbide can still be affected by oxidation or chemical contamination.

- Applications: Commonly used in cutting tools, wear parts, and high-performance applications.

Methods for Removing Oxidation or Contamination

Removing oxidation or contaminants from tungsten carbide requires careful consideration to avoid damaging the material. Here are some methods:

1. Hydrogen Peroxide Solution

Hydrogen peroxide is effective for removing carbon contamination from tungsten carbide surfaces. This method involves immersing the part in a solution of hydrogen peroxide (concentration: 5% to 35% by volume) for a sufficient time to allow the effervescent action to remove contaminants.

A[Hydrogen Peroxide Solution] --> B[Tungsten Carbide Part]

B --> C[Immersion Process]

C --> D[Effervescent Action Removes Contaminants]

2. Mechanical Cleaning

Mechanical methods, such as sandblasting or using abrasive wheels, can be effective but may damage the surface if not done carefully. These methods are often used when chemical methods are not feasible.

3. Ultrasonic Cleaning

While typically used for delicate parts, ultrasonic cleaning can be adapted for tungsten carbide by using appropriate cleaning solutions and ensuring the parts are securely held to prevent damage during the cleaning process.

4. Chemical Etching

Chemical etching involves using acids or bases to remove surface layers. However, this method must be approached with caution as it can alter the material's properties.

5. Electrochemical Cleaning

This method involves using an electric current to remove contaminants. It is less common for tungsten carbide but can be effective in specific scenarios.

Preventing Oxidation

Preventing oxidation or contamination is crucial for maintaining the integrity of tungsten carbide parts. This can be achieved through:

- Coatings: Applying protective coatings to prevent exposure to corrosive environments.

- Storage Conditions: Storing parts in dry, clean environments to minimize exposure to moisture and contaminants.

- Regular Maintenance: Regular cleaning and inspection to catch any issues early.

Advanced Techniques for Specific Applications

In certain industries, specialized techniques may be required to clean tungsten carbide parts effectively:

1. Aerospace Industry

In aerospace, parts are often subjected to high temperatures and corrosive environments. Advanced coatings and specialized cleaning solutions are used to maintain their integrity.

2. Medical Industry

For medical applications, cleanliness is paramount. Ultrasonic cleaning and sterile environments are often used to ensure parts are free from contaminants.

3. Industrial Manufacturing

In manufacturing, parts may be exposed to heavy wear and tear. Regular maintenance and inspection are crucial to prevent oxidation and maintain performance.

Safety Considerations

When cleaning tungsten carbide, safety is essential:

- Protective Gear: Always wear protective gloves, goggles, and masks when handling chemicals or performing mechanical cleaning.

- Ventilation: Ensure good ventilation when using chemicals to avoid inhalation of fumes.

- Equipment Handling: Handle cleaning equipment with care to avoid accidents.

Conclusion

Removing oxidation or contaminants from tungsten carbide requires careful consideration of the material's properties and the potential risks of different cleaning methods. By choosing the right technique, you can effectively clean tungsten carbide surfaces without compromising their integrity.

Frequently Asked Questions

1. What is the best method for removing rust from tungsten carbide?

Tungsten carbide does not rust in the same way as iron, but oxidation or contamination can occur. The best method often involves mechanical cleaning or chemical treatments like hydrogen peroxide for carbon removal.

2. Can I use acid to clean tungsten carbide?

Acids can be used for cleaning tungsten carbide, but they must be chosen carefully to avoid damaging the material. Hydrogen peroxide is effective for removing carbon, while other acids may not be suitable.

3. How do I prevent oxidation on tungsten carbide parts?

Preventing oxidation involves applying protective coatings, storing parts in dry conditions, and performing regular maintenance to catch any issues early.

4. Is ultrasonic cleaning safe for tungsten carbide?

Ultrasonic cleaning can be safe if the parts are securely held and appropriate cleaning solutions are used. However, it may not be the most effective method for removing heavy oxidation.

5. Can I use household items to clean tungsten carbide?

Household items like baking soda or vinegar are generally not effective for cleaning tungsten carbide due to its hardness and resistance to chemical reactions. Specialized methods are usually required.

Citations:

[1] https://safetykleeninternational.com/how-to-remove-rust/

[2] https://patents.google.com/patent/US5045121A/en

[3] https://www.reddit.com/r/jewelry/comments/z14u4m/meteorite_white_tungsten_cleaning/

[4] https://www.fushunspecialsteel.com/5-ways-to-remove-rust-from-metal/

[5] https://eternaltools.com/blogs/tutorials/how-to-remove-rust-from-metals-in-seconds

[6] https://www.heatsign.com/what-is-the-fastest-way-to-remove-rust-from-metal/

[7] https://impa-catalogue.shipserv.com/59-pneumatic-electrical-tools/deck-scalers/accessories-for-ico-rust-removal-machines/drum-tungsten-carbide-w300mm-11750-0-w300-for-rust-removal

[8] https://www.eng-tips.com/threads/help-with-removing-tungsten-oxidation.295311/