Content Menu

● Historical Foundations of SiC Production

● Raw Materials for Silicon Carbide Synthesis

● Industrial Production Process Flow

>> Stage 1: Acheson Furnace Reaction

>> Stage 2: Post-Synthesis Processing

● Advanced Manufacturing Techniques

>> Physical Vapor Transport (PVT)

>> Chemical Vapor Deposition (CVD)

● Industrial Applications by Sector

● Production Challenges & Solutions

>> Cost Reduction Strategies

● Future Trends in SiC Production

>> Larger Crystal Growth

>> Additive Manufacturing

>> Sustainable Production

● Conclusion

● FAQs

>> Q1: Why does the Acheson process remain dominant in SiC production?

>> Q2: How do manufacturers control crystal structure during production?

>> Q3: What's the environmental impact of SiC manufacturing?

>> Q4: Can silicon carbide be 3D printed?

>> Q5How long does a full production cycle take?

● Citations:

Silicon carbide (SiC) has become indispensable in modern industry due to its extreme hardness (9.5 Mohs), thermal stability (operates up to 1,650°C), and chemical resistance. This synthetic ceramic material powers applications ranging from bulletproof armor to EV power electronics. At the core of its industrial adoption lies a century-old manufacturing process refined through decades of innovation.

Historical Foundations of SiC Production

Edward Acheson's Accidental Discovery

In 1891, while attempting diamond synthesis, Edward Acheson created silicon carbide by electrically heating clay and carbon. This serendipitous experiment led to the patented Acheson process—still responsible for 80% of global SiC production. The first commercial plant near Niagara Falls (1893) leveraged hydropower to achieve the extreme temperatures required.

Evolution of Manufacturing Techniques

By the 1920s, improvements in furnace insulation using refractory bricks increased energy efficiency by 40%. The 1950s saw the rise of Lely process for high-purity crystals, enabling semiconductor applications. Today, over 600 kilotons of SiC are produced annually, with China dominating 70% of global output.

Raw Materials for Silicon Carbide Synthesis

The production of silicon carbide demands three core components:

| Material | Role | Typical Sources | Purity Requirement |

| Silica (SiO₂) | Silicon donor | Quartz sand, rice husk ash | >98.5% SiO₂ |

| Carbon (C) | Reducing agent | Petroleum coke, anthracite coal | Low ash content |

| Additives | Process optimization | Wood chips, sodium chloride | Controlled proportions |

Wood chips create gas escape channels during reactions, while NaCl lowers reaction temperatures by 200-300°C. Recycled SiC scrap (up to 30%) reduces raw material costs.

Material Preparation Innovations

Modern plants use laser sorting to remove impurities in raw materials, achieving 99.8% feedstock purity. Advanced drying systems reduce moisture content to <0.1%, preventing steam explosions during high-temperature processing.

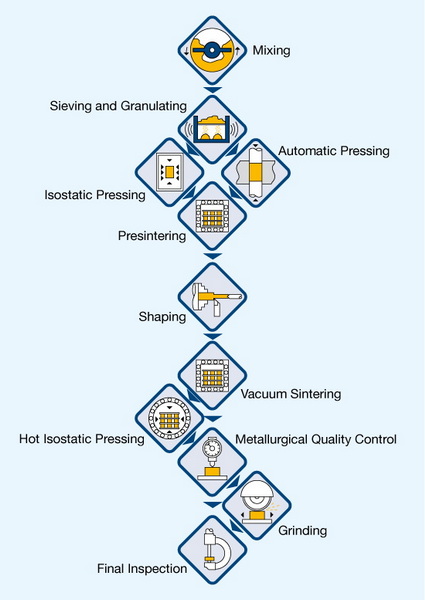

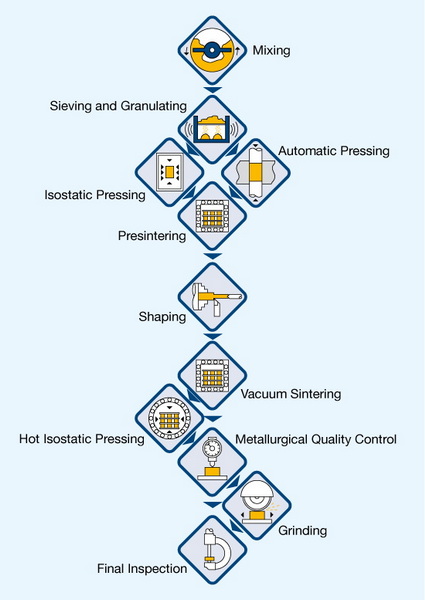

Industrial Production Process Flow

Stage 1: Acheson Furnace Reaction

1. Charge Preparation

- Mix silica sand (55-60%), petroleum coke (35-40%), and 5% additives

- Achieve homogeneous blend through rotary mixers operating at 30 RPM

- Particle size distribution: 80% between 100-200 μm

2. High-Temperature Synthesis

- Load 50-ton mixture into 15m × 4m rectangular furnace

- Apply 10,000-12,000A current via graphite electrodes (resistive heating)

- Temperature gradient:

- Electrode core: 2,500°C

- Outer zones: 1,800-2,000°C

3. Crystal Growth Dynamics

- Radial β-SiC crystals form around electrodes (cubic structure)

- Outer zones develop α-SiC (hexagonal) with 50-200 μm grain size

- Cooling phase: 24-hour controlled descent to 800°C

Stage 2: Post-Synthesis Processing

Crushing & Milling

- Primary crushing: Hydraulic jaw crushers reduce boules to <50mm chunks

- Secondary milling: Tungsten carbide ball mills achieve 10-500μm particles

Advanced techniques:

- Jet milling for submicron powders (0.1-1μm)

- Cryogenic grinding at -196°C prevents thermal degradation

Chemical Purification

| Process | Parameters | Effect |

| Acid leaching | 15% HF + 20% HNO₃, 80°C, 2h | Removes Fe, Al, Ca impurities |

| Alkaline wash | 10% NaOH, 60°C, 1h | Dissolves residual silicon |

| Flotation | Airflow 2 m³/min | Separates SiC (density 3.21 g/cm³) from graphite |

Classification Technologies

- Laser diffraction analyzers sort particles with ±0.5μm accuracy

- Electrostatic separation removes non-conductive contaminants

Final product grades:

- Coarse grit (8-220 mesh): 65% of production

- Micropowders (0.1-10μm): 25%

- Nanocrystalline (<100nm): 10%

Advanced Manufacturing Techniques

Physical Vapor Transport (PVT)

Grows high-purity single crystals for electronics:

1. Sublimate SiC source material at 2,300°C under 10⁻⁵ mbar vacuum

2. Transport vapor to seed crystal (4H-SiC orientation)

3. Deposit 100-150mm diameter boules at 0.2-0.5mm/hour

4. Achieve <10⊃3; cm² micropipe density

Chemical Vapor Deposition (CVD)

Produces ultra-pure epitaxial layers:

- Precursors: SiH₄ (100 sccm) + C₃H₈ (50 sccm)

Growth conditions:

- Temperature: 1,500-1,800°C

- Pressure: 100-200 mbar

- Growth rate: 10-50μm/hour

Applications:

- 10μm-thick layers for 1.2kV MOSFETs

- 100μm layers for 10kV IGBTs

Industrial Applications by Sector

Energy & Power Electronics

- Tesla Model 3 traction inverters use 48 SiC MOSFETs, reducing losses by 75%

- 3300V SiC modules enable 99% efficiency in solar inverters

Advanced Armor Systems

- B₄C-SiC composites (70% SiC) stop 14.5mm API rounds at 18kg/m² areal density

Aerospace Components

- GE9X engines use SiC/SiC CMC turbine shrouds, reducing cooling air by 30%

Semiconductor Manufacturing

- 200mm SiC wafers with <10⊃3; cm² defect density (Wolfspeed 2024 roadmap)

- 5G base stations employ GaN-on-SiC RF chips (3-6GHz operation)

Production Challenges & Solutions

| Challenge | Industry Solution | Economic Impact |

| Energy intensity (30MWh/ton) | DC arc furnaces with 40% lower consumption | Saves $1.2M annually per furnace |

| CO emissions (1.2 tons/ton SiC) | Plasma-assisted CO→CO₂ conversion (95% efficiency) | Meets EU ETS standards |

| Crystal defects | AI-driven thermal profile optimization | Reduces scrap rate from 15% to 4% |

Cost Reduction Strategies

- Recycled metallurgical silicon (up to 50% input) cuts material costs

- Continuous furnaces increase throughput by 3× vs batch processing

Future Trends in SiC Production

Larger Crystal Growth

- 300mm wafer prototypes demonstrated (II-VI Incorporated, 2023)

- Modified PVT systems with multi-zone heating achieve 200mm boules

Additive Manufacturing

Binder jetting with SiC powder:

- Layer thickness: 50μm

- Sintering: 2,100°C argon atmosphere

Applications:

- Rocket thrust chambers (Surmet Corp)

- Nuclear fuel cladding

Sustainable Production

- CO₂ capture systems convert emissions to sodium bicarbonate

- Solar-thermal Acheson furnaces under development (NREL pilot 2026)

Conclusion

The production of silicon carbide has evolved from Acheson's primitive furnace to automated factories producing 200mm single crystals. As industries demand higher purity (99.9995% for semiconductors) and lower costs ($500/m² wafer target), hybrid methods combining traditional carbothermal reduction with advanced vapor deposition will dominate next-generation manufacturing. With global SiC market projected to reach $10B by 2030, continuous process innovation remains critical. Emerging technologies like AI-optimized crystal growth and solar-powered synthesis promise to make SiC production more efficient and environmentally sustainable.

FAQs

Q1: Why does the Acheson process remain dominant in SiC production?

The method provides cost-effectiveness for bulk production (<$5/kg) while achieving 98% purity suitable for most industrial applications.

Q2: How do manufacturers control crystal structure during production?

By precisely regulating cooling rates—rapid quenching creates β-SiC (cubic), while slow cooling forms α-SiC (hexagonal).

Q3: What's the environmental impact of SiC manufacturing?

Modern plants capture 85-90% of CO emissions and recycle 60% process water through closed-loop systems.

Q4: Can silicon carbide be 3D printed?

Yes, binder jetting of SiC powder followed by reaction sintering creates complex geometries for rocket nozzles.

Q5How long does a full production cycle take?

Traditional Acheson process requires 56 hours (32h heating + 24h cooling), while PVT crystal growth takes 7-10 days.

Citations:

[1] https://www.linkedin.com/pulse/silicon-carbide-sic-industrial-production-methods-francois-xavier-xqf7e

[2] https://www.ipsceramics.com/how-is-silicon-carbide-made/

[3] https://www.fiven.com/world-of-silicon-carbide/overview/

[4] https://www.linkedin.com/pulse/comprehensive-guide-silicon-carbide-from

[5] https://www.domill.com/What-is-the-Silicon-Carbide-Powder-Making-Process-Flow.html

[6] https://www.sialloy.com/blog/silicon-carbide-manufacturing-process.html

[7] https://en.wikipedia.org/wiki/Silicon_carbide

[8] https://materials.iisc.ac.in/~govindg/silicon_carbide_manufacture.htm

[9] https://kindle-tech.com/faqs/how-do-you-process-silicon-carbide

[10] https://www.preciseceramic.com/blog/methods-to-produce-silicon-carbide-and-their-advantages.html

[11] https://www.semicorex.com/news-show-8760.html

[12] https://www.washingtonmills.com/silicon-carbide/sic-production-process

[13] https://en.wikipedia.org/wiki/Acheson_process

[14] https://www.atamanchemicals.com/silicon-carbide_u26029/

[15] https://wiredspace.wits.ac.za/bitstreams/09da15cb-8cc1-4573-b55e-b4ed15050145/download

[16] https://www.ntnu.no/blogger/teknat/en/2020/12/15/role-of-silicon-carbide-sic-in-silicon-ferro-silicon-si-fesi-process/

[17] https://idw-online.de/-DHEfBA